In the November 2012 issue of Mopar Muscle, we began building a bracket engine for the '72 'Cuda owned by local Mopar enthusiast Jim Freed, by assembling the bottom end of a 535-inch big-block. In this month's issue, we'll top this durable short-block with Indy Cylinder Head's 440-1 cylinder head and intake package, and dyno tune the engine for power and reliability.

Big-block Mopar engines are known for making big torque and horsepower. What many off-brand racers don't realize, however, is how reliable these engines can be. For the bottom end of this big-block, we chose a cast-iron Mopar Performance siamese bore block, and filled it with a rotating assembly from Scat Crankshafts. The 4.25-inch stroke crankshaft and forged H-beam connecting rods will easily handle the power and rpm this engine will make, and we opted for optional Mahle forged pistons, which are a nice blend of strength and light weight.

The cylinder heads are vitally important and must be able to flow enough fuel and air to support the engine's relatively large 535-inches. Available in several configurations for both the low deck B block as well as the higher deck RB block, Indy's 440-1 kit includes everything needed between the block and carb, and is economically priced, especially when compared to purchasing each piece individually. Even in un-ported form, these heads have been shown to add up to 100 horsepower to a properly built 440, which is difficult (or impossible) to achieve with any factory big-block cylinder head.

For our 535-inch engine, we selected the 440-1 CNC 345 heads along with Indy's aluminum single-plane intake manifold. As an upgrade, we opted for Jesel rocker arms, which incorporate pairs of rocker arms mounted to individual shafts. These rockers require the top surface of the cylinder head to be machined to attach the Jesel mounting plates, and can eliminate the need for external oiling provisions normally required with the 440-1 heads. The Jesel rockers can be oiled by either spray bars mounted in the valve covers, or, as in our case, they can actually be oiled through the pushrods from the lifters. Oiling through the pushrods is somewhat simpler, with the only sacrifice being a reduction in idle oil pressure. Fortunately, the big-block Mopar oiling system supplies plenty of oil volume to critical engine parts, so a reduction in idle oil pressure isn't a concern, especially in a race engine like ours.

With our short block complete, we bolted the cylinder heads in place utilizing ARP head studs and Cometic multi-layer steel gaskets. We've had great luck with Cometic head gaskets, finding them to seal as well as copper gaskets without the requirement of stainless-steel o-rings around the cylinders. Cometic does require a fairly smooth finish on the deck of the block and cylinder head sealing surface, so make sure your machine shop can meet this requirement prior to purchasing any MLS gasket. Fortunately Auto Performance Engines is equipped to machine the surfaces to the proper finish, so this wasn't an issue. As an alternative, we've found Cometic gaskets to seal well with a standard finish on the deck and head, so long as a small amount of silicone is used around the water jackets. It is certainly better, however, to machine the surfaces to the proper finish.

With the heads in place, we assembled our Jesel rocker arms and bolted them to the cylinder heads. Jesel shaft mounted rockers set the standard in valvetrain stability, and while they may be slight overkill for an engine like this one that won't see rpm over 7,500 the Jesel rockers will ensure this engine is durable and will require very little maintenance. The Jesel rockers are lightweight as well, further enhancing valvetrain stability and reducing the tendency for the pushrod to flex during valve opening.

Topping this big-block, we utilized a single-plane, aluminum intake manifold from Indy Cylinder Head with a Holley 4500 series Dominator carburetor flange. An engine this size definitely needs an appropriate amount of fuel and air to run properly, and the Indy intake matched with a 1050 cfm Dominator carb will provide a good baseline for this engine. In reality, an engine of 535 inches may like a larger carburetor and could even benefit from dual carbs. But for the purposes of this build, the 1050 will allow us to dyno the engine, and get an idea of the power it will make. Once installed in Jim's 'Cuda, we'll likely try a variety of carburetors on the big-block to optimize the combination.

