Whether you service your own ignition or need more troubleshooting savvy for road rallies and cruising, this month's lesson focuses on spark and ignition system basics. Understanding ignition fundamentals will improve your tuning skills.

Internal combustion gasoline engines require metered fuel and ignition spark at the right time. The traditional ignition system consists of a gear- or slot/key-driven conventional distributor, a distributor cap, and live wires leading to each spark plug.

Spark must be delivered at the right time. Timing is critical to complete fuel combustion and maximize the energy yield in the fuel. When the spark ignites fuel too early, the rising piston receives a counterforce. The rattling sounds of detonation, or what we call "ping," signals the ominous piston shake that results from this counterforce. Be aware: Ping also occurs when overly volatile, low-octane fuel burns across the piston's crown too quickly.

For best performance, spark begins at a precise number of degrees before each piston reaches top dead center (TDC) on its compression stroke. The time interval or duration of the spark across a spark plug's gap is relatively constant. Correct spark timing begins a specified number of degrees before the pistons reach TDC. Since spark duration is constant as engine speed increases, the ignition point must begin earlier.

Ford's Cobra Jet 428 V-8 engine rates 335 hp--when the ignition fires correctly. This high-performance classic used a breaker point ignition. The stock appearing distributor has a Pertronix breakerless (electronic) conversion, which eliminates breaker point service. A Pertronix kit works with stock or performance coils.

Ford's Cobra Jet 428 V-8 engine rates 335 hp--when the ignition fires correctly. This high-performance classic used a breaker point ignition. The stock appearing distributor has a Pertronix breakerless (electronic) conversion, which eliminates breaker point service. A Pertronix kit works with stock or performance coils.

When air/fuel ignites, the expanding gases push the piston downward. Ignition and the expansion of gases must start sooner when piston speed increases. The goal of spark timing advance is to light off the air/fuel mix in a way that allows a peak energy release--ideally, a strong downward push just as the piston crests TDC. Too early, and the piston is still rising. Too late, and the utilization of energy will be diminished.

Fuel octane plays a role as well. Lower-octane fuels are more volatile and burn quicker across the piston's crown. The energy release takes place sooner, and if timing is not retarded, the result is a counterforce, which is why ping occurs when octane is too low. One means for compensating is to retard spark timing. This may cure ping, but it also reduces the horsepower output.

Spark Advance Mechanisms

Most conventional distributors use two methods to accomplish this variation in spark timing: a centrifugal advance mechanism and a vacuum advance mechanism. Some vintage distributors, like Ford's Loadomatic type, use solely vacuum advance (in conjunction with a particular carburetor design). The late '50s and muscle car era high-performance dual-point distributors typically have a mechanical advance with no vacuum advance.

Centrifugal/mechanical advance mechanisms consist of flyweights and calibrated balance springs. The weight and spring method responds directly to engine speed. Vacuum advance, by contrast, receives signals from an engine vacuum source and advances the timing. The factory recommends a base (idle or static) timing for each engine, described in tuning literature under the vehicle's make, model, and engine type.

Ported vacuum is a high-vacuum signal available just as the throttle opens. While engine load might drop manifold vacuum substantially at part throttle, ported vacuum does the opposite. As the throttle begins to open, vacuum increases just above the throttle valve(s) of the carburetor. This is where ported vacuum receives its signal.

Of the two advance sources, the one that varies most is vacuum advance. As the throttle opens further, vacuum to the ported source drops. If timing calibration is correct, the increasing centrifugal advance takes over the spark timing. Centrifugal timing advance is now sufficient to meet the engine's needs without the support of vacuum advance.

A key wear point on older breaker point ignitions is the distributor cam. These lobes take the brunt of punishment from breaker rubbing block pressure. Over time, and especially with inadequate point lube, the lobes wear or scratch. You can polish these lobes with a Dremel, polishing pad, and quality metal polish. Often, an electronic conversion is the solution for a worn out distributor cam.

