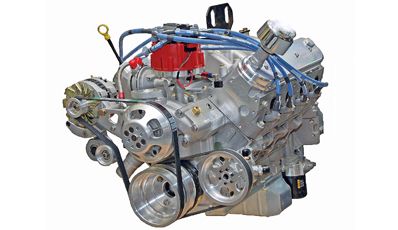

This Wegner Spec engine, used in selected NASCAR Series, is based on the General Motors LS engine platform. Comp Cams is aggressively pursuing development of a variable valve timing package for this engine family.

This Wegner Spec engine, used in selected NASCAR Series, is based on the General Motors LS engine platform. Comp Cams is aggressively pursuing development of a variable valve timing package for this engine family.

In order to set a stage for what follows, let's first revisit some of the fundamentals involved in how valve timing relates to power output. And to further clarify how "power" is defined in the context of this story, let's simply say horsepower is a mathematical function of torque which, in essence, is closely related to volumetric efficiency. Increase volumetric efficiency at any point in an engine's rpm span, and at least the potential for a torque gain will result.

Relative to how valve timing plays into volumetric efficiency, let's further say the designed ability of a camshaft to "time" intake and exhaust valve events (particularly as they relate to piston/crankshaft position) is key to achieving proper volumetric efficiencies. For example, when a given piston is at or near maximum downward speed during an inlet cycle, you'd like for intake valve event to support a high level of volumetric efficiency. And, in a similar fashion, other piston motion patterns should be accompanied by valve action that helps optimize cylinder evacuation during the exhaust cycle.

The cam phaser kit is supplied (as provided for the Ford applications) complete with special tools for disassembly of the stock components and phaser limiter plates and detailed instructions for re-assembly and a guidance on subsequent engine tuning.

The cam phaser kit is supplied (as provided for the Ford applications) complete with special tools for disassembly of the stock components and phaser limiter plates and detailed instructions for re-assembly and a guidance on subsequent engine tuning.

Historically and largely because camshafts are characterized by a "fixed" design, we've only been able to advance or retard their installed orientation to an engine's crankshaft. We were limited to the amount of "variability" achievable, relative to where in the rpm range valve timing plays into volumetric efficiency. Simply stated, we "advance" cams to enhance lower rpm torque output and "retard" them (both in relationship to the crankshaft or piston position) for higher rpm output. Ideally, at least from one perspective and outside the realm of a fully-computerized valve train with true valve timing variability, it is plausible to provide some means for advancing and retarding the camshaft during engine operation.

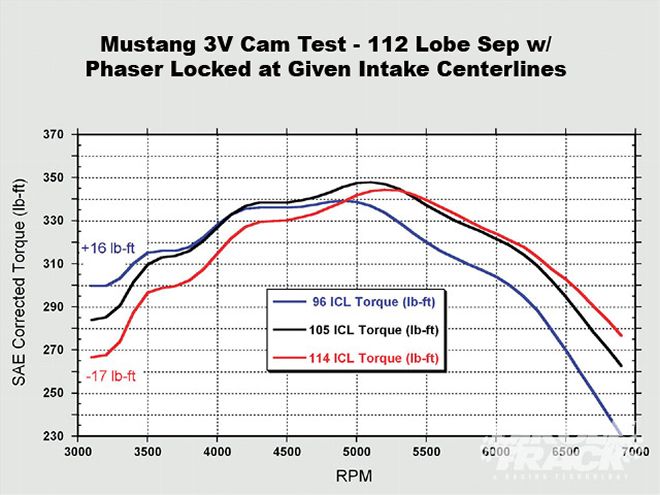

By the employment of "cam phasers," it's possible to find a middle ground between either advancing or retarding a cam. What this means is that while advancing and retarding a given camshaft won't necessarily boost (or even shift) peak torque values, it's now possible to increase torque below and above this point. In essence, the overall torque curve becomes "flatter" (or wider) over a broader range of engine speed. (See graphical illustrations of torque curves with and without phased camshafts on the next page.)

These specially-engineered components are designed to limit the amount of camshaft positioning (phasing) available, thereby allowing for more "creativity" in producing cams that take advantage of this technology, providing torque gains above and below peak torque rpm.

These specially-engineered components are designed to limit the amount of camshaft positioning (phasing) available, thereby allowing for more "creativity" in producing cams that take advantage of this technology, providing torque gains above and below peak torque rpm.

Actually, as an outgrowth of Ford's introduction of computer-controlled cam gears on its '05 modular, Three-Valve engines for Mustangs, Comp has used this technology platform for further improvements. Ford's approach allows the cams in these engines to include a range from 20-60 degrees retard during part-throttle operation, thereby reducing friction horsepower and enhancing fuel economy. Based on the use of their computer-controlled camshaft phasers and regardless of engine speed, this approach enables camshaft positioning for optimal power throughout the rpm range. The net result is an extended power range.

Using a specific routing of engine oil through cylinder heads and camshafts, the on-board computer regulates a pair of solenoids which, in turn, control the phasing of the camshafts. The span of control can be as much as 60 degrees of camshaft retard. As you would expect, the extent and precision to when the cams undergo a phase change is a function of the software written into this portion of the onboard computer. Stated another way, there appears be a way to provide valve timing (camshaft design) that takes further advantage of this technology, enabling a window for exploring this concept in other engines and applications.

