E-Mail: Pitstop@Hotrod.Com • Mail: Hot Rod Pit Stop, 6420 Wilshire Blvd., Los Angeles, Ca 90048 • Fax: 323/782-2223 • Message Board: Hotrod.Com

As we get into August's hot summer nights, we hope your hot rod is bookin', not cookin'; that your ignition is sparkin', not fryin'; that the engine is pourin' it on, not packin' it in. But if you do have a problem, we're here to help. Send in your tech questions and I'll answer as many as we have room for. When e-mailing, don't forget to include Pit Stop in the subject line, as well as your real full name and town or military unit, base, or ship in the message. If you have quality digital photos of the car or problem, and if they're at least 1,600x1,200 pixels or larger in size (the larger the better), we may throw them in as well. -Marlan Davis

Holley Blower Carbs

Why is it that in articles about Roots-supercharged engines, rarely, if ever, is there any mention besides the usual "topped by a pair of Holleys?" What mods or tuning needs to be done to the carbs to run them on a 6-71 or 8-71 blower? I know that boost- or manifold-referenced carbs for these apps are now made, but blowers have been around for years before these specific carbs came around.

Sil Sichirollo

Calgary, Alberta, Canada

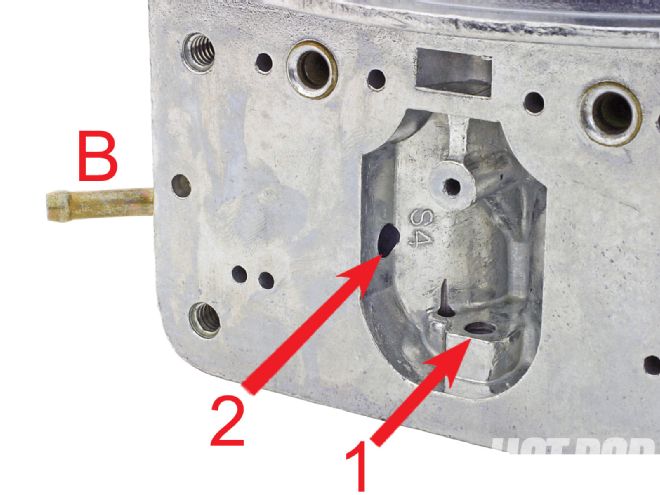

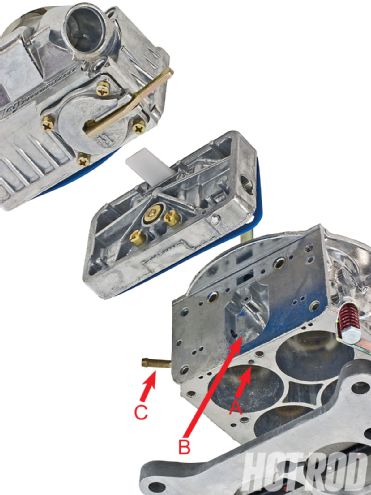

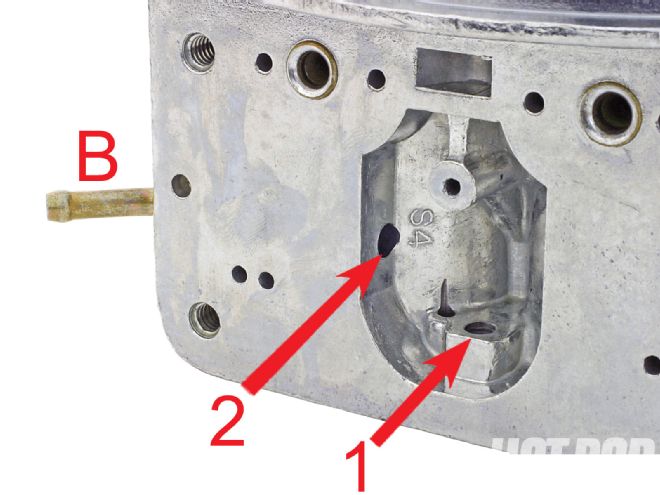

This current Holley supercharger carb, a 950-cfm double-pumper (PN 0-80577S), is typical of the breed. The original main body vacuum passage to the power valve is plugged with a lead ball (A). In the main body's power-valve channel (inset), the original passage (1) at the bottom of the well is no longer active. Instead, a new passage (2) is drilled through the side of the channel that leads to an external nipple (C), which accepts a hose routed from a vacuum source below the blower case.

