CLASSIFIED-EYES-ONLY MATERIAL: June 2009 Summerstown, Ontario, Canada. Jesse Robinson and his elite cadre at SKMFX had been planning their assault on the relatively peaceful town of Lima, Ohio. They just got the big break they were looking for-the testing facility for their Weapon of Mopar Dominance (WMD) was finally completed, and they could begin final preparations on their ambitious plan to take out the competition at the 2009 Engine Masters Challenge.

The crew at SKMFX Engines spared no expense when it came to creating the facilities in which they would work. A division of SKM, a company who produces industrial electronics components, SKMFX is a group that specializes in building racing engines for circle track, drag, and hot street applications and has access to the full complement of CNC machines, powdercoating operations, and engineering facilities of their parent company. With brains and brawn on their side, it made it a relatively easy task to build this 471ci pump-gas Mopar without breaking the bank. In fact, the budget for this operation was a scant $8,000-far from the cost of an MX missile.

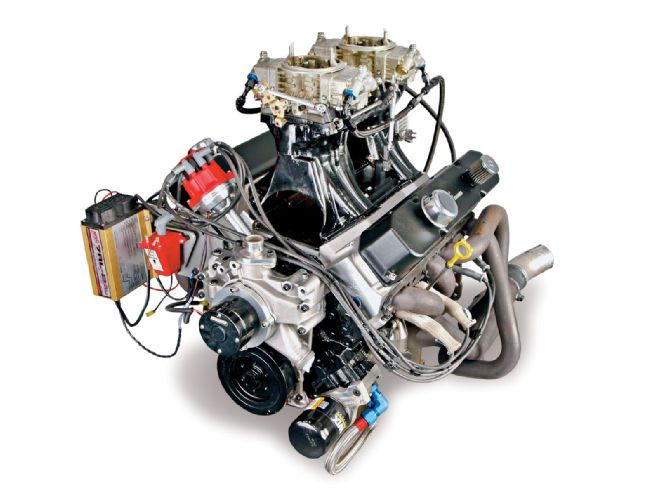

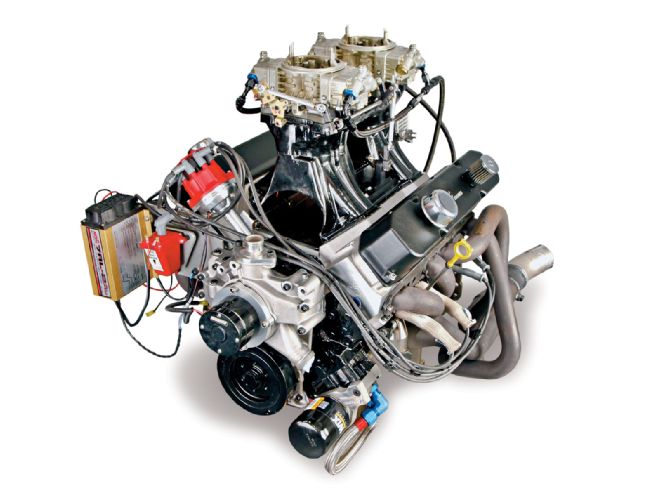

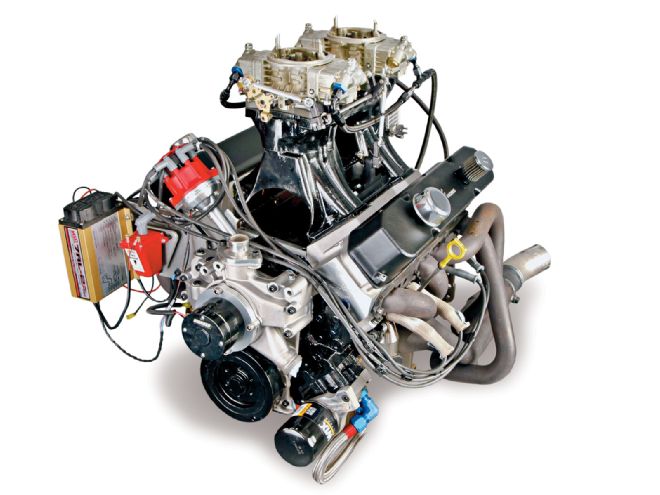

The 471ci Commando in its natural habitat is prepared for battle by the SKMFX team and the students at the University of Northwestern Ohio where the Challenge took place.

