Engine oiling is an often-overlooked subject. The way an engine receives its oil and the type of oil it demands drastically affect the longevity and efficiency of its performance. Other factors, such as temperature, volume, and blueprinting can make a difference in the life span of various internal, engine-related parts. To find out more about this subject, we contacted some of the top lubrication companies in the business to find out what it takes to build a high-performance oiling system.

The viscosity of an oil is measured by the amount of resistance to flow it generates at a given temperature.

The viscosity of an oil is measured by the amount of resistance to flow it generates at a given temperature.

Colors, Weights, Blends, and More

Motor oil comes in a variety of weights and blends to aid in various engine environments. Sometimes it comes in colors, too. Why? Coloring motor oil is one way for manufacturers to brand their oils. Royal Purple found its name by originally supplying a large commercial customer with its high-endurance brand of heavy-duty oil featuring a standard yellow color. According to legend, Royal Purple's oil outlasted other competitors' oils, saving this particular customer thousands of dollars. But one day, a mechanic mistakenly used a competitor's oil. This caused many of the industrial engines to fail making for a costly error. The owner of the large commercial plant and the head of Royal Purple got together to make a purple oil that could not be mistaken for another oil. Ever since, Royal Purple has branded itself the purple oil manufacturer.

To discuss improved engine oiling, we must first cover the basics about engine oil itself. We put in a call to the Royal Purple engineers and found out a few interesting facts relating to temperature, weight, and viscosity. Oil originates from two basic sources. On one hand, there is crude or conventional base-stock oil that is a natural, earthly substance manufacturers can extract and refine into a usable product. This method is the most cost effective, but the oil will always have traces of chemical impurities no matter how well it is refined. Oil can also be produced using technology that allows engineers and scientists to combine various chemicals to build their own synthetic base stocks. With a 100 percent pure synthetic base stock to work from, additional chemically designed polymers can be mixed and matched to develop multiple products of varying blends and grades at various price ranges. While synthetic oil is more costly, it offers improved features conventional oils cannot.

When discussing engine oil, the weight of a product is the most common way to differentiate various grades. The Royal Purple engineer offered one rule by which this subject should be held: The viscosity of an oil is measured by the amount of resistance to flow it produces at a given temperature. This means that a thick, honey-like substance will flow through an engine more slowly than a thin, water-like substance. The thicker oil can handle harsher conditions but is limited in its ability to lubricate properly at low engine temperatures; a low-viscosity oil flows more easily at low temperatures but will be limited at higher temperatures. That said, we can break down the usefulness of a standard-blend 10W-30 motor-oil designation.

Through the World War II era, most motor oils were of a single weight makeup. The first number, e.g., 10, is an SAE numeric representation of the oil's viscosity. Oil viscosities are typically measured at SAE 5, 10, 20, 30, 40, 50, and 80 weights, with the smaller numbers representing low viscosity/thinner oil. Therefore, 10, in SAE oil terms, represents a grade of oil that is fairly thin, with the ability to lubricate quickly at cold temperatures. The SAE rule for measuring different viscosities is taken at 40 and 100 degrees C (or 104 and 212 degrees F, respectively).

Behind the first SAE numeric representation is the letter W. This symbol stands for Winter Grade with relation to a range of temperatures the oil is capable of operating within. A 10W designation informs the user of the oil's viscosity with relation to low operating temperatures in accordance with an SAE 10-weight scale that can be measured at 40 and 100 degrees C.

As for the SAE 30 designation, in our 10W-30 example, this addition is a blend of induced polymers injected into the original base oil to thicken at high temperatures. The blended oil will then take advantage of the low-viscosity rating of an SAE 10-weight oil at lower temperatures and cold starts while also having the ability to withstand harsh environments at high temperatures without breaking down. The polymers used in the '50s did not last very long and broke down quickly, reducing a multigrade oil back to its single-weight makeup. However, today's multigrade oils feature highly advanced polymers capable of lasting the entire duration between recommended oil changes.

Conventional-base motor oils should operate within an approximate temperature range of 180-200 degrees F. Synthetic blends offer better performance at low temperatures, and their makeup allows them to handle slightly higher temperatures, offering a safe range of approximately 160-250 degrees F. As engine oil exceeds these temperature ranges, it begins to break down faster. This does not mean a sustained oil temperature of 300 degrees with a synthetic oil will cause an engine to lock up due to failing oil. Today's motor oils are superior to today's metals. However, dramatically increased oil temperatures will require more frequent changes.

Synthetic oil typically lasts longer because it has a more highly refined base stock combined with a stronger and better additive package that can handle a wider range of temperatures and the abuse that comes from operating in a performance environment. Conventional oils will break down faster and should be changed more frequently (see manufacturer's recommendations). Beyond lubrication, oil also has the job of cleaning the engine internally. This means that debris needs to be taken to the filter, and acidic combustion contaminants must be trapped.

