HOT ROD equipped an otherwise-stock 6.0L truck short-block with new LS3 rectangular-port heads, then threw Comp's best-selling LS cams in them. With a carburetor, we made more than 550 hp and 480 lb-ft with the biggest grind, but even the smallest generated more than 490 hp and 460 lb-ft.

HOT ROD equipped an otherwise-stock 6.0L truck short-block with new LS3 rectangular-port heads, then threw Comp's best-selling LS cams in them. With a carburetor, we made more than 550 hp and 480 lb-ft with the biggest grind, but even the smallest generated more than 490 hp and 460 lb-ft.

With free-flowing heads and high-ratio rockers stock, General Motors' LS engine series (and by LS we also include the LQ9, L99, and L92) just cries out for dual-pattern cams with quick-opening-and-closing, high-lift lobes. These engines are not your father's small-block. The Generation III and IV small-block family has been out more than 10 years now and continues to evolve, so there are lots of variations. Currently, LS engines in wide use by hot rodders range from 5.3 liters (327 ci) through 6.2 liters (364 ci). And for the Daddy Warbucks crowd, aftermarket blocks and heads are available that make it possible to build near-500ci, LS-based engines. Meanwhile, the old cathedral-shaped intake-port heads are being superseded in performance applications by new, big-block-sized rectangular-port heads. Add in the different characteristics of EFI versus carburetion, and cam selection becomes trickier. When HOT ROD decided it was time to test Comp Cams' best-selling LS cam grinds, we had to make some decisions or we'd be running the dyno for a year.

First, what size engine? We decided on the 6.0L/364ci size (4.000-inch bore x 3.622-inch stroke), an iron-block truck motor widely available in wrecking yards (although our test engine was actually based off a GM LQ9 crate motor). A 6.0L's cylinder bores are large enough to accept the new-generation rectangular-port heads, and there are enough cubes to benefit from the new, high-flowing heads and modern cams.

Second, which heads? The new rectangular-port heads were the obvious choice. They've taken production 6.2L-and-larger LS-based engines to a whole new level. L92 6.2L Caddy Escalade engines and the new Vette and Camaro all use some variation of these castings. The newest player is the LS3 Corvette package with lightweight intake valves. At the time of the cam tests, Comp's new Ultra dual valvespring for LS engines (PN 26926) was not yet available; using LS3 heads with lightweight valves allowed us to retain Comp's PN 26918 spring for all tests and still rev more than 6,800 rpm if needed.

Third, which engine management system-old-school carburetor or high-tech electronic fuel injection (EFI)? Our readers have wildly divergent tastes in this regard, so we ran both. For EFI, a GM computer was reflashed with HP Tuners software to control 45 lb/hr injectors, a 90mm throttle body, a low-profile factory GM LS3 intake manifold, and the stock GM coil-ignition system. For the carbureted tests, we used a Holley HP 950-cfm carburetor on Edelbrock's new single-plane Victor Jr. intake for rectangular-port heads, plus a programmable MSD box to run the ignition coils. All tests were conducted with the assistance of Ed Taylor on Duttweiler Performance's Henan-Froude F24 dyno controlled by Digalog/AVL software.

Now, which cams to test? This was determined by Comp's sales figures. All five top-selling LS cams are hydraulic roller grinds (although Comp does make solid roller LS racing cams). The top three cams' sales are practically neck and neck, with their rank order changing almost monthly. The fourth- and fifth-ranked grinds are pretty radical and apparently are being bought by the really hard-core weekend warrior types. In any event, all five cams are optimized for EFI with wide lobe-separation angles (LSA, see cam specs table). How they'd run with a carburetor remained to be seen.

Click here for the Comp LS engine cams chart

Comp's mildest cam is also its most popular. Even with only 216/220 degrees duration at 0.050, the XR269HR-14 was able to make nearly 500 hp with a carburetor; more than 480 hp with EFI.

