If there’s one trick that any car can benefit from, it’s cleaning up the path of airflow to the intake and providing a route for the coolest air possible. Unfortunately, in stock form most muscle cars suck underhood air, which is always less than optimal since it’s guaranteed to be much hotter than the ambient temperature.

One method that has a racing pedigree is true cowl induction. No, not the rearward facing hoodscoops made famous on ’60s GM muscle cars, though those operate on the same principle. We’re talking about true cowl induction that sucks air through a cowl vent much like NASCAR still employs today. The idea is to take advantage of the high-pressure zone that naturally builds at the base of the windshield (on all cars that have windshields) to get a strong, steady supply of cool air with a very short route to the engine.

We do have to give GM the credit for our inspiration though; there were a handful of ’66 Z11 Chevelles equipped with air ducting into the cowl, and Smokey Yunick famously did a double-ducted version on his ’66 Chevelle NASCAR racer. Considering Max’s rather extreme engine setback and lack of HVAC equipment under the dash, ducting the intake directly to the cowl seemed like a no-brainer to us.

As far as performance benefits versus other methods of cold air induction, it’s really up for debate and truly depends upon the airflow dynamics of the car. One thing to keep in mind is that this sort of induction doesn’t really offer any true ram effect, and, in fact, most ram-air-style systems don’t either until very high speeds—and even then the pressure increase is pretty negligible. Since cooler air is denser air, and denser air makes more power, the real goal is to provide the engine with an easy source of the coolest air possible. Once Max is out for testing we’ll tape tufts of string around the inlet to see what the air is doing and whether we need to address the flow into the intake.

This also marks the first of our collaborations with Cris Gonzalez and his crew at JCG Restorations and Customs on our ’67 Cougar. JCG has turned out some gorgeous muscle cars with exceptional fabrication work, so we’re definitely in good hands. Plus, Gonzalez prefers to build his cars for function and speed, and then find ways to make that aesthetically appealing, so he’s completely on board with the Cougar’s ethos. He even has some great ideas brewing that may make the Max Effort Cougar even better!

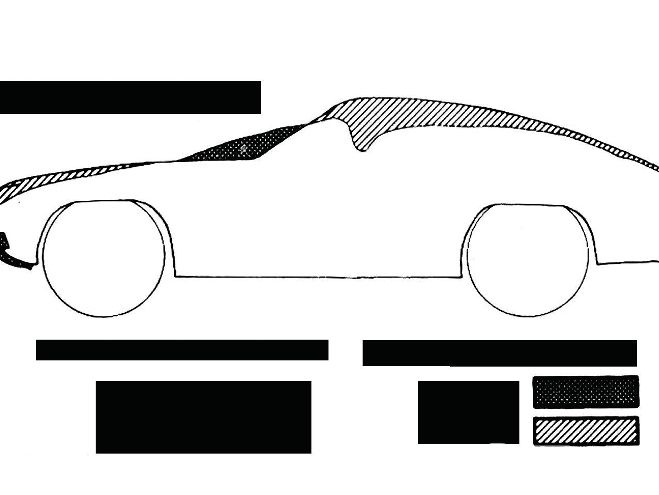

This airflow diagram of a '63 Corvette is typical of the high-pressure areas common to most cars at the base of the windshield, especially traditionally styled coupes and sedans. Yes, it's a Corvette, but the concept is the same with the Cougar.

With roughly 10 inches of setback and 3 inches of drop, the FAST throttle body on our Dart-based 438-inch Clevor was only 6 inches forward of the cowl and below the floor of it.

The Cougar’s cowl vents (like the Mustang’s) aren’t removable, so our first step is to cut out the grille to gain access to the inner cowl. Our partner in fabrication is Primo, one of JCG’s top metal shapers.

Since the Max Effort Cougar will not have any HVAC systems, our plan is to turn the cowl into an airbox that channels and feeds air directly into the induction system.

To create the airflow exit, Primo cut a box opening into the cowl on the underhood side. He then cut two slits into the floor of the cowl and pushed it downward roughly 2 inches. If you still have a stock firewall in place, you’ll need to notch that first for clearance. A triangular piece of steel welded into the gap created a nice wide mouth.

Air under pressure will always seek a path of least resistance, and it detests sharp curves, so we curled a sheet of steel to create a gentle transition from the angle at the base of the windshield to the exit of our cowl induction.

To eliminate air leaks from the factory interior vents and cowl drains, Primo cut cardboard templates to create block-off plates that will channel air toward the cowl induction exit.