With our big-block assembled, we bolted it to the Superflow dyno at Auto Performance Engines to tune it and measure its power output. An engine dyno doesn't just determine the power and torque an engine makes, it's also a useful tool when it comes to experimenting with different timing and carburetor specs, and is a nice way to check for leaks or problems prior to bolting the engine in a car. With our engine warmed up we applied a slight load on the dyno servo to help seat the rings, then made a partial power pull to check the engine under a full load. The big-block sounded powerful, making respectable power and torque on the short pull, so we pulled the oil filter to check for contamination and checked valve lash prior to making power pulls. Finding the valve lash to be just where we had set it and no excessive metal in the oil filter, it was time to tune this engine and see what kind of power it would make.

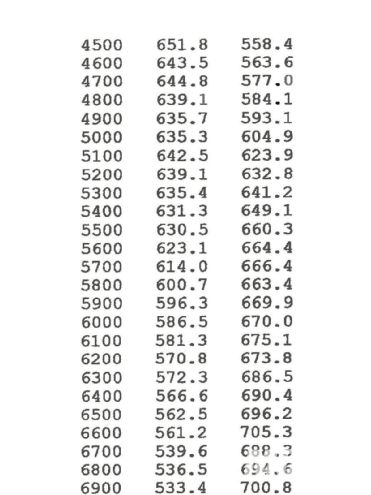

With the ignition timing set with a conservative 33 degrees of total advance (17 degrees at idle), our first pull to 6,000 rpm netted more than 640 lb/ft of torque and 676 horsepower. Increasing ignition timing and carburetor jetting netted additional power, and peak horsepower was achieved at a leisurely 6,600 rpm. With peaks of 642.5 lb/ft of torque and 705.3 horsepower, this engine should easily propel the '72 'Cuda to sub-ten second elapsed times, while remaining reliable and durable. To see videos of this engine running on the dyno at Auto Performance Engines be sure to visit our website, moparmuscle.com, and look for updates in future magazine issues to see how the car performs at the dragstrip.

Price Tag

Indy 440-1 CNC345 cylinder heads assembled$4,058.00 Jesel Rocker arms$1,499.00 Indy 440-14-3 Intake$399.00 Holley 1050 cfm Dominator Carb$947.78 Machine Heads for Jesel rockersvaries by shop Dyno Timevaries by shop

Cylinder Head Flow Table

LiftIntake flowExhaust Flow .200154.5127.1 .300235.9171.2 .400295.1207.3 .500329.7233.5 .600347.4254.8 .700354.9268.0 .800356.1280.0

*Remember, each flow bench is slightly different; these numbers are used as a reference and could vary depending on what shop flows the heads and what flow bench is used.

<STRONG>10</STRONG> We initially jetted our Holley 1050 with size 90 jets in the front and rear, but eventually jetted the carb all the way up to size 96 jets to optimize the air/fuel ratio. It is not uncommon for a big wedge like this to utilize 96 or even larger jets as these engines need an abundance of fuel to make their power.

<STRONG>10</STRONG> We initially jetted our Holley 1050 with size 90 jets in the front and rear, but eventually jetted the carb all the way up to size 96 jets to optimize the air/fuel ratio. It is not uncommon for a big wedge like this to utilize 96 or even larger jets as these engines need an abundance of fuel to make their power.

<STRONG>11</STRONG> We were hoping for more than 700 horsepower from this combination, and we achieved it with power to spare. Even better, peak horsepower was obtained at a leisurely 6,600 rpm, ensuring this engine will last a good long time before needing to be freshened up. Check out the power and torque this big-block made. These numbers should easily propel Jim Freed's '72 Plymouth 'Cuda to sub-ten second elapsed times in the quarter mile. Be sure to check out our website for videos of this engine making dyno pulls.

<STRONG>11</STRONG> We were hoping for more than 700 horsepower from this combination, and we achieved it with power to spare. Even better, peak horsepower was obtained at a leisurely 6,600 rpm, ensuring this engine will last a good long time before needing to be freshened up. Check out the power and torque this big-block made. These numbers should easily propel Jim Freed's '72 Plymouth 'Cuda to sub-ten second elapsed times in the quarter mile. Be sure to check out our website for videos of this engine making dyno pulls.