Some engines have a certain sound. Fury. Hate. Anger. They emanate total power. This engine makes that sound. It makes that power. When the throttle goes WFO on this thing, the little hairs on your arm stand straight up, and you get that special feeling that lets you know something really good is happening. Like listening to Metallica's "One," it just builds and builds and you can't help wanting more. Once the final notes have played, the silence that remains is just as deafening.

Before breaking down the notes on this engine, let's first take a little trip back in time. In 1967, GM began selling high-performance engines over the counter and their line of offerings has steadily grown into the full-blown GM Performance Parts array of crate engines that we see today. Dr. Jamie Meyer of GMPP says the 572 that they based their build on was originally offered for sale in 2003 and has been a number one hit ever since. He also stresses that GM is the only source for brand-new Chevy engines. "If you buy a 350 Chevy from someone else, you just bought a used engine. That holds true for the big-block series as well-427 and 454. We are still making brand-new Chevy big-blocks every day." As a side note, we just got word that GMPP dropped the pricing of their ZZ427 so that enthusiasts can pick up a modern version of the fabled L88 direct from GM on the cheap. They even have a few of the limited Anniversary Edition 427s floating around in dealer inventory if you want something real special.

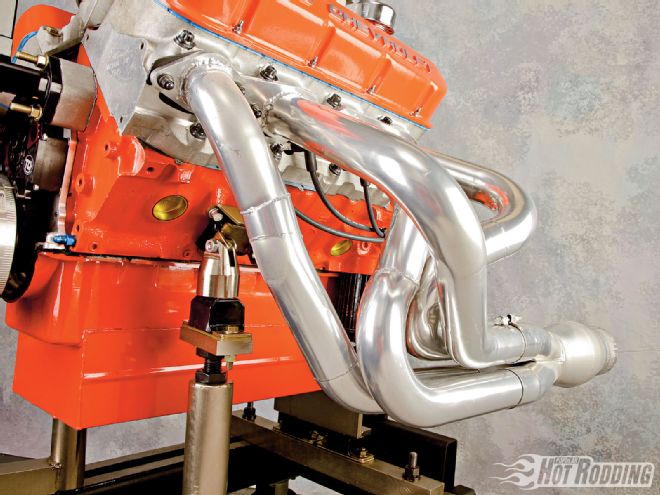

Like a lot of hot rodders, we figured we could do some things ourselves a little cheaper than buying them-like building headers. Wrong. If we had to do it again, we'd buy a set of headers and maybe swap out the collectors for the awesome ones that Edelbrock makes. Our jaws dropped when they picked up 40 horses and an equal amount of torque over 4-2-1 collectors in testing. The one thing we don't regret is having Nitroplate coat our headers. Every time we've used them, we've seen an increase in power as well as bling.

Like a lot of hot rodders, we figured we could do some things ourselves a little cheaper than buying them-like building headers. Wrong. If we had to do it again, we'd buy a set of headers and maybe swap out the collectors for the awesome ones that Edelbrock makes. Our jaws dropped when they picked up 40 horses and an equal amount of torque over 4-2-1 collectors in testing. The one thing we don't regret is having Nitroplate coat our headers. Every time we've used them, we've seen an increase in power as well as bling.

