A camshaft's primary task is to open and close the intake and exhaust valves at specific points of crankshaft rotation, and small specification differences can have drastic effects on an engine's attitude. A cam designed to allow for 6,000-rpm performance will usually idle rough and make a typical vehicle laborious to drive in normal situations. While low-speed street manners may be less important if going fast is the goal, the best cam for a street-driven application is usually a subjective compromise of strong performance and tolerable street manners.

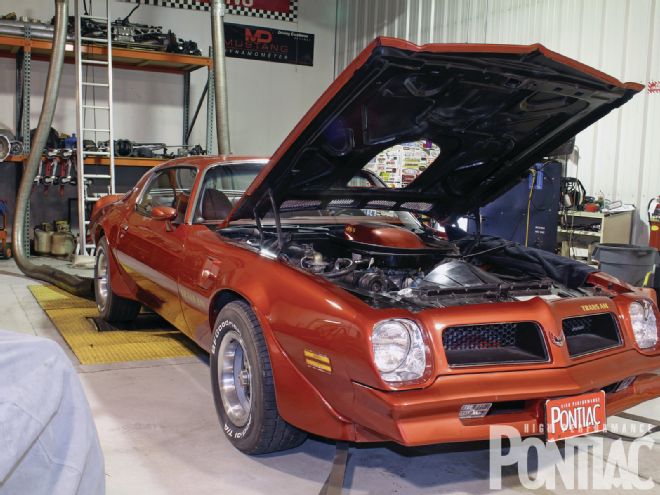

When we built our Trans Am’s 467ci in the early 2000s, we used an aftermarket single-plane intake manifold, square-bore carburetor, and a long-duration hydraulic flat-tappet camshaft. We recently decided to change directions, and installed a factory dual-plane intake manifold and Quadrajet to improve street manners. While these components had a noticeable effect, a cam swap gave it the largest attitude adjustment. So how much did the cam affect engine output? Read on to find out!

When we built our Trans Am’s 467ci in the early 2000s, we used an aftermarket single-plane intake manifold, square-bore carburetor, and a long-duration hydraulic flat-tappet camshaft. We recently decided to change directions, and installed a factory dual-plane intake manifold and Quadrajet to improve street manners. While these components had a noticeable effect, a cam swap gave it the largest attitude adjustment. So how much did the cam affect engine output? Read on to find out!

Our Pontiac engine rebuilds generally feature such factory-issued components as cast-iron cylinder heads, a dual-plane manifold, and a hydraulic flat-tappet camshaft with specifications similar to one of Pontiac's performance grinds. The approach rewards us with excellent reliability, driveability, and performance, while maintaining original appearance. And because of their reasonable cost and ease of installation, we can try another flat-tappet cam if the initial selection doesn't live up to our performance or drivability expectations.

We deviated from our usual plan when building the 467ci for our '76 Trans Am. The engine was fitted with an aftermarket single-plane intake manifold and carburetor, and a long-duration camshaft to improve its high-rpm potential. We were willing to tolerate its boisterous low-speed attitude to achieve the desired performance level, but after several years in this configuration, we decided to tame the 467ci slightly. The easiest and most cost-effective way to change its demeanor is to replace its aggressive flat-tappet camshaft. Follow along as we document that process and measure the results.

To measure the cam swap’s effects on engine performance, we took our Trans Am to C&S Dyno Shop in Omaha, Nebraska. After a complete tuning session, it peaked at 355 rwhp and 402 rwtq on the company’s Mustang chassis dyno with the No. 2043NHL camshaft, cast-aluminum 455 H.O. intake manifold, and modified Quadrajet. When factoring the driveline loss, the engine was producing about 450 hp and 500 lb-ft at the crank.

To measure the cam swap’s effects on engine performance, we took our Trans Am to C&S Dyno Shop in Omaha, Nebraska. After a complete tuning session, it peaked at 355 rwhp and 402 rwtq on the company’s Mustang chassis dyno with the No. 2043NHL camshaft, cast-aluminum 455 H.O. intake manifold, and modified Quadrajet. When factoring the driveline loss, the engine was producing about 450 hp and 500 lb-ft at the crank.

