Mopar Engines West set the horsepower standard in last year's challenge when their 500-inch big-block screamed to more than 760 hp. How much power do you think this year's small-blocks will make?

Mopar Engines West set the horsepower standard in last year's challenge when their 500-inch big-block screamed to more than 760 hp. How much power do you think this year's small-blocks will make?

When it comes to engines, small-blocks used to be small, and big-blocks used to be big. Today, the term small-block doesn't necessarily mean that an engine is small. Mopar guys are lucky now since stroker kits, aftermarket heads, and numerous other aftermarket parts are made specifically for the small-block Chrysler engine. We remember when building a small-block Mopar meant using mostly factory parts because that's all that was available. Since the small-block Mopar is gaining popularity as a foundation for big cubic inches and big power, we decided it would be fun to feature the small-block Mopar in this year's engine challenge to really show what Mopar's LA engine is capable of.

If you've been following our engine challenges you know the basic rules. We try to encourage the builders to make big horsepower reliably and do it on pump gas, while sticking to a tight budget. For this year's small-block challenge, engine displacement will be limited to 410 ci and all will have to run on the same 93 octane Rockett Brand fuel, but otherwise we're pretty much letting anything go. Like in past years, we're sure we'll see engines built strictly for high power, but since the price of the parts is factored into the power the engine makes, it will likely take a combination of good power and economical parts to win.

This month, we'll introduce you to the builders and give you a peek at the engines they're building for our third annual engine challenge.

Diamondback Engines specializes in Mopar engines, transmissions, carburetors, and parts. For this year's challenge, they'll be building a 408ci small-block.

Diamondback Engines specializes in Mopar engines, transmissions, carburetors, and parts. For this year's challenge, they'll be building a 408ci small-block.

Located in Richmond, Texas, Diamondback Engines is a newcomer to our challenge. We look forward to seeing how much power they can make with a small-block Mopar.

Located in Richmond, Texas, Diamondback Engines is a newcomer to our challenge. We look forward to seeing how much power they can make with a small-block Mopar.

Diamondback Engines

Richmond, Texas

Diamondback Engines was formed by business partners Dave Schultz, Dallas Schultz, and Damon Kuhn because they recognized a need in their area for a quality-oriented, Mopar-specific performance shop. As drag racers, the guys at Diamondback design and build each engine to their customers needs, paying the same attention to detail when building their street engines as they do when building race engines. In addition to their full-service engine shop, Diamondback also builds transmissions and carburetors, and has a retail parts store.

For this year's engine challenge, Diamondback Engines will be putting together a 408ci small-block. Engine builders Damon Kuhn and Dallas Schultz will be using an Eagle stroker crank in a factory 360 block to achieve their 408ci displacement. Brodix B-1 cylinder heads should provide plenty of flow for big power, and a Diamondback 750 or 950 carburetor will handle the fuel mixing. As of this writing, the engine isn't complete, but the guys at Diamondback guaranteed their engine would be dyno'd and delivered to the Mopar Nationals by the deadline.

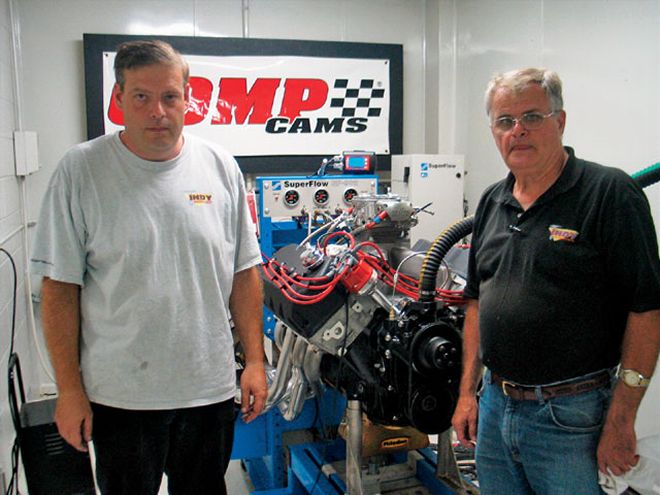

The crew from Indy successfully tuned the Hemi they brought to the '05 Engine Challenge to impressive power numbers. With so many good small-block parts available, we look forward to seeing what tricks they have up their sleeve for this challenge.

The crew from Indy successfully tuned the Hemi they brought to the '05 Engine Challenge to impressive power numbers. With so many good small-block parts available, we look forward to seeing what tricks they have up their sleeve for this challenge.

Engine builders Ken Lazzeri and Russ Flagle of Indy Cylinder Head are no strangers to power. In our '05 Engine Challenge, they brought an impressive Hemi; we can't wait to see what they bring to this year's small-block engine challenge.

Engine builders Ken Lazzeri and Russ Flagle of Indy Cylinder Head are no strangers to power. In our '05 Engine Challenge, they brought an impressive Hemi; we can't wait to see what they bring to this year's small-block engine challenge.