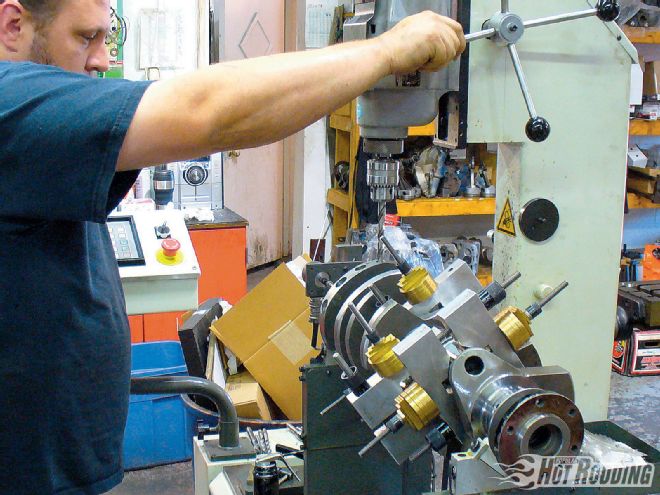

The 572 offered from GMPP is designed as a 4.560-inch bore by 4.375-inch stroke combination using rectangle-port aluminum heads on a tall-deck Gen VI block. We built our instrument using a short-deck version of the famous Bow Tie block with the bore and stroke dimensions matching that of the crate engine. Naturally, we used a torque plate to stress the block while honing, simulating the effects of torquing the heads in place. For the honing procedure, it seems like all machine shops have their own secret way of finishing the bores. We've found great results with our Sunnen CK10 by roughing it in to the last thousandth of an inch with a 180-grit stone, using a 220-grit to get to finished size, then running four strokes with a 280-grit and four strokes with a 400-grit. Since we were going for the gusto, we also hit this block with four strokes of a 600-grit stone. Clean honing fluid, the right pressure on the stones, and a good feel for the machine are the tricks to getting the holes round and straight to within a couple ten-thousandths of an inch.

The rotating assembly is sort of like the rhythm section of this band. It is always moving, making the cadence and striking the beat that the rest of the players follow. At the very bottom, a Kryptonite crankshaft made from EN30B billet steel spins to the beat. It was a bargain that engine owner Kris Henderson scored from a buddy's blown-up offshore powerboat. A couple hundred bucks for a crank that usually costs close to $3K is a real deal.

With an engine nearly as big as the team, the guys at Revolutionary Performance and Machine were proud of their handiwork. From left, Shannon Carnathan, engine owner Kris Henderson, author Daryl White, Derrick Goodwin, and Michael Schoeder put in a lot of effort to make this piece of heavy metal look like just another crate engine with an intake swap.

With an engine nearly as big as the team, the guys at Revolutionary Performance and Machine were proud of their handiwork. From left, Shannon Carnathan, engine owner Kris Henderson, author Daryl White, Derrick Goodwin, and Michael Schoeder put in a lot of effort to make this piece of heavy metal look like just another crate engine with an intake swap.

Eagle Specialty Products supplied a set of their Armor-coated 6.385-inch-long H-beam rods with the L19 bolt upgrade. Using a rod bolt stretch gauge, we determined that it takes right about 80 ft-lb to give the bolts .0058 inch worth of stretch. That tension on the bolts is what keeps the fasteners from backing out and the added tensile strength of the L19 material keeps the rod bearing bore from elongating and stretching out when the engine is at speed. I'll be honest, I was slightly skeptical of the Armor coating that was on the rods, but really the oil would just about bead up on it, and you could feel how much slicker it was than an untreated rod. For the small amount of the upgrade price, it was absolutely worth it.

Bearing the brunt of the internal combustion process, we used a set of custom CP pistons designed by Dave Calvert to transfer heat energy into force. Calvert is a veteran in the piston world and knows all the right questions to ask when building custom slugs. Besides the basic bore and stroke issues, there is also the task of making sure the bottoms of the piston skirts don't hit the crankshaft, and that the ring grooves are far enough down so they don't have a weak spot where the valve notches are cut, while still being high enough up to let combustion gasses seal the rings immediately. Making sure the widest portion of the skirt is higher than the bottom of the cylinder bore is another attribute that Calvert takes into consideration. Finally, just making sure that the valve notches are deep enough and in the right places is a critical detail (that we will revisit shortly). The rings we chose were a set of Total Seal Advanced Profile rings designed to be exceedingly flat and smooth. With the knowledge that we were using those rings, CP was able to match the ring grooves perfectly with just the right amount of vertical and lateral spacing to work at maximum efficiency.

GMPP valve covers are the hottest thing on this engine. We've had tons of people ask if it is a 620- or 720-horse crate motor. Yeah, it's just a 620 crate motor ...