The 471ci Commando in its natural habitat is prepared for battle by the SKMFX team and the students at the University of Northwestern Ohio where the Challenge took place.

Robinson had thoughts of this mission for years. As a youth he had always been a Mopar guy and when the opportunity presented itself, he jumped at the chance to build one of his favorite engines. He told PHR: "Back in 1995 when I first got into the trade, I started piecing a 451 combo together based on a 440 steel crank. My partner Joe ended up turning that very same crank for me. I finally got that engine going in 2000, and it made a ton of power, and it's still running in my friend's '72 Road Runner. It's just kind of near and dear to my heart." When asked how SKMFX got involved in the Challenge Robinson told us: "I followed Engine Masters since 2002 when it was the first year for it. I've always wanted to do it. I've always been a Mopar guy ever since I can remember. I've built a number of big-blocks for myself and for customers, and felt it would have been a good fit for those Edelbrock heads." Starting with a stock 400 block they got for free, Robinson's teammate Joe Rutters did a half fill of Hard Block and made sure all the specs were dialed in. Boring and honing the block to 4.375 inches with the torque plates they made on site with their CNC mill was first on the checklist. "When it comes to cylinders, Joe's just about the best guy out there." History told them that the stock-block would be more than strong enough to handle a solid 800 horses. With their eyes planted on the 700-horse mark, they knew this Commando would survive the mission. "We didn't line hone it. We just put studs in it and a 440Source girdle, and pretty much put the bottom end together. No magic there."

Big-block Mopar engines often went by that Commando moniker, and rightfully so, as they took charge of making power. They first appeared in Plymouths bearing the Sonoramic Commando name in 1958. Though that first year the engine was a mere 350 cubes, it was poised to push the bounds of current technology by being offered with either a dual four-barrel carb setup or an extremely high-tech (for the day) Bendix electronic fuel injection. During this early Cold War era, casting and machining techniques were being improved rapidly, making the old WWII heavy flathead engines obsolete. Lightweight thin-wall castings and overhead-valve designs allowed the new engines to flourish as the space age came into being. As the budding big-block program gained its footing, it expanded into the massive 440-cube Super Commando by 1966. Dubbed the Magnum in Dodges, or the TNT in Chrysler trim, the 440 used its long-rod, big-valve, high-compression design to destroy the enemy on the asphalt battlefield. This was, of course, most notable with the Plymouth Superbirds and their potent 440 six-pack cannons.

The HP1000 carbs sitting on the tunnel ram were a pair of standard out-of-the-box pieces that performed flawlessly. The SKMFX team tried various carb spacers with very little change between each one, so they stuck with an open half-incher.

The HP1000 carbs sitting on the tunnel ram were a pair of standard out-of-the-box pieces that performed flawlessly. The SKMFX team tried various carb spacers with very little change between each one, so they stuck with an open half-incher.

Most big-blocks of the era came with a 5140 forged steel crankshaft, and that dense steel allowed them to be internally balanced. Robinson followed suit on that design by installing a 440Source 4340 forged steel stroker crank that would pump up the displacement without sacrificing strength or quality. Internally balancing the crank was done to keep the forces acting on the shaft from whipping it about like a spaghetti strand and stressing the block. Robinson claims their crank is good for a 1,000 hp in capable hands. Scat big-block Chevy rods were cheap and easy to use, owing to the fact that a lot of aftermarket cranks like the 440Source piece are designed for them. The slightly smaller rod bearing of the Chevy reduces the bearing speed and cost at the same time. Mahle-Clevite bearings were used to cushion the blow as the power is transferred from reciprocating to rotating energy.

