If you're forced to meet minimum vacuum numbers for your race class, how do you race legally, without giving up tons of power? With good cam choices, you can meet your track's vacuum rules without giving up the grunt.

If you're forced to meet minimum vacuum numbers for your race class, how do you race legally, without giving up tons of power? With good cam choices, you can meet your track's vacuum rules without giving up the grunt.

It's a spinoff rule that came from trying to make racers use stock components. Engines in street cars produce a lot of vacuum in the intake manifold because they are designed to spend the majority of the time at rpm levels barely above idle. Puttering around town. Looking for the best parking place at the grocery store. Stuck in traffic on your way to work. That sort of thing. The result is a cam with short intake and exhaust durations and very little valve overlap.

Vacuum may be good for powering the brake booster in your everyday car, but besides providing good signal to the carburetor, we have little use for it in racing. Instead, camshafts are optimized for high-rpm operation. That means more duration for both the intake and exhaust lobes, because at high rpms it can be difficult to get air and fuel into the combustion chambers and exhaust gasses back out in time. The longer lobe durations are combined with more overlap to use the effect of scavenging to actually pull the air/fuel charge into the combustion chambers. Together, those qualities in a camshaft harm the amount of vacuum any engine will pull in the intake manifold plenum.

After dyno'ing the first cam, we began pulling the engine down. Everything except the lifters and the camshaft were kept the same.

After dyno'ing the first cam, we began pulling the engine down. Everything except the lifters and the camshaft were kept the same.

That's not a problem unless your racetrack has implemented a vacuum rule in your class. Vacuum rules are most common in Street Stock-level race classes where the idea is to force the racer to use as many stock or stock-replacement parts are possible. The idea is that the requirement for a certain amount of vacuum-measured at the intake manifold plenum with the engine at idle speed-will require smaller cams which will cut power.

So the obvious question becomes how do you meet the vacuum rule at your track while maximizing horsepower at the same time? Well, it turns out with a little camshaft savvy you can use the vacuum rule at your racetrack to gain an advantage on your competition. You can also influence vacuum with other components, such as carburetor size, different types of intake manifolds, and even engine compression, but since all those things are usually controlled by the rule book as well, the cam almost always is the best area to work on if you are hoping to get the best of both worlds.

Here's the nitride Comp Cams hydraulic flat tappet pulled out after our first test. After the break-in procedure and extensive dyno pulls, the nitriding on the cam still looks like new. This is definitely the way to go if you're trying to get the most aggressive lobe possible to work in a flat-tappet application.

Here's the nitride Comp Cams hydraulic flat tappet pulled out after our first test. After the break-in procedure and extensive dyno pulls, the nitriding on the cam still looks like new. This is definitely the way to go if you're trying to get the most aggressive lobe possible to work in a flat-tappet application.

"Making vacuum is all about overlap," explains cam designer Billy Godbold of Comp Cams. "But there is no way I, or anybody else, can tell you exactly how much you need because how much vacuum your engine will run depends on a lot of factors like the compression ratio, how well the rings seal, port size, the header size, and all kinds of other little things. But we can get you close, and if you're trying to run the absolute minimum amount of vacuum your rules allow, you may have to be willing to get it close with a test cam and then dial it in with a second."

Overlap is a tool to help improve engine performance at high-rpm levels, but it can also hurt how well an engine runs at idle speed when the engine is moving relatively slowly. Basically, during overlap both the intake and exhaust valves are open, so the piston moving down in the cylinder produces no vacuum in the manifold.

So the trick is to figure out how much valve overlap you can have and still meet your minimum vacuum number to pass inspection. Overlap can be changed by adjusting the camshaft in one or two ways. The first is to change the duration that the lobes hold the valves open. Shortening the duration-and the amount of time the valves are open-generally reduces overlap. What you have to avoid is extremely long intake duration where the intake valve is held open past bottom dead center. When that happens, the piston starts moving back up the cylinder and pushing air back into the manifold. The second option is to change the lobe separation angle (LSA). The LSA is the distance between the centerlines of the intake and exhaust lobes for a single cylinder. It is measured in degrees of crankshaft rotation. Most performance cams use an LSA in the 110-degree range. And as you might expect, a greater LSA reduces overlap (because it spreads the intake and exhaust lobes apart) while a smaller LSA increases it.

Since the old lifters had been broken in with the old cam, we also put in a new set of Comp Cams hydraulic flat tappet lifters (part number 8400-16) to go with the new cam. Breaking in a new set of cam and lifters is very difficult on the cam when using aggressive flat tappet lobes, so take a few extra precautions. These should include a coat of spray-on graphite lubricant (the black stuff) as well as plenty of assembly lube on the face of the lifters.