A key wear point on older breaker point ignitions is the distributor cam. These lobes take the brunt of punishment from breaker rubbing block pressure. Over time, and especially with inadequate point lube, the lobes wear or scratch. You can polish these lobes with a Dremel, polishing pad, and quality metal polish. Often, an electronic conversion is the solution for a worn out distributor cam.

On vacuum advance-only Loadomatic-type distributors, the carburetor has special passageways to provide vacuum from both the ported and venturi areas. As ported vacuum falls off, the carburetor's speed-related venturi vacuum takes over. Venturi vacuum, unlike manifold vacuum, does not drop dramatically under engine load.

Many high-performance ignition systems have only a mechanical (centrifugal) advance. Performance engines use a racy camshaft profile and higher compression. Racy camshafts provide a limited amount of manifold vacuum at lower engine speeds, and high compression does not tolerate substantial spark advance at low speeds. Such engines "come on" at higher speeds and benefit from a speed-regulated ignition--without vacuum advance.

For the typical performance engine, launch or throttle tip-in performance comes from more degrees of base or initial spark advance. This couples with a somewhat quicker response of the mechanical (centrifugal) advance. Base timing plus centrifugal advance degrees target a total number of advance degrees, achieved at a prescribed rpm. The purpose for limiting this total is to prevent detonation as engine speed continues to increase.

Primary And Secondary Ignition Systems

The secondary ignition system is easy to recognize. It consists of a distributor cap, a rotor, the coil lead, spark plug wires, and the spark plugs. The distributor cam drives the rotor, and the distributor driveshaft drives the cam.

The drive gear press fits to the bottom end of this GM distributor shaft. An interference fit, the gear holds in place with a roll pin. Some distributors call for a "spiral" type roll pin, stronger and less apt to shear. MSD supplies spiral roll pins with their high performance drive gears. Unlike Chevrolet, this Olds distributor shaft rotates counterclockwise.

The drive gear press fits to the bottom end of this GM distributor shaft. An interference fit, the gear holds in place with a roll pin. Some distributors call for a "spiral" type roll pin, stronger and less apt to shear. MSD supplies spiral roll pins with their high performance drive gears. Unlike Chevrolet, this Olds distributor shaft rotates counterclockwise.

As current flows through the coil, the rotor "distributes" spark to each spark plug contact in the distributor cap. At the correct time for each cylinder, spark crosses the gap between the rotor's tip and the spark wire contact in the cap, sending spark to each spark plug in the firing order. The intensity (voltage) of the spark and spark plug gap determine the spark's duration.

The ignition signal at the coil comes from the breaker points or an electronic ignition module. Since breaker points are common to vintage trucks, and the aims of a breakerless ignition are similar, let's use breaker points to illustrate how a primary ignition circuit works.

Think of the breaker points as an on/off switch. When they open, a crisp spark (generated in part by the condenser) jumps across the point gap. This triggers the coil to unload its built voltage, sending current through the high-tension spark wire lead to the distributor's rotor. Here, the rotor transmits that current to the available spark lead contact. The lead carries the current to its spark plug.

Depending upon the number of cylinders, this process repeats itself until each of the cylinders has fired. Then the rotor repeats the process, once again distributing spark to each cylinder in the firing order. As a point of interest, the distributor rotates at half the speed of the crankshaft. On an eight-cylinder engine, coil discharge takes place 12,000 times per minute at 3,000 crankshaft rpm--eight times for each two rotations of the crankshaft!

The Coil Winding And Signals

How does the coil build up the voltage necessary to fire a spark plug under engine compression? The coil, essentially a transformer, consists of primary and secondary windings. An ignition's breaker points are part of the "primary" coil circuit. That circuit operates on battery voltage--or less. Many 12-volt systems resist or drop the primary voltage to 9 or less volts to extend point life and keep the coil running cooler.