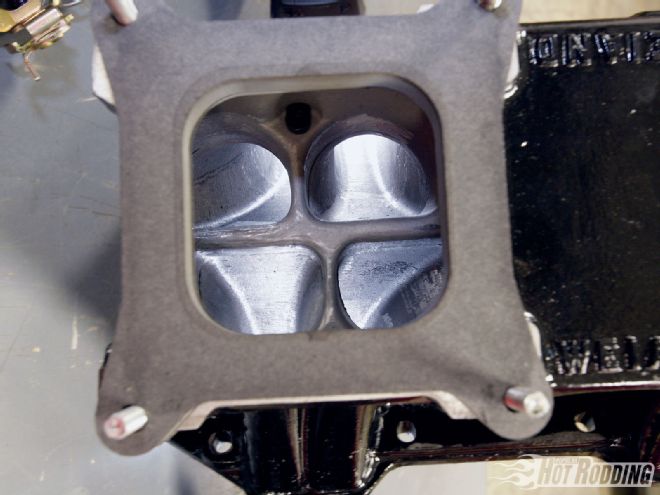

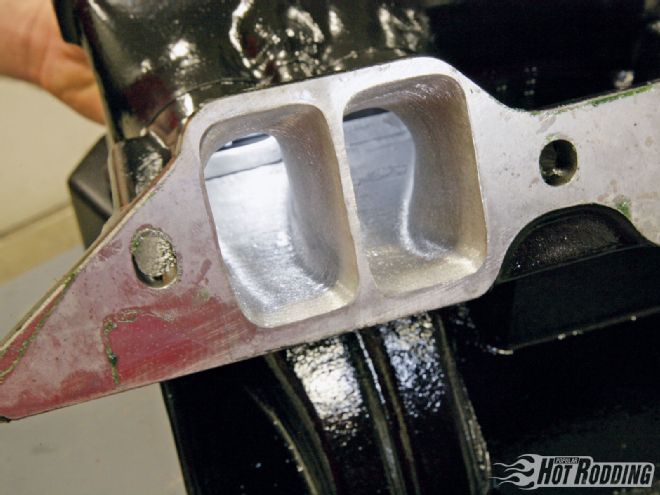

The intake runners are cast in a D shape, and Jesse Robinson of SKMFX kept the same basic design, blending and sizing it as it neared the cylinder head.

The intake runners are cast in a D shape, and Jesse Robinson of SKMFX kept the same basic design, blending and sizing it as it neared the cylinder head.

For the oil system, again, there's no magic there-only solid, proven technology. They used a common oil filter adapter: "That was just your standard Milodon single inlet and a static pickup in the sump. You just block off the 3/8-inch pickup in the block with a pipe plug and enlarge a couple of the main feeds."

T&D Machine makes these beauties that are as stout as they are sexy. Motivating a set of Howards springs under titanium retainers, the valvetrain had no problems turning 7,000.

T&D Machine makes these beauties that are as stout as they are sexy. Motivating a set of Howards springs under titanium retainers, the valvetrain had no problems turning 7,000.

The name Keith Black is synonymous with high-powered engines, and it is no coincidence that it is also associated with top-quality pistons bearing the KB badge. Though previously known for their hypereutectic pistons, a few years ago KB Performance Pistons strengthened their line card with a series of new forged pistons which is what the SKMFX team chose for their operation. They worked perfectly with the low-tension Mahle ring package and had no modifications beyond fly-cutting the intake valve notch to make sure they could advance the cam far beyond a normal setting during the test sessions. "We took sixty thousandths off the intake notches and that was the extent of the modifications. We don't have any kind of coatings at all," Robinson says. The pistons sat out of the hole slightly and the guys used a thicker head gasket to knock the piston-to-head quench down to a tight .035 inch. "I'm a big believer in quench. I've been practicing that theory since probably the mid '90s and I think we set ours at 35 thou." Some theorize that having the piston sit above the deck brings the top ring closer to the wide head gasket opening and lets the rings seat under combustion slightly quicker and make more power. In a war where every shot counts, that was just one more weapon in Robinson's arsenal.

