A connecting rod may be the most stressed component within an engine—absorbing compressive loads and resisting centrifugal forces during each crank revolution. When considering how robust a connecting rod must be, it’s no wonder most feel that the lowly cast connecting rod is the weakest link in the Pontiac performance chain. Some actually believe it will spontaneously self-destruct when exposed to any significant load in a high-performance engine. Not true.

Pontiac constructed its cast rods of ArmaSteel, a pearlitic malleable iron that possesses some steel-like qualities. Introduced for select applications in ’63, Pontiac felt it was durable enough to use in all regular production engines from ’67 forward, including its Ram Air and High Output mills. Failure was rare on street engines, but when raced competitively on the dragstrip, the cast rods’ 3⁄8-inch-diameter rod bolts sometimes stretched at very high rpm, resulting in spun bearings and occasionally complete rod failure.

When developing its Super-Duty 455 in the early ’70s, Pontiac included a strong forged-steel connecting rod with stock dimensions and 7⁄16-inch rod bolts. Though quite expensive, it was the only option racers had at the time, and PMD’s supplier couldn’t keep up with the orders. Once production ceased during the ’80s, it left no viable forged-rod options, and racers and performance enthusiasts were paying top dollar for an NOS set or expensive custom rods.

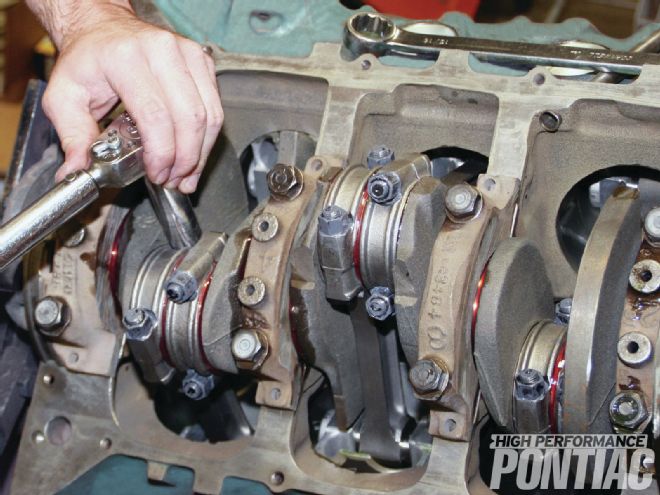

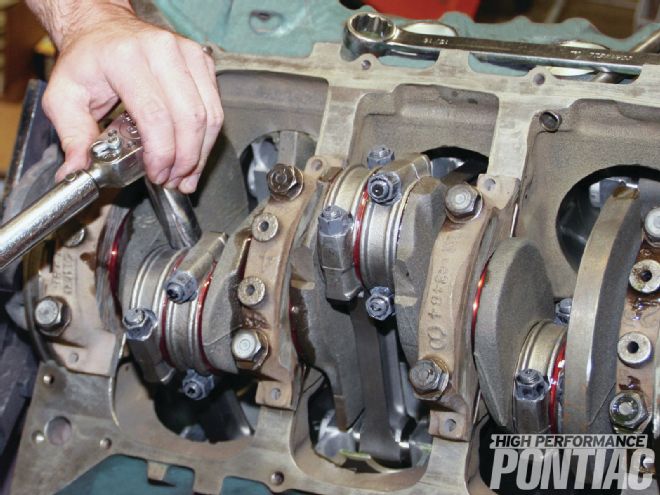

1 When a forged connecting rod fails, it tends to twist and bend. The failure is generally related to an installation or lubrication issue. This bearing of this H-beam lost its lubrication film, which severely overheated the rod.

1 When a forged connecting rod fails, it tends to twist and bend. The failure is generally related to an installation or lubrication issue. This bearing of this H-beam lost its lubrication film, which severely overheated the rod.

Today, however, there is a wide array of durable, aftermarket connecting rods available that are ideal for everything from basic rebuilds to high-end race engines. All regular production Pontiac V-8s, from the 326 to 455, used a connecting rod that measures 6.625 inches from the center of the wristpin bore (small end) to the center of the crankshaft bore (big end), a wristpin bore of 0.980 inches, and a crankshaft journal bore of 2.374 inches. A typical cast Pontiac rod weighs nearly 900 grams, while the SD-455 forgings typically weight 850 grams or slightly more.

