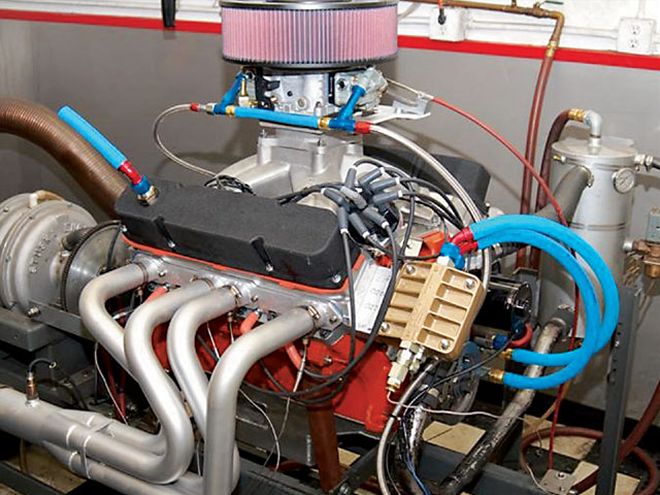

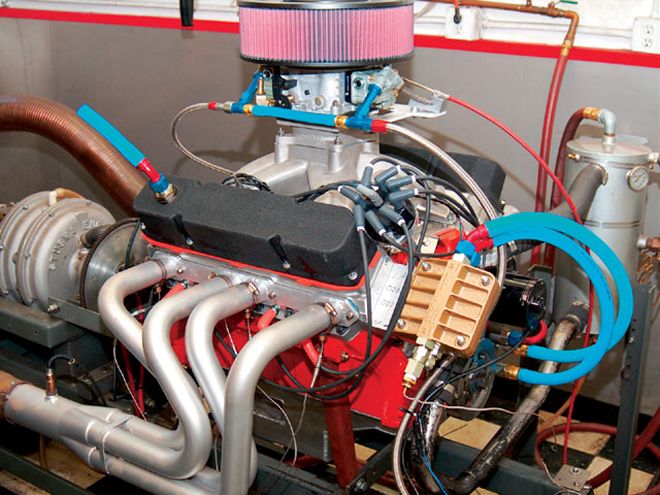

Our 505-inch dyno mule had enough power to really put the Ultra HP carbs to the test. With the Indy top end and the big Comp camshaft, we didn't have any trouble cranking out more than 700 hp.

Our 505-inch dyno mule had enough power to really put the Ultra HP carbs to the test. With the Indy top end and the big Comp camshaft, we didn't have any trouble cranking out more than 700 hp.

The Plan

One of the most common performance tricks is upgrading the cam and the carburetor on a musclecar engine. So that is exactly what we decided to do with our 505 motor once we finished the cross-ram testing that was featured in our August '07 issue. We had seen a peak of 705 hp during those cross-ram tests, and we wanted to compare those numbers to a combination that uses a big carb on a single-plane manifold. Since we were going to be twisting the wrenches anyway, we grabbed the opportunity to use Comp's new CamQuest 6 cam selection software to help us pick a cam. Our plan came together like a charm with the new cam-and-carb combo blasting our 505 motor to a new peak horsepower recording.

The Carbs

Holley recently introduced a line of Ultra HP carburetors that have a lot of new features. These super-high-performance carbs have billet base plates, billet metering blocks with full adjustability, notched floats, glass float level sights, and replaceable air bleeds. The metering on these units is dialed in for race-type engines with big camshafts, so they are ready to run right out of the box. We had seen some information on these new carbs at the shows, but hadn't been lucky enough to get our hands on any until this dyno test was scheduled. For this test, we ordered both a 4150-style carb with a 950-cfm flow rating and a big 4500 series Dominator with a 1050-cfm rating, so we could compare them back to back.

These new Ultra HP carbs have replaceable jets in the idle circuit, as well as the emulsion tubes and the air bleeds. What this means is if the original metering isn't correct for your particular application, it can be easily changed. This ease of tuning solves one of the more frustrating issues that carb tuners have had to deal with for a long time. There have been numerous magazine articles written over the years telling people how to stick a small wire into the idle feed jets to restrict the idle fuel flow, and other articles have shown how to drill out the power valve restrictions for more fuel at WOT. Now with the Ultra HP version of the carb, you don't need to drill or fill any of the passages since you can now change the metering of the various circuits with jet changes.

The main circuit in Holley carburetors has always been easy to tune with replaceable jets, and that wasn't changed in the Ultra HP series. Likewise, the acceleration circuits on these new carbs are tunable by changing the pump cam, the shooter nozzle-size, or the size of the accelerator pump just like any other Holley carb. The difference in the Ultra HP series is the addition of jets for the idle circuit, as well as jets in the emulsion wells and in the power valve restrictions.

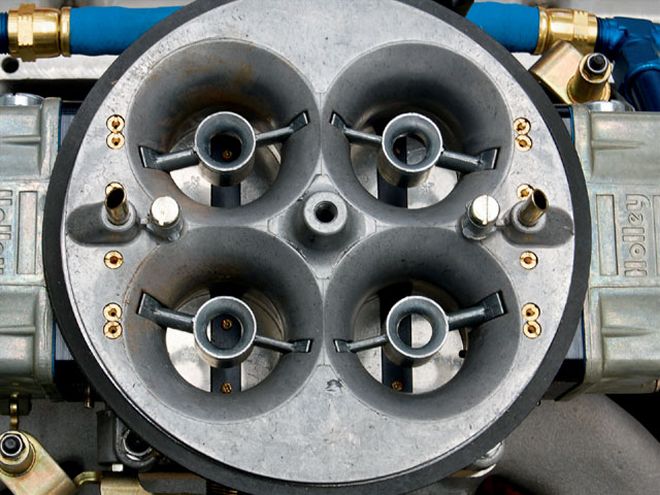

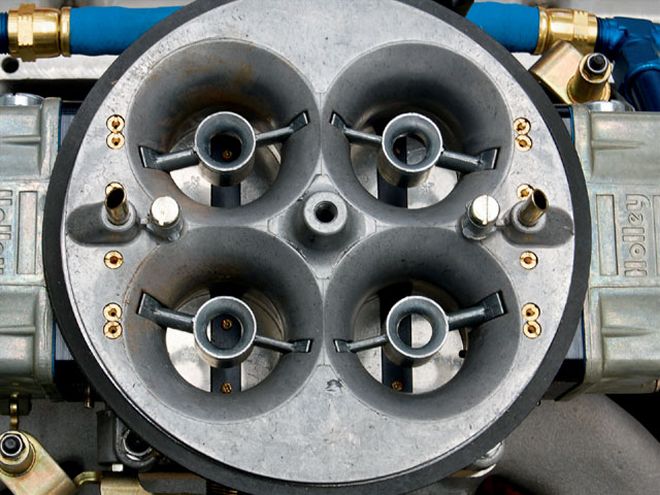

A top view of the 1050 carb shows the smooth inlets into each venturi, as well as the large annular boosters and the three air bleeds per venturi. the 1050 has three air bleeds per venturi. The additional air bleed is for the intermediate circuit.

A top view of the 1050 carb shows the smooth inlets into each venturi, as well as the large annular boosters and the three air bleeds per venturi. the 1050 has three air bleeds per venturi. The additional air bleed is for the intermediate circuit.

Sometimes the idle mixture screws just don't have enough adjustment range to get the idle mixture correct when using a large camshaft with a lot of overlap. In the Ultra HP carb you can quickly change an idle jet in the metering block to get the idle mixture screw back into its proper control range. For instance, if the idle mixture screws have to be adjusted almost all the way in for the motor to idle, you know the mixture is too rich. By reducing the size of the idle jets inside the metering block, the mixture screws can be returned to the normal 1.5 turns open.

The traditional Holley power valve circuit is like an on/off switch where the fuel flow is fixed by passages drilled in the metering block. In the Ultra HP carb, the power enrichment circuit also has jets in it so you can adjust the amount of fuel that flows thru the power enrichment circuit without having to drill or epoxy the metering block. This is especially valuable in applications where a tuner would want to set up the carb to be fairly lean while cruising down the freeway, but have the carb be safely rich when operating at wide-open throttle. With the ability to change jets in the power enrichment circuit, tuners now have the capability to easily change the A/F ratio at WOT without disturbing the part-throttle A/F ratio.