Comp's mildest cam is also its most popular. Even with only 216/220 degrees duration at 0.050, the XR269HR-14 was able to make nearly 500 hp with a carburetor; more than 480 hp with EFI.

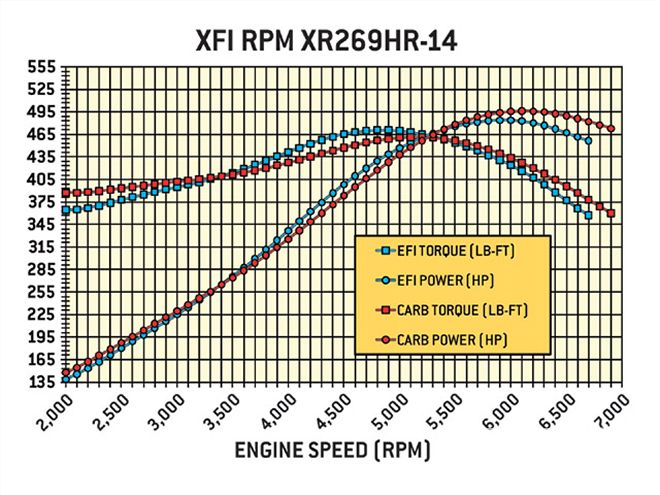

1. XFI RPM XR269HR-14

Comp developed its XFI (Extreme Fuel Injection) cam profiles from its very successful Xtreme Energy series of grinds. The main difference is the softer XFI profiles have a slightly slower acceleration rate to reduce pushrod loads and spring requirements. Combined with a wider LSA than the previous XE series, the result is more top-end rpm and power without overtaxing the stock valvetrain. LS motors really want to rev, so "most people running LS motors wanted more rpm than a typical small-block Chevy guy," Comp says. The XR269HR-14 is Comp's top-selling LS cam as this is written. It's tailored for '00-and-earlier, pre-LS6 engines using stock cathedral-port heads and is OK with stock valve-springs, (although stouter springs are recommended). At least in our engine, the XR269 and all subsequent cams tested achieved reasonable valvetrain geometry with Comp Magnum 5/16-inch-od pushrods, 7.350 inches long with a 0.050-inch wall (PN 7637-16).

Comp Cams says this cam should "pick up a ton of midrange torque and a bunch of top-end power," and even with the big rectangular-port heads on our motor, we weren't disappointed. With EFI and 45 lb/hr injectors, this cam made 470.7 lb-ft at 4,800 to 4,900 rpm with more than 400 lb-ft on tap from 3,200 through 6,200 rpm. Horsepower eclipsed the 400 mark from 4,600 on up, with a peak 483.9 hp available at 5,900 rpm. Not bad for a cam that Comp considers "your first step on the hot rodding journey."

The Holley carb and Edelbrock intake traded off peak torque for power: Its 461.3 lb-ft was down by 9.4 lb-ft and occurred 300 rpm higher at 5,200 rpm; but power was up by 12.3 hp for a peak of 496.2 hp at 6,100 rpm. The carburetor was stronger than EFI through 3,500 rpm and above 5,400 rpm but fell short in the midrange between those points, a trend that would continue with all cams tested. Idle vacuum was at least 14.5 in-hg at 950 rpm-enough to suck a golf ball through a garden hose.

Comp says XFI-series cams "are a safe, 6,500-plus-rpm design that will run all day without getting you into trouble." In our tests, this cam was worth about 23 hp and 8 lb-ft over the baseline XR269HR.

Comp says XFI-series cams "are a safe, 6,500-plus-rpm design that will run all day without getting you into trouble." In our tests, this cam was worth about 23 hp and 8 lb-ft over the baseline XR269HR.