With this information, you can see how the aftermarket offerings compare in our Connecting Rod Tech Guide. Your favorite Pontiac engine builder or parts vendor can help you decide which may be the best rod for your particular build. Chances are they already stock some of them at a very competitive price!

RPM International in Cerritos, Cali-fornia, began producing forged-steel connecting rods for Chevy and Ford at its China-based facility in 2000. “We own the factory and employ all the employees. That helps us control quality and consistency. We saw an opportunity within the Pontiac hobby and introduced two different stock-length connecting rods in 2005,” explains Sales Manager Toby Aldrete.

Reconditioning a set of 30-plus-year-old cast Pontiac rods can cost as much as $200. “Our stock-replacement rod is aimed at those who might reuse cast Pontiac rods during a rebuild,” says Aldrete. “A set retails for less than $250 and fits without any modifications. At nearly 750 grams, our rod is lighter than a cast original, but its 5140-steel construction and two-piece, 7⁄16-inch ARP fasteners (also available with one-piece cap screws) make it far more durable. We rate it up to 500 hp and 6,200 rpm.”

RPM Inter-national also produces Pontiac-spec H- and I-beam forgings constructed of 4340 steel, a more durable material. “Our H-beam is more popular because it looks beefier. It weighs about 760 grams, while our I-beam weighs 30-40 grams less. Strength isn’t necessarily an issue at the relatively low rpm range where Pontiacs typically operate, but weight savings is important to some as it can improve high-rpm performance in certain applications,” adds Aldrete.

The 4340-steel connecting rods are fitted with 7⁄16-inch-diameter ARP 8740-series cap screws and retail for under $400. “We have customers running more than 800 hp and turning up to 7,000 rpm with them,” he says. “We recommend installing ARP’s 2000-series cap screws in higher-horsepower applications or when forced induction or nitrous is used. The sudden acceleration rate associated with such engines can severely load the fastener, so upgrading can improve reliability.”

While the stock-replacement 5140 forging is only available with a press-fit pin, the Pontiac-spec 4340 forgings are also available with a bronze bushing for floating wristpins. RPM International offers its forged-4340 H- and I-beam rod in 6.7- and 6.8-inch length with a smaller diameter crankpin bore for use with stroker crankshafts. It also offers an H-beam with a precisely machined hole through the beam to positively lubricate the wristpin for supercharged applications.

Eagle Specialty Products (ESP) in Southaven, Mississippi, filled a large market void with its Pontiac-spec, forged-steel, H-beam connecting rod in the mid-’90s. “We began developing a high-quality connecting rod during the ’80s,” says ESP Marketer Alan Davis. “We wanted to offer an economic-but-durable option between stock rods and high-end customs. We chose the H-beam design to maximize strength, and by producing it on a mass scale using overseas labor, it could feature high-end durability at an affordable price.”

ESP formed a partnership with an overseas company, providing it with the equipment and material, and training its employees to make sure each rod met ESP’s stringent specifications. “We use a material alloyed and heat-treated to AISI 4340 specifications,” Davis explains. “Our rods are forged in two pieces, where the beam forging is one and the cap is another. The cap is pressed perpendicularly to the beam to further enhance strength. Each rod is CNC-machined and shot-peened to remove the external imperfections that could compromise integrity. And the big-end bore is sized using Sunnen Krossgrinding equipment.”

ESP’s Pontiac-spec H-beam is available in a press-fit pin design or with a bronze bushing for floating wristpins. Weighing nearly 760 grams, ESP claims its standard H-beam can sustain up to 850 hp and 7,000 rpm in a typical Pontiac 455. “Our rods will handle 1,500 hp, but we use 7⁄16-inch ARP 8740-series bolts to keep the cost down,” Davis adds. For the few racers building engines that exceed 850 hp, we offer ARP 2000- or L19-series cap screws as an upgrade, which pushes the limit to 1,500.”

A complete set of Pontiac-spec H-beams retails for less than $550, and upgraded fasteners add about another $100. “Our stock-dimension rods remain popular for high-performance street and race engines, and our longer 6.7- and 6.8-inch rods with a smaller crankpin diameter are quite popular with those performance hobbyists building stroker Pontiacs; they sell for about the same price.”