Assembling the Combo

When assembling the drivetrain combination for our '76 Trans Am several years ago, we wanted a high-performance engine that produced around 500 hp, and ran and drove as well as it could. A '74 code-YY 455, which had been bored 0.030-inch, was the foundation of our buildup, and Chuck Willard of Willard Auto Machine (WAM) in Omaha, Nebraska, resized the nodular-iron crankshaft's rod journals to 2.2 inches and lengthened its stroke to 4.25. Total displacement measures 467 ci.

A pair of round-port No. 197 455 H.O. cylinder heads were shipped to Nunzi's Automotive in Brooklyn, New York, where owner Nunzi Romano modified them to improve airflow. Knowing that our Trans Am would be primarily street driven and the already high-flow intake port would provide strong top-end charge, Nunzi maximized low-lift airflow to promote strong throttle response and low-speed performance.

We selected a Nunzi’s Automotive No. 2042NHL camshaft for its 232/243 degrees of 0.050-inch duration, 0.490/0.500-inch valve lift with 1.6-ratio rocker arms, and 113 degrees of lobe separation. It’s designed to produce strong full-throttle performance, while offering excellent low-speed street manners when using stock-type components. It retails for about $250 and is available directly from Nunzi’s Automotive.

We selected a Nunzi’s Automotive No. 2042NHL camshaft for its 232/243 degrees of 0.050-inch duration, 0.490/0.500-inch valve lift with 1.6-ratio rocker arms, and 113 degrees of lobe separation. It’s designed to produce strong full-throttle performance, while offering excellent low-speed street manners when using stock-type components. It retails for about $250 and is available directly from Nunzi’s Automotive.

To complement available airflow and help us reach our performance goal, Nunzi recommended his No. 2043NHL hydraulic flat-tappet camshaft, featuring 244/252 degrees of 0.050-inch duration and 0.500-inch valve lift, an Edelbrock Torker II intake manifold, and a Holley 950 HP-series four-barrel carburetor. Based on similar combinations he's built for other customers, he estimated that our 467 was capable of generating 475-500 hp and 500-plus lb-ft of torque with proper tuning. We also added a five-speed manual transmission and 3.73 gears to maximize engine acceleration.

On the street, the Trans Am's lumpy idle let everyone within earshot know that a far-from-ordinary 455 was under its hood. We spent a great deal of time maximizing idle quality and low-speed street manners by adjusting the Holley carburetor and HEI distributor. Even with the long-duration cam, the car drove exceptionally well and its docility was impressive. Matting the accelerator, however, unleashed a near-500hp beast that happily pulled to 6,000 rpm without a hint of submission.

A camshaft swap is a fairly involved process that requires partial engine disassembly. After draining the coolant system and removing the engine accessories, intake manifold, and timing cover, we were able to extract the existing camshaft and install the new unit. The replacement was inserted into the block, and its valve events were verified using a camshaft-degree kit from Comp Cams. Since we already featured a step-by-step cam swap in a previous issue of HPP, we decided not to repeat it here. For that story, log onto the HPP website at www.highperformance pontiac.com/tech/hppp_0709_pontiac_comp_cams_camshaft_swap/index.html.

A camshaft swap is a fairly involved process that requires partial engine disassembly. After draining the coolant system and removing the engine accessories, intake manifold, and timing cover, we were able to extract the existing camshaft and install the new unit. The replacement was inserted into the block, and its valve events were verified using a camshaft-degree kit from Comp Cams. Since we already featured a step-by-step cam swap in a previous issue of HPP, we decided not to repeat it here. For that story, log onto the HPP website at www.highperformance pontiac.com/tech/hppp_0709_pontiac_comp_cams_camshaft_swap/index.html.

Back To Basics

After nearly 10 years and several thousand miles, the Trans Am's lumpy idle and deep rear-axle gearing began taking its toll on the driving experience. It just wasn't as much fun to drive on the street as it had once been, and it wasn't safe or practical to wind the engine out to 6,000 rpm in each gear. Driving in traffic meant continually shifting gears to keep the large-cube engine in its happy range, and that roused its healthy appetite for 91-octane fuel. We began searching for reasonable ways to shift engine power downward into a range that was more practical for normal street speeds.

Knowing that a spread-bore carburetor and dual-plane intake can enhance engine efficiency at lower rpm, along with a modified Quadrajet, we installed a factory cast-aluminum 455 H.O. manifold, which had been previously modified to increase airflow. As predicted, the newly installed components shifted the 467's power band downward several hundred RPM. Low-speed performance had noticeably improved, and though it still pulled very hard toward 5,500 rpm, it didn't feel quite as strong up top.

