Developed during a crash, 90-day engineering program in 1964, the 427 SOHC engine was Ford's response to the Chrysler Hemi's dominance in NASCAR during the '64 racing season. Based on the successful 427 FE engine, the cammer featured a chain-driven roller cam in each cylinder head, actuating big valves in hemispherical combustion chambers. Horsepower was rated at 616 for the single four-barrel version and 657 for the dual quad, and Ford tested the factory engines to more than 8,000 rpm on the dyno. The engine was shaping up to be a formidable NASCAR competitor.

Unfortunately for Ford, a variety of factors conspired to keep the engine from being approved for NASCAR racing, including screams of protest from Chrysler and the higher speeds the SOHC would undoubtedly bring to the racetracks. Having made the commitment to limited production and unable to compete with the engine in NASCAR, Ford scrapped its plans for building cammer Galaxies for NASCAR homologation and focused on promoting the 427 SOHC as a drag racing engine. It immediately made its mark on the dragstrip in the world's first flip-top blown fuel Funny Car--Jack Chrisman's '65 Mercury Comet. In 1966 Sneaky Pete Robinson won the NHRA Top Fuel crown with his SOHC-powered dragster, and in 1967 Connie Kalitta won the AHRA Winter Nationals and the NHRA Winternationals with his SOHC rail. With Danny Ongais driving, Mickey Thompson dominated the new NHRA Funny Car class in 1969 with his awesome cammer-powered Mach 1s. Racing legends such as Ohio George Montgomery, Dyno Don Nicholson, Les Ritchey, and Don Prudhomme also campaigned cammer race cars in the '60s and early '70s, and the sounds of the SOHC zinging to 9,000 rpm were not uncommon at dragstrips across the country.

Never made available in a production vehicle, the estimated 750 to 1,500 SOHC crate engines sold over the Ford parts counter were raced heavily in the late '60s and early '70s. But after Ford withdrew factory support, the parts supplies began to dry up, and by the late '70s, a SOHC became an unusual sight. By the '80s and '90s, the engine had acquired collector status, with few engines together and running and small caches of scarce SOHC parts scattered in unknown warehouses and garages from coast to coast. Enthusiasts interested in building a cammer were forced to collect the factory parts piece by piece, often over many years, before a complete engine could be assembled.

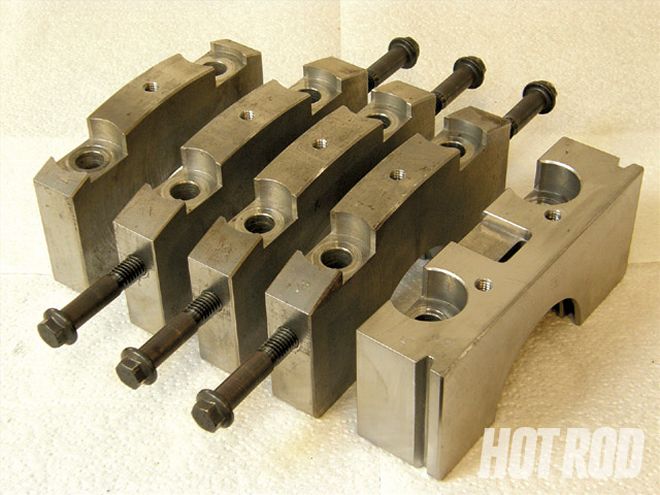

Main caps for the Pond block are extremely rigid and use larger-than-stock, 7/16-inch cross-bolts.

Main caps for the Pond block are extremely rigid and use larger-than-stock, 7/16-inch cross-bolts.

Nevertheless, interest in the 427 SOHC endured, and over the last few years several manufacturers have stepped up to fill the demand for the parts required to build these legendary engines. In fact, it is now possible to build a complete cammer from scratch, using only aftermarket parts. We decided to take advantage of this situation by putting together an all-aftermarket SOHC using the best components and adding some cubic inches to the mix in a quest for 800 hp.

