Every year some of the smartest minds in the engine building business gather for the Advanced Engineering Technology Conference (or simply AETC for those who don't feel like spitting out that mouthful every time they say the name) to discuss the latest advancements in engine building.

How often can you have engine builder Doug Yates share with you his secrets for building winning race engines? Stuff like this happens every year at the AETC conference.

How often can you have engine builder Doug Yates share with you his secrets for building winning race engines? Stuff like this happens every year at the AETC conference.

For the last several years, the AETC has held its three-day gathering in Orlando, Florida, directly before the PRI tradeshow. It's always an interesting conference with lots of great information traded and freely discussed, but this year the featured topic was "Circle Track Racing Engine Technology" which made it a can't-miss for the Circle Track staff.

The standard protocol for the meeting is to feature several speakers each day. Each speaker is a respected leader in the engine building community who covers a unique topic. Some of the speakers are engine builders, while others are engineers or other tech people from component manufacturers. Then, sprinkled liberally throughout the day, there are several opportunities (breakfast, lunch, breaks, and even a cocktail hour) for informal discussions with presenters and other attendees to make new contacts, ask additional questions, or simply do a little bench racing.

Because this conference was so particularly interesting, we thought we'd share a little of what went on at the latest gathering of the AETC. There's no way we can pass along all the great information we learned in the three days there, but we can share some of the highlights. We're also planning future stories based on some of what we've learned here. For 2011 there will be no specific topic, but we're sure there will be plenty to be learned about making power in stock car racing engines. If you want to attend, check out the AETC website for more information, and make sure to look for us when you get there!

Ron Shaver of Shaver Racing Engines gives a college-level lesson on fuel system tuning for Sprint Car racing.

Ron Shaver of Shaver Racing Engines gives a college-level lesson on fuel system tuning for Sprint Car racing.

Failure Analysis

If you're a regular reader of Circle Track, then you're probably already familiar with the name Keith Dorton. Dorton is a longtime engine builder, owner of Automotive Specialists, and a frequent resource of many of the engine tech stories that appear in the pages of this magazine. Dorton was also the opening speaker for this edition of the AETC.

Dorton spoke on his development process for circle track racing engines, but also touched on his methods for failure analysis. Many engine builders we've met wouldn't admit that they've ever even had a failure, but Dorton's philosophy is if you aren't failing stuff occasionally, you aren't pushing hard enough. The trick is to catch problems before they cost teams races and to learn from them so that you can improve the product.

One important aspect Dorton found that he pointed out is that component failures are rarely simply because of a bad design. Instead, there's often what he calls a "human element" at play. In other words, the real reason for a failure is usually an error in assembly, machining, or even handling.

It's not all hard-core tech; sometimes the great engine builders also provide a glimpse of where they came from. Here, the one-and-only Gary Stanton provides a photo from his early days when they actually installed cam bearings in a block sitting on the shop floor. You better believe you won't find that in his shop today.

It's not all hard-core tech; sometimes the great engine builders also provide a glimpse of where they came from. Here, the one-and-only Gary Stanton provides a photo from his early days when they actually installed cam bearings in a block sitting on the shop floor. You better believe you won't find that in his shop today.

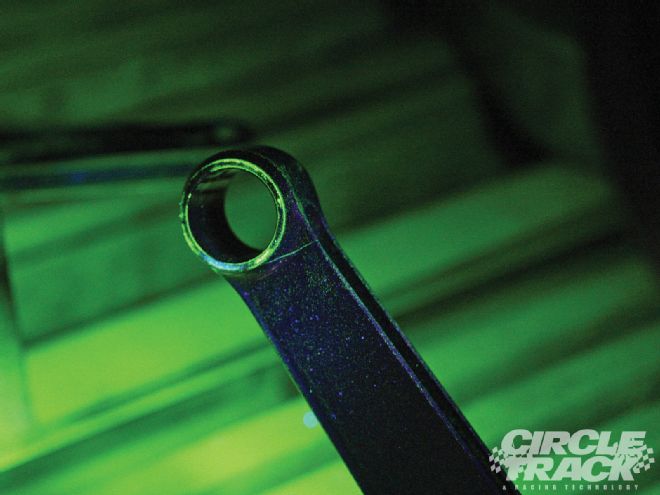

As an example, Dorton displayed a connecting rod that had developed a crack just underneath the pin end. Dorton caught the crack during a rebuild and pulled the rod before it caused an engine failure, but instead of counting his blessings that a possible engine failure was diverted he set about trying to determine the real cause.

