A minor amount of work by your local machinist can be worth some serious airflow, which is the direct route to more horsepower and torque.

A minor amount of work by your local machinist can be worth some serious airflow, which is the direct route to more horsepower and torque.

'Breathe in . . . breathe out. Simple respiration is what keeps us alive, and your engine is no different. On a normally aspirated engine, atmospheric pressure pushes air in through the carb, intake manifold, intake ports, and intake valve on its way into the cylinder. If all engines were built with a straight shot directly into each cylinder, engines would certainly make a bunch more horsepower and torque, and life would be grand. But the reality of low hood lines and other packaging compromises creates a much more tortuous path to the cylinders. Each change in direction, twist, or bump in the induction path creates a flow loss that results in less power and torque.

The search for horsepower is literally a quest to eliminate these flow losses. Big cylinder heads with properly sized ports and larger valves along with more efficient intake manifolds and headers are all parts intended to minimize these flow losses. The problem with big intake-port heads and giant intake manifolds is they are expensive and involve some compromise to streetable power.

So what if we showed you a simple little trick that will work on just about any engine, costs very little money, and is just short of guaranteed to increase both torque and horsepower? Would you be interested? We'll take a wild guess and assume you're on board. Here's the skinny.

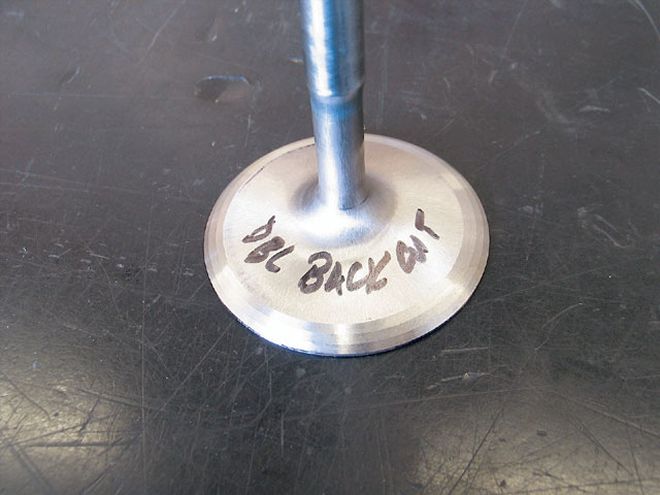

This is a Manley stainless steel intake valve with a 30-degree back cut just to the inside of the 45-degree seat as evidenced by the machined surface (arrow).

This is a Manley stainless steel intake valve with a 30-degree back cut just to the inside of the 45-degree seat as evidenced by the machined surface (arrow).

Valve Angles

One of the most critical areas in a cylinder head is the transition from the port to the valve and into the cylinder. This is why multi-angle valve jobs have evolved-the search for improved flow. Our simple trick that anyone can do is to add a 30-degree back cut to the inside diameter of the 45-degree seat angle on an intake and/or exhaust valve as a way to improve flow.

We talked with many cylinder-head specialists, and they all made one common point: Adding a back cut to the valves almost always results in improved flow. We decided to test that theory on several different cylinder heads. Jim Grubbs Motorsports helped us by allowing us access to the company's SuperFlow 600 flow bench, which is equipped with both the SuperFlow FlowCom digital software and Performance Trends' Port Flow Analyzer v3.0 software. It's a very useful program that not only records the data very quickly, but also averages and plots the results, making our evaluation process much easier and more accurate.

We began our test using an Edelbrock Performer RPM Oldsmobile head with a 30-degree back cut on both the intake and exhaust valves. The Olds' exhaust port did not respond to this modification, so we concentrated our efforts on the intake side.

