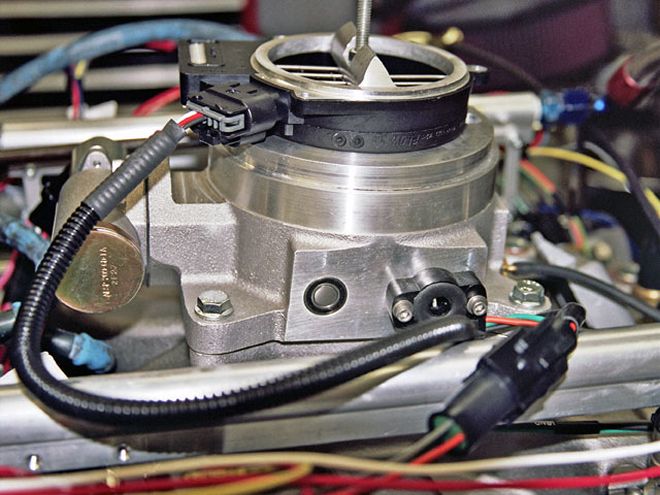

The Mass-Flo throttle body fits nicely on the Edelbrock intake manifold and packages.

The Mass-Flo throttle body fits nicely on the Edelbrock intake manifold and packages.

It's been a long time coming, but we finally are where we were supposed to be months ago with this series of articles. To refresh your memory, this series started out as a comparison of a modern EFI system stacked against an age-old Q-Jet on a chassis dyno and on the street. But that was before the SD-455 developed a rod knock on Ida Automotive's chassis dyno.

The Firebird owner, HPP contributor Melvin Benzaquen, seized the opportunity to work with RaceKrafter's Automotive Machine to upgrade the SD while it was being rebuilt. Cylinder-head work, along with a new crankshaft, connecting rods, and pistons, were on the list and accompanied the installation of a Comp Cams hydraulic-roller bumpstick.

Our camshaft choice, though light-years ahead of anything Pontiac offered in 1974, did throw a snafu into the project. The aftermarket valley pan that was required to clear the taller roller-valve lifters wouldn't accept the production-Pontiac intake manifold.

As a result, since the modified-for-EFI Edelbrock Torker II intake that was part of the Mass-Flo EFI kit fit with no problem, it was used for testing. This issue turned into an asset since it allowed a more modern carburetor to perform the A-B testing. Since HPP was pitting a modern EFI system against a carburetor, it was only fitting to use a state-of-the-art fuel-mixing device as well.

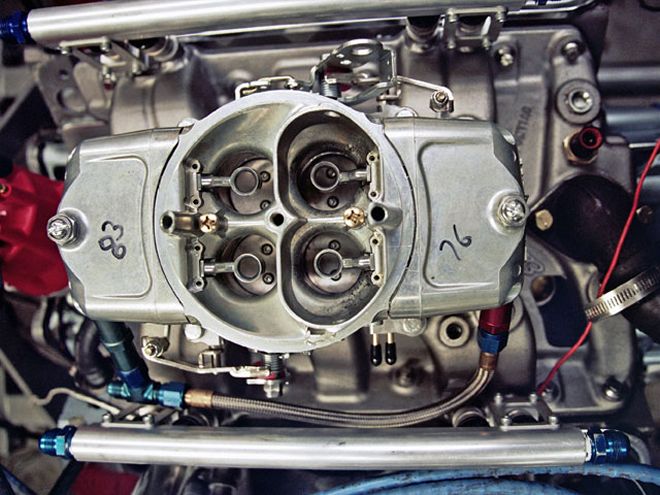

To this cause, Barry Grant stepped up with a 750-cfm Speed Demon mechanical secondary carburetor. In many ways, this would be a more accurate comparison since the Speed Demon would bolt right in place on the Edelbrock manifold, and thus, both fuel system theories would employ the same intake and eliminate any variables in flow or tuning characteristics. Finally, a real-world EFI-versus-carburetor test on a Pontiac engine!

