What better way to enjoy a waning summer evening than by jumping into your vintage Pontiac and heading to a local cruise-in for a few cold beverages and a burger off the grill? If that sounds like fun, imagine you're in the driver seat for a moment.

After tapping the accelerator pedal to inject a few shots of fuel into the Quadrajet, you hit the key, the Delco starter churns mercilessly, and the Pontiac V-8 roars to life, emitting an authoritative exhaust bark through its tubular headers. Once underway, your finely tuned engine purrs right along at highway speeds without a hiccup. Life as a hobbyist just couldn't be any better!

Upon arrival, you park your Pontiac amongst your friends and spend the next couple of hours socializing. Your honey-do list prevents you from staying any longer, however, so you slide behind the steering wheel and give the ignition key a twist, fully expecting anyone within earshot to take notice of the exhaust cackle. Instead of cranking the engine, however, the starter motor protests with a defiant click.

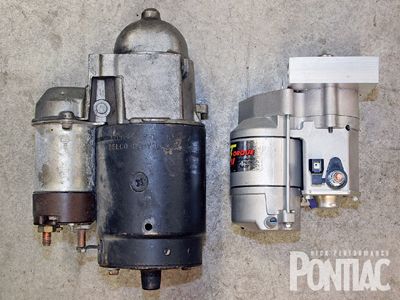

Most hobbyists can relate to this "hot-start" scenario-or one similar to it. It's often remedied by installing a remote-mounted solenoid relay or high-amp battery with oversized cables, and while such action might alleviate some hot-start issues, the real solution oftentimes requires replacing the original Delco starter. Even a new stock-replacement can't prevent hot-starts indefinitely, however.

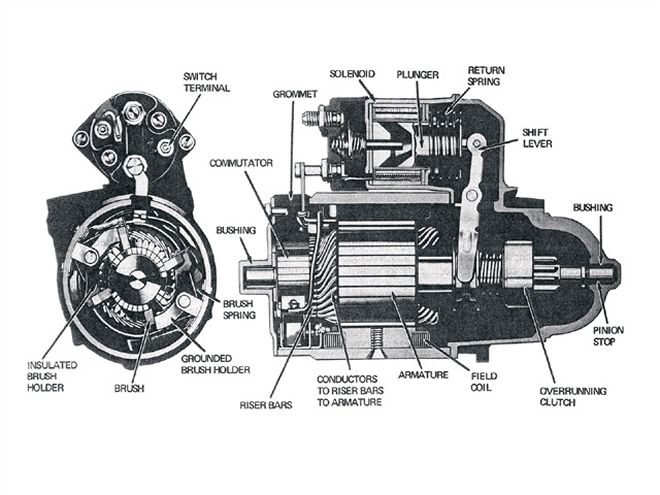

Delco-Remy produced a number of different shift-lever starters for General Motors' applications, and this cross-sectional diagram of a typical shift-lever type starter is a common sight in virtually any Pontiac V-8 Service Manual. Notice the positions of the electric solenoid and motor, and the shift-lever connecting the two. The armature and pinion gear share a common main-shaft and subsequently spin at a 1:1 ratio.

Delco-Remy produced a number of different shift-lever starters for General Motors' applications, and this cross-sectional diagram of a typical shift-lever type starter is a common sight in virtually any Pontiac V-8 Service Manual. Notice the positions of the electric solenoid and motor, and the shift-lever connecting the two. The armature and pinion gear share a common main-shaft and subsequently spin at a 1:1 ratio.

Starter Motor Basics

A typical vehicle's cranking system is comprised of a 12-volt battery, keyed ignition switch, series of associated wiring, and a starter motor. Two types of starters are commonly found on most passenger vehicles today-shift-lever and gear-reduction. Vintage Pontiac applications were originally equipped with a shift-lever-type, while modern Pontiacs feature a gear-reduction unit.

A shift-lever starter typically consists of a large, cast-iron housing containing an electric motor with an electric solenoid attached to it. The electric motor's main-shaft has an armature on one end and a pinion gear mated to a spring-loaded overrun-clutch on the other. These two ends rotate at the same speed, or a 1:1 ratio, which is commonly referred to as direct drive. The overrun clutch is connected to the electric solenoid via a pivoting shift-lever. As the electric motor spins during cranking conditions, the solenoid plunger retracts, forcing the pinion gear rearward where it meshes with the flywheel ring gear, rotating the engine.

A gear-reduction starter motor operates using the same basic principle as a shift-lever unit. Unlike its brethren, however, its pinion gear is mounted on the opposite end of the solenoid plunger and a small, high-speed motor mounted on it transmits power via an offset gear. The result is a compact unit that's more efficient, weighs less, and cranks the engine at a higher speed with more torque than a typical shift-lever type starter.