Deeply entrenched in the engine was a COMP Cams solid roller camshaft. Taking advantage of the Commando's large .904-inch diameter lifters, aggressive lobes were carefully plucked from the COMP lobe catalog that would best take advantage of the combination. "I had ordered a custom cam prior to that one we used, and it was quite a bit smaller. The averages were quite good. What happened was I wanted that big number, so I called COMP Cams four days before we had to leave for the competition. Buddy at COMP Cams had it in my hands two days later. So we slapped it in pretty much straight up. It really did wake it up, but it cost us about 30 lb-ft at the peak at that point. So pointswise, it was a wash. We picked up a little average horsepower but it definitely penalized us heavily in the way that we were tested." Robinson says: "I was a little too hung up on the peaks and not enough on the valleys." They decided upon a single-pattern 269-degree cam that would give the engine plenty of breathing room but still make gobs of torque, 615 lb-ft to be exact. That's enough to get an armored personnel carrier cruising with the right gearing.

A fairly small combustion chamber lets these engine builders get 11.4:1 compression with a pretty basic flat-top piston. Avoiding a dome helps the flame travel in the chamber more evenly and efficiently.

A fairly small combustion chamber lets these engine builders get 11.4:1 compression with a pretty basic flat-top piston. Avoiding a dome helps the flame travel in the chamber more evenly and efficiently.

They used a Milodon adjustable gear drive to motivate the cam and were pleased with how much it helped in terms of being able to make changes quickly. "It was a beautiful thing for quickly indexing the cam on the dyno-just to see how much that moved the curves around. Lo and behold, like everyone else, we found that we seemed to have the best averages when we kept advancing it, pretty much until we ran out of positions. It was really eye opening at how convenient the gear drive made that."

Solid-roller cams demand stability on the pushrod end of things, which is why they chose these superbad dual-taper pushrods from Trend. Lightweight components on the valve end of things evens out the formula.

Solid-roller cams demand stability on the pushrod end of things, which is why they chose these superbad dual-taper pushrods from Trend. Lightweight components on the valve end of things evens out the formula.

Another weapon available to the team was a pair of Edelbrock Victor cylinder heads. The big "E" is known for having exceptional castings and leaving nothing on the table when it comes to quality components. "I had never used the Victor heads before so it was kind of a learning curve." Using a SuperFlow SF1020 flowbench as his guide, Robinson spent countless hours sizing the ports and finessing the curves in the heads. He had a target minimum crosssectional area (MCSA) that he was shooting for to get the flow numbers that he wanted while keeping the runners high and tight. That combination makes for ports that build a ton of velocity quickly in the rpm range and add to the torque curve. It is a fine line that experts like Robinson tread between building velocity and making the runners so small that they won't let the engine build power up top. Experience, science, and art all combine to make it happen correctly. "I measured a lot, but I was very concerned with pushrod clearance because every time I opened the intake ports at the pushrod pinch or the flange, flow would pick up quite a bit but I felt I was running out of pushrod room and I didn't want to make a hole." Regarding how the stock style big-block heads are located on top of the cylinders, Robinson let us in on a little secret: "In the past I've actually reverse angle milled them with great success. I thought about doing that, but to be honest, time just ran out."

The open chamber design of the Victor heads was only modified to the extent that the intake side was laid back a touch. That modification was not only good for flow but placed the fuel mixture more evenly in the chamber for a good burn.

A little detonation down low put the Mahle/Clevite rod bearings to the test but they passed with flying colors. The pistons are a basic enough shelf stock design that anyone can buy to repeat this combination.

A little detonation down low put the Mahle/Clevite rod bearings to the test but they passed with flying colors. The pistons are a basic enough shelf stock design that anyone can buy to repeat this combination.

"I used a 5/16-inch stemmed Ferrea valve on the intake side and I experimented with a 50-degree seat, but I just couldn't get it to work with that port and chamber configuration so I abandoned that and went back to a 45-degree seat. We actually went from 2.3-inch back down to 2 1/4-inch valves where I got my best results." The lightweight valves also allowed them to run lower spring pressures and cut some frictional losses. Since the Victor heads were designed as a true bolt-on, they used a 1.880-inch spring height which slightly limited the amount of lift they could run with the available springs. Even so, the guys were able to get a solid three quarter inch of lift!