This current Holley supercharger carb, a 950-cfm double-pumper (PN 0-80577S), is typical of the breed. The original main body vacuum passage to the power valve is plugged with a lead ball (A). In the main body's power-valve channel (inset), the original passage (1) at the bottom of the well is no longer active. Instead, a new passage (2) is drilled through the side of the channel that leads to an external nipple (C), which accepts a hose routed from a vacuum source below the blower case.

Until carbs specifically calibrated for supercharger use were introduced, making a car driveable on the street was an iffy proposition. The biggest problem was the power-valve signal. A Holley carb's power valve is essentially a normally open, spring-loaded valve that is held closed by vacuum. When engine vacuum drops to a point where the spring overpowers the vacuum signal, the valve opens. For example, a 65 power valve opens when vacuum drops below 6.5 in-hg.

Unlike a naturally aspirated engine, a supercharged motor constantly sees vacuum under the carburetor (due to suction generated by rotor rotation within the blower case)-so the power valve never opens, causing a lean condition under heavy-throttle conditions. Back in the day, the crutch was to remove the power valve and jet up six to eight sizes. That worked well under full-throttle but caused the engine to be excessively rich at part-throttle and cruising speeds.

Some aftermarket carburetor modifiers began reworking the Holley's internal passages to reference the power valve to the intake manifold below the blower case, an innovation eventually incorporated on the production line by Holley in its supercharger-specific carbs. Under heavy acceleration or wide-open-throttle conditions, the power valve now sees boost and opens as it should because there is no vacuum holding it closed.

Supercharged engines obviously have higher fuel demands than an equivalent naturally aspirated engine, so Holley blower carbs are also jetted a little richer to accommodate the added demand. Some Holley supercharger carbs may additionally have different idle-feed restrictions and/or air bleeds to help accommodate the extra fuel demand.

All these mods are typical of Holley's line of supercharger carbs, which, as Holley engineer Jay McFarland puts it, are "designed so a customer can essentially bolt it on and go without having to do modifications."

Meanwhile, carburetor modifiers have continued to enhance their own proprietary blower carbs. For example, the supercharger specialists at Blower Drive Service (BDS) offer a whole series of supercharger carbs keyed to specific engines, camshafts, and applications. According to BDS owner Craig Railsback, "It's like building a wall. A 10-foot wall needs a certain level of foundation to support it. A 20-foot wall needs a higher level."

BDS recommends its Stage 1 supercharger carbs for those running cams with 220-230 degrees duration (at 0.050-inch tappet lift) or 270 degrees advertised duration. Standard carbs tend to be over-rich at idle, so BDS initially addresses the idle and transition circuitry. "The accelerator pump must also be addressed," Railsback adds. "You need to maximize the pump stroke, and bigger cams call for bigger shooters."

BDS Stage 2 carbs are applicable to cams with 250-260 degrees 0.050 duration or 290-310 degrees advertised duration. The idle bleeds and high-speed air bleeds are machined and reworked. The choke horn is milled off. New, separate, intermediate circuits are added, calibrated for the actual application the carb will be installed on. The engine displacement, boost level, fuel type and octane, vehicle profile and use, transmission, converter stall speed, rear-gear ratios, overall vehicle weight, vehicle operating altitude, and tire size all factor in to the equation, but the bottom line is BDS feels the additional circuit enhances reliability and fuel economy on vehicles that are occasionally street-driven.

Stage 3 carbs are preferred when running cams over 270 degrees at 0.050 or 310 degrees advertised. At this level, BDS' hard-core carb mods are intended for all-out competition only, with no pretense of fuel economy. Every factor has been taken into consideration. The carb is completely blueprinted, the circuits are qualified, and any manufacturing defects are corrected. The power valves are boost-referenced. Larger needle and seats are installed. Other mods suited for the individual applications are added as needed.

Lincoln Flathead V-12

My dare-to-be-different engine is a '48 Lincoln 292ci Flathead V-12. I'm building for mainly street use and need a bit of help deciding what to do. I'm assuming I'm stuck with the original insides, crank, and cam, since aftermarket sources are few. Maybe you know of some?

I also have some specific questions: The original lifters are hydraulic. Could these be upgraded to something newer and not hurt the cam?

I'd like to replace the ancient dual-point ignition and coil assembly. A crank trigger would seem to be an answer, but the engine is an odd-fire with a 75-degree cylinder block-bank angle. Could two triggers, one for each bank, be installed, or is there an easier solution?

Assuming the ignition problems are solved, how could additional crank pulleys and brackets be added for power steering, air conditioning, and maybe even a supercharger? There is a large spacer between the generator (which has been replaced by an alternator), water pump pulley, and the mechanical vibration damper.