Short-Block

The SOHC block is identical to the 427 Ford side-oiler block with the exception of one feature: The cammer block has an oil drain-back hole for the heads at the back of the block on each side. Strictly speaking, this hole is not necessary because external lines can be run from the heads down to the oil pan to drain the oil. However, the available FE aftermarket blocks all have the option of being drilled for the drain-back hole, so we took advantage of this situation and ordered an SOHC-specific aluminum block from Robert Pond Motorsports. The Pond block features beefy main caps and 7/16-inch cross-bolts, plus head studs that grab deeper in the block than the stock head bolts for better head gasket sealing. In addition to the added drain-back hole on each side, the block eliminates some machining that is not required for the SOHC engine, such as the holes for the lifters.

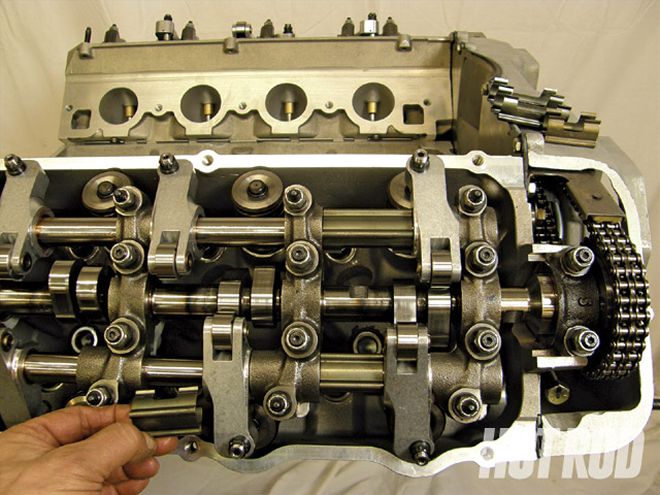

With a cam in each cylinder head, there is no need for a conventional cam in the block. Instead, the SOHC uses a stub cam to mount the timing gears and spin the distributor and oil pump. Oil is fed to the left head around the groove in the second stub cam journal in conventional 427 side-oiler fashion. In a 427- Wedge side-oiler, the fourth cam journal transfers oil to the right head in the same way, but, of course, with the SOHC there is no fourth cam journal. Ford solved this problem by putting a groove in the backside of the fourth cam bearing to transfer the oil to the head. Aftermarket cam bearings with this groove in the back are available, but they won't fit the Pond block, which uses oversize cam bearings. Instead of trying to groove the required bearings, we fabricated a plug to go into the bearing from each side and seal it, thus allowing the oil to transfer to the right head.

We had plans to spin this engine to 8,000 rpm on the dyno, so we stuffed the bottom end with top-shelf components that included a Scat billet 4.375-inch stroker crank with big-block Chevrolet rod journals, Crower billet 6.700-inch rods, and custom 12.0:1 Diamond pistons. Displacement of the engine with the 4.280-inch bore works out to 504 ci. Machine work on the short-block was done at R&R Performance in Spring Lake Park, Minnesota, and included align-honing the mains and the cam tunnel, boring and honing the cylinders, and balancing the reciprocating assembly.

SOHC Heads

The heads on the 427 SOHC are where all the horsepower is. They are a complete departure from any other FE engine and completely change the engine's character. The overhead cams run in split-shell bearings installed in the heads and actuate rocker arms with a roller wheel contacting the cam, essentially combining the lifter and rocker arm functions in one device. Due to the geometries involved, the rocker ratio is only about 1.3:1, so the cam lobes appear very aggressive, with a lobe lift of 0.500 inch required to generate 0.650-inch valve lift. Early SOHC rockers were nonadjustable and used lash caps of varying thicknesses to adjust the lash. Later rockers featured interference fit adjuster screws for more conventional lash adjustment. Factory valve sizes were 2.25 inches on the intake and 1.900 on the exhaust with 3/8-inch stems. The valves were Ford's special, hollow-stem, lightweight units weighing in at between 100 and 110 grams each.

The plug is also shown installed in the block.

The plug is also shown installed in the block.

The ports were far and away the best ever seen on an FE engine. Intakes were perfectly round and 2.1 inches in diameter, while the exhausts were D-shaped but upside down as compared with modern D-shaped exhaust ports. The ports were too big to make a lot of low-end power on a 427ci engine, but once up into the powerband, they really worked well and allowed the engine nearly unlimited rpm potential.

