When we first introduced our Project Old-School engine build, the premise was to build an engine that would remind us of our younger days-when overkill was the way to make power. With our engine, we started out with a lot of compression, a lot of camshaft, and what we thought was a lot of carburetor. I say we thought we were over carbureted, but during our last dyno session, we noticed the power dropping off after about 5,000 rpm-a sure sign that not enough air was being moved. This really surprised us, as with two 465-cfm carburetors (totaling 930 cfm), we thought our 340 stroker definitely wouldn't need any more carburetion.

The Ethanol fuel makes the exhaust cleaner. Now we just have to work on cleaning up the tire smoke.

The Ethanol fuel makes the exhaust cleaner. Now we just have to work on cleaning up the tire smoke.

Over the last several months we have been able to run several gallons of race fuel through our Old-School engine, and to be honest, race fuel can get expensive. The way the engine is built, there is no way that we can simply drive to the local fuel depot and fill up the Valiant with "pump gas"-or can we? Under normal circumstances, the only fuels you can usually buy "at the pump" for use on the highway, are rated from 87 to 93 octane. With an engine running a 12.0:1 compression ratio, a tunnel ram, and a big, solid-roller camshaft, that is not an option. What is an option is running E85 through the carburetors. A couple of years ago, E85 gained a lot of popularity, but at the time, finding a local station that carried this new fuel was few and far between.

As soon as we strapped the car down and made our first pull, we found that we needed more airflow into the engine. Off to the speed shop for bigger carburetors.

As soon as we strapped the car down and made our first pull, we found that we needed more airflow into the engine. Off to the speed shop for bigger carburetors.

E85 has an octane rating that is higher than that of regular gasoline's typical rating of 87 through 93, and this allows it to be used in higher compression engines. Using E85, however, does have the drawback of lower fuel economy, as more fuel will be needed per unit of air (stoichiometric fuel ratio) to run the engine as opposed to traditional gasoline. This corresponds to a lower heating value (units of energy per unit mass) for E85 than gasoline. Because of the lower heating value, E85 has a cooler intake charge but a higher stability level from its higher octane rating. Use of this fuel not only results in lower GHG emissions, but typically results in a measureable percentage increase in horsepower and torque at the wheels. Because of its lower price than race fuels, and increasing availability in certain areas, the use of E85 is becoming more viable.

As soon as we got the new carburetors back to the shop, we started the conversion. First we needed to replace the metering plates with new ones designed for running E85

As soon as we got the new carburetors back to the shop, we started the conversion. First we needed to replace the metering plates with new ones designed for running E85

Simply dumping a tank full of E85 in your car and hoping for the best is not a good idea. There are a few changes that will need to be made. Now, we'll be the first to admit that we have no experience running Ethanol, so in order to avoid looking like idiots, we found someone who does know a thing or two about running E85. Darren Tedder of Prism Racing in Conyers, Georgia, told us, "We regularly see a 3-5 percent power increase simply by converting an engine from race fuel, or "pump" gasoline to clean burning, highly-oxygenated ethanol." Darren told us that several changes would need to be made to our 465-cfm carburetors before any E85 was run through them. Since E85 "burns" differently than conventional fuels, delivery of the Ethanol is handled a bit differently through the carburetor. An E85 carburetor needs to be "converted," by changing the metering plates (different emulsion-orifice properties), and possibly, some air bleed, and needle and seat changes. Normally, a needle and seat assembly with more flow capabilities might be needed, but since we were running two carburetors, he felt we would be ok.

