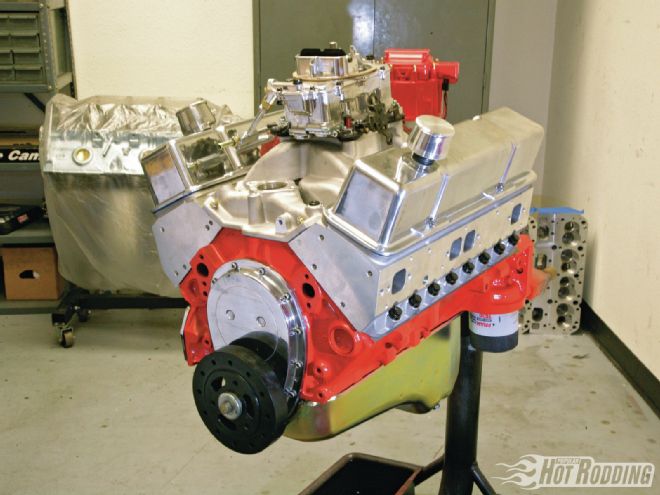

Back in the Stone Age, when Members Only jackets and David Hasselhoff were still relevant, hot rodders built 383ci small-block Chevys. With simplicity and affordability on its side, the 383 was the street/strip setup to have back in the ’80s and ’90s. In the enlightened age that we live in today, however—replete with raised-deck aftermarket blocks and stroker cranks that grow on trees—that archaic combination just seems so last, last, last decade. In some respects, it’s easier to build a 600hp 454 small-block with today’s aftermarket arsenal than it was to build a 400hp 383 with yesteryear’s repurposed stock cranks and junk cylinder heads. Be that as it may, very few people have $15,000 to blow on an engine build, which begs the question: What happens when you combine old-school pragmatism with the cutting-edge technology infused into modern engine hardware? The answer is you hit a sweet spot on the horsepower-per-dollar spectrum, and we have the proof to back it up. Thanks to a value-packed stack of parts from Scat, Summit, and EngineQuest, we just put the finishing touches on a 446hp 383 built for a grand total of $4,360. Best of all, this low-buck recipe is ridiculously easy to replicate.

The impetus for this build started innocently enough as a simple refresh job of the 350 small-block that came equipped in our ’68 Nova project car. That wheezy combo was replaced by a potent Dart 400ci SHP crate motor kicking out 523 hp long ago. Like most hot rodders, we couldn’t bear the thought of letting a perfectly good motor go to waste, so we hatched a plan to rebuild the tired 350 on the cheap. The original plan called for honing the block, turning the crank, dropping in new rings and bearings, sliding in a hotter cam, and topping it off with a set of EngineQuest aluminum cylinder heads. Unfortunately, tearing the motor down revealed a cracked block and a crank that was beyond salvageable. This discovery required a slight change of plans, and since the crank needed replacement anyway, it only made sense to stroke it while everything was apart.

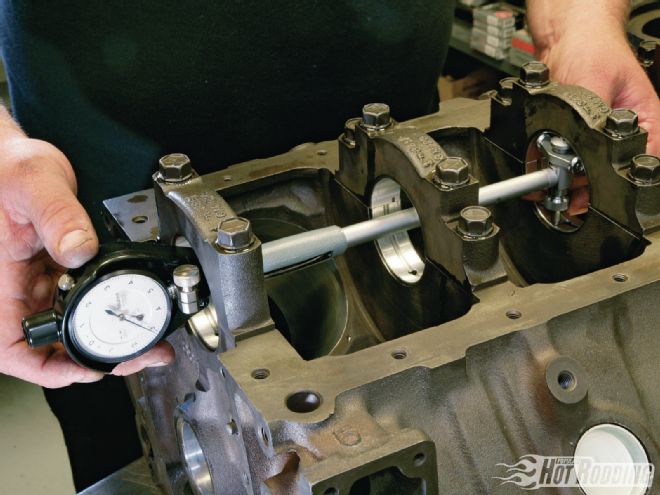

As we’ve come to expect from AA Midwest, our 350 core block was in great shape. Outlaw Racing Engines magnafluxed the block to check it for cracks, then bored and honed it .030-inch over. The block was then decked, and new cam bearings were installed as well.