Different Methods to Accomplish the Same Thing

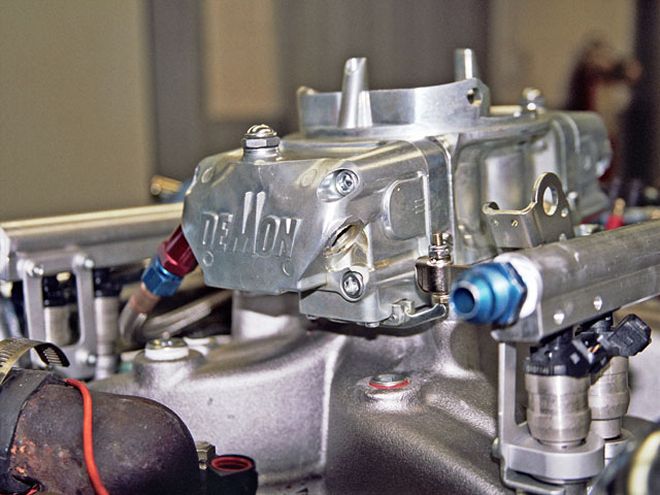

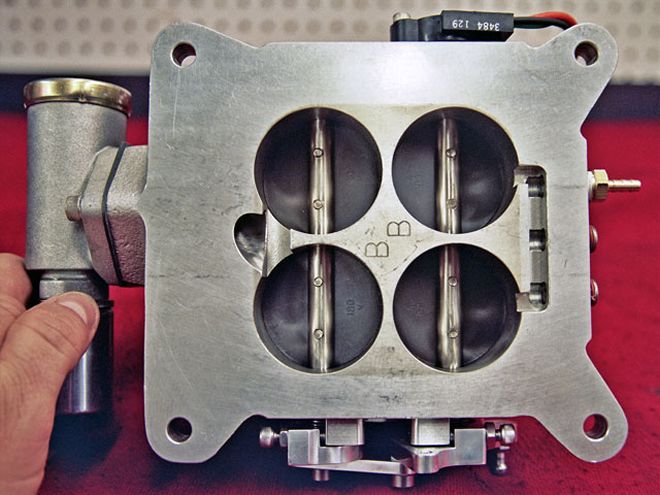

Barry Grant supplied a 750-cfm Speed Demon with mechanical secondary operation for our test. Note the fuel rails and injectors are in place to block the holes in the modified-for-EFI Edelbrock intake.

Barry Grant supplied a 750-cfm Speed Demon with mechanical secondary operation for our test. Note the fuel rails and injectors are in place to block the holes in the modified-for-EFI Edelbrock intake.

Contrary to what many believe, an engine has no idea of how it's being fueled. The gasoline, along with the combustion event, can't tell if there's an EFI system or carburetor attached to the intake manifold. What does impact the engine is what happens to the charge-defined as the air/fuel mixture-on its way to the intake valve.

Carburetor: A carburetor is considered a wet-flow fuel-metering device. The gasoline is discharged through a booster venturi where it's atomized and emulsified (broken down into small particles and mixed with air, respectively). From there, the mixture undergoes a phase change from a liquid (albeit in small particles) to a gas. (not be confused with gasoline-a gas is defined as a liquid in its most rarefied form). The phase change requires heat and is called vaporization. For this to occur efficiently, it's important for the fuel to be atomized as much as possible and for the emulsification process to be thorough.

EFI: In contrast, EFI uses an injector to atomize the gasoline. This is accomplished through high pressure (in relation to a carburetor) that forces the fuel through either a small hole or series of holes in the injector tip. The fuel is then mixed with the air already in the manifold runner, and the vaporization event takes places. An EFI system is considered a dry-flow design since only air travels through the majority of the length of the intake-manifold runner.

What a carburetor does mechanically requires much more complexity to achieve alongside fuel injection. Add to that the reality that an engine does not breathe in a linear fashion-more rpm does not always mean higher cylinder-fill rates. A carburetor handles this by nature of its design. It provides fuel flow in lock-step with air throughput. EFI needs to monitor the airflow of the engine to then calculate the amount of fuel to create a desired air/fuel ratio. For practical purposes, there are only two methodologies that are accurate: speed density and mass airflow.

The Demon line of carburetors flows slightly more air than its competitors (the 750 actually flows around 875 cfm), so it was close in size to the amount of air the original Q-Jet would move.

The Demon line of carburetors flows slightly more air than its competitors (the 750 actually flows around 875 cfm), so it was close in size to the amount of air the original Q-Jet would move.

In a true speed-density system, the EFI controller uses an engine-vacuum sensor (MAP) along with a complex algorithm to model the amount of cylinder fill the engine is incurring. This concept can be made to work accurately at the OE level since all of the variables can be quantified in the test laboratory.