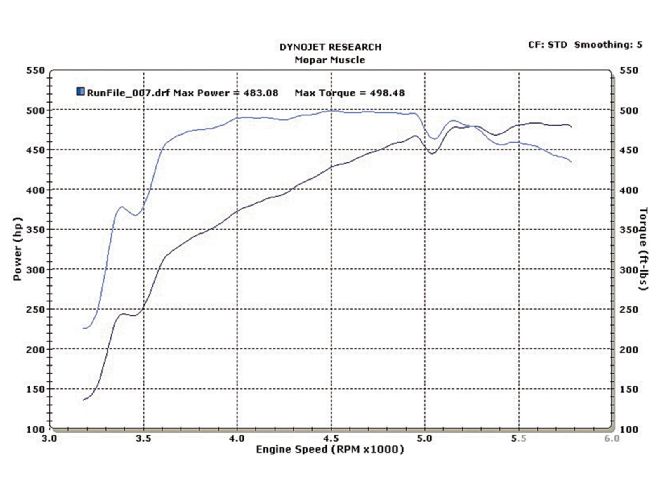

When it came time to strap the Valiant to the dyno at Prism Racing, the guesses as to how much power the car would make were conservative. Let's face it, it's a small-block 340 with no special machine work done to it. We started with a conservative 5,500-rpm pass and noticed we had a small problem. As we mentioned in our opening paragraph, would you believe that 930 cfm of carburetion on our small-block wasn't enough? I didn't. With the relatively small cubes of our stroked 340 (414), I thought that 930 cfm would be plenty. When looking at the dyno chart, Darren noticed a sudden and severe drop off in power, and his experience suggested we needed more air flow. To get more air, we needed bigger carburetors-there goes this month's allowance. It was a toss-up as to whether or not a pair of 600-cfm carburetors would be enough, so the decision was made to get a pair of 650 Double-Pumpers and convert them to run E85.

With the carburetors converted, it was time to make our first pull. We started out with the jets at 76 and 83. Power was at 483.08 hp and 498.48 lb-ft of torque.

With the carburetors converted, it was time to make our first pull. We started out with the jets at 76 and 83. Power was at 483.08 hp and 498.48 lb-ft of torque.

Buying E85 dedicated carburetors is as easy as checking out any performance retailer online. Our problem, however, was that we were strapped to the dyno and needed them right now. We were fortunate in that we were able to locate a local retail warehouse that happened to have two 650 Holley Double Pumpers on the shelf and the required E85 conversion components.

After finally getting the carburetors switched over, we then ran into an issue where our engine developed a hiccup right around 5,300 rpm. This developed a situation that we weren't sure how to overcome. What it sounded like was something in the ignition. Instead of buying a new distributor and hoping it solved the problem, local Mopar guy, Ralph Vaquero came to the rescue with a factory distributor for us to try. After connecting Ralph's distributor, our hiccup went away.

With 32 pulls being made on the Dyno, this was a position that Josh (Captain Jet Changer) found himself in on several occasions.

With 32 pulls being made on the Dyno, this was a position that Josh (Captain Jet Changer) found himself in on several occasions.

After everything seemed to be happy with the Valiant, we proceeded to make 32 pulls on the dyno until we ended up making just 500 hp and 500 lb-ft of torque. There was definitely a lot of jet changes and tuning going on-as with any dyno session. We finally ended up with 40 degrees of timing and jet sizes about 8 sizes larger than were needed with race fuel.

Things To Remember When Considering The Use of E-85

Ethanol contains less BTU energy than gasoline; therefore you need, depending on the application, about 10-20 percent more fuel as opposed to conventional fuel.

The Octane rating is generally around 105. This allows the use of higher compression ratios.

E85 is still suffering from limited availability. Finding E85 depends a lot on your location, as most of the E85 pumps we've heard of are located in the mid-West.

E85 can be more corrosive on some rubbers, plastics, and some metal parts because of its inherent properties. This means that you'll want to research your fuel system parts to ensure compatibility.

Emissions are greatly reduced when using E85. If you don't care about emissions, you should, but just know that what burns cleaner leaves your engine cleaner.

Not Always Equal

If you think that all E85 is the same, we're here to tell you that it's not. When dealing with "mass produced" E85, there are different "blends" depending on things like the time of year or just the primary mixing ingredients, and this can adversely affect peak performance-especially in areas prone to drastic weather changes. Currently, we have also found out that federally regulated E85 allows for a blending of anywhere from 70-85 percent Ethanol (ASTM D5798). While this might not have a huge effect on the normal daily driver, those who've done their best to optimize their engine combinations can really be in for a surprise from week to week, or month to month in regards to how their engine's performance is affected.

