The 5.3L truck engine has been overlooked for too long. We bolted on an intake, a carb, headers, a set of ported heads, and a small cam and made as much as 460 hp from a 325ci engine.

The 5.3L truck engine has been overlooked for too long. We bolted on an intake, a carb, headers, a set of ported heads, and a small cam and made as much as 460 hp from a 325ci engine.

With all the hype about the Gen III LS1 and 6.0L engines, a little 5.3L engine has appeared in well over a million GM trucks since 1998 that's been overlooked in the rush to make horsepower. This engine displaces a mere 325 ci, but what it lacks in displacement, it more than makes up for in horsepower efficiency. Over the years, we've heard about several low-dollar 5.3L truck engines that made excellent power with only a few minor changes, so we thought we'd try our own version and see what happened. We were pleasantly surprised when this basically stock engine made well over 430 hp with just a cam change. But there's much more to this story, so let's get to it.

The Truck 5.3L

The basic 5.3L Gen III engine began its production life in 1999. In its base form, it comes as either an iron-block LM7 5.3L or an LM4 aluminum blockversion appearing in GM light duty pickups, Suburbans, Yukons, and vans, which means there are literally thousands of these used engines now in boneyards. The original LM7 5.3 is basically an iron-block LS1 engine with a smaller 3.78-inch bore (the 5.7 is 3.89-inch) rated at between 285 and 295 hp and 325 to 335 lb-ft of torque in stock GM trim. These engines also share the 5.7L's 3.622-inch stroke, and some enterprising car crafters have built an iron-block 5.7 merely by boring the block to the 5.7 bore dimension and using a 5.7L rotating assembly (the cranks are different due to piston weight). The stock 5.3L comes with a decent 9.5:1 compression ratio right out of the box and uses essentially the same cylinder head as its larger LS1 cousin, but with a smaller combustion chamber.

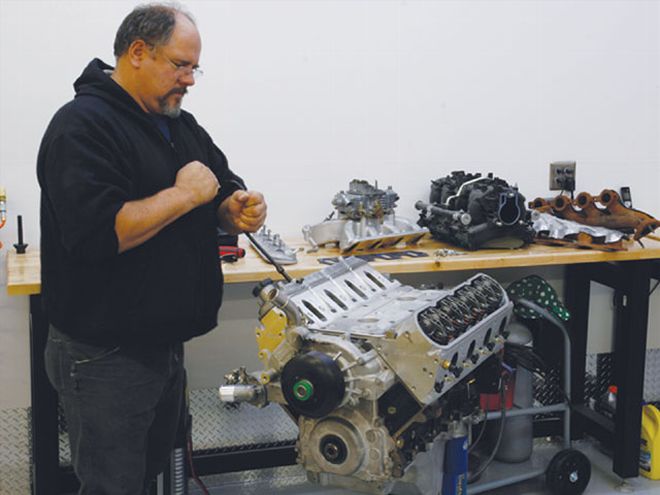

Finding a 5.3L Gen III iron block engine that's been orphaned from a wrecked truck is not difficult. Note how this engine is missing one coil and plug wire.

Finding a 5.3L Gen III iron block engine that's been orphaned from a wrecked truck is not difficult. Note how this engine is missing one coil and plug wire.

GM also built a smaller number of LM4 5.3L engines that are aluminum- block duplicates of the LM7. Thisversion got an inkling of recognition as the original engine for the '04 SSR truck. Otherwise, it is exactly the same as the iron-block 5.3L engine and you can expect to pay more if you find one. Then, just to make things interesting, GM upgraded these engines to a Gen IV configuration in 2005, although they still shared much of the same Gen III architecture. The most plentiful Gen IV iron-block 5.3L is the LH5. There's also the LY5 aluminum-block variation. This engine is rated at 320 hp stock with 340 lb-ft of torque.

