The Combo

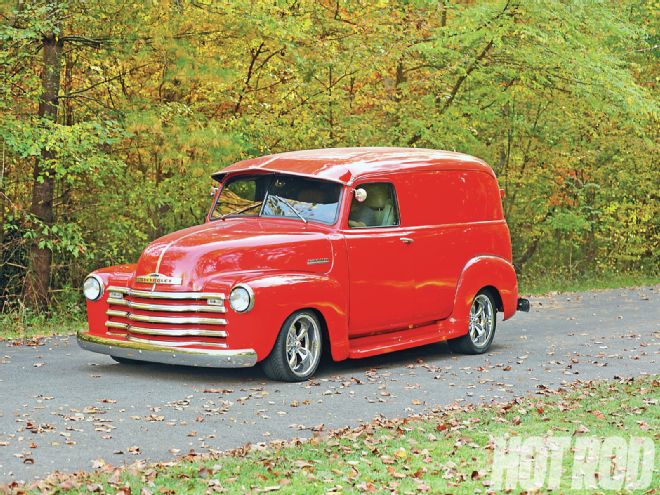

Jimmie Burton has owned his ’50 Chevy panel truck for 10 years. It was one of those slow projects, and Burton didn’t get it finished and on the road until 2010. Intended as a daily cruiser, its propulsion comes from a mild ’75 Chevy 350 small-block backed by a TH400 automatic trans and a 3.08:1-geared 10-bolt rearend. The truck sports a ’69 Camaro (first-gen GM F-car) front suspension clip.

The Problem

From day one, Burton had problems with the 350 engine’s V-belt accessory-drive system. “It just kept eating up the belts,” reports Burton. “The pulleys didn’t line up. There were pieces of shredded rubber everywhere. There was a squeaking sound. At first I just drove it, then I got so disgusted I parked it.” Several shops tried to fix the belts and pulleys, but Burton says “none of them could solve the problem. They just screwed me big-time.” It was time to get the truck over to someone who actually cared—namely, Joe Kiser, owner of Joe’s Garage in nearby Winston-Salem (and also HOT ROD staffer Jesse Kiser’s pop).

The Diagnosis

Besides misalignment problems, Kiser determined that some of the V-belts driven by different accessories were trying to turn those pulleys with multiple grooves at different speeds, leading to binding, squeaking, and accelerated belt wear. This is a common problem today on legacy engines with beltdrive systems cobbled together from a variety of sources. Possible solutions include installing a pricey aftermarket custom drive system, using a matched set of V-belt pulleys off a pristine wrecking-yard engine, or moving up to a modern serpentine beltdrive system. Kiser decided to go with the serpentine option, which offers superior reliability and belt retention.

Burton’s troublesome, cobbled-together V-drive system perfectly illustrates...

Burton’s troublesome, cobbled-together V-drive system perfectly illustrates...

The Fix

Figuring, “let’s not break the bank,” Kiser sought out a relatively affordable production-based small-block Chevy serpentine system that would easily adapt to the Chevy panel truck. Chevrolet Performance Parts offers production-based serpentine-drive systems in kit form under a single part number, but they’re based on car and truck designs with low hoodlines and wide engine compartments. Unfortunately, these kits don’t adapt well to older, street rod–style vehicles like Burton’s truck that have narrow engine bays with more vertical than horizontal clearance.

After scouring the local wrecking yard, Kiser found what he needed: a complete system from a small-block Chevy–powered ’90 G20 van. “It was the most compact unit in the wrecking yard I could find,” Joe says. Unlike other GM small-block Chevy serpentine systems, “both the alternator and air conditioning (A/C) compressor fit within the width of the heads and engine. It’s a very tight system. It should work even on a '32 Ford with the hood closed.”

The same or similar compact drive systems were used on 305/350ci (5.0L/5.7L) small-block V8 and 262ci (4.3L) V6-90 engines installed in '87–'91 fullsize G-vans, '87–'89 Astro M-minivans, and '88–'89 C/K fullsize pickups. Many variations exist, including an alternator-only drive system. One caution: Some of the rear support braces on 4.3L V6 engines won’t fit a V8.