While we tuned our Old-School engine to run on the E85 that's available near our house/shop, we decided to see what happens when a quality, regulated blend of E85 is introduced to our carburetors. Prism Racing is a distributor for Rockett Brand Fuels, and since Rockett blends a quality-controlled E85, we completely drained and flushed the fuel system in the Valiant and added the Rockett Brand E85.

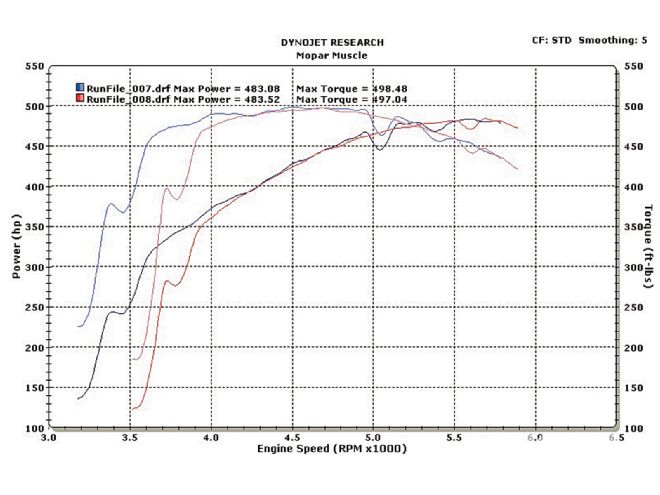

You can see in this graph that the hiccup is gone, and the power didn't change, so as not to skew our results.

You can see in this graph that the hiccup is gone, and the power didn't change, so as not to skew our results.

Simply by running the Rockett Brand E85, our power numbers increased by five horsepower, and our engine had a leaner air/fuel ratio-not a significant amount, but enough to let us know that if we actually tuned with the Rockett E85, we could possibly see a difference of 8-10 horsepower just in the blend of fuel.

Once we got the ignition squared away, it was all down to jetting changes and dyno pulls. When all was said and done, we ended up with a jet setting of 83 and 83, and the timing set at 38 degrees.

Once we got the ignition squared away, it was all down to jetting changes and dyno pulls. When all was said and done, we ended up with a jet setting of 83 and 83, and the timing set at 38 degrees.

Parts Is Not Just Parts

Just converting the engine in your muscle car over to run E85 does take a little more than simply re-jetting your carburetor. We've all heard the horror stories about how E85 can cause damage because prolonged exposure to ethanol may corrode metal and "soften" rubber parts in older engines designed primarily for gasoline. The horror stories are both correct and incorrect. Oil companies are required to add corrosion inhibitors not only to ethanol-blended gasoline but also to other gasoline products (per www.biofuelshub.com). This is because all types of petroleum products have corrosive properties. Changes in humidity and temperature can also affect Ethanol-based fuels more so than petroleum-based fuels. This is because Ethanol-based fuels are prone to absorbing moisture. Ethanol can do some really bad things to some traditional fuel-system materials-like the cork gaskets in some carburetors. Also keep in mind that not all fuel tubing is created equal. Aluminum fuel lines need to be made from anodized tubing. Non-anodized aluminum corrodes when exposed to ethanol.

If you're running a factory, mechanical-style fuel pump, we suggest you change it, as the diaphragm inside might not survive. Even electric fuel pumps are not created equal. We changed ours to a Methanol-compatible fuel pump as our standard aftermarket pump was not designed for this type of fuel. As far as fuel lines, we have gotten mixed reports that standard rubber lines are adequate. Some guys told us that they have had to replace them because of compatibility issues with the E85, and others have been running it for years. Just to be on the safe side, if you're running a large amount of rubber hose (stainless braided and such), it might be a good idea to consult the hose manufacturer about their recommendations.

All in all, this helping the environment isn't all bad. We found a cleaner burning fuel, with a higher octane rating, that doesn't cost as much as racing fuel.

All in all, this helping the environment isn't all bad. We found a cleaner burning fuel, with a higher octane rating, that doesn't cost as much as racing fuel.