You may recall the article entitled "The Slippery Truth About Oil" from the June '06 issue of HPP (also available at www.highperformancepontiac.com). In it, we discussed the negative effects some modern motor oils have on flat-tappet camshaft engines, and explained the organizations that categorize motor oil, the category designations, and the key anti-wear additives that were reduced, which are thought to be behind many of today's camshaft lobe and lifter failures.

At the time, we presented a few long-term solutions that included certain off-the-shelf products, among them commercial-grade oil, and General Motors' Engine Oil Supplement (E.O.S.). All seemed well until we learned that most 2007 diesel engines were gaining an exhaust system catalyst, which likely meant oil reformulation, and that GM discontinued its highly-concentrated E.O.S. product-two serious blows that struck panic into the hearts of hobbyists who relied so heavily on these products.

The fact remains that many hobbyists own vintage Pontiacs with flat-tappet camshaft engines, and the HPP staff is among them. Like you, we too were just as concerned about the matter and set out in search of solutions that wouldn't likely waiver with the next mandated reformulation. So we contacted several large corporations familiar to most hobbyists, and asked for comments on the current situation and any long-term solutions that could quell our concerns. Here's what they had to say.

Amsoil

AMSOIL was the first company to market fully synthetic motor oils for all types of internal combustion engines. Its first gasoline engine offering was released in 1972, which spawned an entire industry. Today the company offers a wide range of synthetic lubricants, including those suitable for flat-tappet camshaft engines. We contacted AMSOIL's Director of Advertising, Ed Newman, and its team of technicians, for the company's perspective.

High Performance Pontiac: Can you discuss the recent oil reformulation that seems to have negatively impacted the automotive hobby?

Ed Newman: Beginning with all 2004 model year vehicles, auto manufacturers were required by federal law to warrant emissions system performance for 120,000 miles, and one system critical to emissions performance is the catalytic converter.

AMSOIL is a synthetic lubricant industry pioneer, and today the company offers a full line of motor oils that includes its (AMO) 10W-40, which is suitable for flat-tappet engines.

AMSOIL is a synthetic lubricant industry pioneer, and today the company offers a full line of motor oils that includes its (AMO) 10W-40, which is suitable for flat-tappet engines.

Part of the phosphorus was removed from motor oil because it had been linked to catalytic converter failure, and it's a key component in the high-pressure anti-wear additive, zinc dialkyl dithio phosphate (ZDDP). Since auto manufacturers must maintain catalytic converter system integrity for 120,000 miles, they began pushing oil companies to modify formulations, and those gasoline-engine oils that meet API SM, ILSAC GF-4, and API CJ-4 standards for commercial specifications to reduce ZDDP levels.

HPP: Can you explain how the reformulation directly affects flat-tappet camshafts?

EN: We've recently released an entire Technical Service Bulletin (No. MO-2007-08-08) discussing just that. Simply stated, engines with flat-tappet camshafts typically have an extremely high pressure-point between the lifter crown and the camshaft lobe, and ZDDP acts as a sacrificial chemical barrier that prevents the two from actually contacting one another. The concern is that the lower levels of zinc may not provide sufficient anti-wear protection in flat-tappet camshaft engines, and, in particular, those with high-tension valvesprings.

HPP: Does your company offer any products intended for use with flat-tappet camshafts?

EN: Extra protection is available with our Premium Protection chemistry, and consumers need to look carefully to find products formulated for flat-tappet camshaft engines. We offer a full line that contains this additive package and has a proven history. Products like our (AMO) 10W-40 and (ARO) 20W-50 gasoline-engine oils contain high ZDDP levels, and are perfectly suitable for flat-tappet cams.

HPP: Is there any chance your company could discontinue or reformulate these products in the future?

EN: As opposed to discontinuing these types of products, we're actually looking to expand the line as required, and are working with flat-tappet camshaft manufacturers to promote its value to this particular market. We're very committed to solving this problem, and are actively pursuing ways to specifically market these lubricants to classic car hobbyists.