As we’ve come to expect from AA Midwest, our 350 core block was in great shape. Outlaw Racing Engines magnafluxed the block to check it for cracks, then bored and honed it .030-inch over. The block was then decked, and new cam bearings were installed as well.

Easy Displacement

In need of a core motor, we contacted the good folks at AA Midwest to see what they had in stock. For $500, they set us up with a 350 short-block equipped with factory four-bolt main caps. Upon contemplating our stroking options, it became quite clear that what made the venerable 383ci small-block combo so popular decades ago still applies today. Factory 350 cores are plentiful and inexpensive, and when punched out .030-inch over and matched with a 3.750-inch stroke crank, the result is a healthy 33ci bump in displacement without having to grind the bejesus out of the block. Try to cram a 3.875- or a 4.000-inch crank inside a production block, and the additional grinding required at the bottom of the cylinders to help clear the rod bolts often breaks right into a water jacket. Furthermore, the extra stroke, when paired with a stock 9.025-inch deck block, pushes the piston wristpins uncomfortably close to the crowns, and shortening up on the rod length to compensate further compromises the already unfavorable rod-to-stroke ratio imparted by a longer-stroke crank.

Radical engine combos often require specific rod lengths, piston compression heights, or dome volumes. The nice thing about a keep-it-simple approach is that a variety of off-the-shelf rotating assemblies will be compatible with your goals. Scat’s turnkey stroker kit includes a cast-steel crank, forged I-beam rods, 10.2:1 hypereu-tectic pistons, rings, and bearings. It comes balanced straight from Scat, cutting down on your machining bill.

Radical engine combos often require specific rod lengths, piston compression heights, or dome volumes. The nice thing about a keep-it-simple approach is that a variety of off-the-shelf rotating assemblies will be compatible with your goals. Scat’s turnkey stroker kit includes a cast-steel crank, forged I-beam rods, 10.2:1 hypereu-tectic pistons, rings, and bearings. It comes balanced straight from Scat, cutting down on your machining bill.

The happy 383, on the other hand, eliminates many of these drawbacks. For those who adhere to the long-rod school of thought, it’s possible to run 6.125-inch connecting rods with a 3.750-inch stroke in a standard deck height block and still retain a reasonable 1.000 inch of piston compression height. While rod-to-camshaft interference can become an issue with long-duration grinds, small base circle cams offer an easy solution. So while a Gen I Mouse motor build is somewhat ordinary in a world that’s gone LS-crazy, building a venerable 383 still makes a whole lot of sense.

Keeping it Cheap Unlike in years past, when building a 383 required procuring a stock 400 crank and grinding down the main journals to fit inside a 350 block, the aftermarket is now chock full of durable cast- and forged-steel 3.750-inch cranks. Given that our goal was to make in the neighborhood of 450 hp, a pricier forged unit seemed like overkill. Consequently, we ordered a complete Scat rotating assembly that fit out budget-stretching endeavors perfectly. It includes a Series 9000 cast-steel crankshaft, forged 6.000-inch I-beam connecting rods, Keith Black 10.2:1 hypereutectic pistons, Total Seal rings, and King bearings. The entire setup was balanced at Scat prior to shipping and lists for just $948. That’s one heck of a bargain in anyone’s book.

Sure it’s not as sexy as a forged piece, but the Scat Series 9000 cast-steel crank is still substantially stronger than a factory nodular iron unit. It features lightening holes in all the rod throws, aero-wing counterweights that reduce windage, straight-shot oiling holes, and micropolished journals.

Sure it’s not as sexy as a forged piece, but the Scat Series 9000 cast-steel crank is still substantially stronger than a factory nodular iron unit. It features lightening holes in all the rod throws, aero-wing counterweights that reduce windage, straight-shot oiling holes, and micropolished journals.

While a forged crank and pistons, along with Scat’s more rugged H-beam rods, would be a wise choice for forced induction or nitrous applications, all that would accomplish is add unnecessary cost without any appreciable benefits in durability for a moderate-rpm, naturally aspirated combination such as ours. Truth be told, even the budget-priced internals used in our 383 build can easily handle a 150-shot of nitrous without much fuss. Andy Mitchell of Outlaw Racing Engines, who manned the boring bar and dial bore gauge during our build, says the need to stretch a buck is a prevalent theme with today’s hot rodders. “The days when people spent $30,000 on 632ci big-blocks are over. People don’t want to spend that much money anymore,” he says. “They see complete motors selling for $5,000 on eBay, so that really changes their expectations. These days, people want economical combinations that they can get some longevity out of. They’re racing cheaper, but that doesn’t mean you have to use low-quality parts. By carefully selecting your parts combination, you can have performance and durability at a reasonable price.”