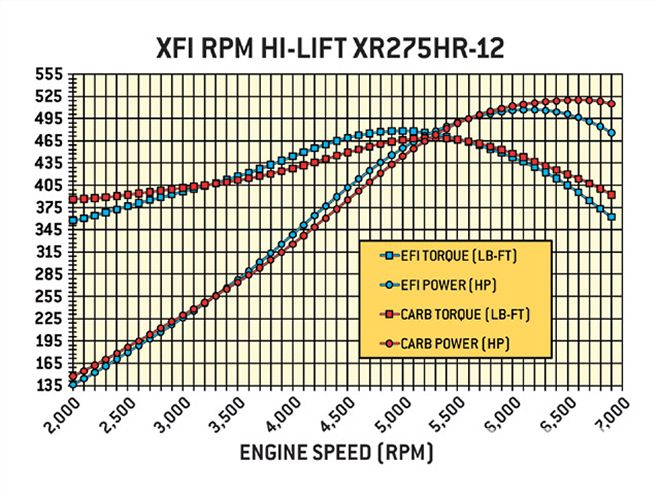

2. XFI RPM HI-LIFT XR275HR-12

As the 21st century began, GM's factory LS cams started approaching 0.550-inch lift. This wasn't hard to do with the LS engine's 1.7:1 rockers. Naturally, the aftermarket wanted to one-up GM, but many companies were still grinding LS cams with essentially classic small-block Chevy lobe profiles originally designed for 1.5:1 rockers. With high lifts and engines often revving above 6,500 rpm, this led to a lot of broken springs and other valvetrain parts. To improve durability, Comp designed a series of XFI RPM Hi-Lift cams specifically for use in LS-series engines with high rocker ratios.

The XFI RPM Hi-Lift XR275HR-12 is a member of this series and is Comp's second most popular LS-style cam. This cam should still be happy with cathedral-port heads and the stock intake; you won't need to do a lot of extra work to the motor to make power. However, Comp recommends at least its PN 26915 valvespring.

With EFI, this cam gave away nothing down low or in the midrange but gained 23 hp and 7.5 lb-ft compared with the XR269HR-14, producing a peak 478.2 lb-ft at 5,000 rpm and 506.9 hp at 6,100 and 6,200 rpm. The engine made more than 400 lb-ft from 3,100 through 6,700 rpm, more than 400 hp from 4,600 rpm on up, and more than 500 hp from 5,800 through 6,500. With the carburetor, the engine was slightly down on torque and power below 3,400 rpm compared with the baseline cam's carbureted showing but more than made up for the loss above that point. A peak 469.1 lb-ft was produced at 5,300 rpm with 520 hp on tap at 6,600.

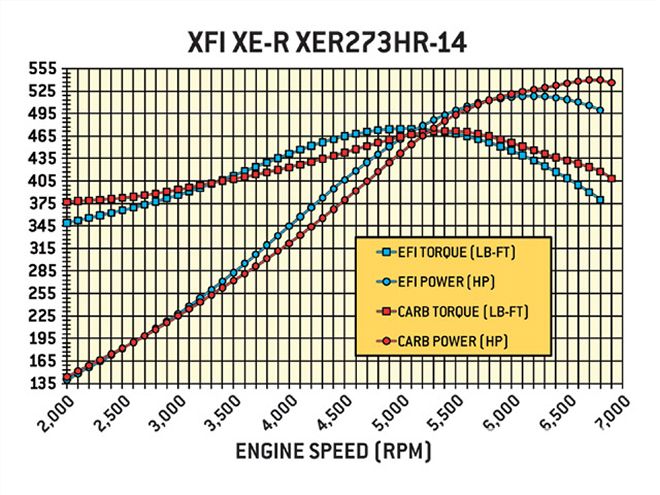

The XER273 usually shows very little gain with stock GM LS1 cathedral-port heads but generates significant improvements on rectangular-port heads and top-line aftermarket cathedral-port heads. EFI's midrange pickup compared with the carburetor was the highest of any cam tested, but the carb was still significantly stronger on top.

