Stock car racing engines are all about efficiency. That's because all the simple solutions for making power have either been maximized or eliminated by the rule book. You aren't allowed power adders like nitrous or a blower (lucky drag racers) and the easy answer of simply upping the displacement (in most cases) isn't allowed.

Checking your own cylinder volumes allows you to determine your exact compression ratio. It is also relatively easy to do and only requires a few tools.

Checking your own cylinder volumes allows you to determine your exact compression ratio. It is also relatively easy to do and only requires a few tools.

So you have to make the most of what you are given, and since every motor on the racetrack is so similar, the game becomes one of who can squeeze the most power out of the same Chevy small-block everybody else is using. And one of the best ways to do that is to make sure you are getting every last bit of compression you are allowed by the rules.

The concept of efficiency when it comes to compression is simple: A droplet of fuel only has a specific amount of energy, but if that droplet can be squeezed into a tighter space before being ignited it is capable of doing more work with that same amount of energy.

Of course, that's the reason many racing series limit compression. They know that's one of the surest ways to limit engine power. Others limit compression without expressly stating it. This can be done by putting minimum limits on combustion chamber size, stroke, and even the shape of the piston top. Either way, to make the most power you have to make sure you are right up against the limits of what's allowed when it comes to making compression. And to do that you have to know how to determine exactly what your compression is.

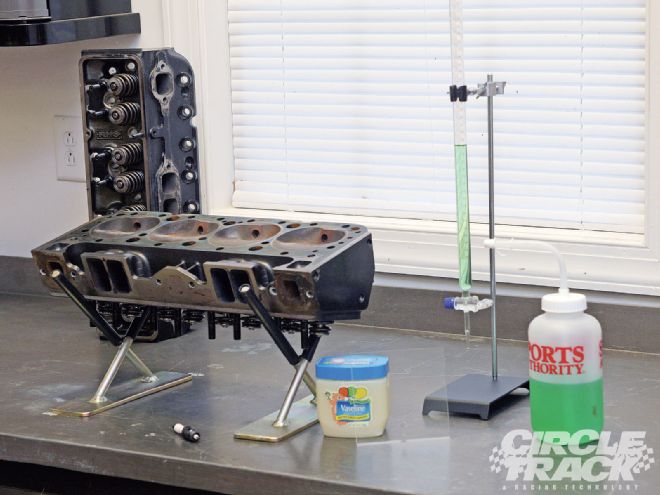

You will also need some method to hold your heads level. A set of head stands, like this one from Powerhouse Products, is invaluable for this and any other time you need to work on a set of heads. They keep the heads up off your work bench so that your freshly machined decks won't get damaged or scratched up.

You will also need some method to hold your heads level. A set of head stands, like this one from Powerhouse Products, is invaluable for this and any other time you need to work on a set of heads. They keep the heads up off your work bench so that your freshly machined decks won't get damaged or scratched up.

Can't Somebody Else Do It?

With buying a new engine, or having your old engine sent out to be rebuilt, your engine builder should normally check the chamber volumes and determine the compression ratio. But there are often instances when you may want to do this yourself. For example, you may be purchasing a set of used heads from another racer or off the internet and need to know that they haven't been reworked so extensively that they are illegal at your track. Or you may be building your own engine.

This is the scenario we faced while preparing for an upcoming story using Circle Track's dyno test mule Chevy 350. So far, we've tested rocker arms, oil pans, and exhaust systems with a standard Chevy crate motor short block. But for future tests we want a stronger bottom end that can handle more power. Along the way, we thought we'd also test to see just how compression affects engine power and to do that we need to see just what we've got.

Displacement

The first step in determining your compression ratio is understanding how to calculate total engine displacement. Displacement basically is the area swept (or displaced) by the piston as it moves from the bottom of the cylinder bore to the top. This does not include the combustion chamber in the cylinder heads or any of the cylinder bore above the piston when it reaches top dead center (TDC). The formula for determining displacement is:

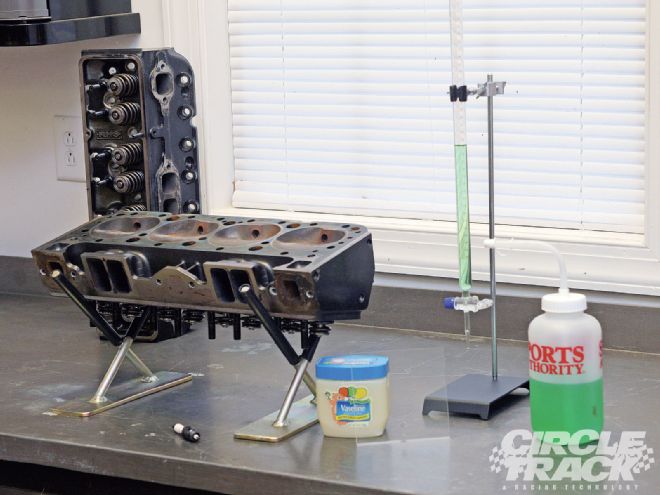

We're working on a set of heads that have just been pulled off a motor, and we're hoping to use them again without any machine work. They'll need to be cleaned up a bit first, though. Resist the temptation to scrub the deck of the head-even with a Scotchbrite pad-as it can warp the deck and cause a head gasket failure. Instead, clean the deck carefully with a razorblade.

We're working on a set of heads that have just been pulled off a motor, and we're hoping to use them again without any machine work. They'll need to be cleaned up a bit first, though. Resist the temptation to scrub the deck of the head-even with a Scotchbrite pad-as it can warp the deck and cause a head gasket failure. Instead, clean the deck carefully with a razorblade.

Bore X Bore X Stroke X 0.7854 X Number of Cylinders = Displacement

For this formula, both bore and stroke must be measured in cubic inches because the fourth number (0.7854) is a constant used to convert to cubic inches. As an example, let's consider standard Chevrolet 350 dimensions-the bore is 4 inches in diameter and the stroke is 3.48 inches. That makes the formula look like this:

4 X 4 X 3.48 X 0.7854 X 8 = 349.849

No big surprise since we said it was a Chevy 350 to start with, but this gives you an idea how the formula works. The bore can be measured with a dial bore gauge, but you can even get by with a dial caliper in a pinch. And the stroke can normally be pulled right off the crankshaft spec sheet. For calculating the compression ratio you will need to know only the displacement for a single cylinder, so to determine that all you have to do is divide by the number of cylinders-or just leave that multiple out of your original equation.

Determining Compression Ratio

The next step is to move on to calculating your compression ratio. We'll call that "CR" and-not to belabor the obvious-the symbol for displacement will be "D." Compression ratio is simply the volume of the cylinder and the combustion chamber when the piston is at bottom dead center (BDC) divided by the volume of the cylinder and combustion chamber when the piston is at TDC.

The combustion chambers are more hardy. This one cleaned up nicely with a Scotchbrite pad and some brake cleaner.

The combustion chambers are more hardy. This one cleaned up nicely with a Scotchbrite pad and some brake cleaner.

Of course, for all the importance given to compression ratio, the number itself is a bit theoretical. It assumes that the valves close exactly at TDC or BDC, and that never happens in a race engine, because high-performance cams have way too much duration for that. It also does not take into account volumetric efficiency, which is the rate that the intake ports flow air and fuel, and that changes throughout the rpm range. Still, compression ratio is useful whenever you are working with an engine package to make sure you are legal.

Before you can determine an engine's compression ratio, several factors must first be nailed down. These include piston volume, deck clearance, gasket thickness, and combustion chamber volume. You might not think piston volume (PV) is important since most stock car racing classes require flat top pistons. But you must also take into account the negative area created by the valve pockets. The piston manufacturer will usually give you this area on your spec sheet, but you can also easily determine this for yourself-which is important if you have cut your own valve reliefs or fly cut the top of the pistons.