Identifying these engines is easy. Look first for the tall plastic intake manifold and then find the 5.3 cast into the block on a pad near the back. But be careful. Many light-duty trucks came with smaller 4.8L (293ci) engines. If the engine is still in the vehicle, look for the emissions decal under the hood. But even that isn't a guarantee. The beauty of the 5.3 is that there are so many of these engines out there, buying one with minimal mileage in good shape for an affordable price shouldn't be difficult. We found ours at a junkyard and landed the engine for $550 without the plastic truck intake manifold and the accessory drive. We also got the starter motor, water pump, coil packs, and flexplate.

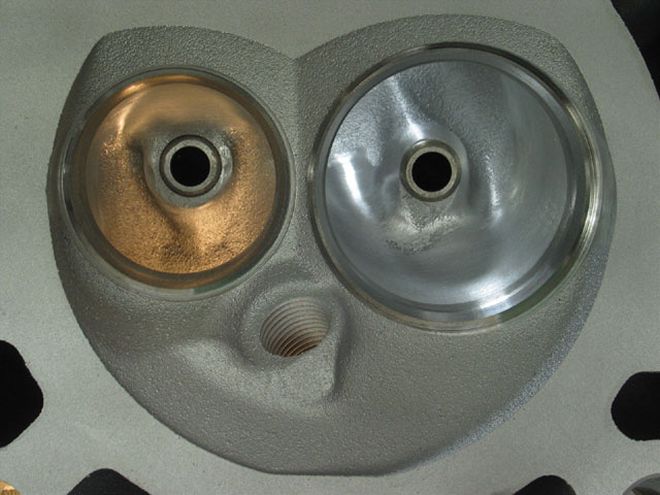

The stock 5.3L head is virtually a clone of an LS1 casting using smaller valves. Richard Reyman at West Coast Racing Cylinder Heads pocket-ports the intake and exhaust to Stage 1 specs with slightly larger valves while leaving the chamber stock.

The stock 5.3L head is virtually a clone of an LS1 casting using smaller valves. Richard Reyman at West Coast Racing Cylinder Heads pocket-ports the intake and exhaust to Stage 1 specs with slightly larger valves while leaving the chamber stock.

