Four years isn't much time for an engine to hang around in production, but the legacy of the 351 Cleveland has been felt throughout hot rodding and motorsports in the nearly four decades since the last one was produced stateside. The 335-series engine family that the 351C belongs to technically served in the Ford engine lineup from 1970 to 1985, but the most famous and highest performance version, the 351 Cleveland, was only available in the United States from 1970 to 1974. The Aussies held onto their derivatives (the 351 and 302C) until the 1980s, but in the United States Ford evolved the Cleveland into the related but more utilitarian 351M and 400 while continuing to refine the Windsor platform.

So what was it about the 351C that was so special? Nicknamed "Cleveland" after the Cleveland, Ohio, engine plant in which most of the engines were manufactured, the Cleveland had free-breathing, canted-valve cylinder heads. Offered in two versions, the 2V version featured small-port cylinder heads with open-style combustion chambers, 2.04 intake/1.68 exhaust valves (larger than the ones used on the 390 and 428FE big-blocks), and round intake and exhaust ports. Over 90 percent of 351Cs produced were 2V. The 4V, on the other hand, had massive 2.5x1.75-inch intake ports that you could just about get your whole hand into. The valves for 4V engines built through 1972 were equally ginormous at 2.19-inch intake and 1.71-inch exhaust. The only other Ford engine with valves that large was the 460 Police Interceptor big-block. Those huge ports and valves were intended for supporting high-revving horsepower (above 3,500 rpm), but when combined with lower compression, smaller cams, and lower operating speeds on the road the big heads created a noticeable drop in torque production.

Drag and oval-track Ford racers, however, loved them. When streetability and low-rpm power was not a concern, the behemoth 4V heads supported big power with ease. Matter of fact, various Cleveland-styled heads atop Windsor-derived blocks was the powerplant of choice that powered Ford's NASCAR program up until the introduction of the clean-slate FR9 engine in 2009.

What hot rodders on the street really needed was a hybrid version of the Cleveland that combined the torque of the 2V heads and the high-rpm rush of the 4V head design. Ford of Australia had such a beast, but it never managed to make it to our shores, and getting your hands on a pair is not cheap or easy. In the ensuring years a few attempts to develop such a head have been made, each showing the big power potential in a properly balanced Cleveland head. Taking note of what worked well, what didn't, and what could be improved, Trick Flow Specialties' engineers took the best qualities of the original factory heads, added a healthy dose of hot rodder ingenuity, and created the PowerPort Cleveland 190 and 225 cylinder heads. These are the heads every Cleveland-powered muscle car has been waiting for.

Cleveland heads will bolt right onto a Windsor block, and there's certainly no debating the inherent strength and oiling benefits of the much more modern Windsor over the Cleveland, which is why every other article you're going to see on these heads will be a Clevor hybrid. We still believe in the good ol' C block though, so we're going to address the weak links and build a true Cleveland that will drop right into any original C-powered car or truck.

We're doing this build as a two-parter with Ford Performance Solutions (FPS) in Anaheim, California, sourcing most of the critical components from Trick Flow and Summit Racing. You'll have to wait until the April issue to see up close the beauty that is the Trick Flow Cleveland head, but for now we'll show you what we have in store for the bottom end that'll be pumping all that air through them.

BY THE NUMBERS Type: 408ci Cleveland (4.030 x 4.00) Block: stock Cleveland Crank: Scat stroker kit form Summit Racing 1-46265BE Rods: Scat 6.200 H-beam Pistons: Scat forged aluminum Rings: Scat file-fit Bearings: MAHLE Clevite 77 from Summit Racing Timing set: COMP Cams double roller Bolts/studs: ARP Cam: COMP Cams solid roller, .612/.612 lift, 245/245 duration at .050, 110 LSA

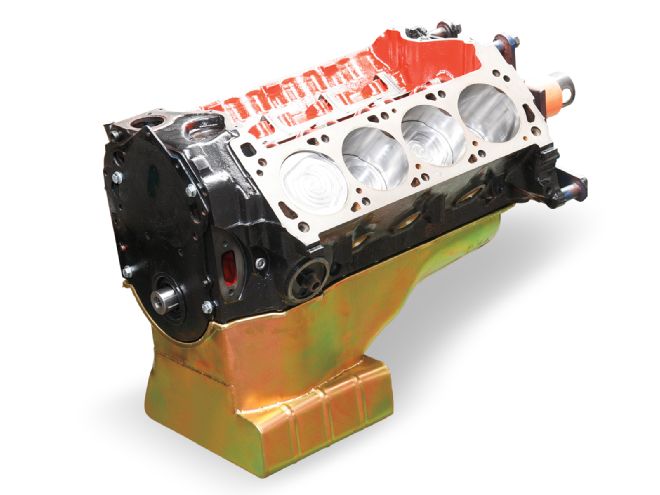

1. Considering the known fragility of the stock Cleveland block, we actually started with two original, standard-bore M-Code 4V candidates. The bores and all critical points were perfect on both and boring .030 over was simple and straightforward. C blocks are rather thin-walled with .040 being the maximum overbore considered safe.