Shell Rotella T

Designed for the harsh environment within a diesel engine, Shell ROTELLA T has aptly earned the reputation as a high-quality, maximum-protection lubricant. With the reformulation of gasoline-engine oil a few years ago, many hobbyists with flat-tappet camshaft engines have found salvation in commercial-grade oils like ROTELLA T, which have typically maintained high levels of the desirable anti-wear additives.

Produced by Shell, commercial-grade ROTELLA T has been a popular off-the-shelf choice for flat-tappet camshaft engines, but rumors of recent reformulation have sent hobbyists scurrying for options. The truth is that the current API CJ-4 category rating offers enhanced levels of anti-wear protection and, according to Shell, ROTELLA T was designed with flat-tappet camshaft protection in mind.

Produced by Shell, commercial-grade ROTELLA T has been a popular off-the-shelf choice for flat-tappet camshaft engines, but rumors of recent reformulation have sent hobbyists scurrying for options. The truth is that the current API CJ-4 category rating offers enhanced levels of anti-wear protection and, according to Shell, ROTELLA T was designed with flat-tappet camshaft protection in mind.

The '07 model year brought on many changes for diesel engines. Among them was an exhaust system catalyst, and another oil classification standard-CJ-4. One would assume from past events that the addition of said exhaust catalyst would ultimately lead to ZDDP reduction, but Shell's OEM Technical Service Manager, Stede Granger, says otherwise.

High Performance Pontiac: You're likely aware that ROTELLA T is used by many automotive hobbyists with flat-tappet camshafts. Are there any negative effects when using commercial-grade oil in gasoline engines?

Stede Granger: Assuming we're speaking about older gasoline engines that are no longer under warranty, and emissions aren't a concern, there are no major negative effects when using ROTELLA T. In fact, it carries an API S-series category rating. The only possible concern I see is viscosity-15W-40 will not circulate as quickly during initial start-up in extremely cold climates as a lesser viscosity, and our 5W-40 synthetic is then an option.

HPP: We've heard that the current CJ-4 category rating has significantly reformulated diesel oil for 2007. Can you elaborate on that?

SG: Most diesel engines for 2007 utilize an EGR system, an exhaust catalyst, and a Diesel Particulate Filter (DPF) to help lower emissions, and the new CJ-4 category is designed to ensure that there are no detrimental effects to this equipment, maximizing its service life.

HPP: Does the addition of an exhaust catalyst mean a drastic reduction of the high-pressure wear additives found in ROTELLA T oil?

SG: The exhaust catalyst found on diesel engines isn't the same as that of a typical passenger-car application, so we're able to retain high ZDDP levels. The API specification change to CJ-4 for 2007 has resulted in moderate zinc reduction from about 1,400 ppm to 1,200 ppm. And even at these slightly decreased levels, ROTELLA T 15W-40 conventional and 5W-40 synthetic still contain three to five times the amount of the desirable anti-wear additives as some current gasoline-engine oils.

HPP: Is there any chance your company could reformulate ROTELLA T in the near future, and drastically reduce its high-zinc content?

SG: Historically speaking, commercial-grade oil classification changes occur every two to four years, but the new CJ-4 category offers the best all-around protection of any previous rating. So I feel there's little reason for any immediate change, and expect to see it around for at least a few years.

A point to remember is that zinc not only protects flat-tappet camshafts against wear, but also any high-pressure metallic surface that relies on pressurized oil for lubrication, such as the piston rings, cylinder walls, and rocker arms/pushrods. When oil can't carry the load, zinc steps up and creates a chemical barrier, and the high levels of zinc in commercial-grade oil contribute to the fact that some diesel engines run a million miles or more. I don't see us reducing the zinc content in ROTELLA T unless an organization like API imposes a lesser chemical limit on a subsequent category.

COMP Cams suggests using its No. 159 Camshaft Break-In Oil Additive at all times with any flat-tappet camshaft. Stating that it's compatible with any mineral-based or synthetic oil, the company suggests combining it with mineral-based oil during break-in, and any high-quality mineral- or synthetic-based oil after that.

COMP Cams suggests using its No. 159 Camshaft Break-In Oil Additive at all times with any flat-tappet camshaft. Stating that it's compatible with any mineral-based or synthetic oil, the company suggests combining it with mineral-based oil during break-in, and any high-quality mineral- or synthetic-based oil after that.