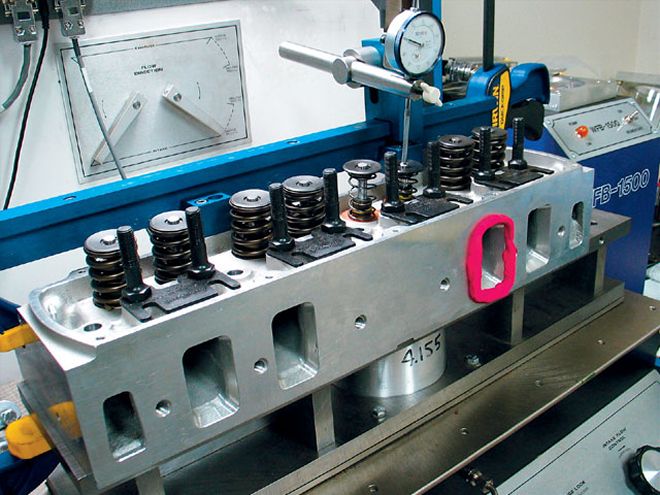

We started by flow-testing several different cylinder heads from three completely different engine families to get a baseline. This particular head is an Edelbrock Oldsmobile 455 aluminum cylinder head tested on Jim Grubbs Motorsports' SuperFlow 600 flow bench.

We started by flow-testing several different cylinder heads from three completely different engine families to get a baseline. This particular head is an Edelbrock Oldsmobile 455 aluminum cylinder head tested on Jim Grubbs Motorsports' SuperFlow 600 flow bench.

We also experimented with 35- and 32-degree back cuts on our way to 30 degrees to see which one worked best. From the results, it appears you could make a case for either 30- or 32-degree back cuts on the Oldsmobile head. The 32-degree back cut offers a slight advantage at 0.200- and 0.300-inch valve lifts.

Our testing revealed that, true to our previous research, this trick doesn't work in all applications. But in certain cases, especially when using stock or production-style valves, this simple machining operation can be worth an amazing amount of increased flow.

Olds Edelbrock aluminum 2.072-inch intake valve Valve As a valve opens, a flow area is created by the combination of valve diameter and valve lift. This is called the flow curtain area.

As a valve opens, a flow area is created by the combination of valve diameter and valve lift. This is called the flow curtain area.

The Ford Formula

Production Ford heads are especially limited in terms of flow on both the intake and exhaust sides, which seemed to us to be a perfect candidate for a back-cut test. This was by far the most amazing test we performed. In the results, note how the intake improved by an astounding 25 cfm, which is also 25 percent at 0.200-inch valve lift from 102 to 127 cfm. We did lose a small amount of flow at 0.400 inch and above, but for a mild cam with under 0.500-inch valve lift, flow losses above max valve lift are irrelevant. We didn't test a 32-degree cut, but it's possible there may be some slight flow improvements possible at the higher valve lifts.

We gained almost as much airflow at 0.200-inch valve lift on the exhaust as we did on the intake side, with a total improvement of 14 cfm that was worth 17 percent. This is especially helpful on a stock head with a mild cam. Based on these results, we'll never build another mild small-block Ford without back-cutting the valves.

Ford DOOE 351W iron 1.840-inch OE intake valve Valve Stock valves often have a ditch or undercut just behind the 45-degree seat that can disrupt flow. The stock Ford 351W 1.840-inch intake valve that we tested suffered from this condition. By adding a 30-degree back cut to this valve, we generated a phenomenal 25 percent increase in flow at 0.200-inch valve lift.

Stock valves often have a ditch or undercut just behind the 45-degree seat that can disrupt flow. The stock Ford 351W 1.840-inch intake valve that we tested suffered from this condition. By adding a 30-degree back cut to this valve, we generated a phenomenal 25 percent increase in flow at 0.200-inch valve lift.

Small-Block Chevy Cuts

Anyone who reads automotive performance magazines and is into small-block Chevys knows the production, iron small-block Vortec head is reasonably priced and flows well. One reason is GM figured out that back-cutting both the intake and exhaust valves was worth significant flow increases. This may not seem like a big deal, but consider that back-cutting even high-production-rate valves costs more money, and even an additional penny on a couple million valves a year is a big deal to the OEs. So it's another example of the success of this simple machining operation when GM back-cuts its valves.

Since we know this trick works on a Vortec and virtually any other small-block Chevy iron head, we chose to test an Edelbrock aluminum small-block Performer RPM head to see how this idea would perform on an aftermarket cylinder head. Here, the back-cut improvements were not as dramatic on the intake side, but they were still helpful. It's also possible that a 32- or 33-degree cut might be more efficient, but we ran out of time to fine-tune our test. On the exhaust side, we saw a tremendous improvement at 0.100-inch exhaust valve lift, which could be worth some power. The theory around that is discussed in the accompanying "Low-Lift Flow" sidebar.