Deck clearance (DC) is the volume of the bore between the top of the piston at TDC and the top of the deck of the engine block. The thickness of the head gasket (G) essentially acts as an extension of the deck clearance, just make sure to include the compressed thickness of the gasket which is quite different from the thickness when it first comes out of the box. And finally, you will need to know the volume of one of the cylinder head's combustion chambers (CC).

Make sure to plug the spark plug hole with the same type of plug you will be using in the finished engine. An old plug is OK here.

Make sure to plug the spark plug hole with the same type of plug you will be using in the finished engine. An old plug is OK here.

The formula for calculating compression ratio is just a bit more complex than the one for displacement. Still, as long as you keep a calculator handy it should be no big deal. Here it goes:

(D + PV + DC + G +CC) / (PV + DC + G +CC) = CR

When working this equation, make sure that each variable is the same unit of measure. In other words, don't mix cubic inches and cubic centimeters or you will get some completely useless (and confusing) numbers. This can often be an issue since combustion chamber and piston volumes are often referenced in cubic centimeters. Since your displacement figure is probably already in cubic inches, we'll go with that. Also, it's easy enough to convert cubic centimeters into cubic inches if you need to. Simply divide the number by 16.386.

Each of the volume variables is easy enough to determine with a little patience and the correct tools. Displacement, like we've already mentioned, is for one cylinder only. If you don't have access to the manufacturer's spec sheets, or anything has been modified, you will need to determine the volumes yourself. We've demonstrated the best procedures for cc'ing both your cylinder heads and the volume of the cylinder with the piston at TDC. When you do this, the cylinder volume equals both the piston volume and deck clearance.

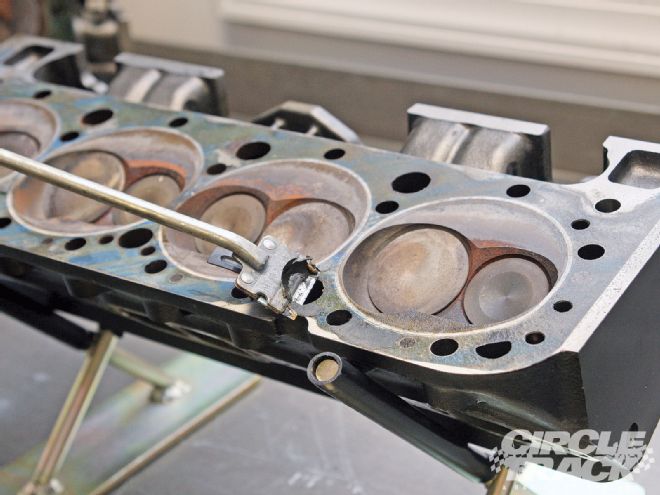

Our heads are still assembled, but if you are checking the combustion chamber volume on a bare head, you can seal the valves against the seat without having to install the valvesprings by wiping a little Petroleum jelly or grease around the valve seat.

Our heads are still assembled, but if you are checking the combustion chamber volume on a bare head, you can seal the valves against the seat without having to install the valvesprings by wiping a little Petroleum jelly or grease around the valve seat.

Deck and Gasket Clearance Volume

Deck clearance volume is calculated almost exactly like displacement:

Bore X Bore X 0.7854 X Distance from piston top at TDC to deck of block = DC

For instance, continuing our example of the Chevy 350, if the deck clearance is 0.033, the deck clearance volume is:

4 X 4 X 0.7854 X 0.033 = 0.41469 ci

Gasket volume is similar:

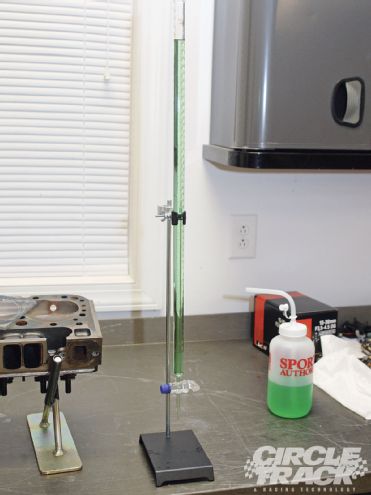

The key tool is a measuring burette which allows you to accurately measure volumes down to a single cubic centimeter. This one is part of a kit from Powerhouse Products. The liquid is isopropyl alcohol (you can use food coloring to make it easier to see, but we found some already dyed green). The squirt bottle is just a cheap water bottle we picked up at a local sporting goods store. Fill the burette to the top, which is the 0 cc mark.

The key tool is a measuring burette which allows you to accurately measure volumes down to a single cubic centimeter. This one is part of a kit from Powerhouse Products. The liquid is isopropyl alcohol (you can use food coloring to make it easier to see, but we found some already dyed green). The squirt bottle is just a cheap water bottle we picked up at a local sporting goods store. Fill the burette to the top, which is the 0 cc mark.

Bore X Bore X 0.7854 X Gasket thickness = G

If the gasket thickness is 0.020-inch, then the formula looks like this:

4 X 4 X 0.7854 X 0.020 = 0.251328 ci

Now, let's assume that the piston's negative volume is 5 cc's (0.305 ci) and the combustion chambers are 64 cc's (3.906 ci). Now we can figure out the compression ratio:

(43.731 + 0.305 + 0.41469 + 0.251328 + 3.906) / (0.305 + 0.41469 + 0.251328 + 3.906) = 9.97

So the compression ratio is 9.97:1. A little low for a race motor, but the numbers work for the purpose of this example. If, by the way, you have a zero deck height, you can leave that one out.

Seal the edges of the combustion chamber with a light coating of grease or petroleum jelly. Then press the cover plate on top.

Seal the edges of the combustion chamber with a light coating of grease or petroleum jelly. Then press the cover plate on top.

Making Your Own Measurements

If there are volumes that you don't know, such as the piston volume, it may be just as simple to make the measurements yourself. All you need is a burette, a cover plate and a little grease. We got our kit from Powerhouse Products, which also includes a stand to hold the burette.

To measure the deck clearance volume, start with at least one piston (with the top ring) and rod installed in the bore of the block and attached to the crank. Move the piston part way down in the bore and wipe a small amount of grease or petroleum jelly around the inside of the bore near the top. Move the piston to TDC and wipe away the excess grease above the piston top. The rest of the grease should seal up the crevice volume, which is the area between the piston and the bore between the top of the piston and the top of the upper ring. This keeps the fluid from leaking past the gaps in the rings. On racing pistons, the crevice volume is minimal, but sealing it up provides you a safety net of sorts. Most tech inspectors allow 1 cc for crevice volume.

Now use some grease or petroleum jelly to provide a seal between the deck and the cover plate. You don't need much here, just enough to keep fluid from leaking out. Fill the burette with either mineral spirits or isopropyl alcohol and then fill the void in the chamber you are measuring. Check the volume on your burette. This is your bore volume at TDC (BVTDC). Measuring the volume of the combustion chamber in the cylinder heads is even simpler since you don't have to worry about sealing the piston. The formula simplifies to:

Now use the burette to fill the void in the chamber with fluid through the hole in the cover plate. You may have to work a bit to get any air bubbles out. It can be easier if you drill several very small holes in the plate to evacuate air.

Now use the burette to fill the void in the chamber with fluid through the hole in the cover plate. You may have to work a bit to get any air bubbles out. It can be easier if you drill several very small holes in the plate to evacuate air.

(D + BVTDC + CC) / (BVTDC + CC) = CR

The ability to precisely deter-mine both your displacement and compression ratio is a vital tool for anyone making alterations to a racing engine. Plus, you can also determine how one change might affect other things. Now you have the tools to know when you're bumping up against the rules and when you have shot right past them.