GMPP valve covers are the hottest thing on this engine. We've had tons of people ask if it is a 620- or 720-horse crate motor. Yeah, it's just a 620 crate motor ...

We absolutely wanted our rod and main bearings to be able to handle whatever loads we tossed at them, so we placed a call to our local Federal-Mogul rep to obtain a set of their coated high-performance bearings. We wanted to set our bearing clearances loose to free up as much frictional horsepower as possible knowing our Melling M-Select oil pump would pass enough lube to keep the bearings happy. I wouldn't recommend .0045-inch clearance for street engines unless you have the intestinal fortitude to stomach 15 psi at idle.

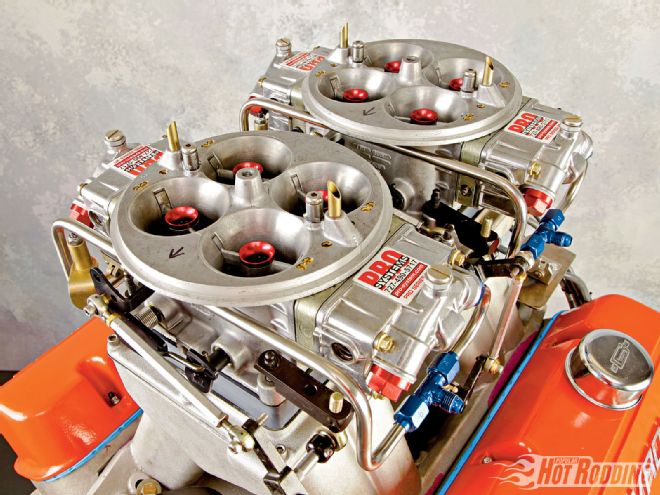

We've used Pro-Systems for several years as our number one choice for custom Holley carbs. These Dominators are a pair of 1150s that worked best with No. 88 jets all around and No. 36 high-speed air bleeds.

We've used Pro-Systems for several years as our number one choice for custom Holley carbs. These Dominators are a pair of 1150s that worked best with No. 88 jets all around and No. 36 high-speed air bleeds.

If the rotating assembly works as the rhythm section, then certainly the cam must be lead guitar. That is the sound everyone wants to hear and bang their heads to. We tried three different grinds with the wildest having nearly an inch of lift! Turns out, that one was just way too agro, and it burned up a pushrod tip and rocker arm cup in a minute flat. We stepped back and ended up running a Mike Jones cam with a reasonable amount of lift and duration that made incredible power. When we originally ordered our pistons, we gave CP some basic dimensions of the lift, duration, and lobe separation of the cams we were going to use, but alas, we still had to cut the intake valve pocket a little deeper to allow us to move the cam around, thanks to our fickle cam choices. Since we had a COMP Cams beltdrive that gave us easy access to cam timing changes on the dyno, we wanted to take full advantage of that. We made sure that we had a minimum .080 inch on the intake and .100 on the exhaust whether we moved any of the cams plus/minus 10 degrees.

The spirit of the late Ronnie James Dio smiled upon us like a rainbow in the dark as we were one of the first to be able to rock COMP Cams new Race Elite Series solid roller lifters. Wow! Light-years ahead of the rest of the market, COMP really listened to engine builders when they designed this new lifter. It has a huge axle that is pinned in place so it doesn't spread out like the cheaper stuff, interchangeable pushrod cups to swap centered to offset cups in seconds, a micropolished surface finish, and an incredibly strong body that showed no signs of wear-even when punished with close to 1,000 pounds of spring pressure. Engine builders have really been waiting for a lifter like this that is designed for a more serious engine, but that still doesn't need a set of $2,000 lifters.

PRW manufactures SFI-approved flywheels like ours for about all of the major engine families. They also make a full line of rocker arms, balancers, and a bunch of other neato stuff.

PRW manufactures SFI-approved flywheels like ours for about all of the major engine families. They also make a full line of rocker arms, balancers, and a bunch of other neato stuff.

