The cylinder block is the foundation of any engine. It houses the crankshaft; connecting rods and pistons; camshaft; and oiling system passages. During each revolution, the block endures extreme cylinder pressure and rotational stress in practically every direction. It must be designed and constructed of material that’s durable enough to prevent fatigue and failure when operating within its intended limits.

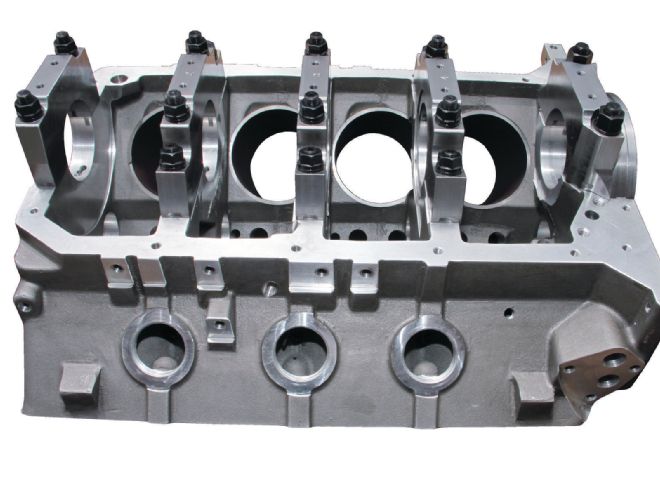

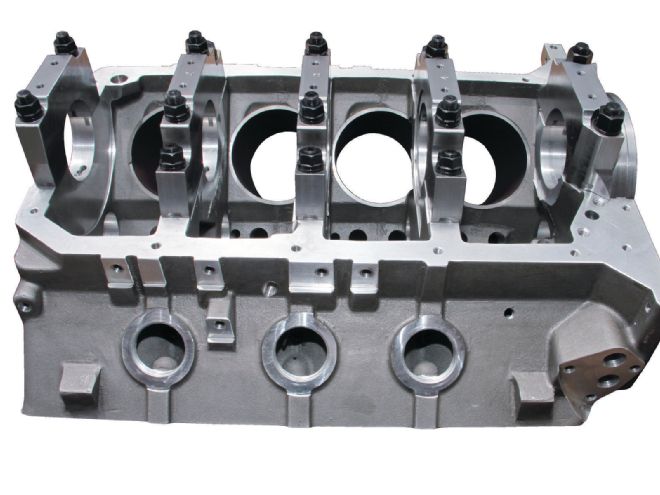

The new aluminum block from All- Pontiac.com is an extremely durable casting that retails for under $5,000 and weighs just 137 pounds with the main caps in place. That’s about 75 pounds less than a similarly prepped Pontiac block, and about 115 pounds less than a typical iron IA II block.

The new aluminum block from All- Pontiac.com is an extremely durable casting that retails for under $5,000 and weighs just 137 pounds with the main caps in place. That’s about 75 pounds less than a similarly prepped Pontiac block, and about 115 pounds less than a typical iron IA II block.

The original Pontiac V-8 block was constructed of cast-iron—an ideal material due to its relatively low production cost and resounding durability. It’s very tough and rarely troublesome in mild-to-moderately modified applications. The displacement, engine speed, and horsepower required to compete at higher racing levels exposed its limitations, however. At least two different aftermarket cast-iron Pontiac blocks are presently available, and both feature OE-like external dimensions, but are much beefier internally, greatly improving reliability in maximum-performance applications.

Cast-aluminum Pontiac blocks date back to the days of Mickey Thompson. Most advantageous for their lightweight construction, only a handful of aluminum Pontiac blocks were produced over the years. Modern racers yearned for a high-quality aluminum casting, and AllPontiac.com in Richmond, Virginia, responded with an aluminum version of its popular iron IA II block in the mid-2000s. It has recently developed a new aluminum casting, giving Pontiac racers the ultimate lightweight block for serious competition. Follow along as a company insider details that accomplishment.

Cast-aluminum engine components have been around for decades. When compared to iron, aluminum is generally lighter and dissipates heat quicker. Without proper heat treating, however, cast-aluminum isn’t nearly as durable as cast-iron, and that’s what plagued manufacturers early on. The heating and cooling cycles associated with normal operation can cause aluminum to harden. Warping, leaking, and cracking were common with cast-aluminum blocks and cylinder heads in the early years.

