Engine-build primers are a main component of the technical aspect of HPP. We pride ourselves on furnishing the readership with detailed information that can be used on their Pontiacs. We've covered the gamut from a basic engine freshening to all-out drag-race powerplants and everything else in between. This time, however, we're doing something different.

We went to Jim Taylor Engine Service (JTES), a well-respected Pontiac shop, to document the freshening and modifying of a 455 for a customer, Bill Wise from Queens, New York. His '74 LeMans is a street/strip car that features a rollcage, a complex stereo system, and other accoutrements. The Pontiac weighs approximately 4,300 pounds and is driven everywhere it goes. The previously Taylor-built engine was strong-proven by numerous 12.54 timeslips-and reliable, with more than 10,000 problem-free miles of street/strip service.

But Bill wanted more-an 11 second e.t. was the goal, and Jim Taylor Engine Service believed it could accomplish that.

The trick is to achieve the customer's goals, despite the heavy race weight and without sacrificing the street driveability of the Pontiac or adding nitrous. That means engine vacuum must be good; only straight pump gas exits the carburetor boosters; and it has to do everything a stocker does-just go a lot faster.

Over the years, the term street car has become skewed, since to many magazines it means a license plate, windshield wipers, and a rearview mirror. HPP's definition of a street car is one that can start in all weather, sit in bumper-to-bumper traffic and idle, and the key can be tossed to anyone with a driver's license with no concern for hurting the engine. It also has to be impressively quick-a tall task for a Pontiac that weighs more than two tons.

The Plan

The traditional means of making easy power-raising the compression ratio, and installing a larger (more aggressive) camshaft-isn't acceptable since it diminishes the car's streetability. Thus, Jim Taylor Engine Service needed to further dial-in the already refined 455. This meant an all-out attack on the minute details of the engine.

When building and blueprinting an engine, there are higher levels of tolerance. Extreme attention to detail is nice, but as with anything, a cost/benefit ratio needs to be established. For example, when porting a cylinder head, you can spend 100 extra hours and only pick up a few cfm, which may yield 10 hp. The standard protocol would be not to invest that amount of time because you don't need it. But instead do a good street port and look for the power elsewhere, such as in the cam or compression ratio. The customer has a good product within his budget and everyone is happy.

In contrast, the world of NHRA Stock and Super Stock Eliminator engine building takes the exact opposite approach. Since the rules limit the modifications, every last detail of the engine needs to be machined and assembled to perfection. [A task that takes a huge investment in time and knowledge but allows the relatively large number of stock parts to produce more power than what the factory did.] Though not a Super Stock engine, JTES applied many of the same edicts to this Pontiac, which makes it a unique educational experience for our readers.

Due to the nature of the rebuild, we chose to skip the traditional photos of the crankshaft being dropped in or the assembly of the cylinder heads and other parts. Instead, we spent three days documenting some of the exacting procedures employed on this engine.

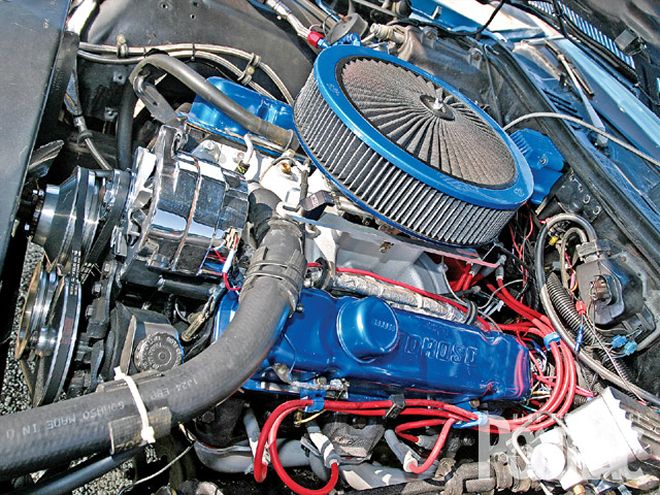

What's interesting is that other than the consumables (rings, bearings, gaskets) only the intake was changed. The 6X cylinder heads were treated to a precise porting on the intake side to increase flow from 230 cfm (the previous porting) to 255 cfm at 0.550 inch. The additional power was sought in a few other areas beyond the cylinder-head intake port: the installed position of the camshaft and a swap to a port-matched Torker II from a worked Holley Dominator and its precise alignment with the cylinder heads. The cam, which was ground 6 degrees advanced, was installed straight-up for the first build. For this one, it was retarded 4 degrees. The other work was based on producing exacting dimensions and meticulous assembly by Mark Erney.