We’ve always had great success using Fel-Pro gaskets. The gasket sets used for this project include the No. MS90123 intake manifold, No. TCS13383-3 timing cover, No. VS50005AC valve cover, No. PS50045C pushrod cover (or valley pan), and No. 11497 distributor.

We’ve always had great success using Fel-Pro gaskets. The gasket sets used for this project include the No. MS90123 intake manifold, No. TCS13383-3 timing cover, No. VS50005AC valve cover, No. PS50045C pushrod cover (or valley pan), and No. 11497 distributor.

Once we determined that the cast-aluminum H.O. manifold and Quadrajet were permanent items, it was clear that the long-duration camshaft was overkill for the revised combination. It was designed for and performed extremely well with the aftermarket single-plane manifold and carburetor, but the factory dual-plane was limiting its effectiveness. A cam change would allow us to further improve its attitude, and if we selected the right camshaft profile, we could do it without seriously degrading performance.

To determine if our cam swap is a step in the right direction, we needed to first establish a performance baseline. On the Mustang chassis dyno at C&S Dyno Shop in Omaha, Nebraska, the Trans Am made 355 hp and 402 lb-ft of torque at the rear tires. When factoring a driveline loss of 25 percent, the 467 was producing about 450 hp and 500 lb-ft at the crank. That's about what we expected with our changes, and it also confirmed Nunzi's original estimation—our engine was producing more than 475 hp with the aftermarket intake manifold and carburetor.

We’ve run Brad Penn Racing oil in our Pontiacs for the past few years with excellent results. It features a high concentration of the desirable anti-wear additives intended to protect flat-tappet camshafts. In addition to its complete line of fully synthetic multi-viscosity oils, Brad Penn Racing also offers 30W Break-In oil, which is specifically designed for flat-tappet cam break-in.

We’ve run Brad Penn Racing oil in our Pontiacs for the past few years with excellent results. It features a high concentration of the desirable anti-wear additives intended to protect flat-tappet camshafts. In addition to its complete line of fully synthetic multi-viscosity oils, Brad Penn Racing also offers 30W Break-In oil, which is specifically designed for flat-tappet cam break-in.

Selecting a Camshaft

Hydraulic-roller camshafts are a popular upgrade during modern rebuilds. The roller action reduces friction and they're not susceptible to failures related to modern-spec oil. While the upgrade may add a few hundred dollars to the cost of a complete engine rebuild, it can cost $1,000 or more to retrofit a hydraulic-roller cam into an existing engine. While we'll certainly consider a roller cam when the 467 is due for a refresh, hydraulic flat-tappets can still perform remarkably well, and with their reasonable cost and ease of installation in an existing engine, they remain an easy and affordable performance modification.

Our experience with high-performance Pontiac engines using mostly stock components and a compression ratio of 9.5:1 or more is that they seemingly run best with 0.050-inch duration of 230 or slightly more, and about 10 degrees more exhaust duration. A relatively wide lobe-separation angle (112-114 degrees) reduces valve overlap, improving idle quality and low-speed performance, and tends to allow the engine to produce a substantial amount of midrange torque.

After breaking in the cam, we let the engine cool down and double-checked all of the carb and intake fasteners.

After breaking in the cam, we let the engine cool down and double-checked all of the carb and intake fasteners.

We considered a number of popular options, including an original Pontiac No. 041, but we were impressed with Nunzi's initial choice, so we contacted him again for his opinion on what he felt would work best with the revised combination. We explained that maintaining strong peak power was very important, but we also wanted to improve idle quality and low-speed street manners as much as possible. He suggested his No. 2042NHL, and within a few days, a new camshaft and lifter kit were on our doorstep.

The Cam Swap and Break-In

The cam swap was very straightforward, not unlike many of the others we've performed before. We reused a set of 1.6:1 cast-alloy Crower roller rocker arms to maintain near-0.500-inch valve lift with the new cam and set valve lash at one-half turn of lifter preload. The carburetor was primed and the engine fired within the first few revolutions after twisting the ignition key. The extended break-in process started immediately after.