Indy Cylinder Head

Indianapolis, Indiana

The name Indy Cylinder Head is synonymous with Mopar power. The guys at Indy recognized the need for Mopar-specific aftermarket parts before most, designing some of the best heads around for Mopar applications. Since then they haven't looked back and have been engineering heads, intakes, blocks, and numerable other parts for all Mopar and AMC applications, even the new Hemi. With so many new and cutting edge products, we wonder when these guys sleep!

While we expect big power from a name like Indy Cylinder Head, the crew at Indy was undecided about how to approach this contest. One approach would be to build a powerful engine, highlighting their parts and building prowess, and not worry about the cost factor. Another approach is, of course, to build an economical engine and go for the win based on cost. Turns out the guys at Indy built one of each and will decide which engine to bring based on each engine's in-house dyno results. Both engines will displace 408 ci, but the budget engine will use cast-iron heads, a stock oil pan, and other budget goodies to keep costs down. Their potent engine is an all-out powerhouse that should churn out some impressive numbers. We'll have to wait until the Mopar Nationals to see which one they enter!

Mike Liston of MRL Performance barely missed winning last year's engine challenge when his budget-minded 500ci wedge fell just 200 rpm shy of the contest rules. This year he assures us he'll bring a very competitive small-block to the Engine Challenge.

Mike Liston of MRL Performance barely missed winning last year's engine challenge when his budget-minded 500ci wedge fell just 200 rpm shy of the contest rules. This year he assures us he'll bring a very competitive small-block to the Engine Challenge.

Knowing he barely missed placing well in last year's challenge, we're sure Mike will pay attention to every detail of the engine he builds for this year's competition.

Knowing he barely missed placing well in last year's challenge, we're sure Mike will pay attention to every detail of the engine he builds for this year's competition.

MRL Performance

Jackson, Michigan

When Mike Liston of MRL Performance isn't building powerful Mopar engines, he's working at the Chrysler proving grounds testing current Mopar iron like the new Dodge Challenger (and we thought we had a good job). Mike will build anything Mopar, but is a self-proclaimed small-block specialist, which is why we're eager to see what he brings to the engine challenge.

When we asked Mike what engine he was going to build for this year's challenge, he quickly answered, "A 318, baby!" Inside his 318, Mike will use a stock forged crank, Keith Black forged pistons, and Scat H-beam connecting rods. A Comp Cams solid flat-tappet camshaft will work the valves, and the engine will be topped by hand-ported Magnum cylinder heads. Mike states that going for a win will take good power and a tight budget, and it sounds like his combination might have just the right mix of both.

Mid America Racing Engines had just the right combination to win last year's engine challenge. This year, engine builder David Bruns is hoping his small-block will net him back-to-back first place finishes.

Mid America Racing Engines had just the right combination to win last year's engine challenge. This year, engine builder David Bruns is hoping his small-block will net him back-to-back first place finishes.

Soft-spoken and mild-mannered David Bruns did his homework last year, building a powerful, yet economical, big-block to win our challenge. We're eager to see if his small-block packs a similar punch this year.

Soft-spoken and mild-mannered David Bruns did his homework last year, building a powerful, yet economical, big-block to win our challenge. We're eager to see if his small-block packs a similar punch this year.

Mid America Racing Engines

Washington, Iowa

Mid America Racing Engines is another engine shop founded by a die-hard drag racer. Having built his own race engines for years, engine builder David Bruns recognized the need for a quality machine shop, and since opening, he's provided engines for racers all over the country. If you followed last year's contest you already know that David tuned his 500ci wedge to a first place finish, making some 740 hp and more power than any of last year's Edelbrock-headed engines. David assures us the small-block he brings to this year's challenge will have the potential to win as well.

David Bruns hit his combination perfectly last year, earning him a win in the '06 engine Challenge. This year he plans to back up his stellar performance with a 410ci engine based on a factory 360 block. Inside the 360, David will utilize an Eagle crank and rods, and SRP pistons. The engine will be topped with Indy cylinder heads and will utilize a MSD ignition. When asked about camshaft selection, David would only say he is considering a couple of different cam profiles, stating cam selection as being vital to placing well in this contest. We're sure that once the decision is made, this will be an impressive engine.

Another returning competitor is engine builder Mike Ware of Lansing, Michigan's Muscle Motors. Mike participated in our inaugural engine challenge and plans to show his prowess with the Chrysler small-block this year.

Another returning competitor is engine builder Mike Ware of Lansing, Michigan's Muscle Motors. Mike participated in our inaugural engine challenge and plans to show his prowess with the Chrysler small-block this year.

Each year our engine challenge draws quite a crowd. we can't wait to see what the Six-Pack-adorned Muscle Motors entry does this year.

Each year our engine challenge draws quite a crowd. we can't wait to see what the Six-Pack-adorned Muscle Motors entry does this year.