The original exhaust is quite restrictive with 180-degree bends. Where do I find header flanges, or do I just need to weld my own? I would probably need O2 sensors.

The two-barrel carb allows only a few cfm. Do you think it practical to build a fuel-injection manifold? What kind of computers would work for all of this?

What other advice do you have for problems I haven't anticipated? Jim Harries Portland, OR

Advantages of the Lincoln Flathead V-12: It's different and looks unique. On the other hand, there are plenty of disadvantages: Parts (where available) must be ferreted out from a variety of sources, it's hard to cool, and, in the opinion of flathead engine builder Dave Tatom, the Lincoln "won't make power and torque-it's the worst motor." The Lincoln has decent rods and bearings, Tatom says, "but you need a bigger oil pump. The Melling M-15 is what we recommend. It's still made-and we have 'em." Tony Baron is another engine builder who can tackle your Lincoln. According to Baron, the heads are the biggest bottleneck: "In stock form, they just don't breathe.

Tatom also manufactures custom pulleys and headers. Off-the-shelf headers that fit the '40-'48 Lincoln Continental and Lincoln Zephyr 292/305ci V-12 engines are under development by Red's Headers. Roadrunner Engineering is yet another source for custom pulleys. You could also have the Lincoln water pump converted to accept a small-block Chevy-type water pump hub. This would permit the use of all sorts of commonly available custom pulleys. A good aftermarket water pump rebuilder should be able to handle this makeover. ASE Industries is one possible source. It is also feasible to modify the stock crank snout to accept a small-block Chevy harmonic damper.

Many internal engine parts are still available through Egge Machine. The company offers overhaul kits and pistons. Most bearing sizes are available. New stock rods are hard to come by; the original rods can be reconditioned at least once. The stock crank can be reground. If you really have bucks, custom billet rods and cranks as well as custom forged pistons are doable from the usual aftermarket sources.

There are no new cam billets available for this engine. Tatom, Egge Machine, or Schneider Cams can regrind the existing cam into a performance profile. No new-design hydraulic lifters can be made to work in the Lincoln, but the existing hydraulic lifters can be reconditioned. Alternatively, if the cam will be reground anyway, have it turned into a mechanical profile and use readily available flathead Ford V-8 mechanical lifters (requires periodic lash adjustments). Once converted to a solid cam, the Lincoln accepts most flathead Ford valvetrain parts, including the valvesprings.

Electromotive can supply electronic ignition and engine-management systems. These are distributorless, crank-fired multicoil setups that are PC-reprogrammable. To run only the ignition with conventional carburetion, use its XDI-2 system. Set it up for an even-fire V-12, then go into the software's trim control and offset the second bank by 15 degrees. For full electronic fuel injection, use Electromotive's Tech 3R ECU. Naturally, these modern products require a 12-volt electrical system.

By definition, sheetmetal intakes are a custom job, so (again, if your wallet is deep enough) it's no problem to get a custom sheetmetal intake from outfits such as Wilson or Hogan. This is the preferred solution for individual-nozzle, direct-port EFI.

Another fuel-injection alternative that preserves the classic retro look is available from Retrotek Speed, which offers Stromberg 97-like fuel-injection throttle bodies in single or multiple configurations. The nozzles mount in the throttle bodies instead of individually on the intake runners. A setup like this works with existing Stromberg intakes.

Speaking of Stromberg, a modern rendition of the classic three-bolt Stromberg 97 carb is now available from Barry Grant: its Demon 98. New, genuine Strombergs are being built again by Stromberg Carburetor. To mount three-bolt Stromberg-type carbs (or look-alike throttle bodies), both Ken Austin's Rod Shop and Empire Motors offer two-, three-, or even four-carb manifolds. Austin also has GMC blower intakes and even a single four-barrel Holley manifold. Empire manufactures new '36-'48 Lincoln V-12 replacement aluminum cylinder heads; they're offered with or without fins, in either a textured or polished finish.

Where Do I Get...

Information on how the engine oil lubrication system is designed and routed through the engine; also, how the cooling system is designed and routed?