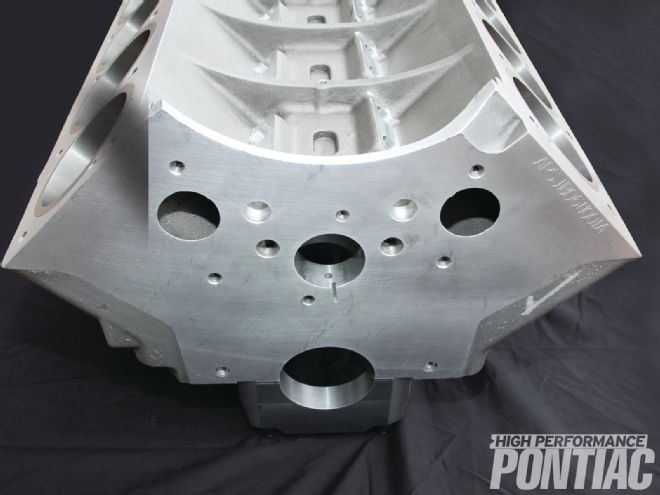

The front surface of the new aluminum block is made thicker, and ties directly into the main webbing and oil-pan rails. It’s ready to accept a motor plate for serious competition. Cam bearing choices range from standard size to 60 mm.

The front surface of the new aluminum block is made thicker, and ties directly into the main webbing and oil-pan rails. It’s ready to accept a motor plate for serious competition. Cam bearing choices range from standard size to 60 mm.

With modern casting techniques and heat-treating processes, today’s cast-aluminum engine components are nearly as durable as any vintage cast-iron original. Cast-aluminum intake manifolds, cylinder heads, and blocks are commonplace in modern production vehicles, and warranty claims stemming from failure when operating within the intended limits are extremely rare.

A number of companies produce a wide array of cast-aluminum aftermarket Pontiac engine components today. That includes stock-replacement and high-performance intake manifolds, cylinder heads boasting increased airflow capacity, and high-strength blocks. The appealing appearance and performance-oriented aura of cast-aluminum makes such components popular with hobbyists. Racers are also enamored with aluminum’s lightweight yet sturdy nature, and its ability to help them run quicker.

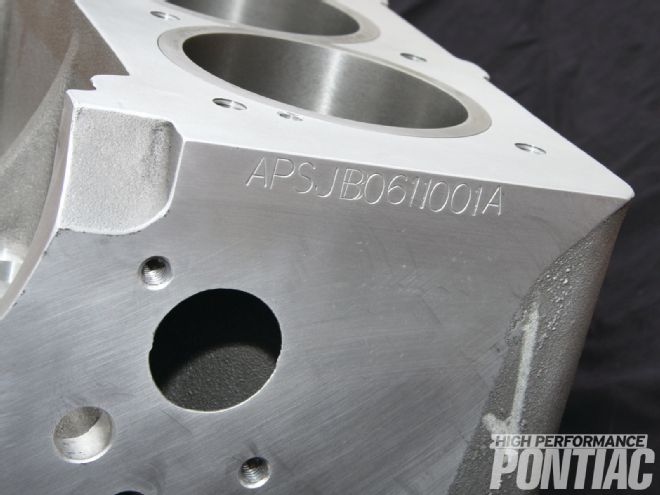

Featuring a deck height of 10.24 inches like the OE unit, the cylinder-head deck surface is extremely thick and boasts a dry deck. Coolant passages are easily drilled using a head gasket as a template.

Featuring a deck height of 10.24 inches like the OE unit, the cylinder-head deck surface is extremely thick and boasts a dry deck. Coolant passages are easily drilled using a head gasket as a template.

“At AllPontiac.com, we’re always looking for ways to improve traditional Pontiac performance and satisfy our customer’s needs,” says co-owner Frank Gostyla. “We pride ourselves in the high-quality, high-performance components that we’ve brought to market, such as the 400-cfm Tiger Head (originally designed by Don Johnston of DCI Motorsports) and the large-bore, cast-iron IA II block. We feel as if both have helped take Pontiac performance to the next level.”

An aluminum block reduces front-end vehicle weight, and that can improve the performance of most any nose-heavy car in any form of racing. “It also improves braking and cornering, and reduces overall stress on the entire mechanical system of a vehicle,” adds Gostyla. “Many customers asked us to produce a high-strength cast-aluminum block similar to our iron IA II for one or more of those reasons. So we converted the iron IA II mold to produce about 50 aluminum IA II blocks around 2007. They worked well but the original tooling wasn’t designed for aluminum, and it was costly to convert it back and forth.”

The steel cylinder sleeves are replaceable. A shrink-fit design, the sleeves feature strategically located flat surfaces that positively lock them into place and they are .005-inch above the deck surface to promote maximum gasket seal. A maximum-bore diameter of 4.35 inches is suggested, but 4.375-inch or slightly more may be possible with the 0.500-inch wall thickness.

The steel cylinder sleeves are replaceable. A shrink-fit design, the sleeves feature strategically located flat surfaces that positively lock them into place and they are .005-inch above the deck surface to promote maximum gasket seal. A maximum-bore diameter of 4.35 inches is suggested, but 4.375-inch or slightly more may be possible with the 0.500-inch wall thickness.