To the chagrin of the Blue Oval and Brand X camps, Mopar designed its engines with shaft rockers from the factory. T&D Machine built the rockers for the SKMFX engine, and they fit perfectly on the Eddy heads. For years some complained that aftermarket big-block shaft rockers had problems with the aluminum side spacers locking up when the engine was hot and creating a condition similar to valve float. The aluminum locators would expand and sandwich the rocker arms where they couldn't move. T&D addressed this by making their lateral locators from a composite material. Robinson said their rockers worked perfectly.

SKMFX team members Ron Maclean, Joe Rutters, and Jesse Robinson were proud of their Commando in black, and were relieved that they didn't have to declare this WMD as they crossed the border back to their homeland of Canada.

SKMFX team members Ron Maclean, Joe Rutters, and Jesse Robinson were proud of their Commando in black, and were relieved that they didn't have to declare this WMD as they crossed the border back to their homeland of Canada.

Since the Challenge was fairly open as far as intake manifold rules, Robinson's team went for the kill and chose a Weiand tunnel ram. Careful searching on eBay led them to their quarry where they were able to pick up their intake for pennies on the dollar. The used manifold and the engine block were toted over to the SKM powdercoating shop for a slick black finish. Naturally the valve covers were treated to the traditional Mopar wrinkle finish but with the SKMFX logo CNC machined in the top.

Once the parts were back from powdercoat, Robinson continued the port work from the cylinder heads all the way up the intake runners where it terminated in the plenum. They tried several versions of spacers on top of the intake but stuck with a basic half-inch phenolic open spacer from Holley. Running a tunnel ram definitely changes how the engine pulls fuel, and the jetting can be quite different. "The first couple of tests we did with the tunnel ram we didn't have enough jet in it and we pushed a head gasket once." A quick swap of a head gasket and fattening up the jets set everything back in order.

The use of a Milodon oil filter adapter is standard operating procedure in the big-block Mopar world. Instead of pulling oil through the little 3/8-inch hole in the engine block it pulls oil directly from the sump in the pan, bypassing some narrow, sharp bends that rob oil pressure.

The use of a Milodon oil filter adapter is standard operating procedure in the big-block Mopar world. Instead of pulling oil through the little 3/8-inch hole in the engine block it pulls oil directly from the sump in the pan, bypassing some narrow, sharp bends that rob oil pressure.

Holley was their choice for carburetors. Dual 1,000-cfm HP Series carbs were sourced and given the SKMFX treatment. They used annular boosters to get better fuel atomization down at the low end of the rpm range and it still kept from creating any restriction up top. Robinson felt quite comfortable tuning the carbs: "That's really all I've ever done. I really haven't messed with fuel injection a whole lot. The bulk of my experience is with carburetors. I was really hoping to show up with two Thermoquads to be honest. Just for fun. I've had fantastic success with the Thermoquads but it probably wouldn't have worked as well as the Holleys."

Some ignore the ancillary components but Robinson made sure his engine was loaded for bear. A Moroso electric water pump was installed that has been proven to free up 20 horses and with the CNC-machined billet impeller; it moves up to 21 percent more water than comparable pumps while only drawing 7 amps. Even under the stress of three back-to-back pulls after warming up, the engine never climbed over 163 degrees.

Ignition was rock solid thanks to the engineers at MSD. Using a 7AL2 ignition box and a Pro Billet distributor, the SKMFX team was able to monitor and dial-in the engine easily. "It had always made best power at what I thought was 36 degrees on the dyno, so when we put the last camshaft in it, we started testing at 32, and power was excellent. Whenever we bumped it up to 36, we'd lose power and it had never done that before. It was actually during the photo shoot that I happened to rest my hand on the damper on the end of the crank and I thought the whole front of the crank moved forward like the thrust was out of it, but it wasn't. The damper had failed and the outer ring had moved forward like a quarter inch. What had happened was at the contest, on the dyno during the tune up period, I had elected to put two more degrees in and I think we must have already been at 36 or 38 degrees in, and we must have run with about 40 or 42 degrees." The added timing showed as it rattled pretty hard down low but she was tough and held up.