Danny Pitts

Detroit, MI

Modern Automotive Technology (Sixth Edition) by James E. Duffy (ISBN 978-1-59070-186-7, published 2004) provides an excellent overview of all automotive systems and technologies, including the cooling and lubrication systems (Goodheart-Wilcox Publisher; Tinley Park, IL; 800/323-0440 or 708/687-5000; www.g-w.com). Want to dig deeper? Automotive Cooling System Basics by Randy Rundle (ISBN 0873416805) is geared to hot rodders and restorers; although currently out of print, used and new copies can usually be located using Amazon .com's locator service. The definitive work on automotive lubrication systems is Wilfried J. Bartz's 832-page Engine Oils and Automotive Lubrication (ISBN 9780824788070; Cat. No. DK4671), published by CRC Press (Boca Raton, FL; 800/272-7737; www.crcpress.com). But get out your wallet-it'll set you back $279.95!

...aftermarket parts for an '02 T-bird, including wire wheels, a performance exhaust, and maybe even a Continental kit? Bill Ward Porter, IN

All these parts are available from Thunderbird Concepts (Shelter Island, CA; 800/206-1966; www.thunderbirdconcepts.com).

...a kit to install a small-block 327 Chevy engine in my '90 Jeep Wrangler? Will the stock Chrysler automatic trans bolt up? Alan Greenburg Warwick, RI

Advance Adapters (Paso Robles, CA; 800/350-2223 or 805/238-7000; www.advanceadapters.com) offers a Chevy V-8 into '87-'95 Jeep Wrangler bolt-in engine-mount kit (PN 713087). Hook your pre-'86 internally balanced Chevy V-8 to the Chrysler automatic using Advance Adapter kit PN 716131-A. Advance also offers radiators and other ancillary parts for this swap.

...the sending unit (aka the black-box) for an old Sun tach? eBay is just too much hassle for this old man to fool around with. Lyle Barringer Sammamish, WA

Williamson's Instrument Service (Chester, AR; 479/369-2551; www.williamsons.com) services and restores old Sun tachs and components. It can convert Sun two-piece tachs to solid state so they no longer need the hard-to-find, expensive, and environmentally unfriendly Mercury 1.35-volt batteries. The tach can be made compatible with any modern ignition system. If desired, the separate black box shell can be preserved; alternatively, everything can be made to fit within the tach body itself.

'50-'64 Ford Pickup Disc Brakes

Can you tell me how to put disc brakes on a '50-'54 Ford pickup? Does someone make spindles so I can adopt junkyard parts?

Skip Kinnan

Moreno Valley, CA

The early Ford pickups have a straight front axle with kingpin-style steering knuckles; no late-model knuckles will fit. Instead, aftermarket conversion kits available for these vehicles from Classic Performance, ECI, and Master Power use custom brackets and different wheel bearings to adopt late-model factory disc brake calipers and rotors to the original steering knuckles. Major parts like the rotors and calipers can come from the wrecking yard, the local auto parts store, or directly from the aftermarket bracket source as part of a comprehensive kit. A sanitary conversion should also include upgrading to a modern dual master cylinder and proportioning valve.

One of the most comprehensive series of options is available from Classic Performance. It offers conversion kits for the stock Ford truck 5-on-5 1/2-inch wheel bolt circle, the Ford passenger-car 5-on-4 1/2-inch pattern, or the GM 5-on-4 3/4-inch pattern. Camaro/Firebird (or equivalent) '70-'76 calipers (Hollander Salvage Yard Interchange No. 122) and '70-'78 rotors (Hollander 1452) are used on the 5-on-4 3/4 conversion, which also requires size A2 outer wheel bearings, A13 inner bearings, and 8871 bearing seals. The same Camaro calipers plus '76-'80 Chrysler 11-inch-od Aspen/Volare rotors (Hollander 1467) are used for the 5-on-4 1/2 conversion, along with A2 outer bearings, A17 inner bearings, and 94065 bearing seals. The 5-on-5 1/2 Ford truck pattern kit uses '73-'93 Ford F-100/F-150 two-wheel-drive rotors (Hollander 1448), '71-'87 GM 1/2-ton two-wheel-drive truck (or equivalent) calipers (typically, Hollander 116 or 267), A2 outer bearings, A13 inner bearings, and 4148 bearing seals.

Classic offers three types of kits: a basic bracket kit for those end users who want to procure the preceding major parts themselves; a disc brake wheel kit that includes all necessary mounting brackets, rotors, calipers, brake hoses, and ancillary hardware; and a complete disc brake kit that includes everything in the disc brake wheel kit plus a modern dual master cylinder, a power booster, and a proportioning valve. Exact part numbers vary per kit type, options, and model year. All kits include comprehensive, step-by-step, illustrated instructions, most of which can be downloaded in PDF format from Classic Performance's Web site so you know what you're in for before shelling out the bucks.