The circling of primary current around the fine secondary wire within the coil creates a magnetic line of force. (That force moves away from the coil's iron core.) The field builds until it is interrupted by the opening of the breaker points. Essentially, the circuit interruption redirects the magnetic field's line of force. This interruption causes a surge of voltage from the high number of fine secondary wire winds. The surge moves inward to the soft iron core of the coil.

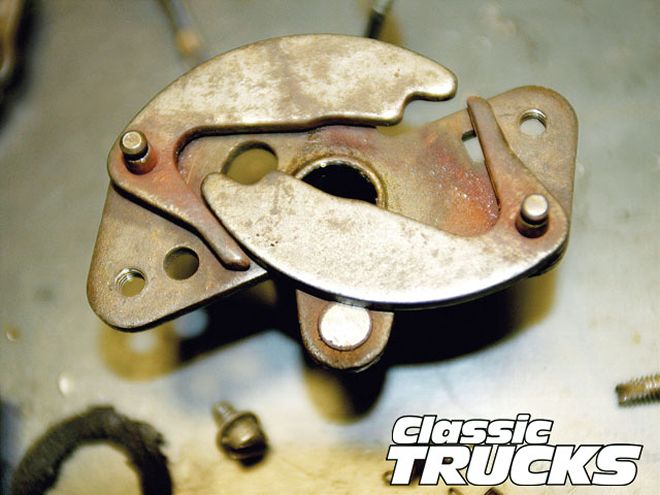

These centrifugal flyweights and return springs have the right calibration for this engine. Polish used weights to assure free movement. GM window cap and HEI distributors feature centrifugal advance beneath the rotor, accessible and easy to service or modify. This was another ingenious Delco-Remy feature. In 1956, Cadillac pioneered the window cap distributor, followed quickly by other GM divisions.

These centrifugal flyweights and return springs have the right calibration for this engine. Polish used weights to assure free movement. GM window cap and HEI distributors feature centrifugal advance beneath the rotor, accessible and easy to service or modify. This was another ingenious Delco-Remy feature. In 1956, Cadillac pioneered the window cap distributor, followed quickly by other GM divisions.

Summed up, the magnetic line of force builds while the points are closed. We call these distributor degrees "dwell." On a breaker point ignition, the dwell period is also referred to as the distributor "cam angle." This is the number of cam degrees between the point set closing and reopening again. The primary (battery or resisted) voltage moves slower around the fine wire of the coil's internal secondary winding. As the points open, the abrupt change in the magnetic field's force sends the high voltage of the secondary winding into the soft iron core of the coil.

The iron core takes the spiked voltage and sends it to the high-tension spark wire that connects the coil to the distributor cap. This voltage can range to 25,000 volts in an original breaker point coil, 50,000 volts or more in an HEI ignition. The rotor now delivers spark to the aligned spark wire contact in the distributor cap. In turn, spark travels through each spark lead to its spark plug. This spark is sufficient to fire across the spark plug gap under high cylinder pressures.

In this whole process, the coil becomes very hot. One means of cooling the coil is oil. An "oil-filled" coil is much like an oil-filled transformer; the oil serves as a coolant. Also critical to cooling is the resistor or "ballast resistor." Six-volt ignitions do not generate excessive heat at lower engine speeds--but 12 volts may.

To compensate for the hotter coil temperatures at lower engine speeds, the resistor on a 12-volt system lowers the available voltage to the primary winding of the coil. As the engine speed increases, along with quicker coil firing cycles, some types of resistors cool slightly. This raises the primary voltage, providing higher spark plug firing voltages at higher engine speeds.