The 950-cfm Ultra HP is a conventional five-circuit carb with idle, transition, main, power, and acceleration circuits. these circuits all have removable jets for tuning. The 1050-cfm Ultra HP version of the Dominator has an additional intermediate circuit for a total of six circuits. The intermediate circuit in the 1050 picks up fuel from the float bowls through a set of jets in the metering plate, and then discharges that fuel into the air stream above the throttle plates through small tubes. This intermediate circuit is designed to smooth out the air/fuel ratio during the transition from idle to the main circuit's operation. It can be an important tuning circuit for cars that leave off of a transbrake or other situations where part-throttle performance is important. The Ultra HP design allows this intermediate circuit to be tuned by either changing the jets in the metering block or by changing the air bleeds in the main body.

With all of the tunable circuits in the Ultra HP carbs, there are a lot of ways to fix a mixture problem. There are also a lot of ways for a person to get confused, so before going nuts with the changes it is a good idea to jot down the baseline combination. We got lost a few times during our testing, but were always able to quickly return to the original calibration since we had kept good notes.

Cam Selection

Picking a camshaft is often a bit spooky for the average hot rodder. Not only are there a lot of cams to pick from, but also a lot of terms to learn, plus it is a bunch of work to change the camshaft if you pick the wrong one to start with. Over the last several years there have been some computer programs developed that provided dyno simulations of different camshaft profiles, but none of them provided cam-selection help. With the introduction of the CamQuest 6 software, Comp Cams has combined a cam-selection program with a dyno-simulation program to give the novice engine builder an easier way to properly select a camshaft.

The CamQuest 6 software package loaded onto our computer with just a few simple commands, and we were able to quickly fill in the information requested by the program. We input the cylinder flow information for our heads, which is an important piece of data for the program. The program also requested information regarding the bore, stroke, size of carb, intended use of the motor, and so on. Once you fill in all that information, you are then able to select the type of camshaft you want to use, such as solid flat tappet, solid roller, hydraulic roller, and so on.

Once we entered all the necessary information and pressed enter, the CamQuest program came back with a recommendation to use the Comp MM 305S-10 camshaft. The MM 305 camshaft is one of the largest flat-tappet cams in the catalog with .305/.320-degrees of seat duration, .279/.287 degrees of duration at .050-inch lift, and .650/.630-inch of lift on the intake and exhaust. The CamQuest software also recommends the proper valvesprings and rocker arms to use with the camshaft, so a novice engine builder can order the correct parts the first time.

The CamQuest 6 package predicted 741 hp at 6,500 rpm, and 667 lb-ft of torque at 5,000 rpm when using the MM 305 cam with the Dominator carb and 708 hp with the smaller 950 Ultra HP carb. Those sounded like great numbers to us, so we ordered the MM 305 cam from Comp and got ready to make some serious power.

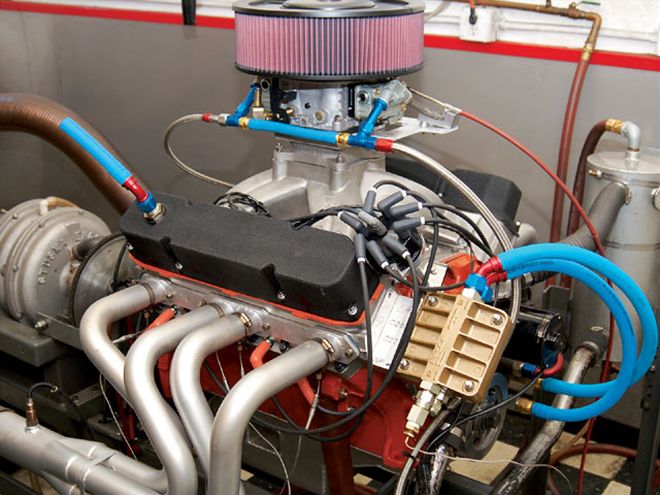

After our first session with the 950, we switched to the bigger 1050 Ultra HP carb. We use a Racor remote oil filter for all dyno testing since it lets us quickly examine the oil filter for any trash that might be circulating in the motor. You can also see the big K&N flow control air cleaner that we used during the dyno testing.

