During the last few years, the talk of new Hemi engines has typically referred to the third-generation units used in Chrysler's late-model products, such as Charger, 300C, and Ram. With the advent of stand-alone controller kits, we've seen more than a few popped in street rods-the most notable example being the SR-392 roadster, which was introduced last fall at the SEMA show.

For many rodders, however, real Hemi engines are the first-generation 331/354/392 mills or the aircraft carrier-sized 426 Street Hemi of the '60s and early '70s. The first-generation engines are long gone from the production scene, but the basic 426 Hemi has lived on for years in aftermarket form. Heads and other engine components sustained enthusiasts' needs, but no new Hemi blocks had been poured for quite a while.

The new casting of the vintage 426 Hemi cylinder block is available from Mopar Performance. It is manufactured by World Products, who updated the design to accommodate contemporary desires for larger-displacement combinations and to improve oiling. World uses this block for its line of crate engines.

The new casting of the vintage 426 Hemi cylinder block is available from Mopar Performance. It is manufactured by World Products, who updated the design to accommodate contemporary desires for larger-displacement combinations and to improve oiling. World uses this block for its line of crate engines.

That changed recently with the introduction of a new Street Hemi block from Mopar Performance. It was designed through a partnership with World Products to be stronger than the previous example and support larger displacement. World Products manufactures the new Hemi block and Mopar Performance sells it, but World Products also uses the Hemi block as a foundation of an upcoming series of crate engines, short block assemblies, and so on.

The thought of new Hemi tech raises our pulse, so we jumped at the chance to check out the innards of a street-intended crate engine package that World Products is developing. Ours was an early glimpse of what was pretty much the first Hemi engine built by World Products. So, the caveat is the regular-production crates packages may vary slightly from what is shown in this story, but World's founder, Bill Mitchell, told us that, apart from some minor details, the engine is very representative of the final product.

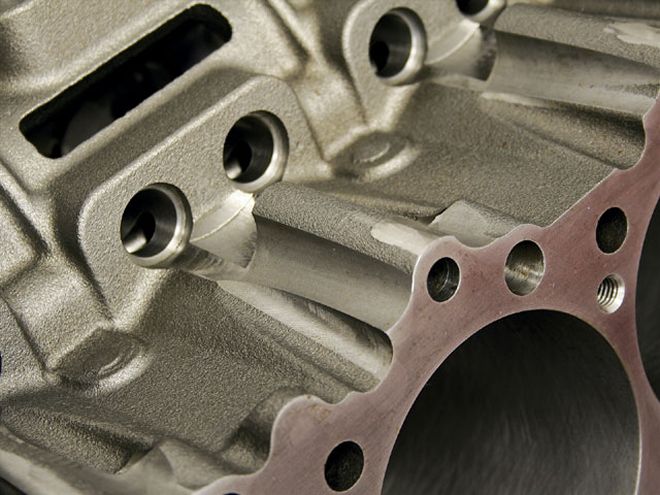

To support large-displacement combinations with the requisite strength, the Hemi block is cast with more material in strategic locations, such as around the cylinders. The maximum safe bore diameter is 4.600 inches. With the capability of supporting a 4.750-inch stroke, the Hemi has the capacity for 632 ci.

To support large-displacement combinations with the requisite strength, the Hemi block is cast with more material in strategic locations, such as around the cylinders. The maximum safe bore diameter is 4.600 inches. With the capability of supporting a 4.750-inch stroke, the Hemi has the capacity for 632 ci.

The basics include a 528-inch displacement, Mopar Performance Hemi heads, a 0.524/0.543-lift cam, and a pair of Holley four-barrel carbs. Naturally, our first question after gazing upon the gorgeous, dual-quad pachyderm was, "How much power did it make?"

Unfortunately, the answer was, "We don't know yet." It wasn't that the World Products folks weren't willing to share their data, but they were hung up on one thing: a global shortage of Hemi rocker arms. At the time of our photo session at World's Ronkonkoma, New York, facility, the engine was missing a couple of arms for one of the heads, so the backorder on the crucial valvetrain parts prevented us from participating in a dyno-test session.

