The days of the $1,000 engine rebuild are long gone, but you can still build a stout big-block on a budget. We didn't cut corners on this engine; we just put together a good, economical set of parts for a solid 383.

The days of the $1,000 engine rebuild are long gone, but you can still build a stout big-block on a budget. We didn't cut corners on this engine; we just put together a good, economical set of parts for a solid 383.

Back in the days before internet auction sites, before leaded fuel became extinct, and when you could still find a cool Mopar for around 500 bucks, if you spent a thousand dollars rebuilding your engine, you ended up with a solid motor that would perform well and last a long time. Times have changed, however, and these days everything costs significantly more than it did in the "good ol' days" that we remember so fondly. These days it's easy to spend several thousand dollars on a basic rebuild, and if you want big power, your engine budget can easily top twenty or thirty thousand dollars. While we all dream of running a huge stroker motor in our cruisers, the fact is most of us can't afford a big-inch stroker . . . or the gasoline to feed it for that matter. We wanted to build a respectable big-block for our '67 Barracuda Formula S clone, but like most, we didn't have a bunch of money to spend, so we chose an economical and logical set of parts from the YearOne Speed Shop to build a good-running 383.

We got the engine for this build from a '66 Monaco that we purchased some years ago from Editor Bolig's brother, Andy. Geez, Andy, did you ever change the oil?

We got the engine for this build from a '66 Monaco that we purchased some years ago from Editor Bolig's brother, Andy. Geez, Andy, did you ever change the oil?

Anytime we build an engine, we start with a core. Sometimes the core is the engine that came out of the car, and sometimes it's not. Regardless of where it came from, knowing that the engine ran prior to starting the rebuild is a good indication that the core engine is buildable. Our engine didn't come in our Barracuda, but it did come from a running '66 Monaco that we purchased from Editor Bolig's brother. The Monaco was cool, but had severe frame rust, and therefore, was only good for parts. Fortunately, the car ran and drove, showing just over 100,000 miles, had good oil pressure, and didn't overheat, so we were pretty confident the engine would be a good candidate for an economical rebuild. While finding an engine that simply needs new rings, bearings, seals, gaskets, and a quick honing like the 318 that Randy and Young Gun Darrel Kunda are putting together would be ideal, the fact is that most of these engines-especially big-blocks-have significant wear and will require a trip to the machine shop.

Once an engine is torn down, cylinders should be measured to check for excessive wear. Even without measuring, we could catch a fingernail on the ridge at the top of our cylinders. This is a good indication that the block will need to be bored oversize. Since this is the first overhaul of our standard bore block, we ordered pistons .030-inch oversized.

Once an engine is torn down, cylinders should be measured to check for excessive wear. Even without measuring, we could catch a fingernail on the ridge at the top of our cylinders. This is a good indication that the block will need to be bored oversize. Since this is the first overhaul of our standard bore block, we ordered pistons .030-inch oversized.

When we disassembled our 383, we found it to be fairly clean inside. Even so, the cylinders were worn and had a ridge at the top. Measuring the cylinders below the ridge told us that we wouldn't simply be reringing and honing this engine; it would need to be bored oversize for larger pistons. Luckily, the rest of the engine looked good. The crankshaft was within tolerances and would just need to be polished, and the main bearings didn't show any abnormal wear that would indicate a bent crankshaft. The connecting rods looked good as well, so we began cleaning our parts and planning our build. We like to clean up our engine parts first, and then purchase the new parts we'll need prior to taking our engine to the machine shop. This way, the machinist can physically measure the new pistons, ensuring the block is bored and honed to the proper dimensions. Also, since we're replacing the pistons and will rebalance the rotating assembly, the new pistons, rod bearings, and rings will need to be weighed when the balance job is performed.

To top our short-block, we chose to stick with the closed-chamber "516" casting cylinder heads that came on this engine. These heads feature a great combustion chamber, with plenty of quench area, and will give us just over 10:1 compression when matched with flat-top replacement pistons. Though the "516" heads have a somewhat small exhaust valve, we'll correct that problem by cutting the seats to the larger 1.81-inch dimension and installing a set of factory exhaust valves from a set of cracked "906" casting heads we had lying around. Since the seats will be cut for the new valve job anyway, having them cut oversize will only cost a little more and will improve power dramatically.

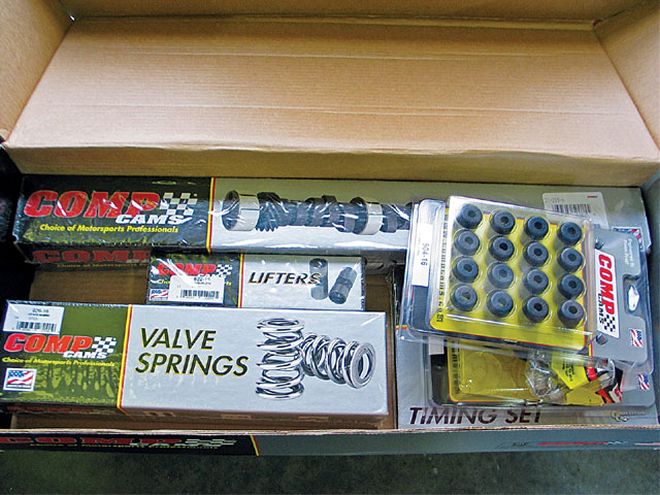

In addition to our overhaul kit, we ordered a Comp cam kit complete with timing chain, lifters, springs, retainers, and locks. We also splurged for brass freeze plugs since we plan on keeping this car for a while. Brass plugs won't corrode so they'll last longer than steel plugs.

In addition to our overhaul kit, we ordered a Comp cam kit complete with timing chain, lifters, springs, retainers, and locks. We also splurged for brass freeze plugs since we plan on keeping this car for a while. Brass plugs won't corrode so they'll last longer than steel plugs.

With our basic combination set, we picked up the YearOne Speed Shop catalog and began looking for parts. While most of us have used YearOne as a supplier of restoration products for our cars, their new Speed Shop catalog is a comprehensive listing of engine, drivetrain, and performance parts specific to musclecars. We found everything we needed for our rebuild in their catalog, and the prices were very competitive. Being budget minded, we ordered a basic rebuild kit and a Comp Cams hydraulic, flat-tappet cam kit, which included new lifters, matching springs, locks, and retainers. We also ordered the correct Mopar engine paint, freeze plugs, and all the gaskets we'd need for our 383. We had a little extra cash for this build, so we decided to spend it where it would make the most sense-purchasing a windage tray kit and upgrading to an Edelbrock Performer RPM intake and 650-cfm Edelbrock carburetor.

When our parts came in, we took our disassembled engine over to Auto Performance Engines to have the appropriate machine work completed. The block was bored with a torque plate, and the crankshaft was checked and polished. The rods were resized, and the new pistons from our rebuild kit were pressed onto them. Since replacement pistons rarely weigh the same as the factory units, we paid a little extra to have our rotating assembly balanced. The cylinder heads were cleaned and treated to a performance, multi-angle valve job and cut for the larger exhaust valves. As usual, machinist Kevin Willis treated us right and had our parts back quickly so we could assemble our 383.

Though not much more than a factory rebuild, the upgrades to our 383 didn't cost much and should boost output well above the factory horsepower rating of 325, ensuring this engine will be fun in our A-Body cruiser.