The vast majority of factory SOHC heads were cast iron, although a few hundred sets of aluminum heads were produced. However, all the available aftermarket heads are aluminum. For this all-aftermarket engine, we selected Bill Coon's heads. The Coon heads feature improvements in design over the original factory castings, including additional support ribs cast in the heads and the D-shaped exhaust ports flipped over for improved flow. Coon's heads also come with studs at all the cam cap positions to avoid stripping the aluminum with bolts and have cast-iron caps like the original factory aluminum castings. All Coon's heads are pressure-checked to more than 100 psi and are beautiful castings with high-quality machine work. The machine work is especially important on the SOHC heads because if not performed properly, the cam may not spin correctly in the head, or the rocker shafts may not be clamped properly by the caps.

Crower billet rods are as strong as they come. The Diamond pistons are ceramic coated on the domes and graphite coated on the skirts.

Crower billet rods are as strong as they come. The Diamond pistons are ceramic coated on the domes and graphite coated on the skirts.

We used Manley custom 2.300-inch nailhead intake valves and 1.900-inch tulip exhaust valves for these heads with 11/32-inch stems to save some weight. Even so, the valves were nearly 40 percent heavier than the stock Ford lightweight valves (which are no longer available). Anticipating some high-rpm dyno action and mindful of the increased weight of the valves, we set up the heads with Comp 26099 springs (with 290 pounds on the seat) and titanium retainers before bolting them on.

Timing Chains And Gears

The cams in the SOHC heads are driven by two sets of timing chains and gears. The primary timing gears and chain look like standard FE fare, but instead of spinning the cam in the block, they spin the stub cam. The secondary chain, nearly 6 feet in length, is driven by the small stub cam gear and winds around a tensioner gear and an idler gear, along with the two gears on the camshafts. Two chain guides are present to control the chain position. The entire setup is enclosed from the rear by a backing plate that bolts to the engine before any of the components are installed and from the front by a cast-aluminum cover.

Over the years, tales of problems with the 6-foot secondary chain have circulated, but the truth is that the secondary chain is very reliable and if tensioned correctly will give trouble-free service on the street or at the track. Suffice it to say, if the secondary chain breaks, there is some other problem that caused it. However, the secondary chain is known for stretching somewhat at high engine speeds, so a common practice with the SOHC engine is to advance the cams a few degrees upon installation to compensate.

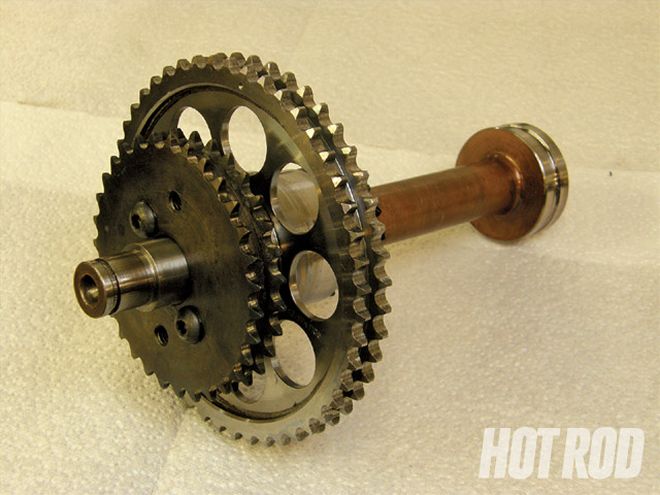

The stub cam is fitted with two gears for the chaindrive and also runs the distributor and oil pump. Note the groove in the second journal for transferring oil to the left cylinder head. We added the button-head capscrews to lock the gears together, eliminating any chance of one gear shearing the key and upsetting the cam timing.

The stub cam is fitted with two gears for the chaindrive and also runs the distributor and oil pump. Note the groove in the second journal for transferring oil to the left cylinder head. We added the button-head capscrews to lock the gears together, eliminating any chance of one gear shearing the key and upsetting the cam timing.

Different types of aftermarket secondary chains and gears are available for the SOHC. Some use the stock chain pitch with the stock pin diameter of 0.222 inch, and some use other sizes. It is important to make sure the gears and chain are sized to work together; mismatching these components could lead to rapid wear or timing problems. We decided to stick with the stock chain sizes for this engine with gears from Jim Barillaro and John Turner and the secondary chain available from Cammer Concepts.

Cams And Valvetrain

The original SOHC cams were cast iron and featured very gradual ramps on both sides of the lobe profile, leading to good valvetrain stability but a very long seat-to-seat duration. Most modern cams for the SOHC are steel billet with shorter ramps and more lift. We selected a Comp Cams single-pattern profile for this engine with duration of 298 degrees at 0.050-inch lobe lift, an LSA of 112 degrees, and gross lift of 0.685 inch. Although the duration at 0.050 sounds very high, it's important to keep the rocker ratio in mind when considering this specification. With a ratio of only 1.3:1, the gross valve lift at 0.050-inch lobe lift is only 0.065 inch with an SOHC. Compare that with a normal wedge FE rocker ratio of 1.75:1, where the valve lift at 0.050-inch lobe lift is 0.87 inch and you can see that the SOHC is behind the valve lift profile of the wedge engine. We use an estimate of 12 to 15 degrees more duration at 0.050 for the SOHC cam to match an FE wedge cam profile, mak-ing the cams selected for this engine equivalent to about a 285-degree-at-0.050 wedge engine cam.

The SOHC rocker and shaft arrangement is unique and requires some special assembly procedures. For this engine, we selected T&D aluminum rocker arms mounted on Precision Oil Pumps rocker shafts. For the larger-than-stock cams, T&D clearanced the rockers to avoid interference with the cam lobes. We also fit the rockers to the shafts, honing the rocker bushings to achieve a clearance to the shafts of 0.002 to 0.0025 inch. The valves can be lashed cold, since we've found that the lash of the SOHC doesn't vary too much over temperature. The Comp spec for our cams was 0.020-inch lash, so we set them at 0.016 cold to allow for a few thousandths of increased clearance at temperature.

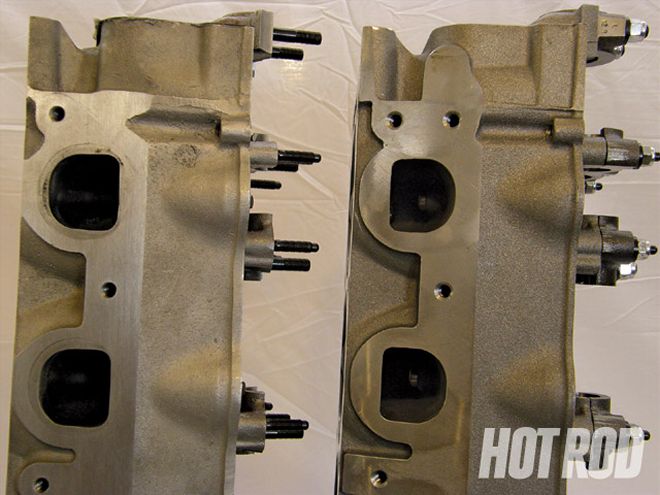

Factory Ford exhaust ports (left) feature a D shape that is backward based on current thinking. The Coon heads (right) turn the port around for better flow.

Factory Ford exhaust ports (left) feature a D shape that is backward based on current thinking. The Coon heads (right) turn the port around for better flow.

Induction And Finishing

Factory cammer intake manifolds were available in single four-barrel or dual four-barrel configurations. The production models were dual-plane designs, and they are, of course, difficult to find. Fortunately, there are now a few aftermarket options available, including copies of the factory 2x4 dual-plane intake from Gilbert Carpio and a couple of custom 2x4 single-plane designs from Dove Mfg. and Paul Munro. But nothing beats the look of the old Hilborn mechanical fuel-injection manifold worn by the SOHC, and as luck would have it, those intakes are still available from Hilborn in mechanical and EFI versions. We had the mechanical version on hand, so we decided to use it on our engine as a tribute to the injected cammers of years gone by, but update it with a modern EFI system.

Finishing off the engine takes mostly stock FE pieces. The oil pump, pump drive, pickup, oil pan, and windage tray are all standard FE components. We used a Canton pan, pickup, pump, and drive from Precision Oil Pumps along with a louvered Moroso windage tray that was modified to clear the stroker crank. The upper alternator bracket is a stock Ford piece, while the lower bracket is for a '65 to '67 427 Galaxie; because they're hard to find, we modified a universal chrome Trans-Dapt arm to fit. We also built a custom bracket to mount the GZ Motorsports vacuum pump and used its drive pulley from a 429/460 Ford kit.