Extreme attention to detail is sometimes overlooked on a Pontiac engine build, but as we hope to prove in Part II of this primer when we test on the dyno, it's an effort worth taking.

High Performance {{{Pontiac}}} Engine Buildup WorksheetEngine Displacement463ciBore/Stroke 4.185-in/4.210-inBlock/Crank ComboFactory 455Bore/Stroke Ratio0.994:1Rod/Stroke Ratio1.5736:1 Bottom EndBlock Description'73 455PreparationClean and Magnaflux; install four-bolt main caps from Program Engineering; align-bore and set thrust, bore, hone, deck; tap lifter feeds for oil restrictors; deflash lifter valleyDeck Height10.215-inCrank'70-'73 Pontiac nodular-ironPreparationReground, micro-polish, deflash, balance w/complete assemblyBalancerBHJ po-ib7-sRodsCrower Sportsman forged-steelRod Length6.625-inPreparationCheck, measure big end and pin endBearingsSealed Power H.D.PreparationCleaned with 0000 steel wool and washedPistonsJE/SRP forged, flat-top with valve reliefsPreparationCoated by Swain Coatings, ceramic top and dry film sidesPiston to Deck Height-0.005-inPiston PinsJE full-floatingMethod Used to Retain Piston Pins in PistonsDouble spiral locks, included with pistonsRingsTotal Seal TS1 gapless, low-tension oil rings (14-pound pull)PreparationSet gaps 0.019-in top and secondRod Bolts/Head BoltsCrower connecting rod bolts, ARP head boltsBalancingBy Hoffman Machine Oiling SystemWindage TrayPontiac 455Oil PanMoroso 8-qt Oil PumpMellings M54D, Moroso pickupPreparation Disassemble, wash, clearance check, make custom oil-pump pickup retainer plate, reassemble HeadsCasting Number 6XChamber Open/ClosedOpenHead ModsPortedCombustion-Chamber Volume 90ccMaximum Flow at 28 inches of water Intake 255 at 0.550-in Exhaust180 at 0.550-inCompression Ratio 9.6:1Valves Ferrea SSIntake 2.11-inExhaust 1.66-inAngles Used in Valve Job Original 30- to 65-deg int, 45-deg exhRetainers Comp Cams titaniumKeepers Crower jumbo locks, 10-deg, w/lash capsValveguides K-Line linersValve Seals Corteco, all TeflonRocker Studs ARP Pro series 2-in Rocker Arms Crower full-rollerRocker Arm Ratio 1.6:1 intake/1.5:1 exhaustPushrods Smith Bros. seamless chromoly 0.083-in wallDiameter 5/16-inLength 9.150-in CamBrandCrane solid-rollerDuration at 0.050252/256-degLift0.598/0.560 gross, 0.578/0.540 net Lobe Separation Angle112-degInstalled PositionDegreed to cam card by retarding 4-degLiftersCrower rollerValvespringsComp CamsTypeDual w/damperSeat Pressure165 psiOpen Pressure425 psiTiming ChainRollmaster -0.002-inType Double roller, prestreched InductionCarbHolley 4781 w/Wilson 1-in tapered spacer (Demon shown in photo)Size cfm{{{850}}}ModsRejetted, added notched rear float and jet extensions JetsPrimaryNo. 81SecondaryNo. 81Intake ManifoldTorker II single-planeModsPort-matched only IgnitionDistributorMSD Pro BilletAmplifierMSD 6ALCoilMSD Blaster 2WiresMSDTotal Timing36-degVacuum AdvanceNone ExhaustHeadersHooker (for the dyno)Primary-Tube Diameter1.75-inCollector Size3.00-in