But, Mitchell has been developing engines for a long, long time. His educated estimate on the combination's output is around 650 hp and 675 lb-ft of torque.

"We tend to estimate a bit on the conservative side," he told us. "But, given the components used in the engine and the airflow capability, that's probably a good idea of the power capability."

The internal oil pick-up location was moved and redesigned with a two-bolt flange. This enables longer-stroke crankshafts to be used without resorting to an external oil pick-up.

The internal oil pick-up location was moved and redesigned with a two-bolt flange. This enables longer-stroke crankshafts to be used without resorting to an external oil pick-up.

And, while 650 naturally aspirated horsepower is a crowning achievement in all regards, Mitchell pointed out the new Hemi block is designed to support larger displacements-more than 600 ci-so the potential of truly astounding power is only a few more cubic inches away. Of course, 6-71 and 8-71 blowers atop Hemis were so ubiquitous in the '60s and '70s that you'd have thought Chrysler offered them as over-the-counter accessories. We'd love to see what a healthy huffer with a vintage-looking Hilborn injection system would do for this engine.

New Hemi Block Details

At a glance, the new Hemi block looks virtually identical to vintage 426 Street Hemi cases. A closer inspection reveals more material in the casting, shoring up the block's strength and laying the foundation for big-cube combinations on the order of 600 ci or more. The block is available with 4.250-, 4.500-, and 4.600-inch bore diameters and can except a crank with as much as a 4.750-inch stroke (as along as an external oil pickup is used), giving a maximum displacement of a whopping 632 ci.

The timing set is closed off with a chrome cover.

The timing set is closed off with a chrome cover.

The block's added material is packed around the cylinders, although the bore centers and deck height remain at the factory 4.800- and 10.725-inch specifications, respectively, so all factory-style cylinder heads and intake manifolds bolt on without a problem. The front and rear bulkheads are thicker than stock, for extra rigidity.

A new feature of the block is a change in the design of the oil pick-up tube mount, which was repositioned and features a new two-bolt flange that enables larger-stroke combinations. An adapter is provided for the original-style screw-in pick-up. Also, the oil circuit is improved; it feeds the rockers from both oil galleys, rather than the cam bearings.

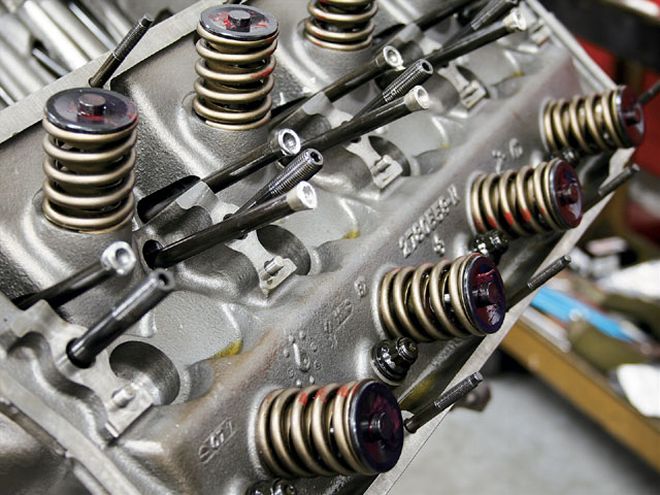

World uses the same iron cylinder heads offered by Mopar Performance. They have 170cc combustion chambers, 2.25-inch intake valves, and 1.94-inch exhaust valves. The compression ratio is about 10.25:1 with the domed pistons.

World uses the same iron cylinder heads offered by Mopar Performance. They have 170cc combustion chambers, 2.25-inch intake valves, and 1.94-inch exhaust valves. The compression ratio is about 10.25:1 with the domed pistons.

Additional updates and improvements over the original 426-style block include:

* Lifter bosses can accommodate 45- or 51-degree angles

* Provisions for Hemi or Wedge engine mounts

* Designed to accommodate all popular aftermarket starters

* Rear bellhousing flange accommodates Chrysler and GM transmission bolt patterns

In its day, the original 426 block was no featherweight; and because of the extra material in the casting, the new Hemi block is a bit heavier, tipping the scales at a pachyderm-appropriate 308 pounds. There's an aluminum version of the block that chops more than 160 pounds off the block's weight.