Comp Cams

COMP Cams is among the most recognizable names in aftermarket camshaft manufacturers. As one of the largest in the industry, the company has publicly addressed oil formulation issues in the past, and with word of reformulation buzzing about, we were confident that it had developed a long-term solution. We contacted the company's Tony McCurdy to address our concerns.

High Performance Pontiac: Is current oil formulation an area of concern for COMP Cams?

Tony McCurdy: Yes, definitely. Because of tightening environmental regulations, modern engine oil isn't the same as it was just a few years back. The federal government recently required the reduction of key ingredients such as zinc and manganese in all types of gasoline and diesel-engine oils, and that continues to plague flat-tappet camshaft engines.

HPP: Have these changes affected the way your company manufactures or markets flat-tappet cams?

TM: No, not at all. Premature flat-tappet camshaft failure isn't necessarily brand or type specific. Many times hobbyists quickly suspect the manufacturing process, but we've found that's rarely the cause. We feel that modern oil has created the potential for failure during break-in and normal use. We have, however, found ways that hobbyists can discourage that trend.

HPP: Can you explain those?

TM: Proper break-in is a key element in the longevity of any flat-tappet camshaft, and we include detailed installation and break-in instructions with each cam and lifter set we sell.

We strongly recommend that the new flat-tappet camshaft and its lifters be liberally coated with our No.153 Cam & Lifter Installation Lube, which is supplied with each set. We also suggest adding a 12-ounce bottle of our No. 159 Camshaft Break-In Oil Additive to the crankcase.

We prefer that the inner valve springs be removed to better allow the lifters to establish rotation and develop a wear pattern. As soon as the engine fires, increase its speed to 2,000 to 2,500 rpm for the first 30 minutes of operation, and it can be periodically varied to ensure direct splash oiling on all areas of the camshaft.

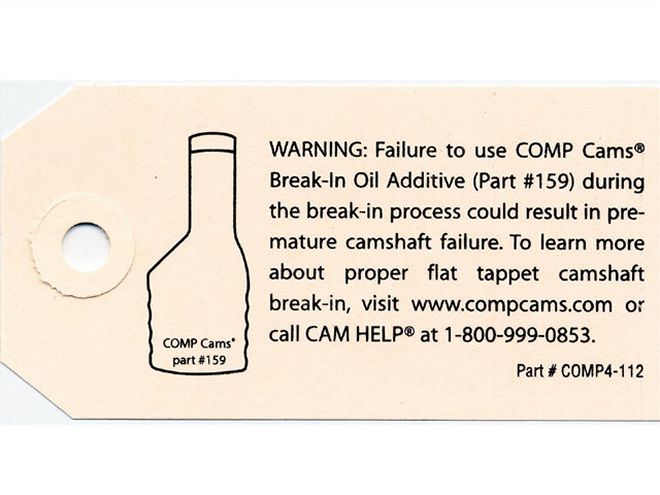

COMP Cams feels so strongly about its Camshaft Break-In Oil Additive that it securely attaches this label to every camshaft it sells.

COMP Cams feels so strongly about its Camshaft Break-In Oil Additive that it securely attaches this label to every camshaft it sells.

After the break-in process is complete, we suggest changing the oil and filter to remove contaminants, reinstalling the inner valve springs, and filling the crankcase with the customer's choice of high-quality conventional [mineral] or synthetic oil, and adding a bottle of our No. 159 Camshaft Break-In Oil Additive.

HPP: You suggest No. 159 Cam-shaft Break-In Oil Additive for long-term use. Can you explain its advantages?

TM: The product was initially developed specifically for break-in protection, but subsequent testing has proven long-term durability benefits for flat-tappet cams. It contains a special blend of additives that replace some of the desirable ingredients that the oil companies have removed from modern oil, and protects the camshaft and lifters against premature wear.

We feel that it's cheap insurance, and is the first step toward avoiding oil-related flat-tappet camshaft issues. In fact, we attach a small label, suggesting its use, onto each flat-tappet camshaft that owners must literally cut off.

HPP: Is there any chance your company could discontinue or reformulate this product in the future?