The airflow (MAF) design measures the incoming air mass and employs a transfer-table-logic internal to the ECM that decides the amount of fuel the engine requires. It then manipulates the fuel-injector opening time to deliver that amount. MAF systems are much more forgiving to typical enthusiast engine modifications since they measure the engine's ability to breathe and care little about what happens afterwards. The Achilles heel of most aftermarket EFI systems is that they don't use the more accurate and forgiving MAF sensor like the Mass-Flo system does.

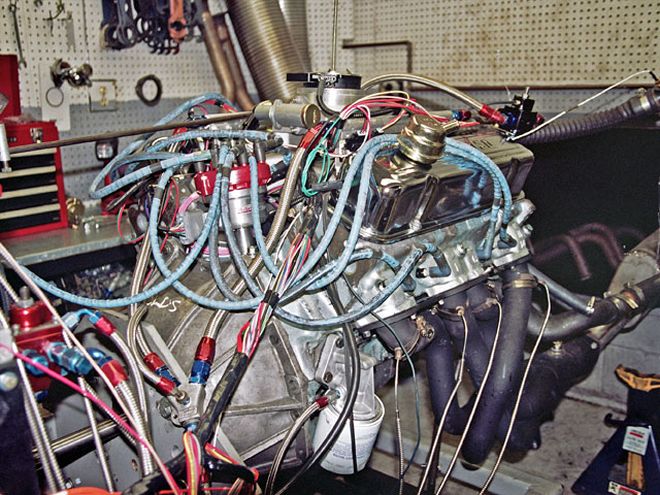

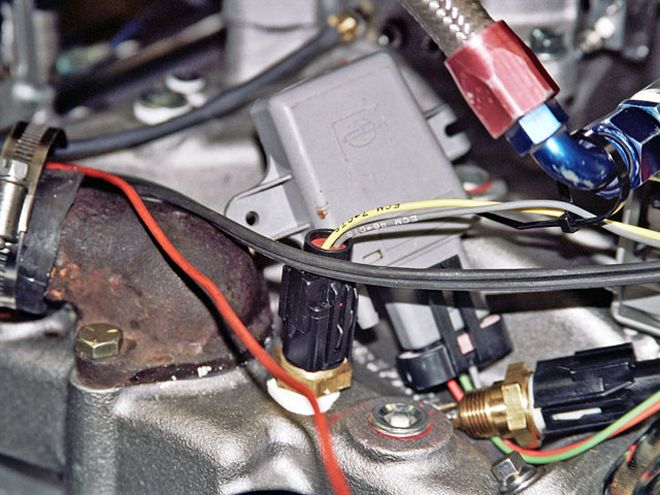

The SD-455 is actually under that pile of wires and was fitted with the Mass-Flo EFI and Hooker Super Comp 1.875-inch headers just before testing began.

The SD-455 is actually under that pile of wires and was fitted with the Mass-Flo EFI and Hooker Super Comp 1.875-inch headers just before testing began.

In addition, the necessary software to create a fuel and ignition curve can be too complex for the average enthusiast. Even though the conventional wisdom may be that EFI would be better on a Pontiac engine, many of those who tried stand-alone systems in the past often struggled with problems they never had with a carburetor-enter Mass-Flo with a fix.

Mass-Flo Fuel Injection System: Seeing a market for a self-tuning EFI system for Pontiacs that employed a MAF sensor, Mass-Flo Fuel Injection Systems came out with an ingenious design that eliminates most, if not all, of the headaches a Pontiac hobbyist incurs converting a traditional engine to injection-a true bolt-it-on-and-forget-it conversion kit.

To achieve the desired results, Mass-Flo owner Chris Richards went shopping in the OE market. This may be a hard pill for a GM-based readership to swallow, but the Ford EEC IV (Electronic Engine Controller, Fourth Generation) system is considered the most reliable, accurate, and tuneable of any made. Thus, the heart of the Mass-Flo design is a Ford 5.0 Mustang EFI controller. When it came to the MAF sensor, the GM LS1 design is respected for the same qualities the Ford ECU enjoys, and through much effort, the GM airflow meter and the Ford engine controller were joined in marriage-truly the best of what Detroit has to offer.