It turns out that the connecting rod design was up to the task of handling the stresses of the engine package it was chosen for. The root of the problem was a ding or mark made just below the rod's pin bore. How it originated isn't known, but it created a stress riser that allowed the crack to form and propagate nearly all the way across the beam of the rod. The crack is nearly invisible to the naked eye, in fact it only really shows up in a magnaflux machine, but it was enough to cause the rod to fail, and if that happened a grenade would be the certain result.

Dorton replaced the rod, but he said that if the ding had been found before the rod had been installed in the engine, it could have been fixed by gently grinding the sharp edges away in the same direction as the forging's grain and the rod could have been saved.

Attendees were also given a first look at an LS-based Sprint Car motor that will be aimed for a spec engine class.

Attendees were also given a first look at an LS-based Sprint Car motor that will be aimed for a spec engine class.

Individual Cylinder Tuning

One topic that was touched on by a handful of presenters was individual cylinder tuning. This is most often done by doing combustion pressure analysis on individual cylinders. The idea is simple-more pressure equals more power-and by tuning the air/fuel mixture to the cylinder as well as the timing of the spark, you can maximize the power each cylinder produces.

Unfortunately, there are a couple of problems with this scenario. The first is that the equipment to accurately perform combustion pressure analysis on individual cylinders of a running engine (and remember, it has to be running at race speed on the dyno since nobody cares about maximizing power at idle) is prohibitively expensive. Currently, this equipment is within the budget of only a handful of the top NASCAR Sprint Cup engine builders, Universities such as Clemson which participated in the conference, and the OEMs. But hopefully, prices will drop in the future to a level that the rest of us can afford.

Doug Yates of Roush Yates Engines, spoke about using a combustion pressure analysis system to aid the development of his Dirt Late Model engine program, and brought up several interesting points. The biggest is that he says it's actually impossible to balance every cylinder in most race engines so that they make the same amount of power. This is because of the common plenum design that's an integral part of a single-plane intake manifold.

Here's a shot of the completed spec Sprint motor.

Here's a shot of the completed spec Sprint motor.

The common plenum allows different cylinders to rob more fuel and air from the manifold depending on the firing order. The best plan, he says, is to try to maximize the power of each cylinder depending on its situation rather than find the cylinder that produces the most power and try to bring the other seven up to that level.

Ring Seal Isn't Always about the End Gap

Matt Hartford of Total Seal Piston Rings gave a very informative presentation on the technology behind performance piston rings. Interestingly, he stressed the point that good ring seal goes way beyond simply filing your rings for the correct end gap. Properly separating the combustion pressure from the crankcase also requires the rings to properly seal between the ring and the cylinder wall, as well as between the ring and the ring lands cut into the pistons. And when you combine this with the fact that most engine builders require the ring package to offer as little friction as possible, it can become a very tricky task.

That's why many modern advancements, such as diamond lapping, high quality materials, and coatings have offered incredible advancements in ring performance. Of course, no matter how much you spend on your rings, they also depend-as always-on pistons with flat and true ring lands and a proper hone job in the cylinder bores.

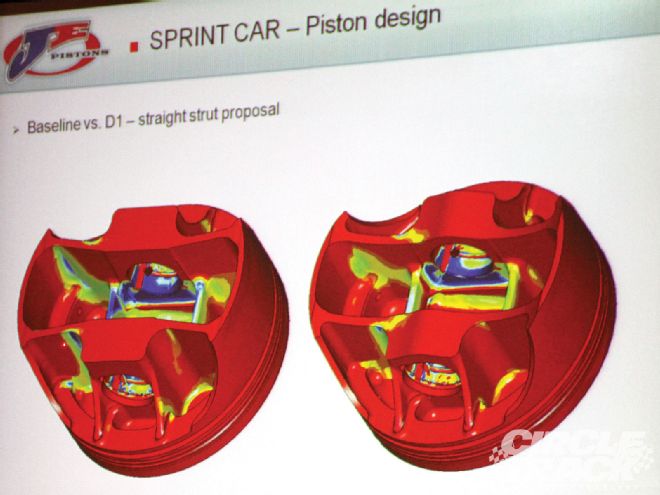

JE Pistons' Stephen Golya shared some very interesting research showing the stressed areas in a forged piston designed for Sprint Car racing.