We had the bottom end of this thing ready to rock out and it was time to bring in the real power players to kick it off. Edelbrock Victor 24 Degree Semi-Finished cylinder heads were a natural choice for us. The castings are extra thick to allow significant amounts of porting, the decks are extra thick to hold plenty of power, and they are available in a HIPPED option (Hot Isostatic Pressing) that squeezes all the little air bubbles out of the casting for anyone who is serious about making 2,000-plus horses. That is a bitchin set of heads. We took a set of Vic's bare castings and pored over them for days, trying to figure out how to possibly make them even more badass. It turns out I had a set of Big Duke heads in the shop at the time and sat them next to the Edelbrocks to compare. It was clear that the ports were completely different, and I was determined to make the standard-port location Edelbrock heads as close to a set of the Pro Stock-inspired heads as possible. That meant raising the runners over a half inch and moving the "long" ports to the side to straighten them out and even up their length with the "short" ports. Rules of the Engine Masters Challenge dictated that we were not allowed to weld on the exterior of the runners or the intake manifold, so I mocked up the intake on the engine and used the very edge of the runner castings as my limiting mark. As the manifold was designed, it looked like we would be able to slide the long port over a solid 3/8 inch, which was great, but it presented a dilemma. The pushrod hole was right in the middle of where we wanted the port. What to do? I channeled the ghost of Smokey Yunick and interpreted the rules a bit. We were not allowed to weld on the exterior of the runners, but there was not a rule stating we couldn't press a solid aluminum dowel where the original pushrod hole was and redrill the hole, so that is what we did. Once the new pushrod location was set, it was just the minor task of removing several pounds of aluminum in the heads to make them flow the numbers that lay ahead.

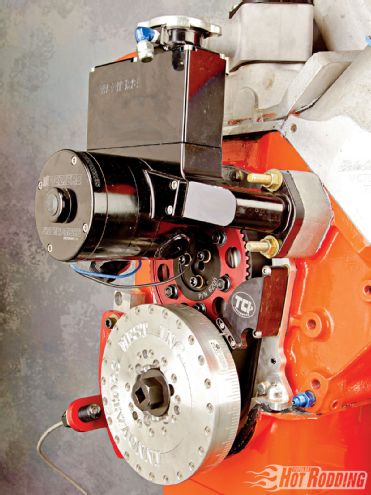

The totally trick-looking Innovators West harmonic dampener is designed to be effective at knocking out crankshaft harmonics and is totally rebuildable. Innovators also makes custom inscribed valve covers for a number of big name engine builders and anyone else who gives them a call. A COMP Cams PN 6200 beltdrive was completely reliable, and a real time-saver on the dyno. Cam timing changes took just a couple minutes.

The totally trick-looking Innovators West harmonic dampener is designed to be effective at knocking out crankshaft harmonics and is totally rebuildable. Innovators also makes custom inscribed valve covers for a number of big name engine builders and anyone else who gives them a call. A COMP Cams PN 6200 beltdrive was completely reliable, and a real time-saver on the dyno. Cam timing changes took just a couple minutes.

We've been big fans of Larry Meaux's PipeMax program as well as Performance Trends' Engine Analyzer software, and used them extensively when designing the ports for this tower of power. We determined that a cross-sectional area of 3.2 square inches would be ideal for getting the air moving quickly down low, and still allow it to blossom to full flow at the rpm range we were running in. We used Splash Zone epoxy to fill in the floors and sides of the runners where we moved the ports and got as close as possible without breaking through the exterior of the ports. I felt pretty happy with the resulting design of 335cc big-block runners that flowed over 430 cfm. We were equally happy that we got the port lengths to under 1/16 inch difference from the long to the short port. That would make tuning the combination much easier.

AC/DC isn't the only high-voltage group to come from Down Under. ICE Ignition outside Melbourne supplied us with nearly unlimited energy via their 10-amp ignition system featuring a 24-volt booster for the coil. It is easily enough for a blown alky engine, so pump gas was no problem. A small-cap distributor would have saved us the hassle of trimming our intake manifold to fit, but we felt it was more important to keep the plug wire terminals as far from each other as possible to avoid any misfires.

