When it comes to making power, there is little need for convincing when the subject of GM LS-Series engines enters the conversation. Right from the jump, these are some of the most powerful OEM engines ever delivered by the Motor City, and that’s just the start. The healthy aftermarket support means the sky is the limit when looking to breathe even more horsepower into these already stout powerplants. Since its inception as an all-aluminum 346-cube unit in 1997, the LS-series has been produced in a wide range of OEM configurations, using both aluminum and cast-iron blocks. OEM displacements range from 4.8-liter (290 cid) using a 3.78-inch bore, to the substantial 4.125-inch bore, 7.0L configuration of the LS7. Any of these LS-family engines can swallow a meaty stroker crank, however the bigger bore engines are naturally better endowed when outright power, torque, and displacement are the goal.

While the 4.125-inch bore blocks offer the most displacement potential, their limited production makes them an unlikely candidate when considering a budget build. On the other hand, the iron 6.0L truck blocks offer an ample bore size of 4.00 inches, right in the sweet spot for a big-cube stroker. The abundant production of the 6.0-liter ensures that they are plentiful in the salvage yards. To Bret Bowers of Racing Engine Design, this seemed like a reasonable basis for a hot LS engine build. The engine featured here was built to compete in the AMSOIL Engine Masters Challenge, our annual engine-building competition. Stretched to 426 ci and producing 643 hp, this combination illustrates the potential of the 6.0L LS.

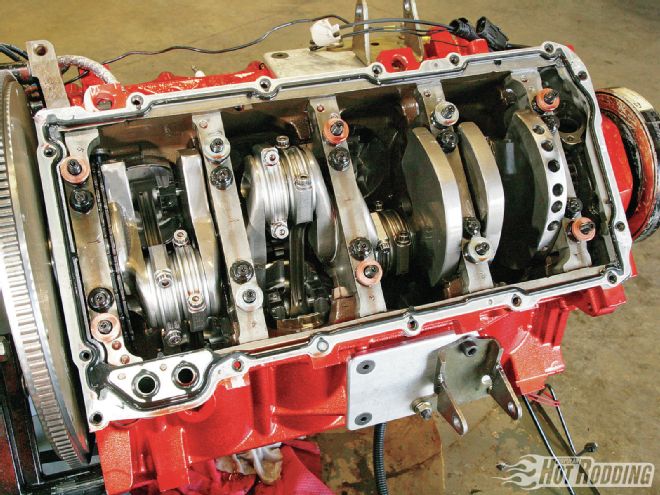

Want to build a rock-solid LS-Series engine on a reasonable budget? Start with a common iron 6.0L truck block and stuff it full of cubes via a 4.100-inch stroker crank and the corresponding rods and pistons. You’ll have 425 cubes at your disposal! This block will accept the big stroker crank without modifications. The Manley crank rides in a set of Clevite bearings, and the main caps are secured with ARP fasteners.

Want to build a rock-solid LS-Series engine on a reasonable budget? Start with a common iron 6.0L truck block and stuff it full of cubes via a 4.100-inch stroker crank and the corresponding rods and pistons. You’ll have 425 cubes at your disposal! This block will accept the big stroker crank without modifications. The Manley crank rides in a set of Clevite bearings, and the main caps are secured with ARP fasteners.

Configuring The Cubes

The starting point for this build is a ’04 6.0L truck engine core, and as Bowers explains, these units are virtually bulletproof in a performance application: “We have used this block in very high-horsepower applications; because it’s iron, the cylinder walls are very stable, as is the main structure in the crankcase. It doesn’t change shape with heat as much as an aluminum block, and that’s why we tend to use an iron block for a pure horsepower application.” Owing to the robust OEM configuration, the bottom end really needed a minimal amount of modification, and, in fact, it is remarkably stock. As Bowers tells us: “I really didn’t change anything in the block besides the crank and reciprocating assembly. I left the oiling system and oil pump stock, just like the truck. We added some extra drain back in the windage tray to control the oil a little better. For the most part, all we needed to do is blueprint the block and torque-plate hone it.”

The iron 6.0L truck engine is already packing ample cubes for a small-block engine, using a bore of 4.00 inch and a stroke of 3.622 inch for a stock displacement of 370 ci. This is where Bowers made a major departure from the OEM configuration, upsizing the cubes big time with a 4.100-inch stroke Manley crank. The long-stroke combination is just the setup for a broad powerband with a huge increase in available torque. Bowers tells us that the long arm drops right into the 6.0L block: “You don’t have to do a thing to make the stroker crank fit. There is no clearancing or anything needed.” With a finished bore size of 4.060 inches and the 4.100-inch stroke crank, the volume is pumped up to 425 cubes.

The stroker combination is completed with a set of Eagle lightweight H-beam rods in a length of 6.125 inches, and Manley pistons specific to this combination. The pistons feature an antifriction moly coating on the skirts. The Total Seal ring package consists of a 1.5mm moly top ring, followed by a 1.5mm Napier-faced second ring, and a 3mm oil ring.

