Reliably sealing the cylinder heads to the engine block when running extreme high-boost or a big nitrous load has always been a challenge for engine builders. For economic reasons, ease of assembly, and daily driveability (for dual-purpose, street-driven hot rods), some sort of conventional head-gasket solution would be the preferred choice. Yet while technology has advanced by leaps and bounds over the last 20 years, even the best of the modern conventionally based composition and MLS (multi-layer steel) head-gasket solutions may run into problems when subjected to extreme combustion loads, particularly on engines like Ford V-8s and GM Gen III small-blocks that have only four head bolts sealing each cylinder.

When normal head gaskets can't do the job on full-race, conventional American V-8s, engines builders usually resort to O-ring wire and copper gaskets. But cutting O-ring receiver grooves and installing the O-ring wire in the block or heads is an expensive, labor-intensive task. There is no going back to a conventional solution once the parts are modified, and the copper head gaskets usually used in conjunction with stainless steel O-ring wire can weep coolant-not the best solution for extended-duration applications.

Beyond receiver grooves and O-ring wire, there is metallic combustion-seal technology that uses separate, discrete, purpose-built, rigidly confined, metallic rings around each cylinder, the ultimate manifestation of which is gas-filled O-ring technology. Originally pioneered on World War II-era aircraft piston engines, the alloy rings provided a resilient substrate and the right amount of sealing stress around the cylinder bore. Traditionally such rings replace conventional head gaskets entirely, which meant that coolant and oil transfer slots also required special O-ring-like seals. In the automotive world, the expense and complexity of modifying engines designed for mass-production generally confined this technology to Indy, Formula I, and similar venues that use specialized powerplants.

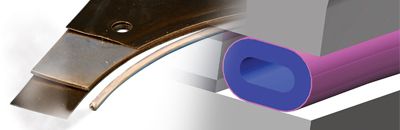

Cometic's new Phuzion technology combines a conventional MLS head gasket with a gas-filled, aerospace-alloy O-ring for the ultimate in head sealing without the need for special block modifications. The three-layer MLS gasket consists of embossed spring-steel outer layers with a steel inner layer, which provides support and thickness to the gasket.

Cometic's new Phuzion technology combines a conventional MLS head gasket with a gas-filled, aerospace-alloy O-ring for the ultimate in head sealing without the need for special block modifications. The three-layer MLS gasket consists of embossed spring-steel outer layers with a steel inner layer, which provides support and thickness to the gasket.

Several years ago, Garlock Helicoflex, a prime manufacturer of metal seals for the aerospace, defense, fuel-cell, gas-turbine, nuclear, and semiconductor industries, formed an alliance with Cometic Gasket. The goal was to come up with a solution that permitted budget engine builders to utilize gas-filled O-ring technology on standard automotive engines at a relatively affordable price. The result of that research is Cometic's Phuzion system, which "fuses" MLS head-gasket technology with the gas-filled O-ring. The beauty of this product is that it permits any engine builder to utilize the high-end O-ring sealing system without special block or cylinder-head preparation. No receiver grooves are needed. The only requirement is that the head and deck surfaces be flat within 0.002 inch and have a 50RA-or-finer surface finish-both of which are pretty standard prep these days on high-performance engine builds.

O-ring receiver grooves are not needed because the MLS gasket actually controls the compression on the gas-filled O-rings and rigidly retains the ring od. And since a flat MLS head gasket with embossments around the fluid-transfer passages is still used, there are no problems with seepage or a need to machine sealing grooves around the transfer slots. In fact, the system is installed dry with the normal torque values as recommended by the engine and fastener manufacturers.

The gas-filled Phuzion O-rings themselves are capable of withstanding very high temperatures and pressures. The nontoxic gas trapped in the ring is the result of a proprietary chemical reaction that occurs after the ends of the rings are resistance-welded during the manufacturing process. The chemicals are added just prior to the weld and are put into an oven after welding to react irreversibly and generate the gas. After the ring is cut, welded, and pressurized, it is silver-plated to further increase the ring's performance. The plating acts as a lubricant so head-to-block movements don't score the ring, head, or block. The silver also flows into the machined surfaces for a much tighter seal.

Engine builders running extreme cylinder pressures provided a testbed for the new sealing system during its development process. One of them was Chris Gesek, owner of Kinetic Racing Engines. On its GM Gen III supercharged drag-race motors, Gesek runs 30 pounds of boost, generating over 1,800 hp with 385 ci. Even the GM "race" C5R block and heads Gesek uses weren't intended to withstand that much cylinder pressure. Previously the best solution was dry-decking the block, but the extreme mods needed to utilize individual Garlock rings without a head gasket plus seal the transfer passages ran $5,000-$7,000 per engine. At the price of $200 per gasket, the MLS/Garlock combo eliminated the need for exotic prep, reducing the sealing cost by 92 percent and saving lots of time and labor in the bargain.

Obviously most engines don't need such an exotic solution. There is no magic crossover point where the Phuzion becomes mandatory. After all, different engine designs may be more head-gasket limited than others. The bottom line is that if you have been blowing head gaskets, it's nice to know there's a user-friendly solution available through Cometic that can be implemented immediately without the need for special machining operations.

Phuzion Availability

At present the gas-filled O-rings and the corresponding MLS head gasket are separate components. The engine builder must order the Phuzion gas-filled O-rings by bore size, then Cometic will supply the rings along with a modified MLS head gasket for the specified engine configuration. Cometic can modify any of its existing MLS gasket designs to accept the Phuzion rings by leaving out the traditional integral fire-ring during the manufacturing process. Additional Phuzion bore-sizes will be available in the future, but as this is written the lineup is as follows: