The big-block Chevy first saw the light of day back in the '60s when it first appeared as a NASCAR powerplant known as the "Mystery Engine." Here we are some 45 years down the road, and getting real horsepower from this engine is still somewhat of a mystery to many, so here's the fix: we're going to ask--and answer--the 10 most important questions you should be considering when buying cylinder heads for your big-block. But first some background.

When Chevrolet introduced the mystery engine, it looked (with its then less-than-orthodox canted-valve heads) like a pretty exciting deal. Shortly after its intro, it became known as Chevrolet's "porcupine-headed" engine, and subsequently, because a porcupine is sort of a member of the rat family, it was known as the Rat Motor. With its canted valves, Chevrolet had obviously made an effort to improve the breathing capability of its then-new offering, and that brings us squarely to the first commonly asked question for new-millennia cylinder heads in an age of new-millennia power:

1. Why can't I use my stock heads as they are?

The whole issue with the canted-valve heads was to produce an engine that could take on Chrysler's deep-breathing Hemi. While Chevy's big-block was a step forward for the day, those seemingly high-tech canted-valve heads did not in fact, breathe quite as well as it appeared they might.

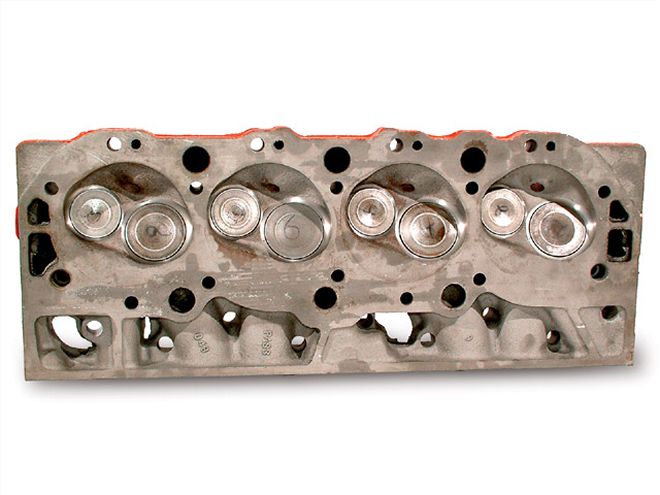

Among the factory heads, the "049" casting shown here are among the best for all-around results for the street, but they still fall way short of what a good set of aftermarket heads can do.

Among the factory heads, the "049" casting shown here are among the best for all-around results for the street, but they still fall way short of what a good set of aftermarket heads can do.

If we fast forward to 2009, even the best of the production factory heads are way short of satisfactory in a world of conventional, but highly refined designs. To make the point, let's look at a comparison of the valve size per cube of a typical performance small-block 350 versus a 454 big-block with stock valves. The most important factor toward making horsepower is the circumference of the intake valve in relation to the cylinder's cubic inches. With a typical 350 small-block, each inch of intake valve circumference has to feed 6.89ci of displacement. Even without the usual 0.060-plus overbore or even a stroker crank, a lowly 454 with the stock 2.19-inch intake valve has 8.25 cubes to feed for every inch of valve circumference. This means that even a 454 is potentially air starved, and your common quarter-inch stroker with a 0.060-inch over bore is, at 496 inches, really air starved.

2. Can't I just port the stock heads?

Any one of the stock big-block heads can be ported to show big gains in airflow. That said, most of the so-called high-performance castings (and especially the big rectangular port castings) were produced at a time when casting techniques were far less capable of producing a clean and precise port shape that would be conducive to airflow. Sure, bigger valves could be installed, but at the end of the day, porting a set of factory castings involves removing so much metal it becomes a career instead of a weekend hobby. But the time to port is far from the only issue. To get these stock heads (shown) in shape for a dyno test, I had to install new guides and valves, as well as cut a high-performance valve seat job. By the time the cost of springs, retainers, and more, was factored in, the bill was about $700, and I still only had a set of 30-year-old heads that were still in serious need of 50 hours of port work. That money could have been put toward new aftermarket high-flow castings, which would've gotten the job done right out of the box.

At 2.190 diameter, the stock intake valve is too small even for a stock-displacement 454, but the room to put in bigger valves is limited. After installing a valve as large as possible, the only solution is to develop the port's high-lift flow to the greatest extent possible, and even then, employ a high-lift valvetrain.

At 2.190 diameter, the stock intake valve is too small even for a stock-displacement 454, but the room to put in bigger valves is limited. After installing a valve as large as possible, the only solution is to develop the port's high-lift flow to the greatest extent possible, and even then, employ a high-lift valvetrain.

3. What are some cost-effective alternates to porting stock heads?

The answer to this question is easy, and there are three choices I've had hands-on experience with that I feel confident in recommending. [Editor's note: These are based on the author's own dyno data, and do not take into account all available possibilities.] Dart's Iron Eagle, World Products' Merlin, and RHS's iron offerings represent cost-effective, entry-level, high-performance heads for a budget-constrained big-block engine builder. But there is a point here that needs to be made really clear. The term "entry level" refers only to the price, because as far as performance is concerned, these heads, when used in the right combination, will produce nothing less than pro results. As far as "used in the right combination" goes, we will cover the principle issues as we move along.

By purchasing heads as a complete package, we get not only a set of new, high-flow castings, but also new hardware. Aftermarket head manufacturers are well aware that without springs with a high natural frequency, the valvetrain will ultimately let down the head's ability to deliver optimal results. Purchasing a package means you get the benefit of both their knowledge in this department, and their bulk buying power.

4. If I replace stock heads with aftermarket iron heads, what's the payback?

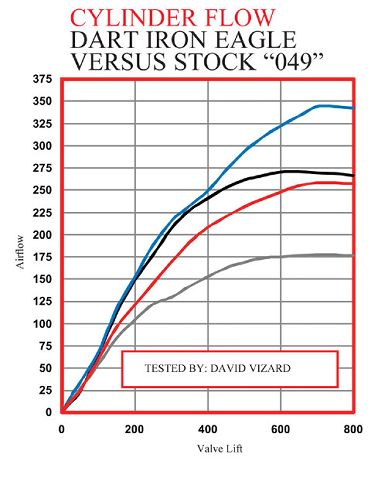

Most of my recent experience with aftermarket iron heads has been with Dart's Iron Eagle, however, all three (Dart, World Products and RHS) can currently be had at street prices of a little over $1,500, ready to install. My test data on the Dart heads is well worth studying. First, let's look at the flow figures comparing a factory "049" casting versus Dart's Iron Eagle 308cc rectangular port (the smaller of their two offerings).

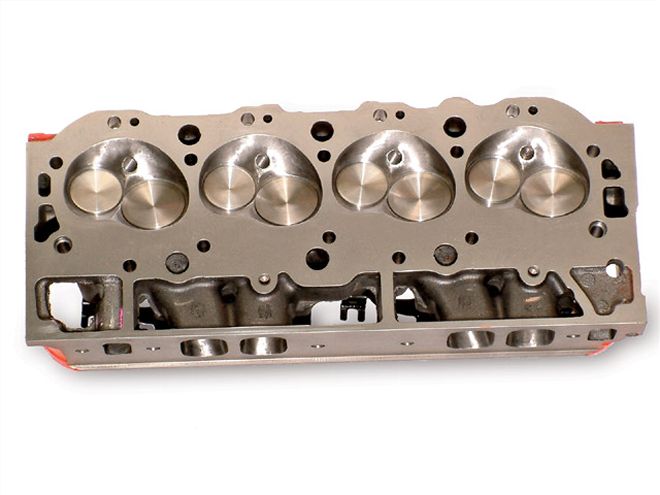

The Dart Iron Eagles are a cost-effective way to get a new set of heads equipped with quality hardware. As-cast or ported, they can be part of a big horsepower combination.

The Dart Iron Eagles are a cost-effective way to get a new set of heads equipped with quality hardware. As-cast or ported, they can be part of a big horsepower combination.

From the graph, you can see what a $1,500 investment buys in terms of airflow. Though instrumental toward the production of more power, flow is far from the only factor. At the time I did the following dyno test, Dart had just introduced their wet-flow technology to the Iron Eagle casting. Good swirl, a port area well suited for a street engine between 454 and 530ci, and good wet-flow characteristics deliver some good dyno results. The following dyno test shows what you can expect from a set of these heads should you replace a well-prepped set of 049 castings.

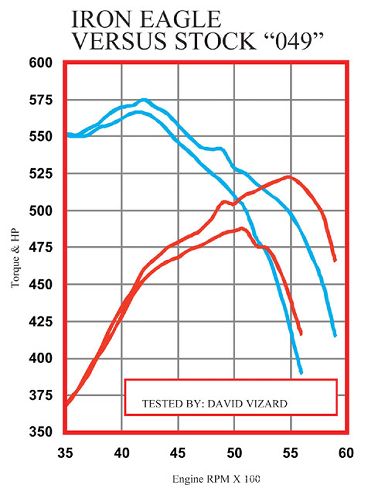

Although these are some impressive gains, they may not have been as good if some aspects of the flow characteristics had not been taken into account. Note from the flow curves that most of the Iron Eagle's extra flow happens above about 0.450-inch lift level. If the valvetrain I used did not generate sufficient lift to access that flow, a sizable proportion of the extra power would've been absent. In this instance, the cam used was a single-pattern Comp Xtreme street roller that delivered some 0.638 inches of lift after lash had been figured in.

If the budget runs to an aluminum head, then all the power advantages of a high flowing set of iron heads can be had with a weight reduction of some 80 pounds. Some recent dyno tests with as-cast AFR 325cc port aluminum heads showed that 675 streetable horsepower is practical from a 10.5:1-compression 505 buildup. As gratifying as these numbers are, it needs to be made clear that they only come about by virtue of an understanding of what it takes to put together a successful combination.

To get results from a set of ported factory heads requires a lot of time, and a flow bench to verify the results. Even then, you still only have 30-year-old heads.

To get results from a set of ported factory heads requires a lot of time, and a flow bench to verify the results. Even then, you still only have 30-year-old heads.

5. Can the current generation of aftermarket big-block heads be ported cost effectively?

Yes they can, in fact, they are very novice friendly, and can be given an effective basic porting job without the aid of a flow bench by anyone with average dexterity. The payback for even a basic porting job is good because no matter what we do, any big-block over about 427ci is short of flow. Personal experience with Dart's iron and aluminum heads, and AFR and RHS's aluminum heads, show that thinning up the guide bosses, then blending out any irregularities, nets as much as 30 cfm of extra air at 0.700-inch lift on both the intake and exhaust. On a nominally 650-horse 10:1-compression 500 incher, this translates into an additional 25 or 30 hp.

6.I just bought heads that flow much more air. What parts will make the best combination?

Because a big-block is always starved for air, it's far more sensitive to certain aspects of the build. Appreciating these acute areas makes for a significantly greater output without spending a dime more. The first rule is that if you have high-flow heads, don't starve the heads of air by using a carb that is too small.

Ninety percent of big-blocks are 454 inches, and up. They are not 350 inches, and they do not like small-block-sized carbs! If a 350 warrants a 750-cfm carb, its 500-inch big-block equivalent will need something on the order of 1,100 cfm just to stay on par. That's Dominator territory. In practice, we find that big-blocks really respond to Dominator-sized carbs on high-flowing intake manifolds. If you must use a two-plane intake for hood clearance, Edelbrock's RPM Performer Air Gap is a sound choice, but because it is designed to take a 4150 carb, it needs to be used with a really high flowing example of such. I would recommend a 900 cfm minimum here. As for single-plane intakes, Dart, AFR, and Weiand each have manifolds that work well with either a 4150 or 4500 series carbs. [Editor's note: Once again, we'll remind readers and manufacturers that these recommendations are based on the author's independent experience.]

Cylinder Flow Dart Iron Eagle Versus Stock "049" <strong>Cylinder Flow Dart Iron Eagle Versus Stock "049"</strong><br>Here's the intake flow of an "049" casting's good port (black curve) versus that of a 308cc Iron Eagle (blue curve). The "049" casting has had the benefit of a good valve job, allowing it to stay close to the Iron Eagle's flow at lower lift, but when the valve clears 0.400 inch, the Iron Eagle just runs away from the stocker. On the exhaust side, the seat/throat design of the port benefits from Dart's Pro Stock experience. The result is higher-than-average flow right off the seat, with a substantial increase over stock at high lift.

<strong>Cylinder Flow Dart Iron Eagle Versus Stock "049"</strong><br>Here's the intake flow of an "049" casting's good port (black curve) versus that of a 308cc Iron Eagle (blue curve). The "049" casting has had the benefit of a good valve job, allowing it to stay close to the Iron Eagle's flow at lower lift, but when the valve clears 0.400 inch, the Iron Eagle just runs away from the stocker. On the exhaust side, the seat/throat design of the port benefits from Dart's Pro Stock experience. The result is higher-than-average flow right off the seat, with a substantial increase over stock at high lift.

7. Other than induction flow, what else do I need to take care of in the cylinder heads?

When choosing your cylinder heads, there are two principle factors you should consider. The first is the intake port size, and the second is the compression ratio. First, the intake port size. Do not fall into the trap of thinking that bigger must be better. To get the best combination of torque and horsepower, select the port volume required using the accompanying chart. Don't overestimate the power your engine is likely to make. Doing so will mean the port selection will be too big, and as a result the output will be less. It's best to underestimate by a small margin.

Another important consideration is the compression ratio. Big-block Chevys like all the compression you can give them. For the street, it is good for mileage and output, especially torque. For a race motor, it's a key factor for winning races. With the stock chamber at typically 119cc, your first move is either to mill the head down so the chambers are as small as possible, or use plenty of inches under the heads, or both. Do not go overboard on piston dome, as excess here can cut combustion efficiency. Most heads will cut to about 102-105 cc; go that route first, then choose a piston crown that delivers the required compression ratio.

Iron Eagle Versus Stock "049" <strong>Iron Eagle Versus Stock "049" </strong><br>The red curves are horsepower, and the blue for torque. The Dart Iron Eagles are the upper curves in each case. From these results it can be seen that the Iron Eagle lost virtually nothing at the lowest test rpm, while they bumped peak power by 35 hp. The power also held on longer at higher rpm, with a gain of some 82 hp being seen at 5,500 rpm. Peak torque was also up by a margin of 9 lb-ft.

<strong>Iron Eagle Versus Stock "049" </strong><br>The red curves are horsepower, and the blue for torque. The Dart Iron Eagles are the upper curves in each case. From these results it can be seen that the Iron Eagle lost virtually nothing at the lowest test rpm, while they bumped peak power by 35 hp. The power also held on longer at higher rpm, with a gain of some 82 hp being seen at 5,500 rpm. Peak torque was also up by a margin of 9 lb-ft.

8. Even if I'm turning lower street rpm, will the exhaust be critical?

Because of the limited valve size, the exhaust system becomes even more critical than for a 350 small-block. A good set of headers feeding into a low back-pressure exhaust system will considerably help a big-block realize its full potential. The key element is to aid combustion chamber scavenging as much as possible, so that the intake charge can start on its way into the cylinder as early as possible. In simple terms, the intake valve will be actively flowing mixture into the cylinder for a longer period during the opening phase. Like the intake ports, the header's primary diameter should not be too big, as this will allow reversion until high rpm is seen. This will defeat the header's ability to scavenge. If the engine is to be used on the street, make sure the mufflers have adequate flow. Target about 2.3 cfm per open-header horsepower.

9. On my street engine, do I really need upgraded valvetrain parts?

For the most part, the valves and valvetrain of a big-block Chevy can best be described as big and heavy. This means it borders on being a cam designer's nightmare. Anything that can be done to lighten the mass at the valve is a plus. The importance of valve lift was mentioned earlier. To be a real powerhouse, a big-block Chevy needs a lot of valve lift because that's where the big flow numbers happen. It also means that the valvetrain has to lift fast to get into that high-flow regime as quickly as possible. Lighter 11/32-inch stem valves (stock is ? inch) are an asset, but that is not the extent of all we need to consider. Valvesprings having a low mass for the poundage they deliver is also an asset.

Such springs are usually more costly because they are made from better steels that can be stressed to higher values without incurring a penalty to reliability. Better steel can lead to a reduction in spring diameter, which in turn can lead to a higher resonant frequency, and the use of a lighter spring retainer.

A basic porting job on a set of Dart Iron Eagles produced a significant increase in flow. Because a big-block Chevy is so air starved, this resulted in an easily achievable gain of over 25 hp on a 500-inch engine.

A basic porting job on a set of Dart Iron Eagles produced a significant increase in flow. Because a big-block Chevy is so air starved, this resulted in an easily achievable gain of over 25 hp on a 500-inch engine.