TM: We plan to market No. 159 Camshaft Break-In Oil Additive as long as we offer flat-tappet camshafts, and there aren't any foreseeable changes in the future.

Crane Cams

Crane Cams has been a flat-tappet camshaft-manufacturing leader since the early '50s, and though the company has ventured into various other valvetrain-and ignition-related-components over the years, camshafts remain among its most popular products. Like any camshaft manufacturer, Crane Cams admits that today's oil formulation is an area of concern. Tony Vigo, Crane Cams' Media Liaison and Technical Advisor, shared some of those concerns-and his suggested solutions-with us.

Crane Cams offers its own highly concentrated lubricant that it suggests for flat-tappet camshafts. An entire 8-ounce bottle of No. 99003-1 Super Lube Break-In Concentrate is combined with certain oils during break-in, while the company suggests combining a lesser amount with any modern mineral-based oil for normal use.

Crane Cams offers its own highly concentrated lubricant that it suggests for flat-tappet camshafts. An entire 8-ounce bottle of No. 99003-1 Super Lube Break-In Concentrate is combined with certain oils during break-in, while the company suggests combining a lesser amount with any modern mineral-based oil for normal use.

High Performance Pontiac: Is current oil formulation an area of concern for Crane Cams?

Tony Vigo: Yes, the reduction of the zinc-phosphorus compound (ZDDP) from most modern engine oil has definitely accelerated flat-tappet camshaft lobe and lifter wear.

HPP: Have these changes affected the way your company manufactures or markets flat-tappet cams?

TV: No, not at all. Our flat-tappet camshafts remain a popular hobbyist choice, and to ensure longevity, we are recommending specific break-in procedures using products like Brad Penn motor oil, or such diesel-specific oils as Shell ROTELLA T, Mobil Delvac, and Chevron Delo 400.

HPP: Can you briefly outline your suggested break-in procedure?

TV: It really isn't that much different than what hobbyists are already familiar with, but we do offer a few suggestions aimed at proper lobe-to-lifter mating. Complete instructions are included with each cam and lifter set we sell.

We recommend that each lobe and lifter be thoroughly coated with our No. 99004-1 Super Moly Assembly Lube, which is included, and to combine said oil with an 8-ounce bottle of our No. 99003-1 Super Lube Break-in Concentrate.

After setting valve lash or lifter preload-and priming the fuel and oil system-start the engine and immediately begin cycling its speed from 1,500 to 3,000 rpm for 20 to 30 minutes. If the camshaft requires high valve spring pressure, we suggest removing the inner spring during break-in. Once the process is complete, the camshaft should be ready for normal use.

HPP: What are your suggested oil change practices during normal use?

TV: We recommend that the first oil change occurs within 500 miles of initial break-in, and then follow that with normal change intervals that include any high-quality 5W-30 or 10W-30 mineral-based oil, and at least 4 ounces of our Super Lube Break-In Concentrate.

HPP: Could you explain the benefits of your No. 99003-1 Super Lube Break-In Concentrate?

TV: It's a product much like General Motor's E.O.S.-an anti-wear additive containing a high concentration of ZDDP that's designed to protect the camshaft lobe and lifter against scuffing and wear during break-in. When used moderately at each oil change, it has little effect on emissions equipment, and greatly enhances the long-term life of the cam.

HPP: Is there any chance your company could discontinue or reformulate Super Lube Break-In Concentrate in the future?

TV: We plan to market it as long as we produce flat-tappet camshafts, and have an ongoing oil additive evaluation program to continually further its development and monitor effectiveness.