The stroker combination is completed with a set of Eagle lightweight H-beam rods in a length of 6.125 inches, and Manley pistons specific to this combination. The pistons feature an antifriction moly coating on the skirts. The Total Seal ring package consists of a 1.5mm moly top ring, followed by a 1.5mm Napier-faced second ring, and a 3mm oil ring.

Now, don’t get the idea that it takes exotic, one-off parts to put together a similar short-block. Bowers used readily available, off-the-shelf parts throughout. “Everything in this engine was off the shelf; nothing was custom. We used Manley pistons and Eagle lightweight 6.125-inch rods. We didn’t change anything in the rotating assembly; we just balanced it. You can readily order any of these pieces to build this engine.”

Bowers did experiment a bit with the pistons, making mill-cut grooves in the piston crowns in the vicinity of the spark plugs: “I looked at the chamber shape and design and tried to gain some turbulence in the spark plug area of the chamber. It was just an experiment. I don’t know if it helped it or not, but it seemed to help reduce the tendency to detonate. I made horizontal and vertical cuts with a ball mill that line up with the spark plug.” Wrapping the pistons are Total Seal conventional rings in a 1.5mm/1.5mm/3mm ring package, featuring moly top rings with Napier second rings to improve oil control.

The Harland Sharp rocker arms are a bolt-in installation on the OEM heads, and provide adjustability in the valvetrain where the OEM engine has none. The 1.8:1 ratio rockers deliver .648-inch lift via a 237-degree duration at .050 Bullet single-pattern cam.

The Harland Sharp rocker arms are a bolt-in installation on the OEM heads, and provide adjustability in the valvetrain where the OEM engine has none. The 1.8:1 ratio rockers deliver .648-inch lift via a 237-degree duration at .050 Bullet single-pattern cam.

Top End, Cam, and Valvetrain

With the wide proliferation of cylinder heads available for LS-series engines, there are seemingly endless choices on how to top the engine. Bowers selected the factory LS7 cylinder heads, based upon flow bench testing. “We took all the cylinder heads that we could use, and filled them to a volume that we thought would be effective in this rpm range, and the LS7 head proved to have the best flow.” The cylinder head was modified to optimize midrange flow and torque production over a wide operating range, with the final intake port volume reduced to 256 cc, from the factory 278 cc. The intake ports feature a vane in the transition from the runner to the bowl, which Bowers designed to improve the wet flow characteristics: “We were trying to direct the air and fuel off of the spark plug. The vane pushes the air to the side and keeps the big drops of fuel that come at low speed off the plug. It also helps to even out the flow and picks up the overall intake port flow.” To fit the LS7 head to the smaller bore of the 6.0L block, the exhaust valve diameter was reduced to 1.560 inches.

Complementing the cylinder heads is an intake manifold from Mast Motorsports. This manifold was purchased fully CNC ported, however, as with the heads, the volume of the manifold was reduced to improve flow velocity and enhance the engine’s torque production in the lower end of the powerband. Completing the induction is a TPIS 114mm single butterfly throttle body, with FAST 36 lb/hr injectors and FAST fuel rails. A FAST XFI ECU operates the injection system. Bowers was impressed with the FAST electronics: “It was absolutely the best stuff we’ve ever used. It is super easy to tune and control, and it is very forgiving, and they have great support for it too.” FAST also supplied the XIM box to control the MSD coil-pack ignition.

In keeping with a goal of maximizing torque over a broad rpm range, the intake ports were reduced in volume from 278 cc to 256 cc, using epoxy where required. An interesting vane design was formed in the bowl area of the intake runner, with the intention of improving wet flow into the chamber.

In keeping with a goal of maximizing torque over a broad rpm range, the intake ports were reduced in volume from 278 cc to 256 cc, using epoxy where required. An interesting vane design was formed in the bowl area of the intake runner, with the intention of improving wet flow into the chamber.

To work the valves, Bowers selected a Bullet single-pattern hydraulic-roller grind with 237 degrees duration at .050. Bowers explained his selection: “We looked at all sorts of grinds, but I thought with the merged header collector and the other things we had going, I didn’t need any extra exhaust duration. I was trying to make a bunch of midrange power, and when I figured everything in, I thought that up to 6,500 rpm the single-pattern cam was great. If I would have added 4-5 degrees of exhaust duration or more it would have hurt the low end.” The lobe separation angle was ground at 104 degrees. Bowers elaborated: “The tight lobe separation seems to make a lot more midrange torque, which was our focus on this engine. If I default to a tight lobe separation cam, that will always pick up midrange torque.”

To allow the Bullet cam to work to its potential, the rest of the valvetrain needs to be up to the task. The heads were filled with Manley LS7 replacement valves, with the aforementioned reduced exhaust valve diameter. The rockers are 1.8:1 Harland Sharp bolt-on aluminum rollers, which feature an adjustable pushrod cup. The rockers work with the Bullet cam to deliver .648-inch lift at the valve. COMP heavy-wall 3/8-inch pushrods transfer the motion from a set of COMP limited-travel hydraulic roller lifters, while PAC beehive springs control the valves. With a peak engine speed target of 6,500 rpm, this valvetrain combination performed beautifully.

