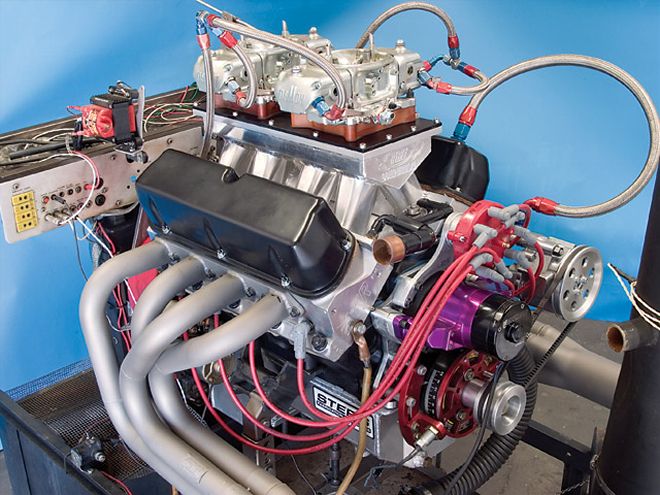

Joe Sherman's 14.5:1, 374ci Ford makes over 800 hp with AFR Windsor-style heads, a TRE sheetmetal intake, a huge Comp Cams mechanical roller cam, a GZ Motorsports crankcase evacuation pump, a lightweight bottom end-and no power-adders.

Joe Sherman's 14.5:1, 374ci Ford makes over 800 hp with AFR Windsor-style heads, a TRE sheetmetal intake, a huge Comp Cams mechanical roller cam, a GZ Motorsports crankcase evacuation pump, a lightweight bottom end-and no power-adders.

This is not your father's Ford. It's not even your older brother's. And it's definitely not for your average part-time bracket racer. What it is, is Joe Sherman's latest monster that pushes the peak of conventional carbureted, normally aspirated, no-power-adder Ford small-block Windsor-head tech to the limit-816 hp and 531 lb-ft from a 14.5:1, 374ci engine equipped with wedge-style Air Flow Research aluminum heads that still maintain the original Ford inline, 20-degree valve-angle configuration. You heard that right: No rolled-over valve angles, no trick-of-the-week Cleveland, Australian, or Yates heads, and it's built off the standard Ford 302/5.0L deck height.

Raising the venerable Ford Windsor small-block to a level that just a generation ago was reserved for Pro Stock big-blocks is no mean feat. It shows just how far technology has come, as well as what separates hard-core professional engine-builders like Sherman from the rest of the pack. Sherman doesn't waste bucks on nonessentials, but he does know how to get the most power per dollar out of a parts combo. The key is optimizing cylinder-head flow with additional porting then determining an intake and cam combo to maximize performance within the limitations of the Windsor port configuration. Add in high-tech coatings, ultrahigh compression, a lightweight rotating assembly, and a ring package tailored for reduced friction and compatibility with a high-tech crankcase evacuation system, and the result can propel a 2,200-pound Super Gas-style car to 8.11-second e.t.'s at 168 mph.

Ford's 302 racing block (PN M-6010-R302) has nodular-iron four-bolt main-bearing caps with angled outer bolts in positions 2, 3, and 4. The splayed caps may hit some stock pans. The blocks come sonic-tested with a signed wall-thickness sheet. This one had nearly 0.400-inch-thick walls at its as-delivered 4.0-inch nominal bore size.

Ford's 302 racing block (PN M-6010-R302) has nodular-iron four-bolt main-bearing caps with angled outer bolts in positions 2, 3, and 4. The splayed caps may hit some stock pans. The blocks come sonic-tested with a signed wall-thickness sheet. This one had nearly 0.400-inch-thick walls at its as-delivered 4.0-inch nominal bore size.

Although this 2.18-hp/ci, $23,500, professional-level engine isn't for everyone (it re-quires constant maintenance and upkeep on par with a serious Competition Eliminator build) dissecting its innards is an instructive introduction to all the research, development, and careful attention to detail that go into an engine of this power level. Examining the design choices and limitations and how Sherman overcame them could prove instructive to those seeking to build any high-end, cutting-edge engine combo.

Block and Bottom End

The engine's foundation is Ford Racing's 302 siamesed-bore wet-sump block, officially rated to withstand up to 1,200 hp at 8,500 rpm. This block has the standard Ford 8.206-inch deck height but comes with semifinished, 0.0005-inch undersized lifter bores and main saddles that must be honed for final fitment. The block also requires common outer-diameter cam bearings. Sherman used a Ford PN M-6261-J351 cam bearing set, which has a common outer diameter but a stock inner diameter to facilitate camshaft interchange.