Talking Heads

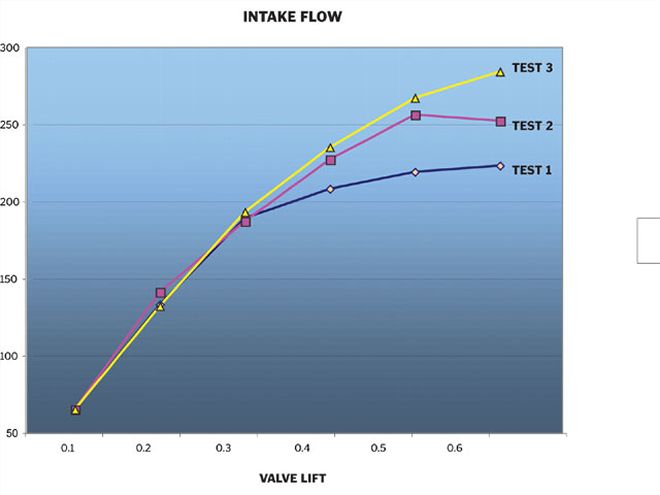

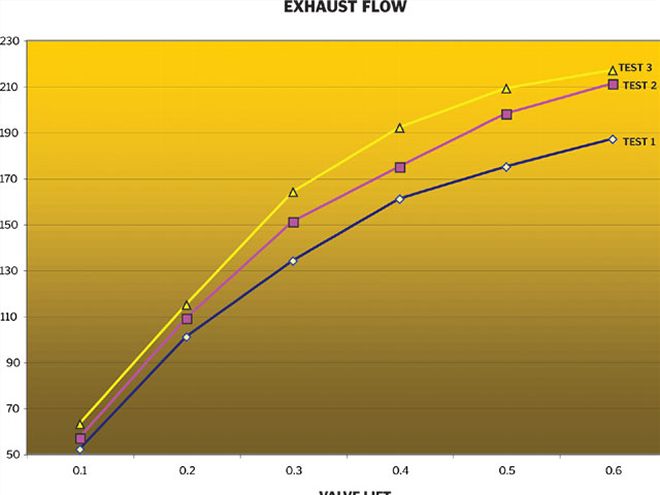

You've probably already skipped ahead to the dyno test numbers, so you know how well our little junkyard dog performed with just a cam and head swap. As we mentioned earlier, the big reason a stock 5.3L does so well with just a cam change is all due to the heads. A stock 5.3L cylinder head uses a similar port configuration to a 5.7L LS1 engine with a slightly smaller (1.89- vs. 2.00-inch) intake valve. As you can see by our flow numbers, even a stone stock 5.3L casting can produce 219 intake cfm at 0.500-inch valve lift. That is more than most production Gen I heads (except for the iron Vortec). On the exhaust side, the story is even better. The stock 5.3L exhaust-port numbers are far higher than all Gen I production heads. In fact, you have to get into expensive aftermarket Gen I heads in order to better the stock exhaust-port flow on this 5.3L head. This is the main reason why this engine makes such good horsepower at the higher engine speeds.

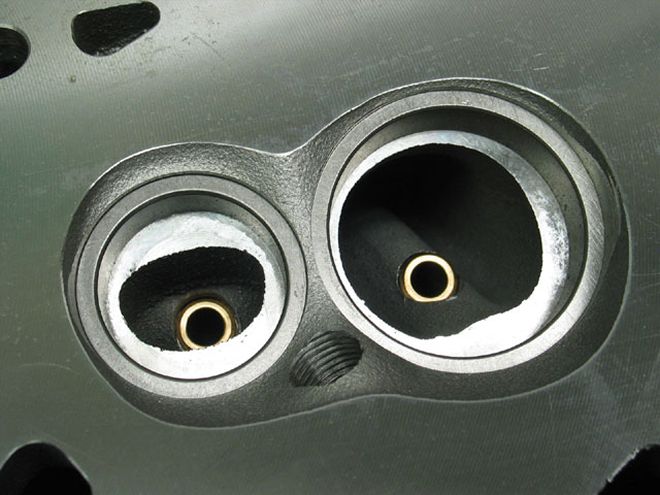

Reyman buys semifinished Edelbrock castings for his fully CNC-machined 200cc version. The ports are purposefully tiny and the bowls are almost nonexistent to give Reyman plenty of room to create his own CNC port.

Reyman buys semifinished Edelbrock castings for his fully CNC-machined 200cc version. The ports are purposefully tiny and the bowls are almost nonexistent to give Reyman plenty of room to create his own CNC port.

While doing our research, we ran across Richard Reyman's West Coast Racing Cylinder Heads company, which has been quietly working on porting the stock 5.3L cylinder heads. He hand-ports the intake and exhaust bowls and adds slightly larger SSI 1.94/1.57-inch valves. As you can see from our flow bench reports, Reyman's deft touch with the grinder combined with larger valves is worth impressive gains throughout the entire lift curve with a massive intake port flow gain of 37 cfm at 0.500-inch lift to 256 cfm. That's roughly the equivalent flow to a high quality aftermarket Gen I head. Remember, this is just larger valves and a bowl job on otherwise stock heads. On the exhaust side, he gains an impressive 23 cfm for a total of 198 cfm from 175 cfm stock. Those are outstanding exhaust flow numbers.

Before the first head hits the CNC machine, Reyman designs the ports on a solid modeling computer program. Once the ports are perfected, the program is loaded into his CNC machine and then the fun begins.

Before the first head hits the CNC machine, Reyman designs the ports on a solid modeling computer program. Once the ports are perfected, the program is loaded into his CNC machine and then the fun begins.

But Reyman doesn't stop there. He also sells CNC ported heads, which start out as a semi-finished Edelbrock casting and are whittled out using 2.00/1.57-inch valves and a 58cc chamber. All this work pushes the flow up to an impressive 267 cfm at 0.500-inch lift when tested on a 3.780-inch 5.3L bore size. Compared to the stock head, this is a significant gain of 48 cfm (22 percent) at 0.500-inch lift, but the gains are also evidenced again throughout the entire lift curve. Once we evaluated all three sets of cylinder heads, it was time to bolt 'em on the engine and see what they would do.