Before storing a vehicle, the oil and filter should be replaced. This will help rid the engine of harmful substances, such as acids, that could potentially break down the oil during storage. Conventional petroleum-base oils will typically adhere to a resting internal component for anywhere from 6-8 weeks, whereas a synthetic-base oil is more likely to coat the engine internals for 3-6 months. After long periods of storage, it is a good idea to pull the coil wire from the engine and use the battery to crank the oil pump and prime the engine. With the oil basics covered, we can move on to the internal hard parts of an engine.

Coolers

Drag racers like their engines cool and their oil hot to make best power. Endurance racers also prefer hot oil, as long as it does not exceed thermal breakdown limits. As for oil temperature recommendations, conventional oils tend to begin to break down at temperatures above 250-260 degrees F. Pure synthetics can operate at much higher levels of around 290-300 degrees F. Synthetic blended oils perform somewhere in between. These temperatures are basically oil-pan average temperatures, but keep in mind that the temperature of the oil at the bearing, for example, will be much higher. It is not unusual for a typical street engine to experience 250-plus degree oil temperatures, and a mere 20-minute session on a road course can elevate oil temperatures well above 300 degrees F for engines not equipped with an oil cooler. This is a great case for using synthetic oil.

Whether it's boosted or not, every engine should carry a high-performance oil filter. These Canton filters are rated at 8 microns with flow rates of 45 gpm.

Whether it's boosted or not, every engine should carry a high-performance oil filter. These Canton filters are rated at 8 microns with flow rates of 45 gpm.

Filters

All engines should be equipped with at least one filter in the system. The oil-pump pickup has a screen to keep out large pieces of debris, but it's the filter's job to trap unwanted solids that may enter the oil. The two most common types of filter elements are fiber and synthetic. Fiber filters cost less and should be replaced with every oil change; synthetic filters are more durable against burst pressure and moisture, and they typically filter with more accuracy.

If you use a remote oil filter, it should be plumbed into the system right after the oil pump and before any remote coolers or engine components. This will ensure only clean oil reaches the engine and dirty oil will be strained through the pump pickup and filter before being recycled through the engine.

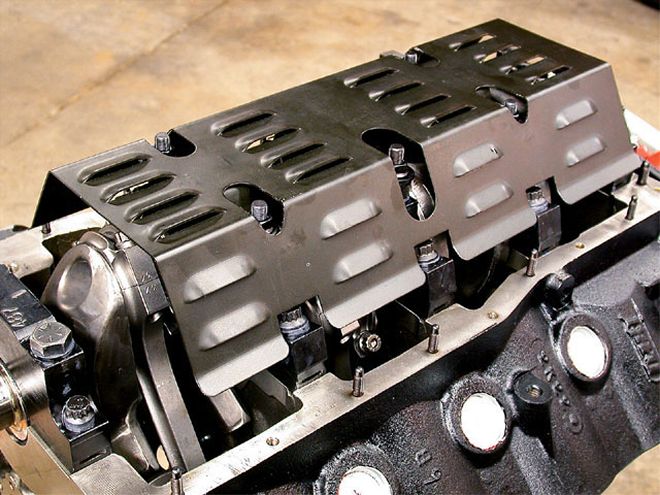

Bolting a windage tray over the main caps keeps flying oil from costing horsepower. This small-block Ford Moroso race-type oil pan is set up on a Dart block that's expected to see 8,000-rpm blasts.

Bolting a windage tray over the main caps keeps flying oil from costing horsepower. This small-block Ford Moroso race-type oil pan is set up on a Dart block that's expected to see 8,000-rpm blasts.

How Much Oil

The type of engine and its intended use will determine how much oil is needed. A high-performance oil pan typically holds an extra 2 or 3 quarts of oil. Some manufacturers rate their oil pan's capacity assuming a 1-quart oil filter will be used, while other manufacturers account only for the amount of oil the pan should hold. The only way to be sure your engine is equipped with the proper amount of oil is to use a dipstick or sight hole. The actual oil level is determined by the pan manufacturer, where it typically sits a minimum of 1 inch below the windage tray to allow for proper drainage. Before purchasing an oil pan, be sure to check with the manufacturer about its measuring method.

Having extra oil in a properly designed pan can have many advantages. Since high-performance engines operate at high rpm, if the oil does not drain back fast enough, the pump can starve. Another starving condition can occur in drag- or road-race situations, where extreme g-forces can cause the oil to move away from the oil pump's pickup. This is the reason for deep-sump pans and all that trap-door engineering.

If you use additional oil filters, remote coolers, and added lines, you'll need to use more oil. We contacted the engineers at Canton about this and were told to begin with the oil-pan manufacturer's recommended oil quantity. Idle the engine for a minute or two and then shut it off to check the dipstick. If a full reading is not shown, add 1/2 quart of oil and rerun the engine at idle. Repeat the procedure until the dipstick reads full.