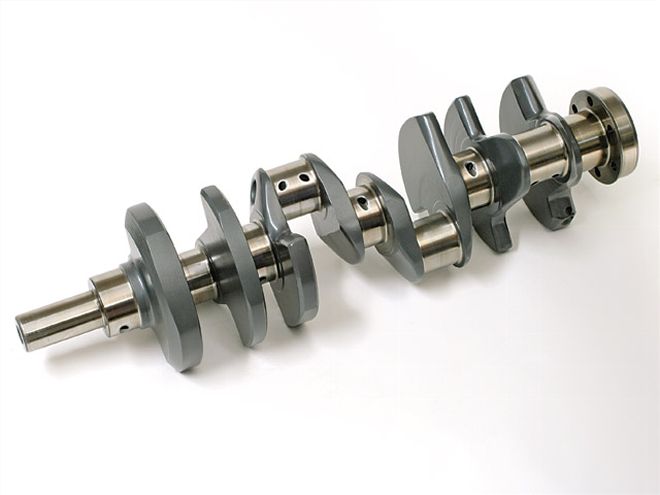

The thick-wall block easily accepted a 4.125-inch final bore size that, when combined with a Scat 3.5-inch stroker crank riding on Clevite 302-Ford H-series race main bearings, brought the little Ford out to 374 ci. The crank carries ultralight Manley aluminum rods and 14.5:1 compression, CP custom pistons retained by Manley lightweight tool-steel pins, and double 0.042-inch Truarcs. Pin clearance is held at a loose 0.002 inch to 0.003 inch. "I like loose," Sherman says. "Loose means less drag and less friction. A drag engine like this is designed to run cold. I keep the motor water at 100 degrees and run 130-degree oil temperature. There's a 20hp difference from running it hot at 170 to 180 degrees."

The custom Scat 4340-steel forged lightweight crank has fully profiled, rounded-off edges to reduce windage losses. Sherman's 3.5-inch stroke was produced by offset-grinding Scat's common 3.4-inch Ford stroker by 0.100 inch, thereby reducing the standard 2.123-inch-od rod journals to the popular (and friction-reducing) 2.0-inch diameter.<BR><BR><BR>

The custom Scat 4340-steel forged lightweight crank has fully profiled, rounded-off edges to reduce windage losses. Sherman's 3.5-inch stroke was produced by offset-grinding Scat's common 3.4-inch Ford stroker by 0.100 inch, thereby reducing the standard 2.123-inch-od rod journals to the popular (and friction-reducing) 2.0-inch diameter.<BR><BR><BR>

The pistons use only two rings: a 0.040 gas-port compression ring back-cut to reduce radial tension (its lateral width is 0.030-inch narrower than standard) and a low-drag 3mm oil ring. The engine is torque-plate honed using the next-to-smoothest bore finish, Sherman says. "I call it a '420 finish'. I've never found the ultrasmooth bore thing to be worth anything. A little bit of surface texture can reduce drag; the engine turns smoother because the increased oil retention on the bore improves film strength." But getting the ultralow-drag package to seal requires a GZ vacuum pump run at 4,500 pump rpm where it develops 15 inches of vacuum.

The rotating assembly is so light that even the crank could be internally balanced without Mallory metal, which is unusual for a small-block Ford. In fact, Scat had to drill lightening holes in the crank. With the crank neutral-balanced, Sherman installed a corresponding TCI SFI-legal neutral-balanced harmonic damper.

Sherman believes engine coatings can add upwards of 15 to 20 hp on a high-end engine. Embee Performance Coatings applied thermal-barrier coatings to the headers, exhaust ports, valve faces, cylinder-head combustion chambers, and piston tops. The piston sides also received antifriction coatings, as did the main and rod bearings. Oil shedders were applied to the crankshaft and connecting rods. Sherman also had the piston pins hard-chromed for reduced friction.

Cylinder Heads

Conventional Ford wisdom holds that modified Cleveland cylinder-head descendents, such as Yates NASCAR cylinder heads, are needed to support a maximum effort like this. But such high-end heads require dedicated and exotic valvetrain parts, so Sherman decided to try to make the big numbers with an inline-valve Windsor-style casting. He selected Air Flow Research's 225cc intake-runner Outlaw casting and wasn't disappointed.