Muscle Motors

Lansing, Michigan

Anyone who's raced Mopars for very long has probably heard of Muscle Motors. Located in Lansing, Michigan, Muscle Motors has been supplying Mopar gearheads with the engines, machine work, and parts it takes to go fast for many years. These guys specialize in stroker kits and carry a full line of Mopar high-performance parts, in addition to their full-service machine shop. In our inaugural engine challenge, the Muscle Motors entry impressed us with its combination of power and torque, so we're eager to see what they bring to this year's challenge.

Like most competitors, Mike decided to base his small-block on a factory 360. Utilizing a Callies 3.79-inch stroke crankshaft with Ross pistons will bring displacement to 400 ci. A solid roller camshaft will actuate the valves, and the engine will be topped with Edelbrock Performer RPM cylinder heads. Since Muscle Motors has CNC programming to port virtually any Mopar cylinder head, we're sure the heads atop this motor will be treated to the works. Feeding this beast will be a trio of Holley two-barrels on an aluminum Six-pack intake manifold.

Comp Cams will again host our engine challenge, and if their hospitality is as good as in years past, we'll likely gain a few pounds while we're there.

Comp Cams will again host our engine challenge, and if their hospitality is as good as in years past, we'll likely gain a few pounds while we're there.

After the dyno pulls, each engine will be torn down for a technical inspection to ensure the builder followed our rules.

After the dyno pulls, each engine will be torn down for a technical inspection to ensure the builder followed our rules.

R.M. Competition

Roseville, Michigan

R.M. Competition has been in business since 1998, but engine builder Randy Malik has more than thirty years experience building high-performance engines at other shops. R.M. Competition specializes in anything high-performance, building engines for drag racing, road racing, and even boats. Randy believes that preparation and tuning are more important than the actual parts chosen for a build, but using the right parts is certainly a step in the right direction to achieve good results. Since parts selection and tuning are major factors in our competition, we feel Randy has a good chance to place well.

Randy used a production 360 Chrysler as the foundation for this build and stuffed it with a Scat crankshaft, Keith Black pistons, and factory Chrysler connecting rods. A Lunati cam will actuate the valves and a Melling oil pump combined with a factory oil pan will handle lubrication duties. The engine will be topped with Engine Quest cylinder heads, a Weiand intake manifold, and an Edelbrock carburetor. Obviously built to make good power at a low cost, this engine should be very competitive.

Located in Maquoketa, Iowa, Schurbon Engine and Machine is another newcomer to our engine challenge.

Located in Maquoketa, Iowa, Schurbon Engine and Machine is another newcomer to our engine challenge.

The crew at Schurbon Engine and Machine takes pride in making big horsepower on a budget. That recipe should make them very competitive in our engine challenge.

The crew at Schurbon Engine and Machine takes pride in making big horsepower on a budget. That recipe should make them very competitive in our engine challenge.

Schurbon Engine And Machine

Maquoketa, Iowa

Engine builder Scott Schurbon of Schurbon Engine and Machine is a self-proclaimed Mopar fanatic. Having raced some of everything, Scott claims you can't beat a Mopar engine when it comes to bang for the buck. He remembers the days when you couldn't find aftermarket parts for a Mopar and still made enough power to keep up with the brand-X guys, so we're eager to see what he can do with the great aftermarket parts available in today's market.

Like the other competitors in this year's Engine Challenge, Scott decided to use a production 360 block for this build. Stuffed inside will be an Eagle four-inch stroke crankshaft, RPM billet I-beam connecting rods, and Probe dish pistons. Magnum heads will be utilized as they are hard to beat for the money. A Comp Cams flat-tappet camshaft will actuate the valves through Pro Comp aluminum roller rocker arms. For induction, Scott chose to use a Mopar Performance single-plane aluminum intake.

Speed-O-Motive has been serving performance enthusiasts since the inception of hot-rodding.

Speed-O-Motive has been serving performance enthusiasts since the inception of hot-rodding.

Using state-of-the-art equipment, Speed-O-Motive is known for their quality machine work and attention to detail.

Using state-of-the-art equipment, Speed-O-Motive is known for their quality machine work and attention to detail.

Speed-O-Motive

West Covina, California

Californians will tell you that the hot-rod craze began in their state, and Speed-O-Motive has served performance enthusiasts both in California and around the country since 1946. Though they'll build anything, the guys at Speed-O-Motive love building Mopar engines because they make so much power. We've been impressed with the Speed-O-Motive entries in our last two challenges and look forward to seeing what they'll bring to the table this year.

Speed-O-Motive will be using a factory Chrysler 360 block for their entry in this year's contest, but will boost displacement to 408 ci with a Scat 4-inch stroke crankshaft. Scat 6.123-inch I-beam connecting rods will also be utilized along with CP forged pistons. A flat-tappet, solid lifter cam will see duty in this engine that will be topped with Brodix B1 AMC cylinder heads. For induction, an M-1 intake manifold will be matched to a Holley carburetor, likely a 750-cfm unit. We can't wait to see what this combination does on Comp's dyno in September.