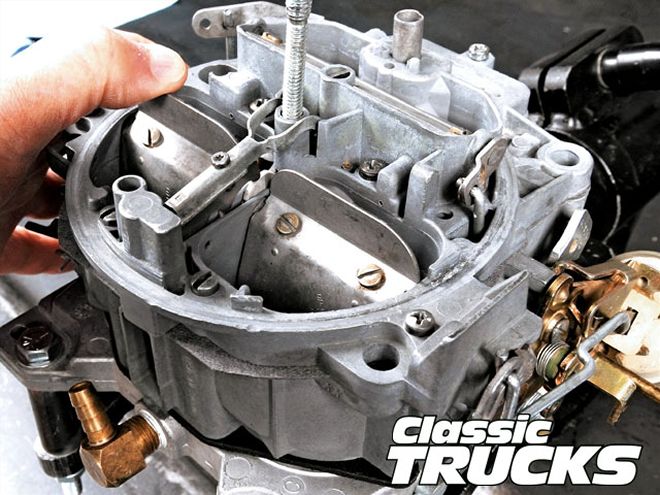

The Rochester Quadrajet is a complex, highly efficient carburetor. Rebuilt and staged properly, this carburetor design is far more tolerant of altitude changes and provides excellent driveability. The Q-jet served on engines ranging from Buick's V-6 to muscle cars and Cadillac's 500ci V-8!

The Rochester Quadrajet is a complex, highly efficient carburetor. Rebuilt and staged properly, this carburetor design is far more tolerant of altitude changes and provides excellent driveability. The Q-jet served on engines ranging from Buick's V-6 to muscle cars and Cadillac's 500ci V-8!

Gasoline is volatile when vaporized with oxygen. As a motor fuel, gasoline burns best at a ratio of 14.7:1-roughly 14.7 pounds of air to each pound of gasoline. This optimal burn, known as "stoichiometric," serves best when the vehicle is at cruise or similar loads. For more power, like passing, accelerating, or moving a heavy load, a richer air/fuel mixture becomes necessary. Under lighter loads, a leaner mixture may suffice and provides improved fuel economy.

In order to "mix" the air and fuel before combustion, the earliest internal combustion engines had carburetors. Although designs changed, the principle of the carburetor has remained the same, as a means for mixing air and fuel in correct proportions for a given engine load. Carburetors, refined over time, served quite well until the advent of electronic fuel injection.

Carburetor Circuits

Engine speed, load, and starting demands each dictate how fuel will be delivered. When the throttle is closed or slightly open, manifold vacuum is high, and fuel can flow by means of engine vacuum. If the throttle opens wider or heavy throttle is demanded, manifold vacuum drops accordingly. A carburetor must flow even more fuel at lower manifold vacuum-the greater the engine load, the lower the manifold vacuum.

To deliver fuel at lower manifold vacuum and wider throttle openings, carburetors maintain fuel flow volume by the venturi effect. The throats of the carburetor have sized-down sections. As a column of air moves through the carburetor's throat, reduction in the bore size raises the velocity (speed) of the air column. This creates a low-pressure effect in the venturi areas. The vents above the float chamber enable fuel to move through the main discharge tubes into the low-pressure area of the venturi. Once discharged, the air/fuel mixture continues down the throttle bores and into the engine.

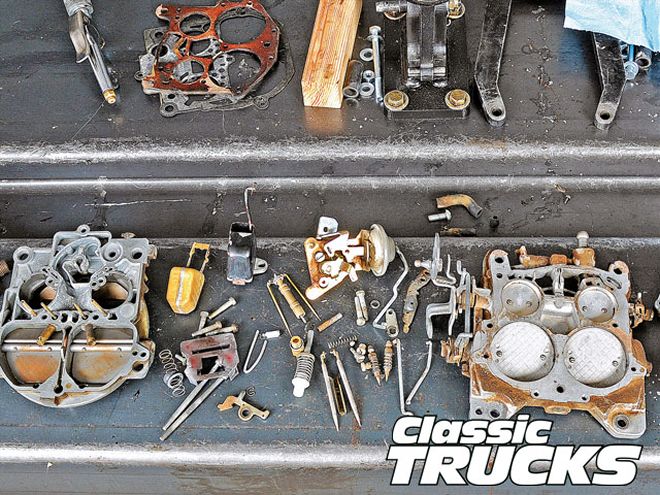

Stripped for rebuilding, the pieces shown require caustic cleaning, thorough rinsing, and compressed air drying. When rebuilding a carburetor, begin with a complete inventory of the parts. Match up identification numbers whenever the carburetor's origins are uncertain. Jets and metering rods have engine-specific sizing and must match your engine's displacement and requirements.

Stripped for rebuilding, the pieces shown require caustic cleaning, thorough rinsing, and compressed air drying. When rebuilding a carburetor, begin with a complete inventory of the parts. Match up identification numbers whenever the carburetor's origins are uncertain. Jets and metering rods have engine-specific sizing and must match your engine's displacement and requirements.