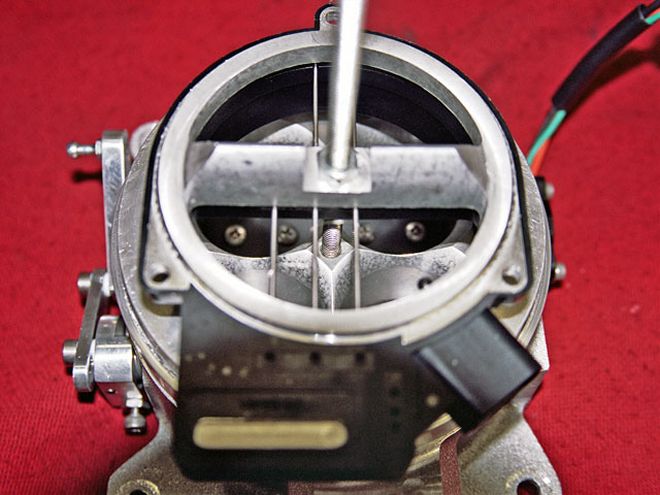

The obstacle with the MAF sensor was always its packaging or how to place it in the airflow stream. With an EFI-converted Pontiac V-8, there was no practical method for doing this. That was until Mass-Flo came on the market. With a design that is surely making the competing EFI companies kick themselves, Mass-Flo took the problem and solved it by attaching the MAF sensor directly to the company's custom-made, four-barrel throttle body. Then a traditional air-filter assembly can be employed, so a Shaker hoodscoop could still be mounted on a T/A, for instance. Since the system is Ford-based, all of the sensors are Dearborn-specific.

Chris Richards from Mass-Flo came up with the great idea of mounting the MAF sensor to the throttle body. GM actually employed this concept in 1988 when the 3800 Series II Buick 3.8 V-6 was introduced.

Chris Richards from Mass-Flo came up with the great idea of mounting the MAF sensor to the throttle body. GM actually employed this concept in 1988 when the 3800 Series II Buick 3.8 V-6 was introduced.

On The Dyno

With the engine completed, Bob and Craig Wise of RaceKrafters bolted it on to their Stuska dyno along with a set of Hooker Super Comp 171/48-inch, Second-Gen, F-body headers. RaceKrafters has one of the most accurate and sophisticated dyno cells around, and it's set up to properly test both EFI- and carburetor-equipped engines. The dyno cell is equipped with the latest Depac brand-control and data-acquisition software. In addition, the cell has two fuel-flow meters, so brake-specific fuel-consumption (BSFC) values for EFI can be determined. Since fuel-injection systems pump more fuel than they use, both the feed and return needs to be measured so the consumption rate can be determined.

After a normal break-in period, the oil was changed and the first full-load pull was made with the Demon carburetor in place on the EFI manifold. The engine performed flawlessly, and the carburetor did likewise. When HPP ordered the Speed Demon, we provided all of the engine specifications so Barry Grant could ship the proper calibration. The company sent us the 750-cfm carburetor with 76/83 jets, and after some trial and error, they proved to be right on the money. All that was required was an idle-speed and mixture adjustment.

With the wet-flow fuel system, the Pontiac produced 520.1 hp and 547.1 lb-ft of torque at 5,300 and 4,400 rpm, respectively, on 92-octane pump gas. The average horsepower and torque from 3,500 rpm to 5,500 rpm was 453.73 and 530.26, respectively.

The Ford engine-management system employs a duty-cycle valve for idle-speed control instead of the GM-style stepper motor.

The Ford engine-management system employs a duty-cycle valve for idle-speed control instead of the GM-style stepper motor.

Even more interesting was the fuel efficiency of the SD-455. The average BSFC value was 0.354 and at peak torque it was 0.30. This means on the average it took 0.354 pound of fuel to produce 1 hp-a remarkable rate of chemical-to-mechanical energy conversion.

Executing the same test with the engine now fueled through the Mass-Flo EFI, the results showed just 3.5 percent less power than the carburetor. At peak, the 455 produced 502.9 hp and 522.5 lb-ft of torque. The average readings showed a similar drop. The horsepower aggregate was 437.48 and the torque came in at 511.54 lb-ft. Also, the engine consumed more fuel as represented by the BSFC readings. The average BSFC increased to 0.468 from 0.354 with the carburetor. In addition, the 455 wanted only 28 degrees of total ignition advance with the carburetor, but the EFI system desired 32 degrees BTDC to produce the best power. With the Speed Demon, the engine would idle nicely at 750 rpm, but the EFI demanded an idle speed 100 rpm higher to achieve not quite the same level of happiness.

The Mass-Flo four-barrel throttle body has a progressive linkage for smooth driveability.

The Mass-Flo four-barrel throttle body has a progressive linkage for smooth driveability.

A Technical Review

It is important that the readers of HPP don't misinterpret these test results. Both the Demon carburetor and the Mass-Flo EFI system performed impeccably.