Evaluation Day

After dragging the used 5.3L truck motor out of the boneyard, dyno guru Ed Taylor stripped and cleaned the long-block and then set it up with a GM Performance Parts single-plane carbureted intake manifold along with a new set of Fel-Pro intake gaskets to seal the carb'd manifold. On top we opted for one of Ed's dyno mule 750-cfm mechanical-secondary Holley carburetors. If you read last month's story on the MSD ignition box, you know how easy the ignition was to set up. We plugged in the sensors and the coil packs and we were ready to go. We bolted on a set of Hooker 13/4-inch coated headers that are actually designed as engine-swap headers for a Gen III engine in an early Camaro.

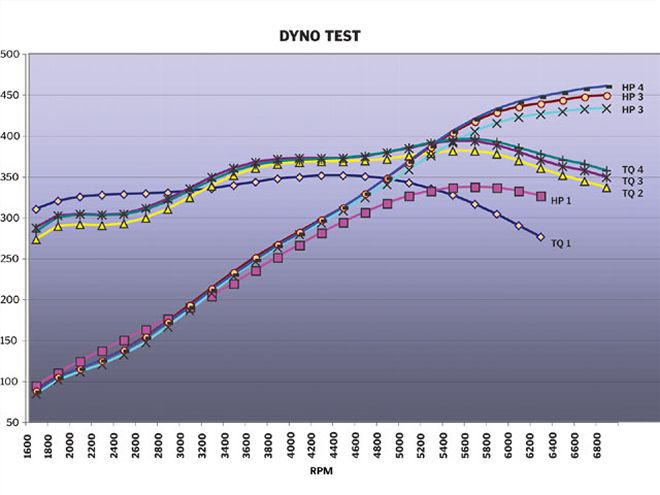

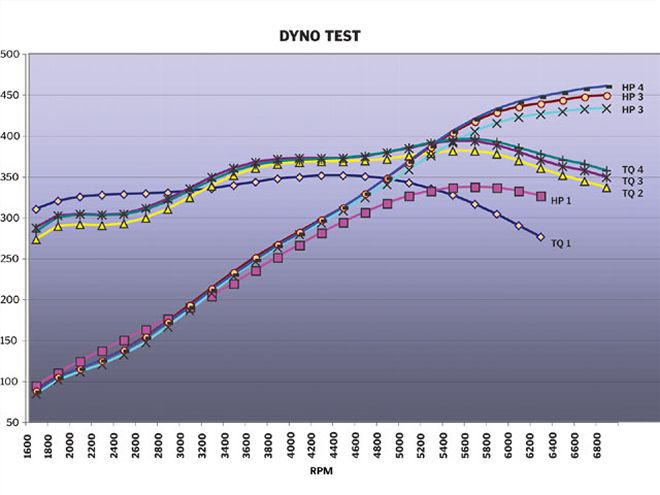

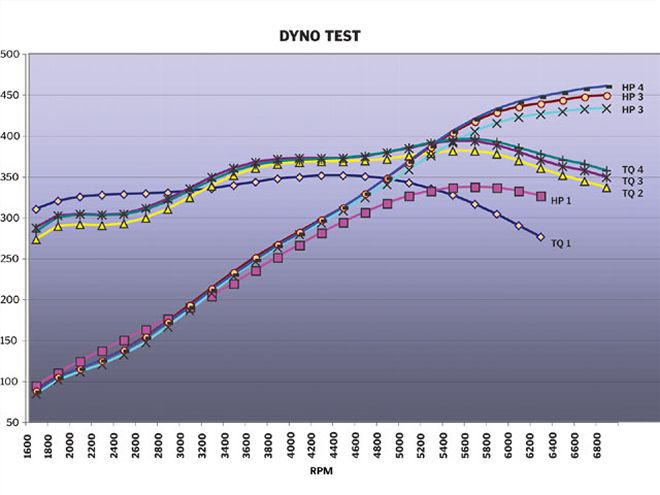

Our first shot was a simple baseline of the stock 5.3 with the carb and headers, making a credible 337 hp and 351 lb-ft of torque. Next, it was a simple task to strip the accessory drive and timing-gear cover and swap the stock hydraulic roller cam for a new Comp Thumpr cam. We also added a set of Comp beehive valvesprings to the stock heads to ensure adequate valve control at what we figured would be a higher peak horsepower engine speed. That's exactly what happened. Just bolting in this new Thumpr cam (it didn't even have a part number) pushed the peak horsepower from 5,600 to a nose-bleeding 6,800 rpm. But more torque at a higher engine speed is the formula for horsepower, which is what happened when the peak power jumped from 337 to 433 with stock heads. That's a 96hp bump with a cam swap!

Of course, this just made us salivate to bolt on the WCRCH Stage 1 ported production castings. That was also a quick swap, since the Gen III engines only use four head bolts per cylinder, which we replaced with a set of ARP head bolts. With the ported Stage 1 heads in place, the power jumped again, this time up to 449 hp, an improvement of 16 while the torque gained 12 lb-ft with the peak occurring at 5,400 rpm. Our final test was with the CNC-ported castings, where again the little 5.3 spun up to 6,800 rpm cranking out 460 hp with 396 lb-ft of torque. Taken as a whole, this simple head and cam swap on an otherwise stock 5.3L short-block was worth a total of 123 hp and 45 lb-ft of torque.