The downside when moving from V-belts to a production-based serpentine system is that most legacy V-belt accessories—including the alternator, power-steering (P/S) pump, and A/C compressor—won’t fit the serpentine brackets. That means besides grabbing all the brackets, the pulleys, the tensioner, and the drivebelt, you’ll need to get all the late-model accessories. You’ll also want to snatch the four-prong CS-series alternator electrical connector and about a foot of its wire harness for splicing into the old wiring harness.

A reverse-rotation water pump designed for the serpentine drives is mandatory; it appears similar to a standard-rotation pump but has internal passages and an impeller designed for counterclockwise operation (as viewed from the front, looking toward the rear). Kiser recommends a new or remanufactured water pump, as the long-term reliability of a salvage yard pump that’s been lying dormant for an indeterminate time is, in his opinion, questionable.

If you want new parts, they must be purchased individually from a friendly GM parts department (such as Elway Chevrolet, which ships nationwide) or an ACDelco dealer (like RockAuto). Unfortunately, some of the smaller rear support accessory brackets are no longer available new, so a good wrecking yard is the only source (if you’re handy, you could fab custom rear supports out of bendable flat stock and/or thick-wall tubing and rod ends).

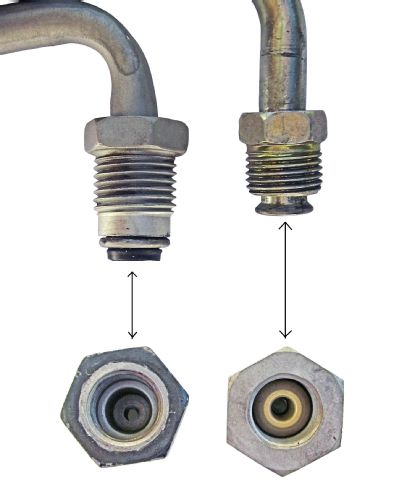

04] The new P/S pump has a piloted O-ring pressure outlet fitting (left); the old pump, hose, and steering box used inverted-flare fittings (right). Kiser swapped the old pump’s pressure fitting into the new one so the old hose would still hook up. The late threads are nominally metric, but it’s a “soft” conversion; the old fitting will screw in if you’re careful.

04] The new P/S pump has a piloted O-ring pressure outlet fitting (left); the old pump, hose, and steering box used inverted-flare fittings (right). Kiser swapped the old pump’s pressure fitting into the new one so the old hose would still hook up. The late threads are nominally metric, but it’s a “soft” conversion; the old fitting will screw in if you’re careful.

So how much lighter does your wallet end up? Going with all new parts (if available) costs at least $1,000. At that point, get an aftermarket setup from March Performance or Billet Specialites. If you’re on a tight budget, grabbing most of the parts out of a friendly wrecking yard like Pull-A-Part and using new parts only as necessary or recommended to finish the job is very affordable, coming in just over $300.

The last hurdle is integrating the late accessories into the vehicle’s existing plumbing and wiring, as well as overcoming some inevitable minor mounting glitches. As shown in the accompanying photos, on Burton’s truck these included:

Results

No more noisy and frayed belts! Burton has a reliable system that should last 50,000-plus miles before even the belt needs replacement. Plus, the late-model alternator puts out more amps at low rpm and will keep all those power-hungry accessories happy. Burton proclaims, “Joe [Kiser] knows his stuff and takes pride in what he does. He wants to do it right! You don’t find many people like that in this day and time.”

Lessons Learned

Drivebelt problems can often be traced to a mismatched drive-pulley system. Be sure all the pulleys come from the same stock application if using production-based parts. When upgrading to a serpentine system, expect to do some wiring and plumbing changes. Some bracket mods may also be needed. Carefully inspect parts for damage and defects.

Need Junk Fixed?

If your car has a gremlin that just won’t quit, you could be chosen for Hot Rod to the Rescue. Email us at PITSTOP@HotRod.com and put “Rescue” in the subject line. Include a description of your problem, your location, and a daytime phone number.