After our first session with the 950, we switched to the bigger 1050 Ultra HP carb. We use a Racor remote oil filter for all dyno testing since it lets us quickly examine the oil filter for any trash that might be circulating in the motor. You can also see the big K&N flow control air cleaner that we used during the dyno testing.

The Test Mule

The big-block that we're using to test this cam and the Ultra HP carbs were constructed for the "Modern Max Wedge" article that ran in our August '07 issue. This is a production 440 block with a 4.250-inch stroke crankshaft, 6.800-inch long rods, and forged Diamond Racing pistons with a healthy 13.5:1 compression ratio. The cylinder heads are Indy EZ units that were ported by Modern Cylinder Head. In the cross-ram dyno tests, this motor made 620 hp with a Mopar Performance cross-ram and 705 hp with the Indy cross-ram, so we know the basic combination is healthy. The only change we made for this test-in addition to the cam and the intake manifold-was installing a Super Stock-style aluminum oil pan. We filled the new pan with 8 quarts of Joe Gibb's break-in oil since the motor is still fairly fresh. we used our typical dyno combination of a remote screen-type oil filter and a Meziere electric water pump.

On The Dyno

It was a cold day when we unloaded the motor at Gray's Automotive in Tigard, Oregon. With the temperature reading in the low 40s, we knew the motor would be making plenty of raw power. Of course, the correction factor on the dyno output calculations take into account the air temperature, but it is always nice to see the bigger uncorrected numbers since that tells you how much power the motor is capable of making at the track.

After a normal warm-up period and a recheck of the valve lash, we started to make some dyno pulls with the 950 Ultra HP carb. The 950 carb calibration was very close right out of the box with the A/F ratio just slightly on the lean side. We only needed to make one jet change from 78 jets to 80 jets to richen the mixture up, and then saw our best power run of 705 hp at 6,000 rpm and 636 lb-ft of torque at 5,600 rpm.

After making enough dyno pulls with the 950 carb to ensure we had the combination tuned correctly, we swapped over to the larger 1050 carb. We could have bolted on a 440-3 intake manifold with a 4500 flange, but we decided to stay with the 440-2 intake manifold by adding a 4150-to-4500 adapter. According to the guys at Indy, the combination of the 440-2 intake with an adapter makes more power than using the 440-3 intake, so we used the adapter.

The big 1050 Dominator carb was very rich right out of the box with an A/F ratio of 10:1, both at idle and during the early portion of the dyno pull. We were able to quickly lean out the idle A/F mixture by reducing the size of the idle feed restrictions in the metering block, but getting the fuel curve to stay at 12.5:1 during the entire dyno pull proved to be a bigger challenge. We eventually needed to reduce the size of the intermediate jets by 10 sizes, and we needed to open up the intermediate air bleeds before we got the A/F curve to flatten out during the dyno pulls. Once we had the A/F curve shaped up, the motor responded with a peak of 738 hp at 6,400 rpm and 641 lb-ft of torque at 5,500 rpm.

Well, there you have it. carburetor selection is crucial when trying to get the most out of your engine. If you're not sure what carburetor will work best for you, then you need to check out Holley's new Web site. They have an interactive program that asks you the appropriate questions, and then tells you which carb will work best for your application.

Well, there you have it. carburetor selection is crucial when trying to get the most out of your engine. If you're not sure what carburetor will work best for you, then you need to check out Holley's new Web site. They have an interactive program that asks you the appropriate questions, and then tells you which carb will work best for your application.

Wrap Up

The most obvious result of the carb testing was the 30-plus horsepower gain in switching from the 950 to the larger 1050. A motor like this 505 can really use the extra airflow that the larger 4500-type carb provides, although the 950 carb would still be the better choice for a dual-purpose-type vehicle.

What also impressed us was how easy these Ultra HP carbs were to tune. On a non-Ultra carb we would have had to plug the holes in the metering blocks with epoxy and then drill them back to the correct size in order to correct the A/F curve. Now that we've experienced the Ultra carb, we're tossing our tubes of carb epoxy into the round file!

Finally, we were stunned with how accurate the CamQuest 6 software was in predicting the power output of the two configurations. In both cases, the software was within just a few horsepower of our actual numbers. The torque values predicted by the software proved to be a little optimistic but only by a few percent. We would say this software package is a very good tool to help select cam profiles, as well as giving an engine builder a good idea of just how the motor will perform.