Seriously Cheap Airflow

Although a two-bolt block would hold together forever at this power level, we couldn’t pass up on the opportunity to snag a factory four-bolt block. To keep costs down, we reused the factory main bolts, which are more than sufficient for this type of build. The main caps looked perfect, and align-honing wasn’t necessary.

Although a two-bolt block would hold together forever at this power level, we couldn’t pass up on the opportunity to snag a factory four-bolt block. To keep costs down, we reused the factory main bolts, which are more than sufficient for this type of build. The main caps looked perfect, and align-honing wasn’t necessary.

A short-block is only as good as the cylinder heads that feed it, and to get the most out of our budget 383, we ordered a set of EngineQuest AC200BS aluminum cylinder heads. These castings boast 197cc intake ports, 65cc combustion chambers, and 2.020/1.600-inch valves featuring a three-angle cut. We’ve had great luck with EngineQuest’s Vortec-style iron castings in past engine builds, so we were eager to give their new aluminum heads a shot. Not only do they weigh 58 pounds less per set than their iron counterparts, at just $1,098 per pair, they cost only $118 more. “We’ve had great success with our iron heads, and our goal was to transfer that same technology over to our new aluminum castings. These aluminum heads are based on our iron castings, both of which relied heavily on wet flowbench technology during their development,” says Don Knetzger of EngineQuest. “Since most of the R&D from the development work on our iron heads carried over into our new aluminum heads, this enabled us to keep costs down. The cooling passages have been slightly revised due to the different cooling properties of iron and aluminum, but otherwise the two heads are very similar in design and airflow. With all the 350 to 383ci motors that are still being built, a 200cc casting seemed like the best fit for the marketplace, although we are considering larger 220cc heads.”

Summit Pro Packs

While flat tappet cams still leave power on the table compared to roller grinds, modern profiles still boast remarkably steep lobe profiles compared to cams of just 10 years ago. Summit’s 246/246-at-.050 grind packs a healthy dose of duration over a relatively mild .500/.500-inch valve lift. It was matched up with Summit 1.5:1 stamped roller-tip rockers, and the pushrods were lifted from the Nova’s old motor.

While flat tappet cams still leave power on the table compared to roller grinds, modern profiles still boast remarkably steep lobe profiles compared to cams of just 10 years ago. Summit’s 246/246-at-.050 grind packs a healthy dose of duration over a relatively mild .500/.500-inch valve lift. It was matched up with Summit 1.5:1 stamped roller-tip rockers, and the pushrods were lifted from the Nova’s old motor.

To make sure that the airflow potential of the EngineQuest cylinder heads didn’t go to waste, we matched them up with an equally capable induction system. Summit Racing isn’t just a premier retailer of major-label goodies; the company has been rapidly expanding its line of private-label parts, and they even bundle them together for you in convenient packages to further maximize cost savings. To finish up the induction system, Summit set us up with one of its top end Pro Packs, which includes a dual-plane intake manifold, a 750-cfm carb, an air cleaner assembly, and intake gaskets and bolts all for $531.

The final link in buttoning the 383 up was selecting the valvetrain hardware, and once again we kept things as simple as possible. To that end, Summit set us up with one of its flat tappet cam and lifter kits, which lists at $134. The cam of choice features 246/246 degrees of duration at .050, with .500/.500-inch lift and a tight 108-degree lobe separation angle. While the duration specs might seem a bit aggressive for a 383ci combination, the motor’s healthy 10.2 compression ratio helps tremendously in terms of retaining low-rpm cylinder pressure and preserving driveability. Furthermore, opting for a flat tappet grind cut down on costs significantly.

Before sliding the pistons and rods in the bores, Mitchell filed the ring gaps to size. Since the 383 won’t see any nitrous, he set the top ring gap at a tight .020 inch, which works out to .0049 inch per inch of bore. The second ring gap was set at .018 inch.