The carburetor must operate over a wide range of throttle openings, airflow characteristics, and manifold vacuum. Distinct "circuits" function in the different operating modes. Modern carburetors have: 1) an idle system, 2) off-idle system, 3) main metering system, 4) power system, 5) accelerating pump system, and 6) the cold-start choke system. Other refinements might include a secondary air valve on a four-barrel carburetor or a fully vacuum controlled secondary throttle. (A vacuum dashpot can control the opening of the secondary air valve.) When the throttle valves open wide, low manifold vacuum signals the air valve to open.

On a carburetor like the Quadrajet, the idle system picks up fuel from the main fuel well. Sized idle tubes draw fuel into discharge tubes that mix this fuel with air from the idle air bleeds and the off-idle discharge ports. The mixture enters the carburetor bores via the adjustable idle needle orifices. These idle needle screws control the mixture flow at an idle and off-idle throttle position.

The off-idle system still relies on manifold vacuum. As the throttle valves begin to open, strong manifold vacuum pulls fuel through the off-idle port. This port is just above each throttle valve and gets a strong vacuum signal as the valve begins to open. Note: This is the vacuum that we call ported. Ported vacuum signals are the typical source for a distributor's vacuum advance canister. Like the vacuum advance, the off-idle system responds with initial tip-in of the throttle.

Here is the primary power piston assembly for a Quadrajet. Use care installing the retaining spring (top) and metering rods. Rod tapers are precisely matched for each engine design. Today, rods are nearly impossible to find through parts sources. Clean parts without removing brass material. Do not stretch the balance spring (bottom). This spring is factory calibrated to counterbalance manifold vacuum.

Here is the primary power piston assembly for a Quadrajet. Use care installing the retaining spring (top) and metering rods. Rod tapers are precisely matched for each engine design. Today, rods are nearly impossible to find through parts sources. Clean parts without removing brass material. Do not stretch the balance spring (bottom). This spring is factory calibrated to counterbalance manifold vacuum.

Primary side main fuel metering begins off-idle and goes through wide-open throttle. The stronger manifold vacuum holds the main metering rods down in their jets. A spring counterbalances the vacuum pull, and when vacuum decreases, the spring pressure moves the piston upward. Tapered metering rods, attached to the piston, move upward and allow more fuel to pass through the jets. This is a smooth balance between a calibrated spring, sized rods, and jets, and the amount of manifold vacuum present. When power is needed, the fuel mixture enriches. At cruise and light loads with higher manifold vacuum, the rods remain lower and provide less fuel flow.

Secondary power on four-barrel carburetors like the Quadrajet rely on vacuum signals, secondary metering rods, and an air valve. The throttle valves may be wide open, but full fuel flow will not occur until the low manifold vacuum signals the secondary air valve to open. The air valve opens and simultaneously lifts the secondary metering rods. This increases fuel flow and richens the fuel mixture.

Other carburetor designs accomplish the same results as the Quadrajet with different means. The Holley carburetors, for example, use their familiar power valve. Fuel flow increases when manifold vacuum drops to the power valve's setting. Regardless of design, the goals are the same: 1) provide richer fuel mixtures when load increases, and 2) allow for more fuel flow under wider throttle openings.

Common to nearly all carburetor designs is an accelerator pump. This mechanism is part of the accelerating system. Some accelerator pumps have cup seals and press fuel out of a round well. Other carburetors, like the Holley or Motorcraft square-flange units, use a diaphragm. The aim with the accelerator pump is to provide a smooth, powerful surge of power when the throttle opens quickly. The added "shot" of fuel is necessary because fast throttle openings mean more airflow with a lag in fuel flow. (Air is lighter than fuel, and fuel flows slower when the throttle opens rapidly.) Without the accelerator pump, there would be a momentary lean condition under hard acceleration.

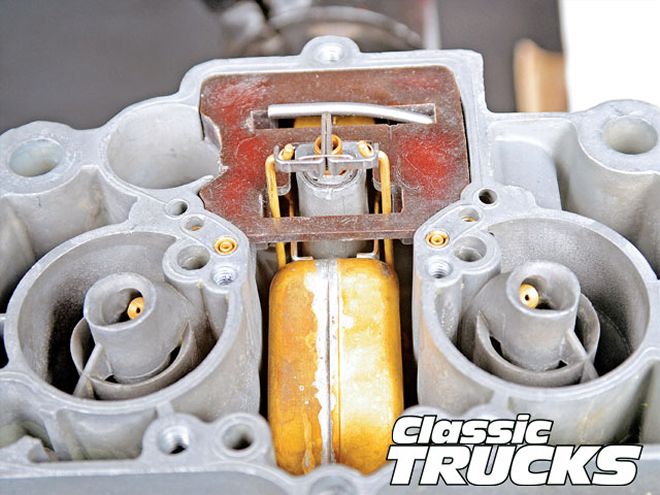

Float and power piston installed, note the tiny fuel and air bleed orifices. Air moving through the venturi rings will speed up. This creates a venturi effect and lower pressure within the boost venturi ring. Fuel moves to the low-pressure area through the main discharge tubes. Venturi flow begins with throttle tip-in and continues to full throttle.