Crower Cams and Equipment Company in San Diego, California, has been producing high-quality aftermarket valvetrain components for decades. It entered the connecting-rod market in the early ’90s with its forged-steel Sportsman line for Chevy and Ford, and then Pontiac in the early ’00s.

“We wanted to provide hobbyists with a high-quality forged-steel connecting rod that could be used in most any type of rebuild at an affordable price,” says Kerry Novak, a Crower sales associate.

Crower’s Big Block Sportsman rods are American-made and constructed of 4340-steel alloy that’s heat-treated to Crower’s proprietary specifications. Fitted with 7⁄16-inch ARP 8740-series cap screws, the unique I-beam forging is extremely rugged. “We’ve seen our Big Block Sportsman rods used in Pontiac engines producing as much as 1,000 hp and turning upwards of 8,000 rpm. We feel they are very reliable for a wide range of applications,” adds Novak.

Crower’s Pontiac-spec Big Block Sportsman rod weighs about 850 grams and is available in a press-fit pin design or with a bronze bushing for floating wristpins. Retail cost is less than $800 per set. In addition to its Pontiac-spec offering, Crower also offers its Big Block Sportsman rod in a wide array of dimensions for those who need stock-length or longer rods combined with Pontiac or Chevy crankpin sizes for specialized or stroker-type applications. Expect to find pricing similar to a Pontiac-spec set.

SCAT Crankshafts in Redondo Beach, California, has been producing forged-steel connecting rods since 1972. According to SCAT President Tom Lieb, his company entered the Pontiac connecting rod market in 2006 when it introduced its H-beam for Pontiacs. “We wanted to give Pontiac engine builders a high-quality connecting rod for all applications, and our Pontiac-spec Pro Sport H-beam has been very popular for us.”

Constructed of high-tensile chrome-moly steel, SCAT’s Pro Sport H-beam is a two-piece forging that’s produced in China under SCAT supervision using a manufacturing process aimed at maximizing strength and consistency. The forgings are then imported to SCAT’s California-based facility, where they’re finish-machined, honed, and balanced, and ARP cap screws are installed. The result is a high-quality connecting rod with stock Pontiac dimensions that’s available in a press-fit pin design or with a bronze bushing for floating wristpins.

“We chose the H-beam design because it’s the strongest overall connecting rod we offer today’” adds Lieb. “Our standard Pontiac-spec rod weighs about 840 grams and includes 7⁄16-inch-diameter ARP 8740-series cap screws. A complete sets retails for $555. We feel that upgrading to an ARP 2000-series cap screw is a valuable investment. It adds just over $100 to the cost, but with 2000-series fasteners, we believe our H-beam can sustain as much horsepower as the best Pontiac engine builders can produce.”

In addition to its Pontiac-spec Pro Sport H-beam offerings, SCAT also offers a variety of Pro Sport rods with various big-block Chevy dimensions for hobbyists using aftermarket crankshafts. “Our 6.7 and 6.8-inch rods with 2.2-inch crankshaft pin journals are very popular with those building stroker engines. They retail for a similar cost to our Pontiac-spec units, but are only available with a bushed wristpin bore.”

Located in Irvine, California, CP-Carrillo supplies premium connecting rods and pistons to racers around the world. “Just like when Fred Carrillo produced his first rods during the ’60s, we strive to provide premium connecting rods for the racing community,” says Customer Service Manager Richard Batchelor. “We feel ours are among the most durable rods out there.”

CP-Carrillo’s rods are American-made and constructed of 4330-steel that’s heat-treated, hardness-tested, and shot-peened for maximum strength. “We specifically chose the 4330 alloy because it’s a bit more ductile than other common alloys, and will absorb more shock load and better resist fracturing. Our forging process gives the connecting rod proper grain flow to improve overall strength. The entire rod is fully machined to further enhance strength,” he adds.

The Pro-H series H-beam is CP-Carrillo’s most durable offering. Weighing about 830 grams, it’s fitted with a proprietary H-11 tool steel 7⁄16-inch cap screw, which utilizes a patented asymmetrical thread design. In a typical 455- to 468-inch Pontiac, Batchelor rates the standard Pro-H rod up to 1,000 hp and 8,500 rpm. “Upgrading to our Multiphase cap screw adds $600 and can increase that to 1,300 hp and 9,500 rpm. We can design a custom rod for applications producing 2,000 hp and significantly more.