The XER273 usually shows very little gain with stock GM LS1 cathedral-port heads but generates significant improvements on rectangular-port heads and top-line aftermarket cathedral-port heads. EFI's midrange pickup compared with the carburetor was the highest of any cam tested, but the carb was still significantly stronger on top.

3. XFI XE-R XER273HR-14

Comp's XFI XE-R cams are like Comp's Xtreme Energy grinds with a little bit of Tabasco sauce added. If you don't have good valvesprings (at least PN 26918), good pushrods, good everything, you're asking for trouble with these highly aggressive, quick-opening, high-lift profiles. One member of this series, the XER273HR-14, is Comp's third most popular LS cam. It is the last one we tested that can be considered remotely streetable in a 6.0L engine, idling with about 12.5 inches of vacuum at 900 rpm.

With EFI, torque actually went down a tad compared with the XR275HR-12, peaking at 474.7 lb-ft at 5,000 and 5,100 rpm, a loss of 3.5 lb-ft. That was more than offset by an 11.3hp gain with 518.2 hp now on tap at 6,200 rpm. On average running with EFI, the engine picked up 7.1 lb-ft and 13 hp above 5,400 rpm. EFI's midrange pickup over the carburetor was also greater than with any other cam. Overall, the XER273 still ran best with the carburetor, gaining both torque and power: 471.8 lb-ft at 5,400 and 539.8 hp at 6,700 and 6,800 rpm. This was a pickup of 2.7 lb-ft and 19.8 hp over the carbureted combo with the XR275HR-12. It was also nearly 22 more horsepower than the EFI setup. And looking at overall average output, the carb's top-end average gain over EFI of 12.8 lb-ft and 11.3 hp above 5,400 rpm more than offset its midrange deficit.

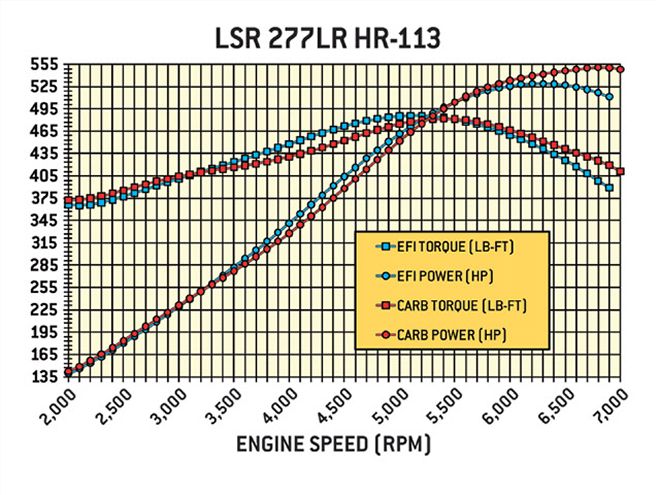

4. 277LR HR-113

The LR and LSR cam series incorporate everything Comp has learned since the previous XE-R cams were introduced back in 2001. As Comp engineer Billy Godbold puts it, "We needed to make a cam tuned for the LS motors with the new good heads. Our new profiles are the best 7,000-rpm-plus cams we know how to make. If you never go to a chassis dyno or the drags and don't run rectangular-port heads or big aftermarket heads, these cams are not for you. But if you want to pick up a couple of tenths on your buddy, these cams are for you."

The 277LR HR-113 has poor idle vacuum, but Comp's most modern lobe profile makes great torque and power. Would you believe more than 480 lb-ft with EFI and a carburetor? Max power rose to 529 hp with EFI; more than 550 hp with the carb.

The 277LR HR-113 has poor idle vacuum, but Comp's most modern lobe profile makes great torque and power. Would you believe more than 480 lb-ft with EFI and a carburetor? Max power rose to 529 hp with EFI; more than 550 hp with the carb.