First off, how many engines can pick up almost 100 hp just from a cam swap? This reveals how good those stock 5.3L heads are, especially the exhaust ports. Combine a small displacement engine with decent exhaust and a relatively stout cam and the result is lots of engine speed. This package does sacrifice torque below 3,000 rpm compared with the base engine, which means this engine would be better matched with a manual transmission or at least an automatic with a high-stall converter. Another important consideration is that a stock 5.3L bottom end won't live forever at 6,800 rpm, so save yourself the trouble of writing to us with that bit of wisdom. Clearly, to keep this combination together, the cam should probably be 5 to 10 degrees smaller on the intake side with a single-pattern design, which would help the bottom end torque and only cost perhaps 10 to 15 hp. Or you could add some forged pistons and rods and have a nice day. Either way, a 100-plus-horsepower gain is reason enough to celebrate. But as impressive as this is, there's a lot more left in this garden-variety truck engine. Next month, we'll push it even harder.

CAM SPECS CAMSHAFT DURATION DURATION LIFT LOBE SEPARATION (advertised) (@ 0.050) (inches) Stock 5.3L, intake N/A 191 0.457 114 Exhaust N/A 190 0.466 Comp Cams, intake 283 227 0.563 109 Thumpr exhaust 303 241 0.546Go With The Flow

Flow Test 1

Stock 5.3L aluminum head

1.89/1.55-inch valves

60cc chamber

205cc intake port volume

Flow Test 2

West Coast ported Stage 1 5.3L head

1.94/1.57-inch valves

60cc chamber

209cc intake port volume

Flow Test 3

West Coast 5.3L CNC-ported Edelbrock

2.00/1.57-inch valves

58cc chamber

200cc intake port volume

Dyno Numbers

Test 1 was the baseline test for the stock 5.3L with a GM Performance Parts single-plane intake manifold, a Holley 750-cfm carburetor, and a set of Hooker 13/4-inch headers complete with a 21/2-inch exhaust system and Flowmaster Super 44 mufflers.

Test 2 was the same engine with the only addition being the Comp Thumper hydraulic roller camshaft.

Test 3 used the same configuration as Test 2 with the addition of West Coast Racing Cylinder Heads (WCRCH) mildly ported stock 5.3L heads.

Test 4 was the same as Test 3 with the change to a pair of WCRCH fully CNC-ported Edelbrock castings.