AC/DC isn't the only high-voltage group to come from Down Under. ICE Ignition outside Melbourne supplied us with nearly unlimited energy via their 10-amp ignition system featuring a 24-volt booster for the coil. It is easily enough for a blown alky engine, so pump gas was no problem. A small-cap distributor would have saved us the hassle of trimming our intake manifold to fit, but we felt it was more important to keep the plug wire terminals as far from each other as possible to avoid any misfires.

After finishing the port work, the heads were sent off to T&D Machine to be fitted for a set of 1.9 ratio shaft rocker arms. T&D has been providing racers with top-notch stuff for decades, and it was easy to understand why. A quick call to Sheldon with the specs and he said "Send 'em." They came back in two weeks perfectly fitted with the stand heights correct and looking like jewels.

While the heads were away, our shop compadre Shannon Carnathan worked over the ProFiler tall-deck tunnel ram. Yeah, tall deck. On a short-deck block. We had moved the ports up so much that the tunnel ram fit perfectly without having to mill it at all. Just a bit of epoxy where the runners were moved to the sides and a whole pile of aluminum to hit the ground as it was matched to the heads.

Pro-Systems hooked us up with an incredible set of modified Holley Dominators that were amazingly responsive and gave a great fuel curve throughout the 3,000-7,000 rpm range that the impending Challenge ran through. When initially talking with Patrick from Pro-Systems, he had us try a pair of 1050s that were built for a smaller engine but finally sent us a set of 1150s that picked up an average 10 horses across the board. His stuff consistently shows up within just a couple jet and air bleed sizes of absolutely perfect for the combination. He attributes this to keeping good records of customers' engines and confidential copies of their dyno sheets.

One Hooker weld-up header kit plus four more "U" bends plus two Edelbrock merge collectors plus three rednecks times 40 hours equals one set of headers that don't fit any car but clear every dyno on the planet.

One Hooker weld-up header kit plus four more "U" bends plus two Edelbrock merge collectors plus three rednecks times 40 hours equals one set of headers that don't fit any car but clear every dyno on the planet.

Getting this whole combo together, it was imperative that, like a band, we practice before the big show. So it was off to Shacklett Automotive and their engine dyno to get this thing in tune. We started off with the short-duration/big-lift cam, but as mentioned above, it didn't last long. Thank goodness we had spare Smith Brothers heavy-duty pushrods to take the place of the early sacrifice. Not wanting to see anymore carnage, I made the executive decision to yank that cam without making a full pull and stick in number two. It performed well with significantly less lift, but with a little more duration. Then we stuck in number three. Third time's the charm they say. It certainly was with this baby. It responded by picking up power across the board and after some fiddling around with cam timing, we knew we had it right.

Naturally every time we moved the cam, the distributor phasing changed some, but thanks to big spark from the ICE Ignition, firing the Champion plugs was a nonissue. ICE's inductive ignition systems are different from normal capacitive discharge systems in that the electrical energy is stored in the coil rather than a capacitor in the ignition box. "So what does that mean for me?" you ask. OK, here it is: With the ICE inductive coil setup, instead of having a short 2-4 degrees of spark duration in which distributor timing and phasing is super critical and very touchy, the ignition box is able to deliver 24-36 degrees of high-energy spark duration. That means that instead of a little short "beep" of spark, like a horn from some ricer driving by, you get a long "honk" of spark, like a big rig. That's what we like, and that's what the engine likes.

We internally balanced the billet Kryptonite crankshaft to keep it from oscillating like a spaghetti string. The shaft already had two sticks of heavy metal in both ends so we just had to drill a couple holes deeper to get it dialed in.

We internally balanced the billet Kryptonite crankshaft to keep it from oscillating like a spaghetti string. The shaft already had two sticks of heavy metal in both ends so we just had to drill a couple holes deeper to get it dialed in.