As for rockers, these are important to the extent that they have to deliver a high lift without undue flexure. Don't even think of using a stock-type, non-roller tip rocker unless you plan on using a wimpy cam. (And why would you do that?) Get a good brand of rocker, and if the budget is there, a Sportsman shaft setup from Jesel is a good idea. As for pushrods, remember that the valvetrain is heavy, and even a good spring will have a substantial over-the-nose poundage. Add to this the fact that even the shorter of the two pushrod lengths used is still a long pushrod. As such, the demands made in this quarter means that a premium pushrod is a must.

10. Do high-performance big-block heads need anything special for a cam?

The cam used with any high-flow aftermarket head is the make-or-break deal for the entire build. The high lift required (0.625-inch minimum) has several major implications. First, for anything but the longest duration, a flat-tappet cam cannot put sufficient lift into the valves. To get sufficient lift, a flat-tappet grind would have a duration of some 300 degrees; that's hardly a daily driver-type cam. Also, the heavy valvetrain mass plus the high rocker ratio brings about high surface loading. Couple this to the fact that many modern oils lack the ZDP (zinc additive) necessary for even a moderately loaded flat-tappet cam and lifters to survive, and you can see that a roller cam is looking like a better option.

For any given advertised duration, there is (for a typical 10:1 500 incher) more than a 20hp difference between a 280 advertised-duration roller and an equivalent flat-tappet. The reason is the extra lift, and a check on the numbers shows why. By way of example, a comparison between Comp's 280 Xtreme solid flat-tappet and a 280 Xtreme street roller shows the flat tappet lifts 0.580 inches, versus the roller's 0.646 inches. The result is no contest. But what about a hydraulic roller? How does this look in practice? The problem is that, once again, the heavy valvetrain and the high rocker ratios involved conspire to make things less than simple. These two factors, plus the need for a higher poundage spring (compared to a small-block) brings about a big increase in roller lifter side loading. This, in turn, causes the lifter to be more prone to collapsing. To minimize this, you need to make sure the heads are equipped with one effective spring (we are back to that resonant frequency thing again) that gets the job done with the least amount of spring poundage. Also, be aware that all hydraulic lifters are not created equal.

The chamber shape of the RHS head is functional as-is, and needs only a cleanup, as seen here, to produce good results.

The chamber shape of the RHS head is functional as-is, and needs only a cleanup, as seen here, to produce good results.

Get the best hydraulic rollers your favorite cam company has to offer. My advice is that unless you absolutely must have hydraulic lifters, go for a solid street-roller setup. Street rollers from Comp or Lunati will go more than 50,000 miles between adjustments. For the minor inconvenience of adjusting them about every five years, you will have the benefit of at least 15-30 more horsepower for a cam of the same (0.050) duration.

So are we done with cam comments? Hardly. Because the air demand of a big-block cylinder can so easily outpace the flow capability of the intake valve until high lift, we need to give it a greater head start than would normally be the case.

This puts the valve at a higher lift earlier in the intake event so that the valve reaches high lift (and consequently high flow) sooner. Because the cylinder can draw earlier, the port velocity in the first half of the opening event is higher. As a result, the ramming effect in the second half of the opening/closing event is increased. In simple terms, we find from port and cylinder pressure measurements that success in the first half of the induction dictates the success in the second half; if the first half is not optimal, there is nothing that can be done in the second half to rectify the problem. What this means is that the opening point of the intake valve for any given overall duration needs to be sooner than for the equivalent cam in a small-block. This translates into having cams with a tighter lobe centerline angle than we traditionally see.

So that you are not left wondering what you should use, here are three grinds that I can personally vouch for using Lunati's big-area-generating Voodoo street rollers: BBDV281-06SRH, BBDV286-06SRH, and BBDV292-06SRH. These are single-pattern cams using Lunati's VSR32, VSR34, and VSR36 profiles, respectively. These cams are optimal for a 489- to 511-inch big-block with typical aftermarket heads and a compression ratio between 10:1 and 11.5:1.

Note From The Editor:

This story is not intended as a complete comparison of all available cylinder heads, intake manifolds, or camshafts. Such a story would be impossible for a complete book, let alone a six-page magazine story. These technical illustrations are one expert's cumulative experience, which is understandably limited. Obviously, there are many other great big-block Chevy cylinder heads, intakes, carburetors, and camshafts that work superbly in a variety of situations, so if we forgot your favorite, please do not be insulted. Rather, it is the desire of the PHR editorial staff that you take away the overreaching technical concepts.