Cam and Valvetrain

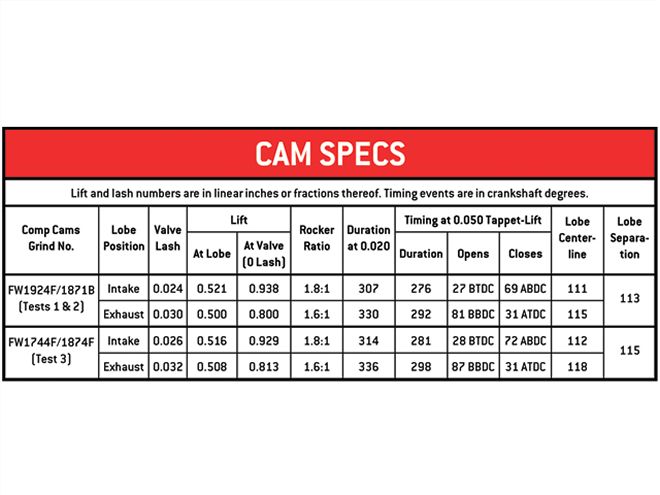

A carefully designed lobe profile is needed to crutch the inline cylinder heads, which can only pass a finite amount of air. On the cutting edge of modern camshaft technology, Sherman's custom Comp Cams profile is way beyond any "shelf" grind. Comp designer Billy Godbold really had to crunch the numbers to configure a profile that would both provide the needed lift and duration numbers while remaining stable past 9,000 rpm.

In theory, Godbold says, "This engine is almost like a restrictor-plate engine, but it's restricted at the port instead of at the top of the intake plenum. We're making a lot of power per cfm, so we need to be more miserly with the air that does come in." In other words, the smaller the heads are in terms of flow and port volume compared with the engine's displacement, the more cam you need. But after a certain point, simply adding overlap doesn't necessarily improve airflow into the engine, especially at the extreme high rpm this engine must turn to generate the big power numbers. Instead, Comp spread the lobe separation, which allows more duration without correspondingly increasing the overlap.

Not for the faint of heart, Comp's custom grind has more than 0.500 inch of lobe lift alone and 0.050 duration in the 280-degree range. The only way such a massive lobe will fit through the cam journals is by radically reducing the camshaft's base circle. Compare the custom cam's lobe and base circle (bottom) with a warmed-over stocker (top).

Not for the faint of heart, Comp's custom grind has more than 0.500 inch of lobe lift alone and 0.050 duration in the 280-degree range. The only way such a massive lobe will fit through the cam journals is by radically reducing the camshaft's base circle. Compare the custom cam's lobe and base circle (bottom) with a warmed-over stocker (top).

Cam development for this combo is still ongoing. So far Sherman has tried two different custom Comp Cams mechanical rollers. Both had more than 0.500 inch of lobe lift with less lift and more duration on the exhaust side. The difference was accentuated with radically divergent rocker-arm ratios-1.8:1 on the intake, 1.6:1 on the exhaust. In Sherman's experience, "More lift on the exhaust side rarely is needed, assuming the cam is close to what the engine likes. The exhaust side likes duration; it acts like a fifth combustion cycle, helping to pull air through the intake like a big siphon. Backing off on the exhaust lift makes more torque down low with no loss of top-end power." Since it was a custom grind anyway, why not just grind the difference on the lobe? "It's hard to manufacture-in such a big lift difference at the lobe; you'd need radically different base-circle sizes. Different length pushrods would also be needed."

After trying the first cam, "The engine peaking speed was only 8,400 rpm-not as high as I thought it would be," Sherman says. "It fell off significantly by 9,000." So on the second go-round, Comp added about 5 degrees more 0.050 duration and spread the lobe separation another 2 degrees (from 113 to 115). This kicked up top-end power at the expense of some midrange losses. The ultimate cam is probably somewhere between the two grinds.

As you might expect, the cam's small base circle, huge lobe lift, radical 1.8:1 intake/1.6:1 exhaust rockers, and tall valves play havoc with valvetrain geometry as well as require humongous valvesprings with titanium retainers to keep everything stable. Jesel's shaft-mounted rockers are longer than normal to help correct the geometry, while tall Ferrea valves provide the necessary clearance to install full-race Comp Professional Series valvesprings (PN 26082) at their proper 2.100-inch installed height. Thick Comp 31/48-inch Hi-Tech pushrods are used to resist flex; Jesel provides a tool to help determine the right length.