For ignition, we chose a FAST EFI distributor that provides the cam and crank signals for easier hookup to the XFI control unit. Plug wires are from Taylor for the Chrysler 426 Hemi, with the SOHC-specific rubber boots from Bill Coon. Headers were fabricated from scratch for the engine starting with SOHC header flanges from Jim Barillaro.

The combustion chamber shows the hemi design.

The combustion chamber shows the hemi design.

Dyno Testing

After assembly, the engine was tested on a Superflow 901 dyno for horsepower and torque characteristics. Prior to running the engine, the dyno's torque link was checked for calibration to ensure an accurate test. The engine was run for about 30 minutes under various load conditions to aid in the break-in process, then after lashing the valves (0.016 inch), we started with low-rpm pulls to get the EFI system dialed in. We found that with the relatively short stacks on the injectors, the engine seemed a little fussy and we spent some time dialing in the base fuel table in the lower speed ranges to get the engine to pull cleanly from 3,000 rpm. At idle, we noticed that the engine was sensitive to the throttle blade adjustment, but once we had that set correctly and evenly across the eight injectors, the engine would start instantly with a push of the starter button and no application of throttle and would idle very smoothly at 1,000 rpm.

Once into the upper rpm ranges, the fuel curve smoothed out nicely and the engine really began to hit its stride and met our goal of just above 800 hp but at a surprisingly low 7,200 rpm. We ran it two different stack lengths and the taller stacks made a lot more average power.

And there you have it--everything you need to know to build a cammer using all brand-new parts.

These are all the pieces that are found under or on the cast-aluminum timing cover. The inspection plates in the front cover provide access to the chain tensioner and the idler gear.

Shown here is the orientation of the timing components and chains. Assembly of the timing components is more involved with the SOHC than with a standard pushrod engine. Since this engine was going to see a lot of street time at lower rpm, we added two oil tubes and tapped off the main oil gallery of each head with 0.015-inch jets to shoot oil at the idler-gear and tensioner-gear bearings. This ensures the bearings get an oil supply at low rpm, when splash oiling may not be available. The water pump is an SOHC-only unit that looks like a standard FE water pump but with shorter legs. Jim Barillaro takes an Edelbrock pump and cuts down the legs then welds on the block flanges to make a high-flow water pump for the SOHC, which we used on this engine. The harmonic balancer and balancer spacer sleeve are the same as a wedge FE, but the crankshaft pulley is a unique piece from a '61 to '63 Thunderbird with power steering. Rather than hunt down one of those, we used a 1.25-inch-thick doughnut spacer machined from aluminum to space out a late-model FE crank pulley from the balancer and line up with the standard FE water pump pulley mounted on the pump.

John Turner manufactures new sets of SOHC gears and chains. Here, the primary stub cam gear is shown installed on one of Bill Coon's stub cams. Coon's stub cams feature a wider and deeper oil groove in the second journal to transfer more oil to the left cylinder head.

The T&D rockers were honed on a pin-fitting machine to achieve 0.002- to 0.0025-inch shaft-to-rocker clearance.

After the cam caps are installed, the engine is rotated around so the rockers can be slid into place over each valve and cam lobe. Six steel spring clips are used on each side to hold the rockers in position.

Barillaro makes all the timing chain and gear components required for the SOHC engine. He also makes this kit for converting the fuel pump gear to drive a hex shaft through the front cover. This can be used to run an injector pump or distributor. The stock fuel pump gear, with the eccentric for running the mechanical fuel pump, is shown at the lower left. Currently, the mechanical pumps are not available.

The cams and gears are drilled with phased holes so that as the gear rotates slightly with respect to the cam, a different set of holes lines up and allows insertion of the alignment pin. The dot on the gear lines up with the dot on the cam for straight-up timing. Advancing or retarding of the cam is done in increments of 1.5 cam degrees. The cam bolt locking plate is bent around the bolts to lock them and also holds the alignment pin in place.

From left to right, the early factory nonadjustable rocker, a factory adjustable rocker (with an aftermarket adjuster installed), a T&D steel rocker, and a T&D aluminum rocker. The factory rockers are excellent pieces but scarce. The T&D steel rocker weighs 251 grams, slightly less than the factory adjustable rocker, but the aluminum version is much lighter at 214 grams. The rockers function as lifters as well as rocker arms, so they are critical components and must be looked at carefully before use.