The Mass-Flo EFI design is a wonderful piece of engineering. As the author, I have many years of EFI-tuning experience and did the dealer training for 15 years for ACCEL/DFI, so don't take what I am about to state lightly. In my opinion, there is no other fuel-injection system currently on the market that could be bolted onto a Pontiac engine, requires no user calibration, and provides turnkey performance without driveability issues. Until the Mass-Flo system was introduced, this was an unheard-of concept.

To the credit of Barry Grant, the fact that an enthusiast can order a carburetor properly, bolt it on and be at peak power is something new to the industry. But the operative word in the statement is properly. All too often the enthusiast is sold the wrong carburetor calibration by the dealer/speed shop because that is what was on the shelf. Demon Carburetion has hundreds of different calibrations, so it's beneficial to speak with the company's technical line to get the proper part number for your use. Armed with that information, you can purchase the carburetor from whomever you want.

If EFI is so great, why did the carburetor do better than the EFI system? Since the manifold was a constant and only the fuel-delivery method differed, some accurate conclusions can be made.

Latent Heat of Vaporization: Since EFI systems are dry-flow, the phase change of the fuel occurs as the charge enters the intake port of the cylinder head. This allows for the air in the runner to become heated as it travels from the throttle body to the point that the fuel is injected. A good rule is that for every 10 degrees the air temperature is increased, power drops by 1 percent. The phase change of the gasoline, demanded by the laws of nature, removes heat as it occurs. Power was down by only 3.5 percent with the EFI in comparison to the carburetor. That would represent an approximate 35-degree rise in inlet air temperature. This is a conservative increase and would probably be higher with the engine in the restricted underhood area of a '74 Trans Am.

A Ford EEC IV ECM is employed with the Mass-Flo system.<BR><BR>

A Ford EEC IV ECM is employed with the Mass-Flo system.<BR><BR>

In addition, it may appear that where the MAF sensor connects to the throttle body, it shrouds some of the airflow path. That would be easy to determine on a flow bench [Editor's note: According to Mass-Flo, the MAF flows 1,000 CFM], but my educated opinion is the charge air heating is where the power is lost, not in the MAF. This is not a design flaw of the Mass-Flo system, but rather the nature of fuel injection.

One reason newer Pontiacs have plastic intake manifolds is due to the heat-transfer problem. The decrease in volumetric efficiency from the less-dense charge may also explain why the engine wanted 4 degrees more advance with the EFI. Most likely it is a combination of the hotter air along with the placement of the fuel injectors.

Injector Placement: Almost all, if not every, company that markets a Pontiac EFI conversion uses a single-plane carburetor intake manifold as a foundation. Due to the nature of this design and the fact that it's being retrofitted, the injectors are placed at nearly a right angle to the manifold runner. This is in direct contrast to an OE application where the injector is laid on its side so it sprays into the port and not against the floor of the runner. With the aftermarket placement of the injector, it wets the bottom of the runner. Also, the distance from the injector pintle to the floor is not sufficient for the atomization to be as effective. At higher engine speeds, port flow increases, and this becomes less of a problem since the air stream carries some of the fuel away. The higher required idle speed, reduced idle quality, and higher rate of fuel consumption over the carburetor can all be blamed on the injector pointing at the floor of the manifold runner.

All-Ford sensors are used for this EFI system. Shown is the digital barometric-pressure sensor and analog-coolant and air-temperature sensors.

All-Ford sensors are used for this EFI system. Shown is the digital barometric-pressure sensor and analog-coolant and air-temperature sensors.

None of this is meant to be a blow to the Mass-Flo EFI system. The company has done a great job of offering an excellent EFI system to the Pontiac community. These guys did their homework and it shows, but the inherent obstacles of fuel injecting what is basically a 52-year-old engine design cannot be eliminated with advanced electronics.

Based on this test, if you want the visual appeal and bragging rights of owning an EFI-equipped traditional Pontiac engine that doesn't require user calibration, you can do no better than the Mass-Flo system, in the author's opinion. You will drive off with a carefree EFI system if you do the installation properly. If your desire is for the most power at the least cost and complexity along with minimized fuel consumption, stick with a modern carburetor such as the Speed Demon by Barry Grant. But don't decide yet because there is more to come in a future issue. We'll see if the chassis-dyno test provides more revelations that could tip the scales further in favor the EFI or the carburetor.