If you want to procure your own master cylinder and proportioning valve, a good starting point would be a '68-'70 Mustang big-block disc brake manual master cylinder or power brake master cylinder and vacuum booster. These more or less bolt to the firewall but may require brake pedal pushrod mods. Wilwood is one source for an adjustable proportioning valve (Wilwood PN 260-8419 or equivalent). Custom brake line fabrication will be necessary. Preserving rear brake light functionality with a late-model master cylinder may require installing an inline brake light switch.

Dropped Spindles For The Maverick

I have a '75 Maverick with a V-8. I'd like to put dropped front spindles on it. Does anybody offer such a part?

Laura Barnard

Via fax

Fat Man Fabrications lists 2 1/2-inch dropped spindles specifically for classic '60s Ford musclecars. It turns out these spindles use '75-'80 Grenada or '73-'77 Maverick disc brake parts. The ball-joint taper never changed, so they'll also fit your Maverick. Conversely-for those who desire to "go the other way"-it's practically a bolt-in swap to install the Maverick disc brakes onto the earlier classic Ford musclecars using your stock Maverick disc brake spindles or the equivalent aftermarket dropped spindles.

Hopping The L29 454

Like many late-model tow rigs, my '99 K2500 Suburban is equipped with the L29 454. I would like to know what modifications are needed to help make even more horsepower and torque. There's gotta be something out there to help me keep up with the Duramax diesel tow rigs. I currently have a Wait4me Performance tune, which really did wake up performance, but I still feel there is a lot to be had from the big-block Chevy derivative.

It already comes with 2.75-inch factory duals and supposedly some pretty decent-flowing heads. What else is needed to really wake up this sleeping giant?

Thomas Martin

Darien, WI

Tony Knight at the Cylinder Head Exchange, a Southern California core bank, reports that the L29 Gen VI big-block engine's heads (casting No. 241 or 279) are pretty decent; the intake runners are back to the large oval-port configuration, the kidney-shaped chamber is a high-swirl configuration, the D-shaped exhausts have a slightly raised floor (although standard exhaust manifolds and headers still bolt on), and both intake and exhaust ports also have a decent shortside radius. Nevertheless, a little bowl work and port cleanup could be worth up to 40 lb-ft. (Note that for retrofit applications these heads won't clear most standard big-block pop-up pistons.)

The factory dual exhaust system only has dual pipes going into the muffler, with a single outlet. Consider having a good exhaust shop fabricate a true dual-pipe system all the way back utilizing a couple of big Flowmasters.

On the inlet side, upgrade the air filter and inlet tract with a K&N Generation II 57-series FIPK performance intake kit. This kit upgrades the entire filter, airbox, and inlet tract assembly and is said to be worth 21 hp at 4,078 rpm.

With the induction and exhaust sorted out, it's time for a cam upgrade. Your Suburban isn't exactly a lightweight, so you'll want to go easy in this department. Crane's PowerMax hydraulic roller cam (PN 168725, see spec table) is a good all-around choice, delivering much stronger low- and midrange torque compared with the stocker. Install the cam with its Crane-recommended valvetrain parts: PN 99896-16 valvesprings (the GM stockers are pretty weak), PN 99955-16 retainers, PN 99098-1 valve locks, and PN 13628-16 3/8-inch-od chrome-moly pushrods. You may also need to convert to an adjustable valvetrain: Crane full-roller extruded-billet aluminum rockers (PN 13750-16), along with a screw-in adjustable rocker-arm stud kit (PN 99152-16, no machining required).

This Crane cam is also compatible with a supercharger-which is the ultimate upgrade. ATI Procharger offers a kit for the L29 (PN 1GG202-SCI). It uses a P-1SC centrifugal supercharger and an included intercooler. Running 8-9 psi boost, you should see a 60-65 percent power gain.

L29 454 HYDRAULIC ROLLER CAM COMPARISON

Lift values are in linear inches. Other values

are in crankshaft degrees (except LSA, which is in camshaft degrees).

VENDOR

PN

APPLICATION

OR

GRIND NO.

DURATION

AT 0.050-INCH

TAPPET LIFT

VALVE LIFT

(1.7:1 ROCKER

RATIO)

LOBE

CENTERLINE

LSA

Intake

Exhaust

Intake

Exhaust

Intake

Exhaust

GM

12552296

Stock '99 L29 K2500, except leaded fuel

204

209

0.480

0.483

108

112

110

Crane

168725

HR-214/325-2S-12 IG

214

220

0.553

0.564

107

117

112