Float and power piston installed, note the tiny fuel and air bleed orifices. Air moving through the venturi rings will speed up. This creates a venturi effect and lower pressure within the boost venturi ring. Fuel moves to the low-pressure area through the main discharge tubes. Venturi flow begins with throttle tip-in and continues to full throttle.

Surely important is the cold start circuit. This is necessary because the air/fuel ratio must be richer for a cold engine. Combustion is poor, and a 14.7:1 stoichiometric air/fuel ratio would cause stumbling, stalling, and poor idling in a cold engine. To compensate, the carburetor has a choke valve above the primary throttle bores.

Chokes can open manually, electrically, or by engine heat. The earliest choke valves were hand-controlled by either a cable or rods. Heated chokes with a bimetallic coil spring and engine heat source became popular in the '30s. Electric chokes, essentially a variation of the bimetallic coil choke, came about in the '60s with the emergence of emission controls. Each design serves the same purpose to reduce airflow while maintaining fuel flow. An enriched air/fuel ratio is necessary for starting and operating a cold engine.

Troubleshooting And Rebuilding

Understanding the functions of a carburetor increases one's troubleshooting skills. By knowing what each circuit of a carburetor does, a tuner or troubleshooter can focus on the area of the carburetor that causes a problem. While a carburetor overhaul will generally provide wide enough coverage to eliminate most circuit quirks, the skilled rebuilder looks for specific components that create trouble symptoms.

An important aspect of carburetor rebuilding is linkage adjustment. Air bleed vents, secondary release linkages, choke rod clearances, and accelerator pump settings are crucial to carburetor performance. It is not unusual for a factory-built carburetor to have incorrectly adjusted linkages.

This month's photo illustrations will increase your knowledge of carburetor circuits. There is more to restoring a carburetor than cleaning the parts. Join me at my workbench, and we'll walk through the functions and needs of a carburetor.

On the Quadrajet, this vacuum brake has two functions: 1) opening the choke further when the engine starts, and 2) unloading the secondary air valve. The brake is also designed to prevent secondary opening on a cold engine. When the engine is warm and the throttle has opened far enough to drop manifold vacuum, the brake enables the air valve to open. A calibrated diaphragm orifice on the brake offsets engine lag by keeping the air valve from opening until steady fuel discharges from the secondary nozzles.

On the Quadrajet, this vacuum brake has two functions: 1) opening the choke further when the engine starts, and 2) unloading the secondary air valve. The brake is also designed to prevent secondary opening on a cold engine. When the engine is warm and the throttle has opened far enough to drop manifold vacuum, the brake enables the air valve to open. A calibrated diaphragm orifice on the brake offsets engine lag by keeping the air valve from opening until steady fuel discharges from the secondary nozzles.

Note: Unless you have an EFI engine or induction system, your classic truck has a carburetor. This month, the focus is carburetor design and trouble spots. Understanding how a carburetor functions will enhance your tuning and troubleshooting skills.

Note: To prevent hesitation as the secondary throttle valves open, the Quadrajet provides a small supply of fuel from the secondary accelerating wells, drawn by manifold vacuum. This is not the accelerator pump system, but rather an auxiliary fuel supply that helps the transition to the secondary metering rods and air valve opening.

What Did You Learn This Month?

Night School" would not be complete without a quiz! Don't worry about your test-taking skills or grades. This is an open-magazine, true or false test. Answers can be found in the "Night School" text, photos or captions. Have a good month!

True or False Questions:

1. In its ideal combustible state, gasoline has a "stoichiometric" air/fuel ratio of 14.7:1.

2. Manifold vacuum decreases as engine load increases. Decelerating creates high manifold vacuum. Manifold vacuum is high at an engine idle.

3. Venturi effect does not rely on manifold vacuum to deliver fuel. In a carburetor bore, air speeds up as it moves through a restricted area, or venturi. This speed change creates a low-pressure zone in the area of the venturi discharge tube. This low pressure causes fuel to flow through the discharge tube's nozzle and into the carburetor bore.

4. Ported vacuum serves the off-idle fuel circuit. Ported vacuum is also the signal for a distributor's vacuum advance mechanism.

5. Hesitation or stumble at throttle tip-in can be caused by a defective vacuum advance in the distributor. A weak accelerator pump can create this same symptom during acceleration.

6. Idle mixture screw adjustments have little effect on engine performance at cruise speeds.

7. The cold start system, typically a choke mechanism, makes the air/fuel ratio lean. Cold engines need a leaner fuel mixture to run smoothly.

8. If the engine still ran before your carburetor rebuild, there is no reason to adjust the linkages. Linkage adjustments have little effect on carburetor performance.

9. The Quadrajet was popular for a wide range of General Motors engines. In outward appearance, Quadrajets look similar. A Buick V-6 application would have the same jets and metering rods as the Quadrajet on a 500ci Cadillac V-8.

10. A worn throttle shaft or throttle plate bore creates vacuum leaks. You can test for a worn throttle shaft or plate before removing the carburetor from the engine.

Answers:

1 true, 2 true, 3 true, 4 true, 5 true, 6 true, 7 false, 8 false, 9 false, 10 true