With the internal hardware in place, what remained was to dress the engine with the final components needed for a running assembly. A Meziere water pump and ATI damper finished off the front of the engine, while a set of Schoenfeld headers were bolted on to handle the exhaust. The 1.75-inch primary diameter headers were fitted with merge collectors, and that helped the midrange output and average torque, with a small penalty in outright peak horsepower. Experimenting with header primary tube length showed the longer tubes tilted the torque curve to favor the lower rpm range, while less tube length had the opposite effect, while the average power over the full rpm range remained little changed.

The coil-on-plug ignition features an array of MSD coils working through a FAST XIM ignition controller, which in turn ties in with the FAST XFI ECU.

The coil-on-plug ignition features an array of MSD coils working through a FAST XIM ignition controller, which in turn ties in with the FAST XFI ECU.

Deliver The Numbers

This engine was built with one goal in mind, and that was to maximize its power output between 2,500 and 6,500 rpm. That means that the torque comes in like a sucker punch right off the bottom—where you least expect it—and keeps coming at you as the needle on the tach swings to the sky. Right off the bottom at just 2,500 rpm, this combination assaults the senses with over 500 lb-ft on tap. From that start, torque piles up in abundance, pouring on the twist until a peak of 600 lb-ft is reached at 4,800 rpm. That’s over 1.4 lb-ft per cube of shove, and it’s on pump gas. Of course, anytime the torque comes on like a wrecking crew, the horsepower is following close behind. On the dyno, the power numbers rolled in at 643 hp at 6,200 rpm—plenty of output to prove a point.

On The Dyno Racing Engine Design 426 LS RPM TQ: HP: 2,500 503 240 2,600 513 254 2,700 518 267 2,800 517 276 2,900 510 282 3,000 502 287 3,100 494 292 3,200 486 296 3,300 476 299 3,400 473 306 3,500 475 316 3,600 477 326 3,700 490 345 3,800 512 371 3,900 538 399 4,000 557 424 4,100 568 444 4,200 578 462 4,300 584 478 4,400 590 494 4,500 594 509 4,600 598 524 4,700 599 536 4,800 600 548 4,900 599 559 5,000 597 568 5,100 594 577 5,200 590 584 5,300 587 592 5,400 584 601 5,500 579 606 5,600 576 614 5,700 573 622 5,800 569 629 5,900 564 633 6,000 558 637 6,100 552 641 6,200 544 643 6,300 535 642 6,400 527 642 6,500 514 636

By The Numbers

426ci LS Chevy

Block: 6.0L LS iron truck, overbored .060 inch

Bore: 4.06 inches

Stroke: 4.10 inches

Displacement: 424.6 ci

Compression ratio: 11.5:1

Crankshaft: Manley, standard weight

Camshaft: Bullet hydraulic roller

Timing chain: Cloyes

Lifters: COMP limited-travel hydraulic

Pushrods: COMP Cams 7.500-inch (3/8-inch diameter)

Springs: Beehive

Installed height: 1.85 inch

Spring load, closed: 160 pounds on the seat

Spring load, open: 410 pounds at 1.160-inch lift

Retainers: Manley 7-degree steel

Valve locks: Manley 7-degree beadlock

Duration, intake: 237 degrees at .050

Intake lift: .648 inch

Duration, exhaust: 237 degrees at .050

Exhaust lift: .648 inch

Rockers: Harland Sharp

Rocker ratio: 1.8/1.8

Lobe separation: 104 degrees

Installed centerline: 102 degrees

Ring pack: Total Seal; 1.5mm, 1.5mm, 3.0mm oil

Ring endgap: .017-inch top, .026-inch second

Piston: Manley forgings with coated skirts, custom tops

Piston clearance: .006 inch

Main studs: ARP

Rods: Eagle 6.125-inch H-beam

Main bearings: Clevite H

Rod bearings: Clevite HN

Main journal diameter: OEM

Rod journal diameter: 2.100 inches

Main clearance: .0025 inch

Rod clearance: .0024 inch

Cylinder heads: GM LS7

Head bolts: ARP studs

Intake manifold: Mast Motorsports two-piece

Intake port flow: 352 cfm at .550-inch lift

Exhaust port flow: 254 cfm at .550-inch lift

Intake valve: Manley stainless 2.200 inch

Exhaust valve: Manley stainless 1.540 inch

Cylinder head gaskets: Fel-Pro 1041 (.041 inch)

Piston/head clearance: .019 inch

Engine gaskets: OEM

Throttle body: 114mm TPIS

Fuel rails: FAST

Injectors: FAST 36 lb/hr

Header: Schoenfeld 1.750-inch diameter with 3-inch merge collector

Coils: MSD

Ignition: FAST XIM

Spark plug wires: Champion

Damper: ATI with 10 percent underdrive steel hub with aluminum shell

Water pump: Meziere electric

Oil pan: stock 6.0 truck

Oil pump: Melling Select

Oil: AMSOIL 5W/30