INDUCTION, IGNITION, EXHAUST

The intake's no-compromise runners won't clear a standard vertical-mount distributor, so a right-angle beltdriven unit was substituted. Jesel makes the beltdriven timing set and distributor drive, the right-angle distributor, and the distributor mounting bracket. Sherman fabbed 11/42-inch spacers so the Meziere electric water pump would clear the beltdrives.<BR><BR><BR>

The intake's no-compromise runners won't clear a standard vertical-mount distributor, so a right-angle beltdriven unit was substituted. Jesel makes the beltdriven timing set and distributor drive, the right-angle distributor, and the distributor mounting bracket. Sherman fabbed 11/42-inch spacers so the Meziere electric water pump would clear the beltdrives.<BR><BR><BR>

Rules permitting, sheetmetal tunnel-ram intakes have become almost standard-issue for competition engines. They can be specifically tailored to enhance the rest of the combination. Sherman went with a TRE intake, which features a unique plenum volume and runner profile, length, and shape, all derived using proprietary formulas that take into account the engine's operating rpm band and displacement. Like a funnel, the equal-length runners actually start out larger at the plenum and taper down linearly approximately 35 percent to match the intake-port entrance dimensions. This achieves the optimum air speed needed to cram additional volume into the limited cylinder-head ports without exceeding the critical Mach number that promotes air/fuel separation.

On the Dyno

An engine at this level is very sensitive to minor changes in the tune-up. Playing with the carburetor calibration and ignition lead can really move the power curve around. Run on 115 octane VP-115 racing gas with the initial Comp FW1924F/1871B cam and slightly rich No. 91 jets in the 825-cfm Demon carbs, the engine produced more low-end torque, low-end being a relative term here, as the effective operating range is approximately 6,000-9,000 rpm-but had only 774 hp at 8,400 rpm (Graph, Test 1).

Leaning out the jets to No. 88s and retarding the cam 3 degrees shifted the powerband up with the new 800hp peak now occurring at 8.900 (Graph, Test 2). This represented about a 26hp gain but came at the cost of 22 lb-ft on the bottom. Sherman says it's not unusual for a slightly rich combo to produce stronger torque numbers, but in a properly geared race car, the power number is usually more significant.

Installing Comp's larger FW1744F/1874F grind shifted the power curve even higher (Graph, Test 3). With this cam, leaner high-speed air bleeds in the carburetors, and 34 degrees of total ignition lead, the engine became stronger over 7,600 rpm, reaching a peak of 816 hp at 9,300 rpm, a gain of 16 hp over the previous test.

Engine Builder's Specs

SHORT-BLOCK

Displacement: 374.2 ci

Bore x stroke: 4.125 x 3.500

Rod length: 5.4

Rod/stroke ratio: 1.54:1

Block deck height: Milled to 8.195

Piston compression height: 1.040

Piston deck height: 0.005

Piston volume: 13.3cc dome

Head-gasket compressed volume: 11 cc

Compression ratio: 14.50:1

Piston-to-wall clearance: 0.006

Main- and rod-bearing clearance: 0.0031

Rod side clearance: 0.012

Crankshaft thrust clearance: 0.007

Piston compression-ring endgap: 0.014

Piston oil-ring rail endgap: 0.022

Floating piston pin-to-rod: 0.002

Piston-to-head clearance: 0.056

Bobweight: 1310 g

Camshaft thrust: 0.005

Camshaft specs: See Cam Specs chart

CYLINDER HEADS

Valve size: 2.080/1.600

Combustion-chamber volume: 58 cc

Intake-port volume: 245 cc as ported

Max flow: 340.1/240.9 cfm @ 28in H2O

Exhaust/intake flow ratio: 70.8%

Valvespring od/id: 1.645/0.635

Valvespring seat pressure: 350 lbs @ 2.100

Valvespring open pressure: 950 lbs @ 1.200

Valvespring coil-bind height: 1.150

Piston-to-valve clearance: 0.020/0.060 at running lash

Spark plugs: NGK R5672-9, 0.055 gap

CRITICAL FASTENERS

Values are with ARP lube; those not listed are the same as production.

Ford Racing Grade 8 main bolts (11/42): 100 lb-ft

ARP head studs (11/42): Bottom hand-tight (dry)

ARP head stud nuts (11/42): 108 lb-ft

ARP Manley rod bolt (31/48): 50 lb-ft

Jesel rocker stand supports (71/416): 60 lb-ft

Jesel mini-shaft bolts (51/416): 25 lb-ft

All dimensions are in linear inches, except as noted.