Since the old lifters had been broken in with the old cam, we also put in a new set of Comp Cams hydraulic flat tappet lifters (part number 8400-16) to go with the new cam. Breaking in a new set of cam and lifters is very difficult on the cam when using aggressive flat tappet lobes, so take a few extra precautions. These should include a coat of spray-on graphite lubricant (the black stuff) as well as plenty of assembly lube on the face of the lifters.

Godbold says that once you learn how much overlap you can get by with, you can begin playing with your durations and LSA to maximize power, while maintaining your minimum vacuum level. He also recommends making your lobe profile as aggressive as possible. Your duration may be limited by the amount of overlap you can get by with, but by raising and lowering the valves as quickly as possible inside those parameters, you can get more air into and out of the combustion chambers.

"You may get more wear and have more valvetrain noise, but a very aggressive cam is definitely the way to get more power while still maintaining vacuum," Godbold says. "As long as you aren't slinging parts everywhere, that's OK. The only way that it can be too aggressive is if you start losing control of the valves at, say, 6,000 rpm, when the engine is capable of running up to 7,000 rpm with a milder cam.

"Sometimes racers will end up running some of our most aggressive solid lifter designs even though they have a hydraulic lifter rule at their track and have to run hydraulic lifters. You don't care whether it was originally designed for a hydraulic or a solid lifter application, you just want the cam that will get you the quickest possible lift off of the seat so that you can get as much flow as possible with a limited duration."

In order to make sure the tests were accurate, we also checked the tension on the Comp beehive valvesprings before both runs on the dyno.

In order to make sure the tests were accurate, we also checked the tension on the Comp beehive valvesprings before both runs on the dyno.

If you are considering going the route of ultimate aggressiveness, you may also want to consider running a nitrided cam. The nitriding process puts a very hard, very slick surface on the camshaft that is much more resistant to wear than any standard hardening process alone. Most vacuum-rule classes also require flat-tappet lifters, which limit how aggressive your lobes can be. With a very aggressive camshaft and flat-tappet lifters, you run the risk of the edge of the lifter digging into the surface of the lobe. Aggressive lobes also require stiffer valvesprings, and when you combine that with flat tappets, the chances of flattening a lobe are also increased. Nitriding helps reduce the chances of both and can help you not only get through the tricky break-in period but also help your cam live longer overall.

To get a better idea of how much cam lobe design affects vacuum, we decided to try our own tests on the dyno. Our test mule was a Chevy 350 built at KT Engine Development for the Strictly Stock class. It's a typical motor for vacuum-rule classes raced at tracks all across America. It features stock heads cut down so that the chambers measure 64 cc's and flat-top pistons to make the compression a mild 10.2:1. The intake is a stock cast-iron dual-plane unit and the carburetor on top of that is a 350 cfm two-barrel Holley.

Another break-in tip, in addition to the precautions taken at assembly, it's always a good idea to use a lighter set of break-in springs for the first 30 minutes on the dyno (with no load). You can also use Comp's break-in lube along with your regular racing oil. In fact, if you are racing with flat tappet lifters, the extra lubricants in this additive are beneficial every time you change your oil for the life of the engine.

Another break-in tip, in addition to the precautions taken at assembly, it's always a good idea to use a lighter set of break-in springs for the first 30 minutes on the dyno (with no load). You can also use Comp's break-in lube along with your regular racing oil. In fact, if you are racing with flat tappet lifters, the extra lubricants in this additive are beneficial every time you change your oil for the life of the engine.

Comp Cams helped us pick out two cams for the test. The first cam was chosen for the typical rule set assuming there's no vacuum rule. Total lobe lift was held to 0.283-inch, and combined with 1.6:1 ratio rockers, the valve lift came out to 0.453-inch. Duration at 0.050 is 238 for the intake and 242 for the exhaust, and with a 110-degree LSA the overlap measured in at 20 degrees. The lifters are stock Chevy diameter hydraulic lifters provided by Comp Cams.

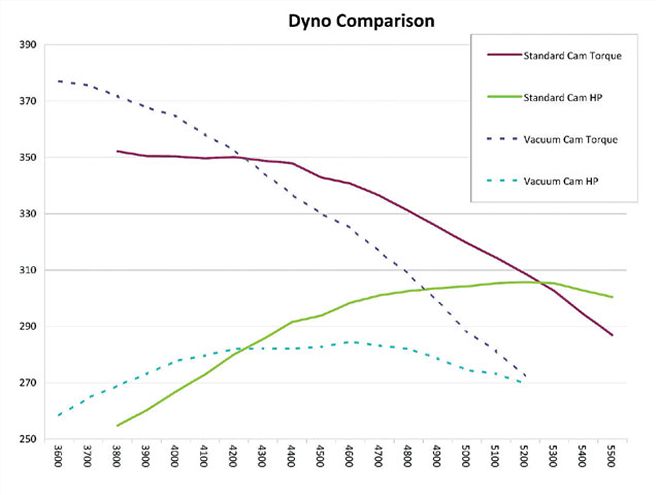

On the dyno this cam produced 352.1 lb-ft of peak torque at 3,800 rpm and 305.7 hp at 5,200 rpm. Nice numbers for the very restrictive rules, but it also was only capable of managing 12 inches of vacuum at 700 rpm.