Inside the Crate Engine

The prototype 528-inch crate engine in our story arrives at its displacement with 4.500-inch bores and a 4.150-inch stroke. That's nearly a 25 percent displacement increase over the original 426 specifications, which used 4.250-inch bores and a 3.750-inch stroke.

Next up were the unique rocker arm assemblies, which use higher-than-stock 1.7 (intake) and 1.65 (exhaust) ratios to maximize airflow. Valve lash is extremely important with a Hemi engine in order to extract all of its performance potential.

Next up were the unique rocker arm assemblies, which use higher-than-stock 1.7 (intake) and 1.65 (exhaust) ratios to maximize airflow. Valve lash is extremely important with a Hemi engine in order to extract all of its performance potential.

Of course, all of the internals on World's engine are forged. They include Arias pistons-providing about 10.25:1 compression-pinned to 6.86-inch-long Eagle rods, all swinging on an Eagle 4340-forged internally balanced crankshaft. The camshaft is a hydraulic roller with 0.524/0.543-inch lift specs. Again, some of these specs, particularly the camshaft, will likely evolve when the production crate engines are finalized.

Doing the breathing for the prototype engine is a set of Mopar Performance Hemi heads. No porting or any other enhancements were made for the prototype engine-just an out-of-the-box evaluation to use as a starting point. A Mopar Performance dual-quad intake manifold straddles the heads, and it is topped with a pair of Holley four-barrels.

Despite the iconic and dramatic appearance of the engine, there is nothing exotic or overly custom about the combination. There's no compromising machine work, no use of "unobtainium" parts, and there's no special needs-such as 110-octane fuel, for example-to run it on the street. Indeed, it's the epitome of World Products' "build it big, but keep it simple" philosophy.

"We design engines for people to simply pull out of the crate, add their fuel and exhaust systems, and turn the key," said Mitchell. "A simple combination gives the owner less to worry about and ultimately makes the driving experience with his or her car more enjoyable. All the elements are available to us to make that happen with the Hemi."

Mitchell says the 650-horse prototype engine is only the beginning. "We're really excited about the possibilities the new Hemi block gives us," he said. "We're just getting started with it."

The second coming of the Hemi launched in 1964 with the 426ci Hemi engine. In production cars, it was called the Street Hemi and was rated at 425 hp. The Street Hemi was available from 1966 through 1971.

The second coming of the Hemi launched in 1964 with the 426ci Hemi engine. In production cars, it was called the Street Hemi and was rated at 425 hp. The Street Hemi was available from 1966 through 1971.

Street Rod Specifics

Certainly, the 426-style Hemi engine is no stranger to the frames of street rods of all makes. And, with its identical exterior dimensions, the new block and engine assembly take up as much space as a vintage Street Hemi. That means cutting holes in the hood sides of some rods or leaving them off altogether. As for fat-fender cars, well, you'd better find an awfully large shoehorn. Also like the original Street Hemi, this modern version is no lightweight-a complete assembly pushes the 900-pound mark. One of the easiest ways to offset its girth is opting for World's aluminum version of the block. It saves more than 160 pounds-and it'll lighten your wallet a bit more, too, over the standard iron block. (See the "The Alloy Options" sidebar on page 128.)

Perhaps the most noteworthy specification of interest to street rodders is the new Hemi block's capability of bolting up either Chrysler or GM transmissions. This makes attaching a popular GM overdrive automatic transmission a no-brainer, with no scrounging for a custom bellhousing adapter. Having a transmission built to handle the Hemi's torque will be the trick.

With its performance legacy in the rodding and drag racing worlds, it's hard to contain the excitement for a new era of Hemi hot rodding. This one promises to take Chrysler's legendary elephant engine to new heights of street performance.