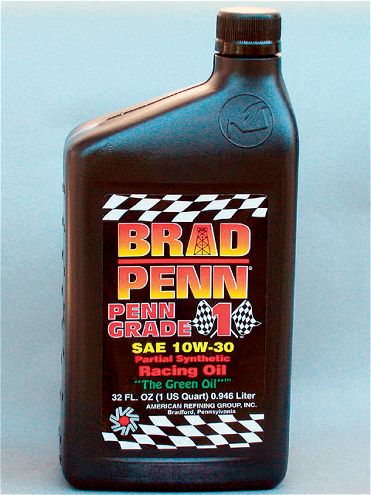

Brad Penn

Industry experts have long considered Pennsylvania-grade crude oil among the best in the world, and one of the most popular engine oils refined from it was Kendall GT-1. The American Refining Group now operates the Bradford, Pennsylvania-based refinery that once produced the Kendall line, and it offers its own line of high-quality race oil. Brad Penn's Penn Grade 1 (PG 1) is available as a partial-synthetic or conventional, and in varying viscosities. We spoke with the company's Director of Branded Lubricants Sales and Marketing, Dick Glady, about its formulation.

High Performance Pontiac: Are Brad Penn's Penn Grade 1 products intended for use with flat-tappet camshafts?

Dick Glady: Simply stated, yes. Our PG 1 has been evaluated by a number of premier camshaft manufacturers, and is now recommended by many for flat-tappet and roller applications. Let me explain why.

Brad Penn oil is refined from Pennsylvania-grade crude, and we obtain a unique cut from our tower. When formulated correctly, it has a greater tendency to cling to engine internals, minimizing wear during dry start-up, and high engine-torque conditions. We add to it a high concentration of ZDDP and our additive package, and the result is high-quality race oil that offers outstanding anti-wear and anti-scuffing protection for flat-tappet cams.

We market our PG 1 product as "The Green Oil," and in addition to our full line of engine and gear lubricants, we also offer Penn Grade 1 Break-In Oil-a specially formulated, 30-weight mono-grade lubricant that was developed for flat-tappet camshaft break-in, and features enhanced levels of ZDDP.

Brad Penn's Penn Grade 1 motor oil is a high-quality race lubricant that's produced by the American Refining Group. It includes a high concentration of the desirable anti-wear additives, making it suitable for flat-tappet camshaft engines. The company's Pennsylvania-based oil tower is heralded as the oldest continually operated oil refinery in America.

Brad Penn's Penn Grade 1 motor oil is a high-quality race lubricant that's produced by the American Refining Group. It includes a high concentration of the desirable anti-wear additives, making it suitable for flat-tappet camshaft engines. The company's Pennsylvania-based oil tower is heralded as the oldest continually operated oil refinery in America.

HPP: Is there a specific amount of zinc additive that your company feels is the minimum required for flat-tappet camshafts?

DG: Our typical ZDDP content is 1,200 ppm, but that doesn't tell the entire tale. Many other manufacturers formulate race oil from its passenger-car offerings, and maintain a lesser amount of zinc to meet current API SM-specifications. Our lubricant is actually uniquely formulated race oil that's suitable for older flat-tappet camshaft engines, and it offers additional engine protection beyond high levels of ZDDP.

HPP: Is there any chance your company could drastically reduce the desirable high-pressure additives in its products?

DG: Our Penn Grade 1 is marketed as race oil, and since we don't license it through API, we don't have to conform to current API and ILSAC standards.

HPP: Where can hobbyists purchase Brad Penn products?

DG: Our Penn Grade 1 products aren't available through local retailers. Instead, present distribution goes through select independent lubricant wholesalers, engine builders, and specialty racing/performance outlets. Contact us via our Web site, and we'll reply with the nearest authorized Brad Penn Racing distributor.

Conclusion

Myriad other lubricant companies and camshaft manufacturers have certainly addressed these issues and developed their own solutions, but it wasn't practical for us to contact all of them. After hearing a recurring trend from those we spoke with, we're confident that answers from most others would closely follow what's presented here.

We learned that current-spec commercial-grade oil, like ROTELLA T, remains a suitable off-the-shelf lubricant for hobbyists with flat-tappet camshaft engines. Other options include specialized lubricants like those from Brad Penn, or to combine modern-spec gasoline-engine oil and an additive such as that from COMP Cams or Crane Cams.

While it's still recommended to follow your engine builder and/or camshaft manufacturer's specific suggestions for break-in and long-term use, hobbyists can rest easier knowing that a variety of solutions are presently available, and after hearing what these companies have to say, we're confident that hobbyists can safely drive their vintage Pontiacs without feeling as if its flat-tappet camshaft is living on borrowed time.