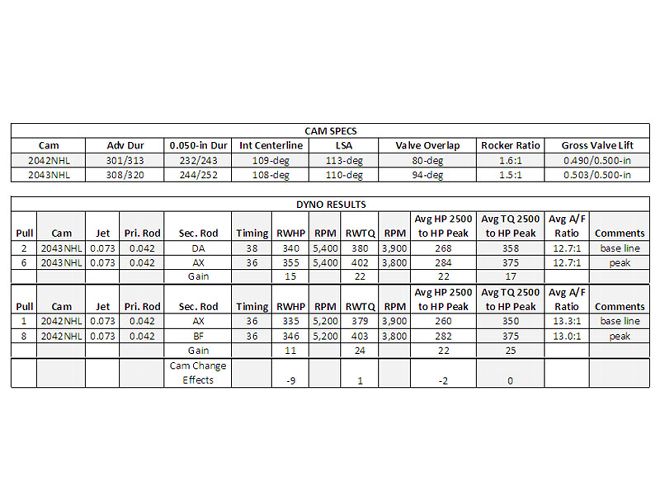

A follow-up dyno session at C&S Dyno Shop with No. 2042NHL installed produced 346 rwhp and 403 rwtq—about 10 peak horsepower less than the No. 2043NHL, but the same amount of peak torque. Average power numbers indicate that the engine hadn’t lost any performance. Subsequent test drives prove that idle quality and low-speed street manners had improved dramatically. That’s the exact result we were after.

A follow-up dyno session at C&S Dyno Shop with No. 2042NHL installed produced 346 rwhp and 403 rwtq—about 10 peak horsepower less than the No. 2043NHL, but the same amount of peak torque. Average power numbers indicate that the engine hadn’t lost any performance. Subsequent test drives prove that idle quality and low-speed street manners had improved dramatically. That’s the exact result we were after.

With the break-in complete, we reset idle speed to 900 rpm and trimmed the carburetor idle- mixture screws in preparation for a quick trip around the block to listen for irregular noises and/or detect leaks. We found that engine vacuum had increased nearly 3 inches and the exhaust note was choppy and aggressive, but not nearly as radical as it once was. Backing the Trans Am out of the garage, we immediately noticed that the 467 needed much less throttle angle to get the car moving, and light acceleration after gear changes was smooth and effortless.

Once back in the garage, the break-in oil was changed for a fresh fill of Brad Penn 10W30. We took the Trans Am out for an extended cruise a few days later and found its demeanor had drastically improved. The car was very pleasant to drive at low speed, and overall, it acted much more like an original high-performance Pontiac. The engine seemed to pull just as hard as it had with the long-duration cam, but we wouldn't be able to substantiate any performance difference without another session on the chassis dyno.

We tried various timing settings, but 36 degrees total produced the most power with both cams.

We tried various timing settings, but 36 degrees total produced the most power with both cams.

Follow-Up Dyno Session

A few days after the cam swap was complete, we took the Trans Am back to C&S Dyno Shop to measure its output using the same dyno and procedure we had just a couple of weeks prior. We were surprised when the first pull revealed a loss of about 20 rwhp and 20 rwtq over our previous best. By tracking and comparing air/fuel (A/F) ratio on subsequent pulls, we determined that the engine was running very rich at low rpm, but that its A/F ratio was nearly ideal at high speed.

We decided to replace the long-tip 0.0397-inch AX rods with a set of short-tip 0.0397-inch BF rods we had available, in an attempt to reduce total fueling. Our thought was that the BF rods' gradual taper would keep the engine lean at low speed and delay maximum available fuel. The combination proved to be just what the engine wanted! The 467 responded with 346 rwhp and 403 rwtq, and no other metering rod or timing variance from 36-degrees-total improved performance.

With the long-duration camshaft, the 467 made peak power using 0.0397-inch AX secondary metering rods. The initial dyno test during the follow-up session revealed that while the high-rpm air/fuel ratio was ideal, the engine was very rich at low speed. Short-tip, 0.0397-inch BF rods provided a leaner, low-speed mixture without affecting high-speed fueling. The engine responded favorably, making peak power with these rods. We determined the AX rods simply introduced too much fuel too quickly, and the engine wasn’t able to overcome it limiting output.

With the long-duration camshaft, the 467 made peak power using 0.0397-inch AX secondary metering rods. The initial dyno test during the follow-up session revealed that while the high-rpm air/fuel ratio was ideal, the engine was very rich at low speed. Short-tip, 0.0397-inch BF rods provided a leaner, low-speed mixture without affecting high-speed fueling. The engine responded favorably, making peak power with these rods. We determined the AX rods simply introduced too much fuel too quickly, and the engine wasn’t able to overcome it limiting output.