“We still offer Pontiac-spec Pro-H series rods on a custom order basis, but since NRHA approved 6.635-inch big-block Chevy connecting rods with 2.2-inch crankpin journals for Pontiacs, we stock and commonly sell that size to Pontiac class-racers. They’re standard with a bronze bushing for floating wristpins, but we can accommodate a press-fit pin design on a custom-order basis.”

CP-Carrillo also stocks a wide array of Pro-H connecting rods with popular dimensions. “We can accommodate just about any required size on a custom order basis in less than 6 weeks. At $2,300 for a typical set, we feel that our rods are an excellent investment. Racers can make a onetime purchase for connecting rods that are durable enough to accommodate power increases each year without causing concern for failure.”

Oliver Connecting Rods in Grand Rapids, Michigan, has been producing premium connecting rods since 1982. “Our rods are aimed at the upper end of the performance market,” says owner Bruce Baldwin. “Ours are specifically designed for high-horsepower and/or very-high-rpm applications. They are extremely durable; it’s not uncommon to find them used for several seasons.”

Oliver rods feature proprietary “parabolic beam” styling. “Our uniquely shaped I-beam gives us the greatest strength-to-weight ratio of any connecting-rod style on the market today,” Baldwin explains. “They are CNC-machined from a billet of American-made E4340 aircraft-quality steel, and we have a proprietary heat-treatment process that includes triple tempering, which eliminates the internal stresses in the steel. It results in extraordinary anti-fatigue properties.”

Pontiac-spec rods are available on a custom-order basis. “We have found that most Pontiac racers competing at the top levels are using connecting rods that measure 6.6 inches or longer with 2.1 to 2.2-inch crankpin journals. We have a variety of Big-Block series rods available for immediate shipping and sell a Jobber for less than $1,300 per set. We can produce Pontiac-spec rods in less than eight weeks for a similar cost. And we can accommodate just about any custom length in that same time for less than $1,800.

“Our standard 6.8-inch Big-Block series rod weighs around 820 grams and includes ARP or A-1 cap screws. It’s ideal for engines producing 1,800 hp or more. Our Big-Block Max series is slightly beefier and weighs about 40 grams more. It’s ideal for engines with power adders producing 2,000-3,000 hp. Our new Super Max Series will handle up to 4,000 hp.”

GRP Connecting Rods in Denver, Colorado, has been producing premium aluminum connecting rods for more than 18 years.

“We supply high-quality billet-aluminum connecting rods for some of the fastest race engines in the world,” says General Manager Brian Scollon. “Intended for competition use only, our rods are machined from a special aluminum alloy billet bar. They feature radial serrations or machined grooves between the rod body and cap that serve to positively locate the two. ARP 2000-series 7⁄16-inch cap screws are used to maximize cap retention.”

A Pontiac-spec aluminum rod presently isn’t available from GRP. “Custom lengths are our specialty,” says Scollon. “However, the largest crankpin journal size we offer for a Pontiac is 2.2 inches. A typical 6.8-inch Big Block rod that a Pontiac hobbyist would use in a stroker application weighs 640 grams—about 200 grams less than a typical forged-steel unit. We can make them lighter or heavier depending upon the application, and can usually have a custom set to a customer in about two weeks.

GRP builds connecting rods for 9,000hp Top-Fuel engines, but those obviously wouldn’t fit into a traditional Pontiac block. “We build our rods for the intended horsepower range. For a Pontiac, the limit would be up to 1,200 naturally-aspirated horsepower and about 1,800 with nitrous, with an rpm limit of 8,500 in either instance. That set of 6.8-inch Big-Block rods retails for approximately $1,200.”

Since aluminum weighs less than steel, an aluminum rod can be made much beefier without excessive weight, producing a rod that’s more durable than a steel one for a given weight. Absorbing the extreme compressive forces associated within a competition engine can cause them to work-harden over time, eventually causing fatigue, and possibly cracking and failure. Periodic maintenance can help prevent it. That includes close inspections during routine teardowns, and even replacing them all together.

Scollon adds, “The typical lifespan of an aluminum rod is application-dependent, ranging from 50 passes in extreme 2,000hp applications, to several hundred passes in a milder application. During teardown, we advise checking the rods for out-of-round big and small ends, and measuring rod-bolt stretch. That will help determine how much abuse they’ve seen and if replacement is required.”