With 750-CFM Speed Demon CarburetorRPMTorqueCounterpoint

Craig Wise welded in an oxygen-sensor bung in each downpipe since the EEC IV looks at the mixture on both banks of the engine.<BR><BR>

Craig Wise welded in an oxygen-sensor bung in each downpipe since the EEC IV looks at the mixture on both banks of the engine.<BR><BR>

When the dyno testing was completed, HPP contacted Chris Richards, owner of Mass-Flo EFI, for comment. What follows are his observations and opinions based upon his experience regarding his fuel-injection system.

"Ours is a closed-loop learning system. Given the opportunity to learn and adjust fuel trims in the real world (something that cannot be accomplished on the engine dyno), I believe this system will provide better fuel economy than any carburetor. A/F ratio will be monitored by the O2 sensors, long- and short-term fuel trims will be set, and the A/F will be correct at all times under all conditions. Also, as the engine's needs change (with altitude, weather conditions, engine wear, and so on), the Mass-Flo system will adjust for those changes automatically (no need to jet up or down). In other words, the Mass-Flo system adapts to the engine's ever-changing needs and improves with drive time."

Chris also states this system is the cure for the poorly maintained and/or maladjusted carburetor since his EFI self-adjusts. "In my experience," he says, "a Mass-Flo-equipped vehicle has much better manners than a carbureted car, especially when cold. Cold starting is worlds better, and I believe once it learns the combination, horsepower and torque will improve. That said, I don't believe anyone spends $3,000 to $4,000 on a fuel injection system to obtain maximum power. The fact is, if the engine is provided with the correct A/F ratio and spark advance, it's going to perform to its power potential regardless of how the fuel was supplied. The real reason you should invest in a Mass-Flo system is drivability, fuel economy, and reliability. This is where the Mass-Flo system shines. Times have changed, and the average enthusiast's time is limited. On the rare occasions you have time to enjoy your car, you should be able to enjoy your car, not fight with your carburetor."

As you have just read, Chris feels that a chassis-dyno test after the fuel injection has the opportunity to learn the engine's operating characteristics on the road would better represent the attributes of Mass-Flo's product. It just so happens that was part of the original plan anyway. So as soon as we can get the engine back into the SD Trans Am, we'll pit the Mass-Flo EFI against the Demon once more-this time on the chassis dyno after putting some miles on the engine so the EFI can learn what it needs to.

Chris tells HPP he is confident the system will perform much better. We will all find out on the dyno!

-Thomas A. DeMauro

Bob Wise handled all of the dyno testing and EFI tuning.

Bob Wise handled all of the dyno testing and EFI tuning.

The Mystery Motor

When building an engine, doing everything right and leaving no stone unturned greatly improves the rate of success over skipping steps and assuming all is well. Our SD-455 came to us with myriad internal problems, some caused by previously done slipshod work, but the fact cannot be denied that the initial failure was the impetus for the engine to be rebuilt.

When dealing with an engine such as this, Craig Wise tells HPP, "With every engine I build, I perform every practical test and measurement, but with something that has a history of problems, I go even deeper, way beyond what would be considered normal even on a NHRA Pro Stock engine." Since the SD had wiped out some of the main bearings and then, in turn, the rod bearings, RaceKrafters spent days checking over the block before doing any machining.

A scratch test-using machinist blue dye on the main caps/saddles and the mandrel from the line hone installed and turned by hand-was performed. Craig also Magnafluxed the block to such an extent that he burned out the black light bulb in the tool. With this data, he performed the necessary machine work, and the 455 ran great, as proven by the dyno results. But the rear main seal developed a leak near the end of our testing.

We all thought the rear main leak was an anomaly, but Craig wanted to look inside the engine after it came off the dyno. His intuition was correct, and everything looked great except for the No. 2 main bearing. It started to show some wear. So despite all of the checking and machining, a ghost is hiding somewhere in the rare Super-Duty block.

Both Wise brothers worked to ensure accurate results for our test.<BR><BR>

Both Wise brothers worked to ensure accurate results for our test.<BR><BR>

At this point, we don't want to jump to conclusions, but RaceKrafters will exhaust all possibilities to save the rare Pontiac casting. Some suggestions are that the oil galley feeding that main cap may have a crack in it and is bleeding off the oil pressure to that bearing. This would be an internal oil leak that wouldn't be exposed by the Magnaflux procedure. The only way it can be confirmed is through an industrial X-ray test-but that is only a possibility, not a diagnosis.

So as you can see, the staff at HPP once again proves we have just as many or more issues with our projects as the readers. Those of you who think of us as King Midas, think again. We will keep you informed of what we find with Melvin's engine block.

-R.B.