This 30-degree back-cut idea works so well, even the very popular Vortec iron small-block Chevy head incorporated this 30-degree technique for both the intake and exhaust valves on all production heads. It's one reason this head works so well on mild street small-blocks.

EDELBROCK

This 30-degree back-cut idea works so well, even the very popular Vortec iron small-block Chevy head incorporated this 30-degree technique for both the intake and exhaust valves on all production heads. It's one reason this head works so well on mild street small-blocks.

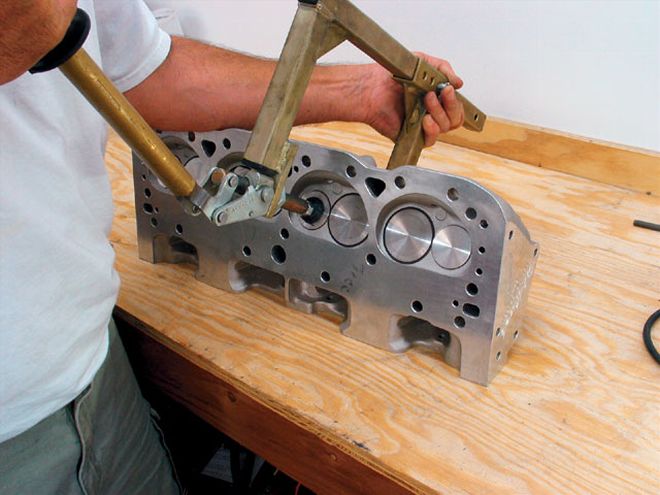

EDELBROCK  This is the Edelbrock Performer RPM head for the small-block Chevy. These heads make good power right out of the box, but if you're not in too much of a hurry, yank the valves and have your machine shop back-cut them. We used a Powerhouse valvespring compressor to remove the springs.

This is the Edelbrock Performer RPM head for the small-block Chevy. These heads make good power right out of the box, but if you're not in too much of a hurry, yank the valves and have your machine shop back-cut them. We used a Powerhouse valvespring compressor to remove the springs.

Flow Curtain Area

The combination of valve diameter and valve lift creates a flow window or flow curtain area. This area increases with valve lift. The area can be calculated by first determining valve circumference (3.1417 (pi) times valve diameter) and multiplying it by valve lift. For example, let's say we have a 2.02-inch intake valve with a valve lift of 0.500 inch. 3.1417 x 2.02 = 6.34 inches of valve circumference. 6.34 x 0.500 = 3.17 square inches of valve curtain area.

Low-Lift Flow

In a majority of the heads we tested, we found the gains with a 30-degree back cut were greatest at the lower lift values between 0.100 and 0.300 inch. At first, this may seem of marginal value, especially if your camshaft is capable of valve lifts of 0.500 inch or more. The reality is that all the valve lifts contribute to filling or emptying the cylinder.

On the intake side, increasing low-lift flow is especially important for mild street engines with max valve lifts of less than 0.450 inch. At 0.225 inch, the valve is already at half total valve lift, so low-lift flow is important. Plus, the valve will be at this lift twice during the complete valve-lift cycle, both on the opening and closing sides of the lift curve. Perhaps most importantly, as the intake valve is closing, a more efficient low-lift flow curtain area will increase volumetric efficiency just as the piston is rising in the cylinder and the intake valve is about to close. Better flow numbers at these lower lift values will allow the heads to fill the cylinders better and therefore make more power.

Jim Grubbs even went so far as to try two back cuts on a small-block Chevy valve, but the results were inconclusive.

Jim Grubbs even went so far as to try two back cuts on a small-block Chevy valve, but the results were inconclusive.

On the exhaust side, the picture is a little different. Cylinder pressure is at its highest point in the exhaust cycle just as the exhaust valve opens. With more efficient low-lift flow, this reduces the cylinder pressure at these lower lift values, which means the engine does not have to expend power to force exhaust gas out as the piston rises during the valve-closing portion of the exhaust cycle. This is called negative work and is subtracted from the power the engine is already making.

In both intake and exhaust applications, low-lift airflow improvements will improve power. It doesn't get much easier or simpler than that.

PARTS LIST Description PN Source Price Edelbrock RPM Olds