The cranking system must operate to its full capacity to carry the electrical demands placed upon it when attempting to crank an engine in extreme hot or cold temperatures, and the starter seemingly lives in the harshest environment. It's typically positioned between the engine block and exhaust system and is regularly exposed to normal underbody grime, precipitation kicked up from the road surface, and engine and exhaust heat.

Continual airflow from the engine's cooling fan and the vehicle's speed during normal operation has a cooling effect on the starter. Upon shutdown, the block and exhaust pipes continue radiating heat and the starter tends to absorb it due to its relative position, increasing its internal temperature. This can cause the starter's internal wire windings to expand and drag during cranking.

The first step in replacing our Firebird's starter motor is removing the ground cable from the battery post.

The first step in replacing our Firebird's starter motor is removing the ground cable from the battery post.

Oftentimes, the battery can at first overcome this resistance and sufficiently crank the engine with little indication of a pending problem. The added resistance places a great load on the battery, however, and will cause the starter motor to crank slowly or in extreme cases, not at all. Many owners then replace the battery, falsely assuming it isn't functioning properly, but the situation primarily lies within the starter.

Our Pontiac

The original 400 in our '67 Firebird convertible was in clear need of a complete rebuild. Since additional performance was a goal, we opted to save the numbers-matching block and drop a mildly-modified 455 between its framerails. While performing the swap, we noticed that the Firebird's original starter motor had somewhat recently been replaced with a remanufactured Delco unit and it seemed as if it was in good working order.

Though not optimal for maximum performance, the Firebird's existing exhaust system was in reasonably good shape and included uncoated tubular headers. We elected to retain the entire system to not risk damaging a new, ceramic-coated header set during flat-tappet camshaft break-in. It wasn't long after initial break-in that the stock Delco starter motor began dragging on hot restart, however. We knew that starter replacement was inevitable, so we began searching for a compact gear-reduction unit.

After taking out the stamped-steel inspection cover, we removed the two long bolts securing the starter to the block using a 9/16-inch socket. (There most likely are starter shims between it and the block. Save them for possible reuse during reassembly.) We were fortunate in that we didn't have to loosen the header to extract the starter. That's usually not the case!

After taking out the stamped-steel inspection cover, we removed the two long bolts securing the starter to the block using a 9/16-inch socket. (There most likely are starter shims between it and the block. Save them for possible reuse during reassembly.) We were fortunate in that we didn't have to loosen the header to extract the starter. That's usually not the case!

IMI Performance Products

Hi-Torque IMI Performance Products (IMI) in Whittier, California, is one company that offers gear-reduction starters for a wide array of vintage applications. "Pontiacs seem to experience 'hot start' conditions more often than other makes," says Jack Isom, a Senior Technician for the company. "I believe it's caused by the starter's mounting location and the Delco starter's steel casing. Our Pontiac V-8 starter was introduced in 1996 and we've had great success with it."

IMI's Hi-Torque starters are created using an American-made OEM Denso unit. In addition to its high-speed electric motor, its solenoid is encased in aluminum, which dissipates heat quicker than steel and also includes a vent tube to increase overall airflow. Featuring a 4.44:1 ratio through gear-ratio reduction, IMI's base unit is rated at 1.2 Kilowatts (Kw)-a typical 1:1 Delco starter is rated at 1.0. IMI offers units with ratings as high as 2.0 Kw for specific applications.

Isom asked us to describe our Pontiac to him, specifically including its engine size, modifications, and intended use. After explaining that the powerplant is only mildly modified and that the vehicle's primary use is street cruising, he suggested his company's 1.4 Kw unit for our application (No. IMI-108N). Cost for our particular one was $225 plus shipping, and it was on our doorstep in days.

Installation was very straightforward, and the supplied instructions provided all the necessary details to properly measure clearances. The task took little more than an hour to complete, and its effects were immediately noticeable. Our 455 was cranking over more forcefully than ever before, and the starter motor seemed unaffected by temperature, no matter how long it sat after being driven.

Conclusion

Whether it's a street-driven cruiser with tubular headers or stock-appearing racer fitted with high-flow cast-iron exhaust manifolds, starter drag on hot-restart is a common malady many Pontiac hobbyists share. While there are a number of solutions to remedy the situation, the simplest and most reliable may be a mild injection of modern technology that's affordable and installs easily. You can rest assured that the high-pitch whine associated with a gear-reduction starter will be music to your ears for years to come!