Analyzing the Results

With the cast-aluminum H.O. intake manifold and Quadrajet, we fully expected to find that the longer-duration camshaft would produce slightly more peak-horsepower and at a higher engine speed in our 467—and that's exactly what occurred. The No. 2043NHL peaked at 355 rwhp at 5,400 rpm, while the No. 2042NHL peaked at about 10-rwhp less and at 200-rpm lower. Average horsepower of both cams from 2,500 rpm to their respective peaks was practically identical, however.

We also guessed that No. 2042NHL would produce as much, or slightly more, peak torque than its longer-duration counterpart, and low-speed and midrange torque would be noticeably greater. That's not what occurred, however. The peak torques and the engine speed at which they occurred were identical—402-403 rwtq at 3,800 rpm. Average torque from 2,000 rpm to horsepower peak was also identical.

The net result of two very different camshafts making the same amount of usable horsepower and torque left us pondering—why does the smaller cam feel so much more powerful at low rpm? The answer likely lies in the fact that No. 2042NHL operates more efficiently than No. 2043NHL. Even though the two produce similar power at the same engine speed, No. 2042 does it with less fuel, which is the result of less duration and valve overlap, which likely dilutes the incoming mixture, requiring more fuel at low speed for proper operation.

Conclusion

Our results may seem to suggest No. 2043NHL is a poor choice when used with factory-issued components. Nothing is further from the truth! It is, however, better suited for use with high-rpm components, and the difference over the No. 2042NHL would certainly be greater than 10 rwhp when used with complementing components. We were astonished at how much power it produced on the dyno, especially the amount of available torque at low rpm. That certainly explains why it always ran and drove so well on the street.

Though hydraulic-roller cams are popular for performance applications, a wide array of flat-tappet cam choices are readily available from many companies, and there are a great number of hobbyists who still run them. For an investment of a few hundred dollars, we were able replace our Pontiac's long-duration camshaft with one better suited for the revised combination, and drastically improve its attitude on the street without grossly affecting full-throttle performance. That's the exact result we were after!

Vehicle Specs Year/Model:'76 Firebird Trans Am Weight With Driver:Approx 3,950 lbs Fuel:91-octane Premium Engine:'74 code-YY 455 Cubic Inches Before/After:455/467 Engine Built By:Willard Auto Machine Induction System Air Cleaner:Original single snorkel with open shaker Carburetor:No. 17057274 modified by Cliff Ruggles Primary Jets/Rods:No. 0.073/0.041 Secondary Rods:BF 0.0397-in Intake Manifold:No. 483674 cast-aluminum Fuel System Pump:Carter stock replacement Heads Casting:'71 No. 197 455 H.O. round-port Head Porting:Prepped by Nunzi's Automotive Flow Numbers at 28-inches:0.100-in 84/57 0.200-in 168/105 0.300-in 214/135 0.400-in 230/153 0.500-in 236/165 Bottom End Pistons:TRW forged-aluminum No. L2359F Rings:Sealed Power replacement Rods:Crower, forged steel, 6.625-in Compression Ratio:Approximately 9.4:1 Crankshaft:Original nodular-iron offset-ground to 4.25-in stroke Rotating Assembly Balanced:Yes Camshaft Brand:Nunzi's Automotive No. 2042NHL hyd. flat-tappet Duration at 0.050:232/243-deg Duration Advertised:301/313-deg Lift with Specified Rocker Arms:0.490/0.500-in Lobe Separation Angle:113-deg Intake Centerline:109-deg Rocker Arms:Crower cast-alloy roller, 1.6:1 ratio Ignition Distributor:Pontiac HEI Coil:Stock ACDelco Wires:Taylor 8mm Spark Plugs:ACDelco No. R45S Total Timing:36-deg RPM Total Timing Is Reached:3,200 Exhaust Headers:Custom Tri-Y style with 1.75-in primary, 2.25-in secondary, and 3.00-in collectors Exhaust Pipes:3.00-in head, 2.50-in over-axle, 2.50-in tail Muffler:Custom crossflow-type from Waldron Exhaust Crossover:3.00-in Dr. Gas X-type Drivetrain Transmission:Tremec TKO-600 Clutch:Centerforce Dual Friction Rear Axle:Original 8.5-in GM 10-bolt Rear Gear Ratio:3.73:1