With everything tacked in place, this is how it looked. Basically what we’re doing here is turning the cowl into part of the airbox and eliminating possible stagnant areas.

Rather than start completely from scratch, we used a cowl induction airbox from Spectre Performance. These airboxes are designed with vintage GM cowl hoods in mind, but can be modified to work on many applications. If you’d rather create your own, the drop base is available separately from many racing parts suppliers.

Since we’ll be drawing air directly from the cowl rather than from above as a cowl induction hood does, we cut the back off of the aftermarket airbox.

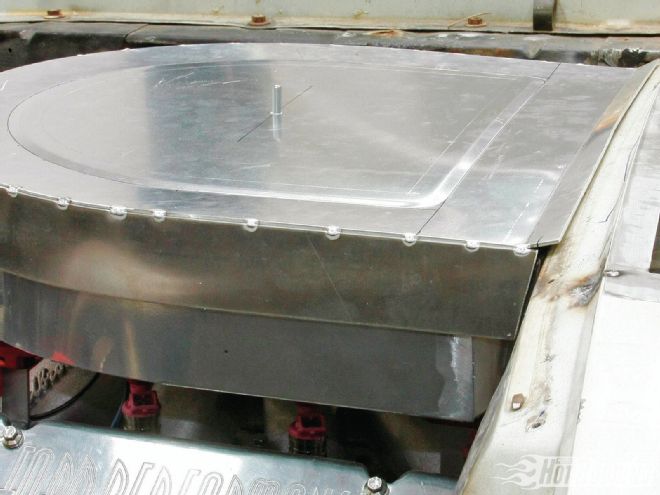

We want the airbox to be sealed to the cowl, so Primo bent and welded in some 90-degree pieces of steel to serve as a flange and add strength to the cowl. An ⅛-inch piece of wood was taped to the flange to set our gap between the cowl and engine airboxes.

Primo then cut two small pieces of aluminum to build side flanges for our aftermarket airbox, as well as a longer one that will join the floor to the cowl.

With the flanges welded into place, we now have a consistent ⅛-inch gap that we can easily seal with a rubber weatherstrip of high-density foam.

When used in conjunction with a cowl induction–style hood and an appropriately tall intake and carb setup, the airbox is designed to seal to the hood. That’s not an option for us, so we need a lid to keep out the hot underhood air.

Beginning with a flat piece of aluminum, Primo first put a slight bend at the back edge so that the back of the lid will rest on the cowl panel.

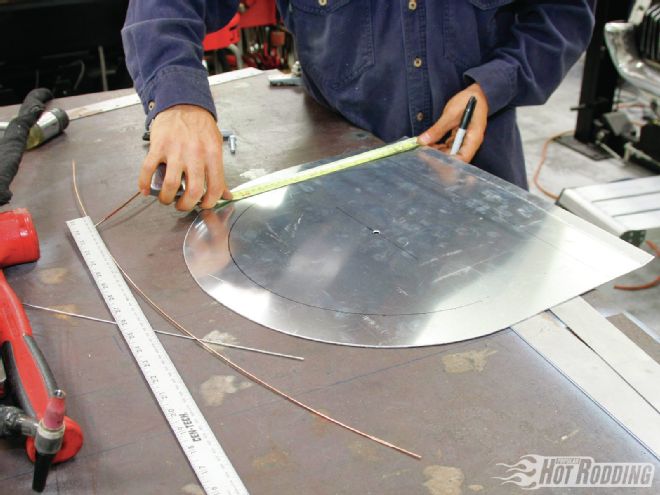

Flat aluminum isn’t very strong, so to add some rigidity (and a bit of style), Primo used a length of welding wire to lay out an arch that mirrors the shape of the lid.

Using light pressure from the stepped wheels on the bead roller, Primo carefully followed the line around the lid to create a light ridge in the lid without creating any shrinkage or distortion in the aluminum.

A flat sheet sitting atop the weatherstrip on the airbox would look a bit hokey, so Primo used the slip roller to curve a 2-inch strip of aluminum that will become a lip for the lid.

By tacking the lip to the lid we not only hid the weatherstrip and added a finished look to the lid, we also got more rigidity that will help clamp the lid down for a better seal. We’ll finish up the welding and seal off any air leaks later.

There you have it, a true cowl induction that should provide all the cold air our Ford Performance Solutions Clevor can ingest. Should testing down the road prove the airflow to be less than ideal, we’ll work on tuning the flow into the cowl grille or add supplemental inlets. As for rain, we’re working on a mini cowl scoop that would cover the grille in a downpour.