Living up to its mission statement, AllPontiac.com decided to provide Pontiac racers with the ultimate lightweight cast-aluminum block. “We felt that a very high-strength, lightweight block was required to compete with a Pontiac at the highest levels. Development began in 2008 and unlike our first aluminum casting, the new block shared no tooling with the iron IA II. To produce the highest-quality block possible, we partnered with the company that built the tooling for the famed aluminum Donovan casting for small-block and big-block Chevy.”

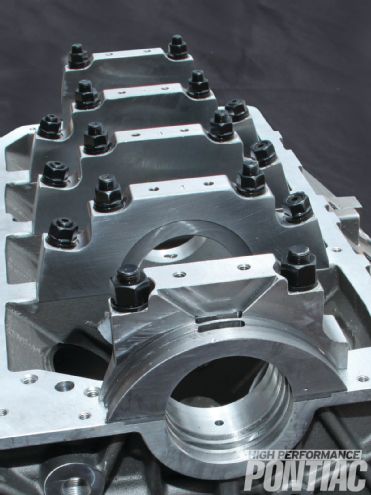

The lifter valley walls of the new aluminum casting are thicker than the iron IA II block. Also taller and wider are the lifter valley support rails, which stem from the main saddles. The lifter bores can be machined to nearly 1 inch to accommodate up to 0.937-inch-diameter lifters.

The lifter valley walls of the new aluminum casting are thicker than the iron IA II block. Also taller and wider are the lifter valley support rails, which stem from the main saddles. The lifter bores can be machined to nearly 1 inch to accommodate up to 0.937-inch-diameter lifters.

AllPontiac.com knew its new cast-aluminum block would be used in high-horsepower Pontiac engines where forced induction was common. “We used valuable input from Rodney Butler of Butler Performance, and Pontiac hobbyist and automotive engineer Tom Vaught when designing the new block. Their experience with boosted Pontiac applications helped us ensure that the weaker areas of the stock Pontiac block were thoroughly addressed,” adds Gostyla.

Additional support ribbing in the bellhousing flange makes the new aluminum casting more rigid. Like the iron IA II, it too features dual bell-housing bolt patterns that allow the use of B-O-P and Corporate-type transmissions.

Additional support ribbing in the bellhousing flange makes the new aluminum casting more rigid. Like the iron IA II, it too features dual bell-housing bolt patterns that allow the use of B-O-P and Corporate-type transmissions.

The AllPontiac.com aluminum block shares many of its specifications with the iron IA II. That includes siamesed cylinder bores, extra-thick main saddles, wider oil-pan rails, and four-bolt main caps. Like its cast-iron brethren, the new aluminum casting uses threaded freeze plugs, and contains a five-bolt motor mount flange for easy and convenient chassis installation. It also shares its external dimensions with a stock Pontiac block and will accept most any other OE-Pontiac component.

The similarities are in appearance only, however. When compared to an iron IA II block, internally the AllPontiac.com aluminum block features additional material in the main saddles, camshaft tunnel, deck surface, and inside wall of the rear main journal. The oil-pan rails are completely solid and have no coolant passing through them. While that may be a concern with a cast-iron block, aluminum dissipates heat so much quicker that it’s a nonissue. All 90-degree angles. are radiused. “This allows ultrasonic vibrations to pass through areas of the block without creating the possibility of fractures,” adds Gostyla.

Billet-steel, four-bolt main caps with 3-inch-diameter journals are standard equipment. The caps are doweled and registered for maximum retention, and the outer cap bolts are splayed, which serves to draw the bottom of the block together.

Billet-steel, four-bolt main caps with 3-inch-diameter journals are standard equipment. The caps are doweled and registered for maximum retention, and the outer cap bolts are splayed, which serves to draw the bottom of the block together.

Using the same foundry that produces the Donavan block for Chevy racers, it takes two weeks to produce the AllPontiac.com aluminum block. It’s constructed of AA356 aircraft-grade alloy that’s Strontium modified. Three times as many chill plates, which are made of four different materials, are used to make the aluminum denser and solidify evenly.

After pouring and cooling, the aluminum block is heat-treated to T-6 temper. The finished block is then blasted with steel shot to remove any external stress risers, and is then fully machined. It retails for less than $5,000, and like the iron IA II, AllPontiac.com offers a number of options so racers can tailor their new aluminum block to fit their specific application.

The AllPontiac.com aluminum block includes additional support straps on both sides of the block, which are tied directly to the main saddles. Five-bolt motor mounts allow for easy installation.

The AllPontiac.com aluminum block includes additional support straps on both sides of the block, which are tied directly to the main saddles. Five-bolt motor mounts allow for easy installation.

Throughout development, Gostyla tells HPP that AllPontiac.com hoped to provide the Pontiac community with an exceptionally strong, lightweight block that can replace any traditional Pontiac block without any modifications. It takes just one look at the new AllPontiac.com aluminum block to tell that it’s quite likely destined to be an affordable favorite with top Pontiac racers!