The spark plugs are slipped into copper tubes, an O-ring is installed over the tube, then the tube is installed through the valve cover into the hole in the head, and the plug is tightened.

This injector setup, in mechanical and EFI versions, is still available from Hilborn 40 years after it was introduced. We had a mechanical unit sitting around and converted it to EFI. Kinsler ram tube holders were adapted to the top of the manifold so that Kinsler ram tubes of various lengths could be tried for tuning purposes.

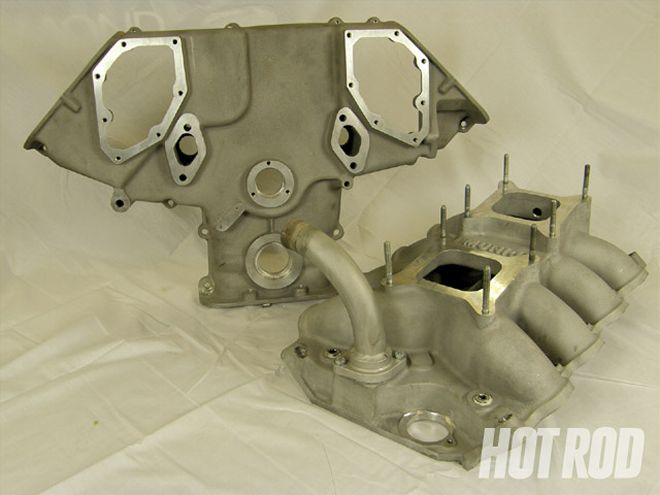

Here are a stock single-four intake on the left, a stock dual-four intake in the center, and a Dove dual-four, single-plane intake on the right. The Dove intake is patterned after a factory experimental tunnel-wedge design made in very limited quantities and features a top adapter to mount two Holley carbs, but other tops could be fabricated.

On the Superflow dyno, the huge motor cranked out 800 hp on 93-octane and idles at 1,000 rpm. This same basic combination is what powered the author's '64 Galaxie 500 on the '08 HOT ROD Drag Week.

Paul Munro in Australia manufactures complete SOHC kits and has all the parts available to build a complete engine, including heads, valve covers, timing covers, and the smaller parts. This photo shows Munro's 2x4 single-plane intake manifold and front timing cover. These are heavy, high-quality castings with nice machine work. Note the water neck attached to the intake manifold, required when running a standard upper radiator hose. Munro also has a SOHC 8-71 blower manifold available.

Flow Numbers

We did extensive flow bench testing on SOHC heads and tried different valve configurations before arriving at the best results. Factory heads came with tulip-style valves on the intake and exhaust and used 30-degree seats on the intake valves. We tested tulip and nailhead valves, and our testing revealed a slight preference for a tulip exhaust and a nailhead intake. However, the intake valve strongly preferred a 45-degree seat. On our ported set of factory aluminum heads, the difference was remarkable. We also discovered that a typical porting job on these heads nets big gains, especially on the intake side. The chart shows a comparison among an as-cast iron head with factory valves, a ported factory aluminum head, and a ported Coon head. The design improvements of the Coon head really show up here, especially on the exhaust port flow.

Click here for the SOHC head flow test chart

Valvetrain Performance

The advantages of a single overhead cam valvetrain design are obvious from an rpm perspective. However, the stock 427 SOHC valvetrain components were excellent parts and designed specifically for this engine, so how this arrangement would perform with aftermarket components has not been totally clear. Bill Conley at Ottodyn is a former Ford engineer and SOHC enthusiast who decided to investigate this by building his own SOHC valvetrain test fixture. Conley has run a multitude of tests looking for the onset of valve float, using various combinations of valves, springs, and cams. The results have been very enlightening for cammer enthusiasts and point out the critical importance of the weight and configuration of the various valvetrain components.

Acknowledgements

The author gratefully acknowledges the assistance of the following individuals, who reviewed this article for historical and technical accuracy: Earl Wade, Ohio George Montgomery, Bill Coon, Jim Barillaro, John Vermeersch, Robert Pond, Barry Rabotnick, Wayne Jeffers, and Bill Conley.