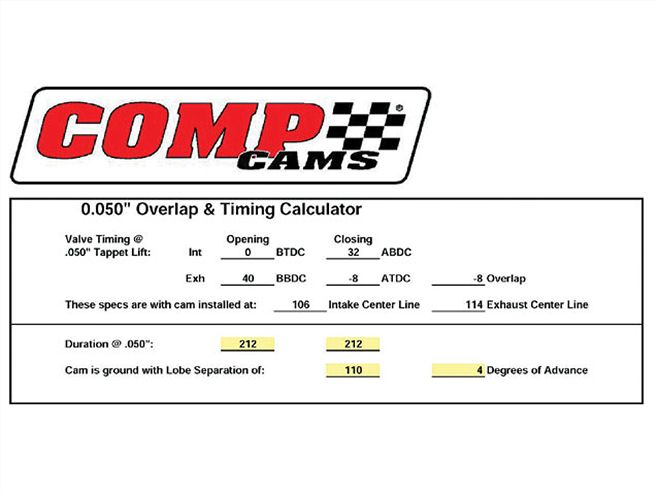

We gave the engineers at Comp a goal of 17 inches of vacuum at 700 rpm, and the second cam tested was ground to meet that target. Like before, this cam was ground with 0.283 lobe lift and a 110-degree LSA. But this time, the duration at 0.050 was much shorter at 212 for both the intake and exhaust. And while there technically is still some overlap, if measuring when the valves are 0.050-inch off the seat, the lobes are separated by 8 degrees.

Finally, other than a jet change in the carburetor and a timing sweep (both cams worked best at 38 degrees advanced), the engine was exactly the same for both runs.

Finally, other than a jet change in the carburetor and a timing sweep (both cams worked best at 38 degrees advanced), the engine was exactly the same for both runs.

This time around, the Chevrolet pulled 17.2 inches of vacuum at 700 rpm. It just barely met the vacuum minimum, which was exactly what we wanted. You never want to give up any more than you have to. But the power curve the new cam produced is really what was interesting. Predictably, the shorter durations and reduced overlap moved the peak power numbers lower in the rpm range, but the smaller cam actually helped torque substantially. This time around peak torque showed up 200 rpm earlier and pulled 377.0 lb-ft. That's an improvement by nearly 15 points! And truthfully, peak torque showed up as soon as we began the dyno pull at 3,600. We could have pulled the rpms down lower, but there is little point in a race motor.

Peak horsepower also moved down the rpm ladder, this time by 600 rpm. Unfortunately, the shorter durations also hurt how well the engine could pull in the air/fuel charge as the rpms climbed, and peak power dropped 21.1 points to 284.6. Although nobody was clicking their heels over giving up horsepower, it's still respectable for a Strictly Stock motor and expected considering how much duration we had to give up to get the vacuum number necessary.

Still, the lessons learned about using aggressive lobes to overcome short durations will be very valuable in any vacuum-restricted class. And with more experimentation, we probably could find a cam to help make back some of that horsepower we lost. But first, we'll allow KT Engines to hand this Chevy over to the customer and see how it fares on the racetrack.

Lash Your Hydraulics

Hydraulic lifters require no lash in normal operation, but Comp Cams' Billy Godbold passed along this power tip that might be helpful depending on how and when your vacuum-restricted car must pass through tech. In vacuum applications, Comp often recommends staying away from the high bleed-down lifters. Instead, use a set that doesn't bleed down as quickly-such as Comp's 8400-16 hydraulic flat tappet lifters-because they increase stability. And if you have trouble meeting your track's vacuum requirements, you can set them with a couple of thousandths of an inch of lash. It won't damage the cam or lifters in the short term, but the extra lash will make the cam act as though it has less duration and will increase vacuum. Then, if you have the chance, take the lash back out before the race for more power.

All reputable cam manufacturers send a cam card with all their camshafts that include most of the pertinent information you will need. But many don't specifically tell you how much overlap is ground into the cam. You can figure it out yourself with a little math, but an easier way is to use the "Overlap Calculator" Comp Cams provided us while working on this story. It is a Microsoft Excel worksheet, so it should work with most Windows-based computers, and it can tell you much more than just your overlap. Simply plug in the information in the yellow boxes (duration numbers at 0.050, lobe separation angle, and even advance if you like) and the program spits out not just the overlap, but also the exhaust and intake centerlines, and even how much tappet lift you should see at 0.050. All of this information is very helpful when degreeing in your cam. You can get a copy of your own by going to www.circletrack.com and typing "vacuum" in the search box.