As produced by Ford, their "stock" phasers provide such a wide range of camshaft retard (up to 60 degrees, as stated), there are limitations based on the amount of available piston-to-valve clearance. As a result, there are corresponding limits that are placed on what can be done with non-stock camshafts, certainly in the areas of net valve lift and valve overlap periods. Also keep in mind that Ford is faced with certain compromises, including exhaust emissions and Federal fuel economy mandates, which further restrict the extent to which they can focus on power output. Such is not the case when you apply this technology to engines in a racing environment.

Comp's "variable cam timing" provides an ability to determine best torque for each camshaft position (relative to crankshaft angle). Once this is determined, a final "curve" will be produced that essentially boosts torque above and below the original peak torque rpm point.

Comp's "variable cam timing" provides an ability to determine best torque for each camshaft position (relative to crankshaft angle). Once this is determined, a final "curve" will be produced that essentially boosts torque above and below the original peak torque rpm point.

As previously indicated, electronics play a major role in this issue. Given the fact it's possible to modify the stock camshaft phasers in engines that incorporate this technology, proper control of their function is key to optimizing power, at both lower and higher rpm. Specifically, computer programming should include addressing the cam retard limiting issue, along with provisions (for street-driven engines) to make certain diagnostic trouble code (DTC) strategies are properly restored. For racing applications, this latter issue is not a concern.

In addition, Comp provides "phaser limiters" that prevent cam retard positions from exceeding 20 degrees, at least for the 4.6- and 5.4L Three-Valve Ford engine. Looking ahead, this same approach is anticipated for other computer-controlled engines for which they plan producing camshafts. And in that regard, you can expect some form of "electronic device" as a companion to any race-bred camshafts Comp offers for circle track applications.

At the time of this writing, Comp is aggressively exploring application of the technology in GM's LS engine family. Given the fact these are and continue to become "spec" engines in the circle track community and GM's inclusion of cam phasing technology in them, Comp is currently evaluating prototype units directed to circle track use. Again, by limiting the extent of OEM camshaft retard, racing camshaft lobe profiles and valve timing can be developed that optimize torque boosts below and above an engine's peak torque rpm, thereby improving both off-corner acceleration performance and straightaway speeds in circle track applications.

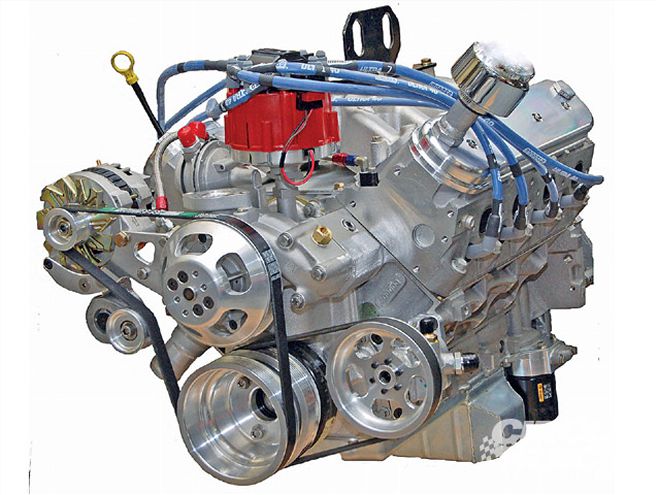

Here you can see COMP's "Phaser Limiter Kit" installed in an otherwise stock Ford 4.6-5.3L cam gear. The same concept is already under development at COMP for the LS series of GM "small-block" engines for circle track application.

Here you can see COMP's "Phaser Limiter Kit" installed in an otherwise stock Ford 4.6-5.3L cam gear. The same concept is already under development at COMP for the LS series of GM "small-block" engines for circle track application.

Virtually any race engine is a combination of compromises. Over time, engine builders have incorporated various techniques to "flatten" or "broaden" torque curves, particularly for applications in which a comparatively wide range of engine speed is required. Especially well suited to circle track engines required to operate over a span of 3,000 rpm or more, the ability to dynamically alter camshaft/crankshaft relationships appears to be a significant step toward minimizing power losses and extending an engine's operational range.

Of particular interest is the fact this technology addresses the time-honored problem of advancing and retarding camshafts when deciding upon where to optimize and where to compromise power gains (or losses). Not only does the prior practice tend to consume inordinate amounts of dyno time, excluding engine wear, it's essentially a trade-off in terms of selective power placement. Given the ability of Comp's concept, it's possible to perform a series of tests (specifically eight) at different camshaft advance locked positions to determine optimum power. Then it's a relatively simple matter to remap the controller's program to incorporate these settings over a span of rpm, thereby eliminating the time-honored "advance compromise" by present-day methods. Essentially, this process of reprogramming the phaser ensures the cam will be at its best power output levels throughout the desired rpm range, not within a narrow span.

Finally, as we move toward electronic valvetrains and "cam-less" engines, the incorporation of variable cam phasing techniques (although initially enabled by the OEM) looks to be an intermediate step to the removal of camshafts altogether. And since it stands to be a while before we get to that point, COMP's "variable cam phasing" packages may be the answer to engines benefitting from enhanced torque both below and above torque peaks. What's the old saying about "having your cake and...?"