Once the engine seemed happy, we were happy. Then the engine started to act not so happy, and we weren't so happy. We had dropped 40 horses between pulls and that is not good, especially when we had to load up the next morning to head to Ohio if we were to remain in the good graces of the Engine Masters staff. A quick leakdown showed several cylinders with 60-80 percent leakage. Not good. We yanked the heads and immediately saw the problem. The massive 2.400-inch intake valves were running into the sides of the 1.850-inch exhaust valves. Argh! That was the kind of sour note we didn't want to hear.

A late night and early morning later, we had installed a set of new 2.350-inch intake valves, scrounged up enough replacement exhaust valves, and recut the valve job so that it would hopefully hold together. We bolted the heads on and immediately loaded the engine in the truck for the seven-hour haul to the University of Northwestern Ohio.

UNOH is an amazing school. Pulling onto campus you would think you arrived at gearhead nirvana. Tractor trailers, combines, diesel and gas engine vehicles, and race cars were being worked on by students more than happy to get their hands dirty while pursuing baccalaureate degrees. Besides art and history, students have access to one of the greatest motorsports education programs on the planet. Multiple buildings filled with state-of-the-art equipment that was kept operating-room clean showed the Challenge competitors that this school meant business. One of the buildings housed a pair of identical DTS engine dynos that we would test our engines on. Calibrated to less than a gnat's short hair difference of each other, the DTS dynos boast the ability to pull just about any engine down to less than 2,500 rpm without any struggle at all, and produce repeatable, accurate results.

We used Total Seal's AP stainless steel top rings gapped at .020 and their ductile-iron Napier-cut second rings gapped at .022. She's a non-smoker, and leakdown registers at less than a percent, so it's definitely sealed up right.

We used Total Seal's AP stainless steel top rings gapped at .020 and their ductile-iron Napier-cut second rings gapped at .022. She's a non-smoker, and leakdown registers at less than a percent, so it's definitely sealed up right.

We bolted our pile of heavy metal to the dyno and hooked up 13 feet of 3.5-inch exhaust pipe to the loud end of our Magnaflow mufflers to best simulate the real-world performance of this pump-gas, crate engine imitator. When we fired it up it sounded pissed off at the world, and ready to rock 'n' roll. The little hairs started to raise up on my arms. The conductor with his hand on the dyno stick jammed it forward. The engine screamed so loud and mean, you just wanted more. More than the 845 horses it was pumping out. More than the 750 lb-ft it was blasting. More loud exhaust. More pressure pounding on your chest. More of everything. Just more.

Eagle Specialty Products rods have come to dominate the industry. With the ARP L19 rod bolt upgrade and Armor coating, we've personally used them in dozens of bracket race and heads-up engines, making 700-1,000 hp with no problems. Our CP Pistons received the full skirt and head coating treatment from Calico Coatings. The ceramic-based coating facing the chamber allows the energy produced during combustion to continue to be used to propel the piston downward instead of being absorbed as heat into the piston head.

BY THE NUMBERS

572ci Big-Block Chevy

Bore:

4.562 inches

Stroke:

4.375 inches

Displacement:

572 actual cubic inches

Compression ratio:

11.5:1

Camshaft:

Mike Jones solid roller

Cam duration:

266/272 degrees

at .050-inch tappet rise

Valve lift:

.842/.813 inch

Lobe Separation:

110 installed at 106.5

Rocker ratio:

T&D shaft style, 1.9 ratio

Top ring:

. .043 Total Seal

Second ring:

.043 Total Seal Napier

Oil ring:

3mm Total Seal

Piston:

CP Pistons dome

Block:

GMPP Bow Tie short-deck

Crankshaft:

L.A. Enterprises Kryptonite

Rods:

Eagle 6.385-inch Armor coated

Cylinder head:

Edelbrock Victor

Intake valve diameter:

2.35 inches

Exhaust valve diameter:

1.85 inches

Intake manifold:

ProFiler tunnel ram

Carburetor:

two Holley 1150 Dominators

by Pro-Systems

Header:

custom 21/4-inch primary with

Edelbrock merge collectors

Ignition:

ICE Ignition 10-amp system

Eagle Specialty Products rods have come to dominate the industry. With the ARP L19 rod bolt upgrade and Armor coating, we've personally used them in dozens of bracket race and heads-up engines, making 700-1,000 hp with no problems. Our CP Pistons received the full skirt and head coating treatment from Calico Coatings. The ceramic-based coating facing the chamber allows the energy produced during combustion to continue to be used to propel the piston downward instead of being absorbed as heat into the piston head.

BY THE NUMBERS

572ci Big-Block Chevy

Bore:

4.562 inches

Stroke:

4.375 inches

Displacement:

572 actual cubic inches

Compression ratio:

11.5:1

Camshaft:

Mike Jones solid roller

Cam duration:

266/272 degrees

at .050-inch tappet rise

Valve lift:

.842/.813 inch

Lobe Separation:

110 installed at 106.5

Rocker ratio:

T&D shaft style, 1.9 ratio

Top ring:

. .043 Total Seal

Second ring:

.043 Total Seal Napier

Oil ring:

3mm Total Seal

Piston:

CP Pistons dome

Block:

GMPP Bow Tie short-deck

Crankshaft:

L.A. Enterprises Kryptonite

Rods:

Eagle 6.385-inch Armor coated

Cylinder head:

Edelbrock Victor

Intake valve diameter:

2.35 inches

Exhaust valve diameter:

1.85 inches

Intake manifold:

ProFiler tunnel ram

Carburetor:

two Holley 1150 Dominators

by Pro-Systems

Header:

custom 21/4-inch primary with

Edelbrock merge collectors

Ignition:

ICE Ignition 10-amp system

Using "X" bearings to gain more clearance and free up horsepower, we set the mains to .0045 and the rods to .003. Realistically, that is too big for street use, but boy it sure makes power.

DYNO DATA

BestQualifyingPull

RPM

TQ

HP

3,000

614

351

3,100

637

376

3,200

661

403

3,300

672

422

3,400

671

435

3,500

663

442

3,600

653

448

3,700

642

452

3,800

635

459

3,900

640

475

4,000

658

501

4,100

681

532

4,200

698

558

4,300

707

579

4,400

710

595

4,500

714

612

4,600

713

624

4,700

712

637

4,800

715

654

4,900

723

675

5,000

733

697

5,100

742

721

5,200

750

742

5,300

754

761

5,400

756

777

5,500

753

788

5,600

747

797

5,700

738

801

5,800

730

806

5,900

723

812

6,000

719

822

6,100

715

830

6,200

709

837

6,300

704

844

6,400

692

843

6,500

682

844

6,600

673

845

6,700

661

843

6,800

650

842

6,900

641

842

7,000

628

838

Using "X" bearings to gain more clearance and free up horsepower, we set the mains to .0045 and the rods to .003. Realistically, that is too big for street use, but boy it sure makes power.

DYNO DATA

BestQualifyingPull

RPM

TQ

HP

3,000

614

351

3,100

637

376

3,200

661

403

3,300

672

422

3,400

671

435

3,500

663

442

3,600

653

448

3,700

642

452

3,800

635

459

3,900

640

475

4,000

658

501

4,100

681

532

4,200

698

558

4,300

707

579

4,400

710

595

4,500

714

612

4,600

713

624

4,700

712

637

4,800

715

654

4,900

723

675

5,000

733

697

5,100

742

721

5,200

750

742

5,300

754

761

5,400

756

777

5,500

753

788

5,600

747

797

5,700

738

801

5,800

730

806

5,900

723

812

6,000

719

822

6,100

715

830

6,200

709

837

6,300

704

844

6,400

692

843

6,500

682

844

6,600

673

845

6,700

661

843

6,800

650

842

6,900

641

842

7,000

628

838