History Of The Hemi

Like so many innovations to burst from Detroit in the years following World War II, Chrysler's first production "Hemi" V-8 had its roots in the war effort. Like other manufacturers, it was pressing light-duty passenger car engines into service in heavy-duty-and just-plain heavy-military vehicles. It was a compromise, at best.

During the war, Chrysler began experimenting with hemispherical cylinder head designs as a way to increase efficiency-pushing more air in and out would boost the power of an engine without the need to increase displacement. The Hemi name is derived from the hemispherical shape of the cylinder head's combustion chambers. The Hemi's design attractiveness to engineers stemmed from the domed chamber's intrinsic ability to support high compression with little worry of detonation, compared to a traditional-and more compact-wedge-type cylinder head.

The efficiency of the Hemi engine led Chrysler engineers to draw up 12- and 16-cylinder designs for tanks and planes, although none were put into production. However, a prototype supercharged V-16 aircraft engine was built and tested in a P-47 Thunderbolt fighter. The engine was inverted-the cylinder "V" pointed down while the crankshaft was on top of the engine. It produced approximately 3,000 hp.

Chrysler introduced its first production vehicles with hemispherical-head V-8 engines for the 1951 model year. The engine was dubbed the "FirePower" V-8 and was standard in the Chrysler New Yorker, Crown Imperial, Imperial, and Saratoga. The FirePower V-8 displaced 331 ci, had a 7.5:1 compression ratio, and was rated at 180 hp-a 45hp jump over the previous year's 324-inch, 135-horse eight-cylinder.

The Hemi configuration of the FirePower V-8 that was available in the '51 Chrysler line gave the company a marketing edge to use against competitors, including Cadillac's ground-breaking overhead-valve V-8 introduced in 1949. Chyrsler's 331ci FirePower V-8 featured the same displacement as the Cadillac V-8, but the Hemi V-8 enjoyed a 20hp advantage over the Caddy.

It didn't take long for the public to acknowledge the performance of the Hemi engine, and Chrysler, recognizing a product hit with greater potential, started to spread Hemi engine design through the rest of its family of vehicles. In 1952, DeSoto offered a smaller, 276ci hemi V-8 called, appropriately enough, the FireDome. It produced just 160 hp, but it still enjoyed an advantage over most of the competitors in its price field. Dodge introduced the Red Ram Hemi in 1953 and made Hemi engines a staple of its truck line throughout the '50s. The only brand left out of the Hemi revolution that decade was Plymouth, which soldiered on with conventional inline six-cylinder and eight-cylinder engines-although Plymouth did offer a "poor man's" Hemi in the form of the poly-head V-8 in 1955 and 1956, a sort-of semi-hemi that was lighter and less costly to produce.

Despite its much-heralded reputation at the beginning of the '50s, there were no production Hemi engines available in Chrysler products by 1960. They ceased production in passenger cars after the 1957 model year, and Dodge trucks stopped offering them after 1959. The reasons why the Hemi disappeared after less than 10 years on the market were simple: complexity and cost. The Hemi was a complicated and costly engine to produce, while advances in combustion technology were making the simpler wedge-head engine more efficient.

The Street Hemi

Chrysler revisited the Hemi-head design in 1964, when it introduced a Hemi-style racing engine for the NASCAR circuit. It was an auspicious reintroduction of the engine design, as 426 Hemi-powered race cars finished First, Second, and Third at the '64 Daytona 500. Richard Petty won the race, after leading 184 of the 200 laps in his Plymouth-including lapping Second-place finisher Jimmy Pardue when the race was only half done.

Not surprisingly, the immediate and obliterating success of the new Chrysler Hemi racing engine caused a stir, particularly among those racers who didn't have one under the hood. After a few more races with similar results, NASCAR moved to restrict Chrysler's not-so-secret weapon by imposing a "production model" rule. This meant that, for the 426 Hemi to be legal in NASCAR competition, it had to be offered in meaningful quantity in regular-production street cars.