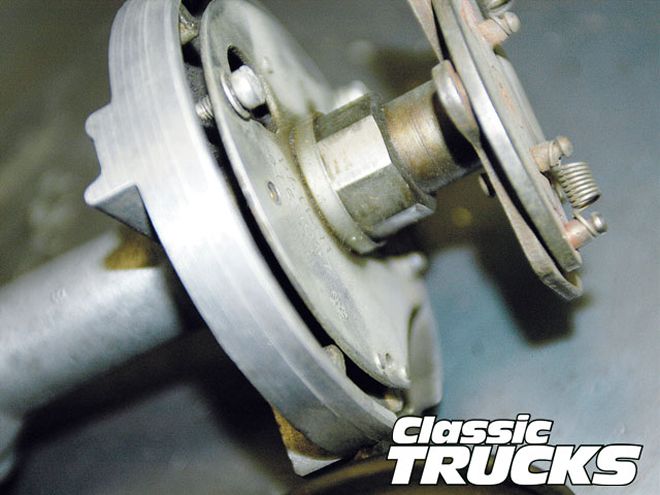

This is a well-worn distributor drive tang. The tang is actually loose on the shaft! The pin facing downward fits a slot in the moveable distributor cam assembly. The width of the slot controls the total number of centrifugal advance degrees. For high-performance tuning, a nylon bushing often fits on this pin, serving as a "limiter" bushing to reduce total degrees of centrifugal advance.

This is a well-worn distributor drive tang. The tang is actually loose on the shaft! The pin facing downward fits a slot in the moveable distributor cam assembly. The width of the slot controls the total number of centrifugal advance degrees. For high-performance tuning, a nylon bushing often fits on this pin, serving as a "limiter" bushing to reduce total degrees of centrifugal advance.

The Importance Of Proper Ignition Tuning

The breaker points need the correct gap and dwell settings to provide the coil with sufficient primary current. Too narrow a gap, and the points will arc and burn out prematurely. Too wide, and the dwell will not be long enough to saturate the coil properly. Ideally, points should always be set with a dwell meter, using the factory recommended dwell setting.

A contributor to breaker point life is the condenser. If the condenser is defective, when the points open to interrupt the current flow through the primary circuit of the coil, current will arc across the point gap. To prevent point arcing, the condenser stores current then sends that current backward against the primary winding to aid in the coil's rapid collapse of the magnetic field and line of force.

Points, condenser, rotor, and spark plugs have been traditional tune-up parts. For breaker point and HEI distributors, there is also periodic distributor cap, rotor, spark wire, and spark plug replacement. The HEI or electronic ignition module is a somewhat common replacement part as well. With a better understanding of how the ignition system functions, troubleshooting and tuning will be much easier.

Yes, this is the same distributor after complete restoration. The rest of the ignition should include a premium coil, spark plug wires, and spark plugs. Test the ballast resistor for reliability. The primary ignition includes the ignition switch and any other resistance points between the battery and coil. On a negative-ground vehicle, turn the key to "ON" and check resistance from the solenoid junction to the positive terminal of the coil. Inspect primary wires for loose connections and fraying.

Yes, this is the same distributor after complete restoration. The rest of the ignition should include a premium coil, spark plug wires, and spark plugs. Test the ballast resistor for reliability. The primary ignition includes the ignition switch and any other resistance points between the battery and coil. On a negative-ground vehicle, turn the key to "ON" and check resistance from the solenoid junction to the positive terminal of the coil. Inspect primary wires for loose connections and fraying.

What Did You Learn This Month?

Night School wouldn't be complete without a quiz! Don't worry about your test-taking skills or grades, this is an open-magazine, true or false test. Answers can be found in the Night School text, photos, or captions. Have a good month!

True or False Questions:

* Ping is the sound of pistons rattling against the cylinder walls, caused by low-octane fuel or too much spark timing advance.

* All conventional distributors have both a vacuum and centrifugal advance.

* Ported vacuum and manifold vacuum are always equal.

* Breaker point dwell is the same thing as cam angle.

* Dual-point systems increase dwell angle without premature point wear.

* A ballast resistor helps reduce the coil temperature.

* If the distributor's cam lobes have too much wear, an electronic conversion may be the best fix.

* A defective condenser will cause hard starting, reduce spark output and cause premature points failure.

* One useful troubleshooting tool is a volt-ohmmeter.

* A cheap roll pin from the hardware store is good enough for a distributor drive gear.