Comp's fourth most popular cam, the 277LR HR-113, idled at only 10.75 inches in our 6.0L test engine. With the stock GM LQ9 truck short-block and stock cast pistons with shallow valve reliefs, piston-to-valve clearance was right on the edge, only about 0.050 inch. That was enough to scrape by on the dyno, but we wouldn't want to rely on going that tight for real-world use...so you're looking at a set of custom, aftermarket, forged, deep-notch pistons to really make this setup run safely with about 0.080/0.100-inch intake/exhaust valve-to-piston clearance.

If you can put up with its marginal manners, running on EFI, the 277LR was worth 11 lb-ft and 10.6 hp over the XER273, with peak output now rising to 485.7 lb-ft at 5,100 and 528.8 hp at 6,300 rpm. The engine made more than 400 lb-ft from 3,000 through 6,700 rpm and more than 450 lb-ft from 4,100 through 6,100. Likewise, more than 400 hp was on tap above 4,500 rpm, rising to more than 500 hp from 5,500 on up. The carb was no slouch, either, pounding out 481.7 lb-ft at 5,400 and 550.7 hp at 6,800 rpm. Peak and average output was the best we'd see with any cam in this test series, with EFI taking the torque crown and the Holley carb and Edelbrock intake receiving best power laurels. On EFI, this fairly radical grind was the overall strongest cam tested between 2,000 and 6,700 rpm as well.

5. LSR Rectangular-Port, 285LRR HR-13

The best results were garnered with the 277LR cam because we did not have the opportunity to actually try out Comp's Fifth Place cam, the 285LRR HR13. This brand-new, no-compromise grind is specifically engineered for the new LS rectangular-port heads with a much larger exhaust lobe than usual to compensate for what Comp says is the rectangular-port head's rather large intake/exhaust flow discrepancy. Unfortunately, with 0.621/0.624-inch valve lift and 235/251 degrees duration at 0.050, this cam was just too big for the stock short-block. We had near-zero piston-to-valve clearance at TDC/overlap. D'oh! Besides custom pistons, to run this cam you should have either a manual trans or an automatic with a 4,000-stall converter. Probably a 400ci-or-larger motor is needed to have any chance at all of running it on the street.

Results Overall

On EFI, the 277LR HR-113 cam was worth 15.0 lb-ft and about 45 hp at the peaks over the XR269 baseline. Gains were even more impressive in carburetor mode: Peaks over baseline numbers were up by 20 lb-ft and 55 hp. The big rectangular-port heads have a lot to do with this 50hp spread. There'd likely only be a 20 to 25hp spread if using earlier, '98-style LS1 heads.

Big heads want big cams to achieve their maximum potential, but-at least on a 6.0L-based engine-the 277 LR and 285LRR cams are pushing the envelope for streetability unless you're building a bracket racer. For one thing, they need custom pistons to prevent valve contact, and the low vacuum output may make it hard to achieve idle stability and good part-throttle driveability running EFI. On the other hand, the three smaller cams should work well on a street car, making decent power and torque at rpm points typically seen in daily street use.

That the carb outperformed EFI on top is no surprise; it's in line with what we've seen on past carb-versus-EFI smackdowns. In this case, it seems that the EFI intake posed a high-rpm restriction, as the carb'd intake allowed as much as an extra 500 rpm, and rpm with supporting airflow means more horsepower. What did make us sit up and take notice was how well the Holley HP carb and Edelbrock Victor single-plane performed down low. It was only in the midrange that EFI surpassed the carb, particularly with the XER273 grind. Yet you could expect to pick up at least another five midrange numbers on a carbureted application by having these profiles custom-ground with a narrower, 109-degree LSA, which usually helps the midrange and picks up the numbers from the peak torque to peak power rpm points, albeit at the expense of the extreme bottom and top ends. Note that a narrower LSA would further exacerbate the piston-to-valve clearance issues seen with the larger cams. As for the flip side of the coin-improving the performance with EFI-FAST will soon have a new intake for rectangular-port LS heads with interchangeable lids that offer a choice of runner lengths. We hope to put this intake to the test once it becomes available.

Click here for the LS engine cam test dyno chart