Chrysler was unprepared to offer the racing-only 426 Hemi in street cars. The company sat out the '65 season while it prepared to retaliate. They returned in 1966 with the all-new 426 Street Hemi and Chrysler quickly went racing again. There was little that was significantly different between the racing engine and the street version. The Street Hemi received two four-barrel carbs (the racing version had a single carburetor), lower compression, different valve timing, and iron cylinder heads. There were a few other minor differences, but the street versions were, for all intents and purposes, simply detuned versions of what Petty was using to run rings around the competition.

In 1966, the 426 Street Hemi was rated at 425 hp (gross) and 490 lb-ft of torque. It would remain in production through the 1971 model year, with its horsepower rating unchanged. Only a handful of changes were made to the Street Hemi during its production run, including upgrades in 1968 to reduce oil consumption and a change to a hydraulic camshaft and lifters in 1970.

Street Hemi-powered cars quickly became the stuff of legend and myth at small-town burger stands and urban street-racing venues. They developed a reputation for being unbeatable-when they were properly tuned. The fact was the twin-carbureted engine, with its high compression and high-rpm performance intentions, suffered when loped around at low speeds. The carbs loaded up and the plugs often fouled. The engine required constant attention and tuning, particularly the carburetors, but when all the dials lined up, the only thing that could catch a Street Hemi was another Hemi.

Third-Generation Hemi

Development of the engine that would become the new Hemi began in the latter half of the 1990s. Chrysler engineers faced the realization that the stalwart 5.9L Magnum V-8 truck engine-an engine known more commonly by its 360ci displacement and whose basic architecture originated in the '50s-wouldn't meet the performance requirements of the coming decade. This included not only the horsepower and torque figures Chrysler needed to remain competitive with new products from General Motors and Ford, but also the federal mandates for emissions and fuel economy.

Retired Chrysler engineer Rich Schaum initially proposed the new V-8 to Robert Lee, Chrysler's vice president of powertrain engineering, in 1996, but the word "hemi" was never mentioned. As the engine would be an all-new "clean sheet" design rather than an update of existing engines, the engineering staff evaluated a variety of engine configurations. One of the favorite designs was the water-cooled flat-six engine of the Porsche Boxster that happened to have hemispherical combustion chambers.

The first new Hemi engine prototype was started ceremoniously and without a hitch, but the engine had not been officially named a "Hemi"-although its design left little doubt. The original name, given even before the decision to go with a Hemi design, was "Ram." The marketing types at the company knew better and the third-generation Hemi, like its predecessors, became an instant success when it was introduced on the '03 Ram pickup.

The Alloy Options

While the iron Hemi block is marketed by Mopar Performance, World Products offers exclusive versions in lightweight aluminum or exotic graphite. The aluminum block is virtually identical to the cast-iron version, but it features screw-in galley plugs and cast-iron cylinder liners. It is also 166 pounds lighter, weighing in at about 142 pounds-that's a huge reduction over the iron block and a better-balanced proposition for street rods.

The aluminum case is a premium piece, cast at a foundry that is renowned for its work with Formula 1 racing teams, with the cylinder liners seated with O-rings to prevent oil from squeezing up between the block and liners. It also features larger cross-valley ribs that enhance rigidity. Because the aluminum block uses iron cylinder liners, its maximum bore doesn't match the iron block's 4.600-inch maximum, but it is available with 4.500-inch bores, which still permits the creation of a 600-inch Hemi.

The admittedly expensive compacted graphite Hemi block, which is designed for the rigors of racing, offers the ultimate in strength; it's about 75 percent stronger than conventional gray iron. If you're not familiar with compacted graphite, it is an extremely dense material-with minute parts of magnesium and titanium-that offers excellent thermal properties and supreme durability. It is neither inexpensive nor lightweight, but it's just about impossible to break.

Graphite Hemi blocks come with rough 4.240-inch bores that are finished to 4.250 inches. In addition to the standard Hemi specs, we understand the graphite version will be available with a raised camshaft position, as well as a shorter 10.200-inch deck and cut-down water jackets.

While the graphite block is at home at the dragstrip, we suspect more than a few enthusiasts will be tempted to build a street-based Hemi with the admittedly exotic aluminum block. Besides a significant weight savings over the front wheels, there's an undeniable wow factor.