1. Considering the known fragility of the stock Cleveland block, we actually started with two original, standard-bore M-Code 4V candidates. The bores and all critical points were perfect on both and boring .030 over was simple and straightforward. C blocks are rather thin-walled with .040 being the maximum overbore considered safe.

2. It broke our hearts when we spotted this old, crudely epoxied crack at the water neck on one of the otherwise perfect blocks, possibly from overheating at some point. It’s very debatable whether this block is salvageable.

2. It broke our hearts when we spotted this old, crudely epoxied crack at the water neck on one of the otherwise perfect blocks, possibly from overheating at some point. It’s very debatable whether this block is salvageable.

3. We’re modernizing and rollerizing this Cleveland. After cleaning and painting, the valley pan was drilled with a No. 3 bit and tapped for ¼-20 cap screws.

3. We’re modernizing and rollerizing this Cleveland. After cleaning and painting, the valley pan was drilled with a No. 3 bit and tapped for ¼-20 cap screws.

4. The COMP Cams roller lifter retrofit kit (Summit Racing, PN 31-1000) bolts into place via those screws, and just like that we’re ready for a roller Cleveland.

4. The COMP Cams roller lifter retrofit kit (Summit Racing, PN 31-1000) bolts into place via those screws, and just like that we’re ready for a roller Cleveland.

5. There is no replacement for displacement, and C-style heads love air volume, so we opted for one of the full Scat stroker assemblies (Summit Racing, PN 1-46265BE, $2,246.97). The pistons are forged aluminum and the rods are 6.200-inch forged 4340 steel H-beam.

5. There is no replacement for displacement, and C-style heads love air volume, so we opted for one of the full Scat stroker assemblies (Summit Racing, PN 1-46265BE, $2,246.97). The pistons are forged aluminum and the rods are 6.200-inch forged 4340 steel H-beam.

6. We decided to go with a moderate size for our 4340 forged Scat stroker crank, so with a 4.00-inch stroke on this 2.750-inch main journal diameter, the 4.030-inch bore will give us a 408ci Cleveland. Note something odd about our original 4V engine: It was drilled for four-bolt main caps but was only installed with a two-bolt cap from the factory. We’re reusing the original caps, but paired with ARP main studs from Summit Racing (PN 154-5404).

6. We decided to go with a moderate size for our 4340 forged Scat stroker crank, so with a 4.00-inch stroke on this 2.750-inch main journal diameter, the 4.030-inch bore will give us a 408ci Cleveland. Note something odd about our original 4V engine: It was drilled for four-bolt main caps but was only installed with a two-bolt cap from the factory. We’re reusing the original caps, but paired with ARP main studs from Summit Racing (PN 154-5404).

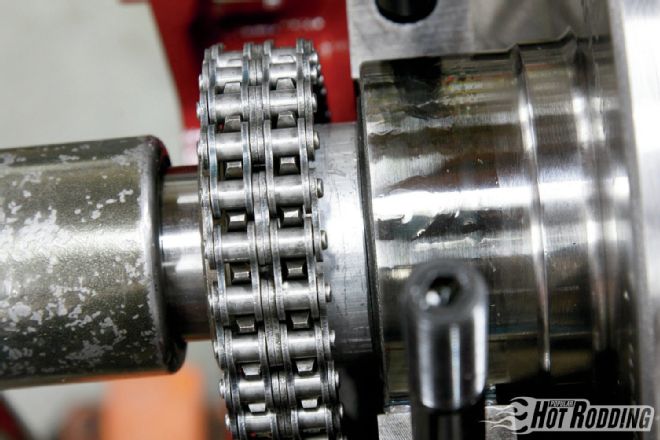

7. Speaking of the crank, most aftermarket Cleveland cranks lack the shoulder that the original 351C uses, so to properly align our COMP Cams timing set (Summit, PN CCA-3120), Ford Performance Solutions milled a .400-inch (1.900-inch od, 1.400-inch id) spacer.