Before sliding the pistons and rods in the bores, Mitchell filed the ring gaps to size. Since the 383 won’t see any nitrous, he set the top ring gap at a tight .020 inch, which works out to .0049 inch per inch of bore. The second ring gap was set at .018 inch.

What’ll She Do?

With most 383 builds, it’s usually necessary to notch the bottom of the cylinders to prevent rod-bolt-to-block interference. Scat’s Pro Stock I-beam rods incorporate a slender, low-profile design and ARP 7/16-inch capscrews to increase clearance. Mitchell simply tapered the head of the capscrews, and no clearancing of the block was required.

With most 383 builds, it’s usually necessary to notch the bottom of the cylinders to prevent rod-bolt-to-block interference. Scat’s Pro Stock I-beam rods incorporate a slender, low-profile design and ARP 7/16-inch capscrews to increase clearance. Mitchell simply tapered the head of the capscrews, and no clearancing of the block was required.

Since the very nature of budget-oriented engine builds is making respectable horsepower on the cheap, there’s always a bit of tension when strapping an untested combination to the dyno. Fortunately, our concerns were unfounded. With Outlaw’s Andy Mitchell doing the tuning and Westech’s Steve Brulé pulling the handle, the 383 served up 446 hp at a very street-friendly 5,900 rpm, and 474 lb-ft of torque at 4,000 rpm. Disproving any suppositions that our 383 is overcammed, it produced a stout 454 lb-ft at just 3,500 rpm. With a hydraulic roller cam of similar duration in lieu of our flat tappet unit, it’s conceivable that the 383 would have netted an additional 15-20 hp. Throw in a solid roller, and another 15-20 numbers on top of that is entirely feasible. Nonetheless, our budget 383 exceeded all expectations, proved extremely easy to assemble, and should provide tens of thousands of miles of hot rodding fun.

Where the Money Went Budget 383 Part: Source: PN: Price: Core 350 block AA Midwest NA $500 Rotating assembly Scat 90450BI $948 Connecting rods Scat 2-ICR6000 part of kit Pistons Keith Black KB122-030 part of kit Rings Total Seal CR3690-30 part of kit Main bearings King MB557 SI part of kit Rod bearings King CR807 SI part of kit Balancer Pro Products 80000 $55 Timing cover Procomp PC3322KIT $29 Timing set core motor NA $0 Oil pan Procomp PC03906 $43 Oil pump core motor M55HV $0 Cylinder heads EngineQuest AC200BS $1,098 Head gaskets Fel-Pro 1003 $76 Top End Pro Pack Summit 03-0221 $531 Intake manifold Summit 226010 part of kit Intake bolts Summit G1491 part of kit Intake gaskets Summit G2410 part of kit Carburetor Summit M08750MS part of kit Carb studs Summit G1422 part of kit Air cleaner Summit G3001 part of kit Cam/lifter kit Summit K00112 $134 Rocker arms Summit 141506 $90 Rocket studs Summit G1675 $13 Pushrods core motor NA $0 Rebuilt stock HEI core motor NA $101 Spark plugs Autolite 106 $12 Plug wires Procomp PC327 $71 Valve covers Procomp PC3251 $55 Exhaust gaskets Fel-Pro 1405 $17 Head bolts ARP 134-3701 $77 Main bolts core motor NA $0 Parts total: $3,850 Machine work Block bore & hone: $235 Deck resurface: $120 Magnaflux block: $80 Check for align hone: $40 Cam bearings: $35 Machine shop labor total: $510 Parts & labor total: $4,360

On the Dyno Budget 383 Small-Block Chevy RPM TQ HP 3,000 427 244 3,100 427 252 3,200 430 262 3,300 437 275 3,400 446 289 3,500 454 302 3,600 460 315 3,700 465 328 3,800 470 339 3,900 473 351 4,000 474 361 4,100 474 370 4,200 473 378 4,300 472 386 4,400 471 394 4,500 469 402 4,600 466 409 4,700 462 413 4,800 453 414 4,900 442 412 5,000 433 412 5,100 425 413 5,200 420 415 5,300 416 420 5,400 413 425 5,500 410 430 5,600 408 435 5,700 406 441 5,800 402 444 5,900 397 446 6,000 389 444