JE Pistons' Stephen Golya shared some very interesting research showing the stressed areas in a forged piston designed for Sprint Car racing.

Pistons May Have a Very Interesting Future

JE Pistons' Stephen Golya gave attendees a glimpse into the future of racing piston development. There was a lot of heavy tech info provided but the piece that caught our attention is the research being done to minimize friction between the piston and the cylinder bore. Traditionally, most manufacturers have attempted to cut friction here by reducing the size of the piston skirts. That's gotten us to pistons that can get by with surprisingly small slipper skirts, but in the future, manufacturers may follow a different track.

The next wave of development JE and other leading performance piston manufacturers may take advantage of is special coatings that are actually "printed" on the piston skirts in specific patterns. Golya shared some research that has shown certain raised patterns actually help reduce friction by controlling oil in the cylinder bore. We're very interested to see how this one turns out in the next few years and will keep an eye on it for you.

This is a photo of the cracked connecting rod that engine builder Keith Dorton used as an example in his discussion on finding the true reason for part failures in order to build better racing engines.

This is a photo of the cracked connecting rod that engine builder Keith Dorton used as an example in his discussion on finding the true reason for part failures in order to build better racing engines.

The Value of Coatings

Several presenters also touched on the value of coatings in various areas of the engine. Engine builder Bill Schlieper pointed out that hard-coating your valves can actually help improve valve control in dirt environments.

Dirt racing is hard on the entire induction system no matter how well you try to seal the engine and filter the incoming air, but it can be especially damaging to the valve seats. The dirt can actually increase the rate of wear of the seat causing the valve to sit deeper in the head. Many racers will simply reset the valve lash and keep going, but this also causes the installed height of the valvespring to be taller. This, in turn reduces the spring pressure and can lead to valve bounce and float. Schlieper says he has seen this phenomenon reduced by using valves that have had a DLC coating applied to the seats.

Gary Stanton surprised attendees by bringing along an SLA model of the clean sheet head he has designed for Midget racing and allowed everyone to handle it and ask all the questions they wanted.

Gary Stanton surprised attendees by bringing along an SLA model of the clean sheet head he has designed for Midget racing and allowed everyone to handle it and ask all the questions they wanted.

The Fight for Efficiency

Dr. Andy Randolph of Earnhardt Childress Racing pointed out research that showed just how much more horsepower could be gained in the racing engines we're building if we can only increase the efficiency at which we burn the fuel by just a few percentage points.

For example, in a modern NASCAR Sprint Cup engine, the fuel flowing through the carburetor is capable of producing 2,430 horsepower. But because of incomplete fuel burn, heat loss, parasitic losses, and other inefficiencies, only approximately 850 to 900 horsepower is making it to the end of the crankshaft.

Some of those losses are unavoidable, like the power required to pump fresh air and fuel into the combustion chamber and then push the spent gasses from combustion out the exhaust port. But others, such as drag from all the moving components can still be reduced. Thermal efficiencies are also an area where a smart engine builder can still find power. After all, think about all that heat the engine is producing that you have to pump water to cool, then pump that water to the radiator just to cool it off too. As the science of performance coatings continues to advance as well as the concept of individual cylinder tuning becomes more accepted, the modern race engine can become considerably more efficient at turning that expensive race gas into torque at the rear wheels.

Our own Rob Fisher took part in a roundtable discussion that centered on utilizing new technology in circle track racing, and our Project G.R.E.E.N. initiative was a large part of the discussion.

Our own Rob Fisher took part in a roundtable discussion that centered on utilizing new technology in circle track racing, and our Project G.R.E.E.N. initiative was a large part of the discussion.

Conclusion

Overall, the 2010 AETC conference was a great success. Many in attendance said that they could take the information presented right back to their shops to improve performance of their own race engines. It definitely gave us plenty of ideas for future stories to help you go faster and suffer fewer engine failures.