7. Speaking of the crank, most aftermarket Cleveland cranks lack the shoulder that the original 351C uses, so to properly align our COMP Cams timing set (Summit, PN CCA-3120), Ford Performance Solutions milled a .400-inch (1.900-inch od, 1.400-inch id) spacer.

8. While their cast crank kits use standard piston rings, Scat’s forged stroker assemblies with their premium forged pistons feature file-fit rings so builders can tailor the gap for the engine’s intended use.

8. While their cast crank kits use standard piston rings, Scat’s forged stroker assemblies with their premium forged pistons feature file-fit rings so builders can tailor the gap for the engine’s intended use.

9. For our naturally aspirated street performance-oriented engine, the gaps were set at .019 1st, .022 2nd.

9. For our naturally aspirated street performance-oriented engine, the gaps were set at .019 1st, .022 2nd.

10. The Scat H-beam rods in Scat’s premium kit includes ARP 8740 rod bolts. Our rod side clearance was at .021, .020, .019, .020, first to fourth.

10. The Scat H-beam rods in Scat’s premium kit includes ARP 8740 rod bolts. Our rod side clearance was at .021, .020, .019, .020, first to fourth.

11. We often go with huge solid lifter cams for our builds, but with this 351C we’re endeavoring to emulate a tough street engine that will be at home in any muscle car and feature good longevity and low maintenance for street driving. COMP Cams spec’d out a hydraulic roller with .612/.612 lift and 245/245 duration at .050 with a 110 LSA.

11. We often go with huge solid lifter cams for our builds, but with this 351C we’re endeavoring to emulate a tough street engine that will be at home in any muscle car and feature good longevity and low maintenance for street driving. COMP Cams spec’d out a hydraulic roller with .612/.612 lift and 245/245 duration at .050 with a 110 LSA.

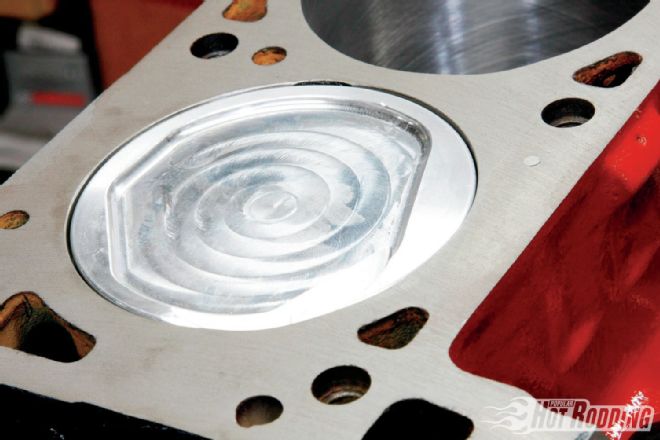

12. At home in their bores, the 16cc dished Scat forged pistons sit .010 below the deck and will be .060 below the heads with the .050 Fel-Pro gaskets.

12. At home in their bores, the 16cc dished Scat forged pistons sit .010 below the deck and will be .060 below the heads with the .050 Fel-Pro gaskets.

13. Ford Performance Solutions always degrees the cams in their engines to ensure the cam is installed to optimize the intake and exhaust valve events.

13. Ford Performance Solutions always degrees the cams in their engines to ensure the cam is installed to optimize the intake and exhaust valve events.

14. To fortify the bottom end of our 4V Cleveland with its two-bolt caps, we added a girdle from Ford Performance Solutions. This beefy brace will keep all the caps in place.

14. To fortify the bottom end of our 4V Cleveland with its two-bolt caps, we added a girdle from Ford Performance Solutions. This beefy brace will keep all the caps in place.

15. Paired with the girdle is this Ford Performance Solutions 351C windage tray to control oil slosh. That’s as far as we’ll take the oiling system for now; we’ll have more parts and tricks to show you in the next installment. Also, be on the lookout for our companion buildup of an all-aluminum 454ci Windsor using Trick Flow’s new High Port 240 CNC heads.

15. Paired with the girdle is this Ford Performance Solutions 351C windage tray to control oil slosh. That’s as far as we’ll take the oiling system for now; we’ll have more parts and tricks to show you in the next installment. Also, be on the lookout for our companion buildup of an all-aluminum 454ci Windsor using Trick Flow’s new High Port 240 CNC heads.