Shell V-Power 91 octane pump gas smelled as good as napalm in the morning as it burned and passed through the Hooker 2-inch headers. Its final destination lay just past the MagnaFlow mufflers and into the cool afternoon air of America's heartland.

Locked and loaded, the Commando in black sounded as deadly as a Barrett 50 cal while stuffing 690 horses down the throat of the DTS dyno. It put up a mighty battle and the boys were pleased by the valiant effort. "That power range is a little more than what I'm used to building. The bulk of our stuff is circle track small Chevy stuff, so to build a big-block in the 700hp range it was a little different experience. Because Engine Masters requires you to run on pump gas, what I've been learning and going back to is that all of our circle track classes are pretty much required to run on pump gas now. So I can take what I've learned from applying it to the Challenge engine and offer it to my customers in their engines." Whether it is a circle track, drag, or street engine, SKMFX is clearly ready to do battle again. One thing is for sure though, the next time they enter the EMZ (Engine Masters Zone) they won't take any prisoners.

BY THE NUMBERS SKMFX ENGINES 471 MOPAR Bore: 4.375 inches Stroke: 3.915 inches Displacement: 471 actual cubic inches Compression ratio: 11.4:1 Camshaft: COMP Cams solid roller Cam duration: 269/269 degrees at .050-inch Valve lift: .752-/.708-inch Rocker ratio: T&D Shaft 1.6/1.5 ratio Top ring: 1/16-inch, Mahle/Clevite Second ring: 1/16-inch, ductile iron Oil ring: 3/16-inch, low tension Piston: KB Pistons, flat top Block: OEM 400 B-block Crankshaft: 440 Source Rods: Scat 6.385-inch BBC Cylinder head: Edelbrock Victor Intake valve diameter: 2.25-inch Exhaust valve diameter: 1.81-inch Intake manifold: Weiand tunnel ram Carburetor: two Holley HP 1000 carbs Header: Hooker B/E body with 2-inch primaries Ignition: MSD 7AL2 The intake runners were a perfect match for the runners in the heads. The finish is done with a semifine cartridge roll to make sure that fuel doesn't "smear" down the cylinder walls and remains in suspension.

ON THE DYNO

471CI

MOPAR WEDGE

RPM

TQ:

HP:

3,000

498

284

3,100

494

292

3,200

487

297

3,300

483

304

3,400

475

308

3,500

461

307

3,600

446

305

3,700

448

316

3,800

492

356

3,900

527

391

4,000

528

402

4,100

548

428

4,200

564

451

4,300

576

471

4,400

585

490

4,500

590

505

4,600

594

521

4,700

598

535

4,800

599

547

4,900

599

559

5,000

601

572

5,100

603

586

5,200

605

599

5,300

608

613

5,400

611

628

5,500

615

644

5,600

614

655

5,700

614

666

5,800

609

673

5,900

606

681

6,000

601

687

6,100

594

690

6,200

583

688

6,300

571

685

6,400

559

681

6,500

545

675

6,600

528

663

6,700

508

648

6,800

496

643

6,900

484

636

7,000

472

629

The intake runners were a perfect match for the runners in the heads. The finish is done with a semifine cartridge roll to make sure that fuel doesn't "smear" down the cylinder walls and remains in suspension.

ON THE DYNO

471CI

MOPAR WEDGE

RPM

TQ:

HP:

3,000

498

284

3,100

494

292

3,200

487

297

3,300

483

304

3,400

475

308

3,500

461

307

3,600

446

305

3,700

448

316

3,800

492

356

3,900

527

391

4,000

528

402

4,100

548

428

4,200

564

451

4,300

576

471

4,400

585

490

4,500

590

505

4,600

594

521

4,700

598

535

4,800

599

547

4,900

599

559

5,000

601

572

5,100

603

586

5,200

605

599

5,300

608

613

5,400

611

628

5,500

615

644

5,600

614

655

5,700

614

666

5,800

609

673

5,900

606

681

6,000

601

687

6,100

594

690

6,200

583

688

6,300

571

685

6,400

559

681

6,500

545

675

6,600

528

663

6,700

508

648

6,800

496

643

6,900

484

636

7,000

472

629