Once the oil level is matched to the manufacturer's full dipstick reading, the engine should be run across its rpm curve. If 10 pounds of oil pressure are present for every 1,000 rpm, the engine's internals will be safe. In some applications, the dipstick will read full, but at high rpm, the oil pressure will begin to drop. Most enthusiasts will then add more oil, making the problem worse. To be safe, it is recommended that only an additional 1/2 quart of oil be added. Run the engine through its rpm curve, and if the pressure stabilizes, the engine needs more oil. However, if a drop in oil pressure continues, 1/2 quart of oil should be drained from the original oil level. Continue to drain 1/2 quarts until the oil pressure stabilizes. It's not uncommon to see too much oil in the pan. This causes the crankshaft to churn up the oil and create air pockets that reduce oil pressure at high rpm.

Oil pans with kick-outs are designed to trap flying oil before it can drown the rotating assembly. This Moroso race piece features special plugs that must be removed before the pan can be removed.

Oil pans with kick-outs are designed to trap flying oil before it can drown the rotating assembly. This Moroso race piece features special plugs that must be removed before the pan can be removed.

Oil Control

While too little oil can cause catastrophic engine failure, too much can hurt the engine's performance. Windage occurs as the crankshaft rotates through the oil in the pan. This creates a chaotic amount of splash that can coat the rotating assembly with excessive oil, costing horsepower. To combat this problem, oil-pan manufacturers, such as Milodon, Moroso, Canton, and Hamburger's, have come out with crankshaft scrapers and windage trays.

A crankshaft scraper is usually built into the oil pan or attached to the oil-pan rail. Often mistaken for a baffle, a crankshaft scraper is a ridged piece of metal located near the crankshaft counterweights. The scraper does not actually touch the counterweights but hovers next to them, directing flying oil to a kick-out in the pan. Below the crank scraper, a windage tray is often bolted in place below the main caps. This is a piece of prebent, rigid metal with holes that's meant to separate flying crank-case oil from the calm oil in the pan. Some racers employ both a scraper and a windage tray, while others use only one or none at all. However, before you ditch the idea of using a windage device, we can assure you there is test-proven data showing considerable gains through proper oil control.

PickUps

We've all heard the stories about oil-pump pickup tubes falling off the oil-pump body, which causes engine failure. While this is not a common problem, it does occur. All the high-performance oil-pan companies have accounted for this situation and have taken precautions to make sure their pickups stay in place. Milodon uses a 4130 chromoly press-fit sleeve in its small-block pickup bodies. The pickup tube is pressed 0.015 inch down into the sleeve and then bolted down by an independent strap to make sure the tube is held in place.

This Milodon oil pump and pickup are outfitted with a bracket hold-down and screen spacebar. These features make sure the pickup tube stays in place while the screen sits a perfect distance off the bottom of the oil pan.

This Milodon oil pump and pickup are outfitted with a bracket hold-down and screen spacebar. These features make sure the pickup tube stays in place while the screen sits a perfect distance off the bottom of the oil pan.

Before the oil-pump pickup manufacturers began addressing this potential problem, many racers often placed a small spot-weld between the pickup tube and the pump body. While this does work, most of today's manufacturers are against this practice, as welding temperatures may stress the pump body, affect the internal gear clearance, or weaken the pickup tube and/or bypass spring. Before doing any welding, contact the oil-pump manufacturer.

DeburRing and Clearancing

Oil-pump modification can be beneficial or detrimental, depending on the method by which it is done. Many of the oil-pump manufacturers recommended leaving their pumps alone, as they are manufactured with quality built into them. However, if a stock pump is in the works, there are a few things that can be done.

First off, cleanliness is key. Make sure every piece of the pump is reassembled clean. As for the actual improvement process, the biggest gains can be had by deburring the pump body's flow path from the internal gears to the pickup. Some engine builders like to deburr sharp edges on the oil-pump gears to reduce wear, but this is questionable, as setting the gears back up requires precise measurement. If at all possible, do not alter the pump gears, as they are set up a predetermined distance apart to ensure an adequate amount of oil is pumped with relation to engine speed.

Virtually all oil pumps operate by squeezing oil through a small passage. To regulate the amount of pressure, most pumps use a pressure regulator that consists of a valve regulated by spring pressure. When the pump exceeds the rated spring pressure, the spring compresses, allowing the valve to relieve the pressure. Engine oil pressure can be increased with a stiffer spring or by shimming to increase the seat pressure. The standard rule of thumb of 10 psi per 1,000 rpm of engine speed is a good place to start. However, with a properly designed high-performance lubrication system and quality synthetic oil, lower oil pressure levels of 45-50 psi for an engine speed of 6,000 rpm is acceptable.