About once a generation, Buick awakens, staggers out of its crypt, and produces a kick-butt performance package that attracts living, breathing, flesh-and-blood hot rodders back into its showrooms. Unfortunately, like a groundhog that's seen its shadow, Buick inevitably shuffles sleepily back into hibernation, ushering in a new Dark Age and leaving yet another generation of Buick performance acolytes slowly twisting in the wind.

You're looking at 708 streetable horsepower of twin-turbo, all-aluminum, 265ci, Buick V-6. Newly available blocks and heads from TA Performance and Ken Duttweiler's turbo and EFI tuning magic make the Buick viable again--if you have the bucks. The intercoolers are top-mounted in this example to fit the sand-buggy package this build was going in.

You're looking at 708 streetable horsepower of twin-turbo, all-aluminum, 265ci, Buick V-6. Newly available blocks and heads from TA Performance and Ken Duttweiler's turbo and EFI tuning magic make the Buick viable again--if you have the bucks. The intercoolers are top-mounted in this example to fit the sand-buggy package this build was going in.

So it was with the '70 455 GS Stage I and the mid-'80s turbo Buick V-6 Grand National: great sexy performance packages, but no long-term commitment. Fortunately, guys like Mike Tomaszewski at TA Performance and Ken Duttweiler at Duttweiler Engineering exist to provide life-support. TA has long supported classic Buick V-8s, and more recently has tooled up its own aluminum V-6 blocks and heads. That's critical, because with the traditional rear-drive-style Buick V-6 long out of production and no current factory heavy-duty parts support, hard-core Buick faithful were jumping ship. Even stalwart Buick V-6 turbo-guy Duttweiler had mostly moved on to Chevys and Fords.

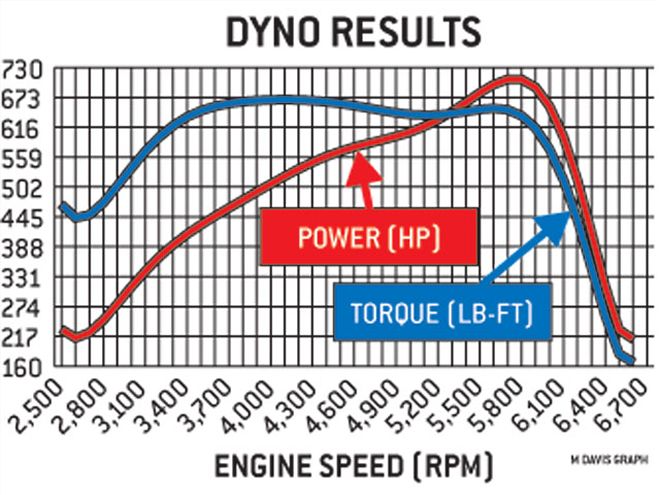

Now, though, hard-core Buick guys are getting ready for a little pick-me-up. Duttweiler is back building a bunch of V-6s, and TA has nearly all the parts (including internals) shown on these pages for the do-it-yourselfer. It's not cheap (the block alone will set you back $4,000), but over 700 hp is attainable on 18 pounds of boost with twin turbos. And the motor still idles at 18 inches of vacuum, enough to please even the country-club set. In other words, the basic package shown here is suitable for street driving--if you got the guts. It's a Duttweiler- built, 265ci Buick V-6 alloy stroker, that on the day we visited KD's shop made 707.8 hp at 5,700 rpm and 668.8 lb-ft of torque at 4,100 on his trick engine dyno. His setup combines a Froude absorber with AVL control and data-logging, offering the capability for truly wide-rpm-band pulls and the ability to prove the package isn't a high-strung, wind-up, bling-bling, sewing-machine import motor. Nosiree, this config makes over 400 lb-ft of torque from 2,500-2,800 rpm, over 500 lb-ft from 2,900-3,200, and over 600 lb-ft from 3,300-5,900. Power output exceeded 400 hp from 3,400-3,900 rpm, exceeded 500 hp from 4,000-4,900, and bested 600 hp from 5,000-5,600. Its peak BMEP of 380 psi and specific 2.67 hp/ci output is up there in Pro Stock territory.

These numbers are with 112-octane VP racing fuel. To accommodate the vagaries of street gas, Duttweiler recommends a less-aggressive spark curve for a daily driver, which'll set you back 100 hp (reducing output to 600 hp in the configuration shown here). However, the initial dyno runs indicated the as-installed turbos were slightly restrictive on the exhaust side, and as we go to press, new turbos were on the way that should up power by another 100 hp or so. That's 800-plus horsepower on race gas, and back to the 700hp level for the street.

Keep in mind we're not just talking about reanimating Grand Nationals. The compact Buick V-6 makes a great sand-buggy engine (that's where the one photographed here is going) and presents interesting possibilities for new-age swaps. An all-aluminum, twin-turbo Buick V-6 weighs in at under 300 pounds. Imagine what a 700hp, 295-pound package could do in a Pro Touring or handling application: Think late-'70s Firebird coupe, replacing the base 231 V-6 two-barrel with one of these monsters. The engine was set way back in those clods to maintain the same trans-crossmember position as its thoroughbred V-8 brothers, so there's ample room in the second-gen F-car's big-block- sized engine bay for the turbos, plumbing, ducting, and intercoolers up front, plus super weight-distribution with the engine's big setback. Or what about stuffing it sideways in a Fiero, shoehorning it into the backseat of an old Corvair, or building a mid-'70s Skyhawk V-6 coupe to run the dry lakes? Buick, arise.

The block deck is drilled for both the production eight-bolt (four bolts per cylinder) or Stage 2 14-bolt (six bolts per cylinder) head-bolt pattern. New external oil-feed bosses are included front and rear. This enables easy dry-sump hookup and bypasses the restrictive Buick front-cover internal passages (see "Oiling System").

The block deck is drilled for both the production eight-bolt (four bolts per cylinder) or Stage 2 14-bolt (six bolts per cylinder) head-bolt pattern. New external oil-feed bosses are included front and rear. This enables easy dry-sump hookup and bypasses the restrictive Buick front-cover internal passages (see "Oiling System").

This motor's broad, flat torque curve should make any hot rodder one of turbocharging's greatest boosters. But there's always room for improvement: The dip in the torque curve is indicative of a restriction or loss of turbo efficiency. Improved turbos are on the way to bust through the 800hp door.

This motor's broad, flat torque curve should make any hot rodder one of turbocharging's greatest boosters. But there's always room for improvement: The dip in the torque curve is indicative of a restriction or loss of turbo efficiency. Improved turbos are on the way to bust through the 800hp door.

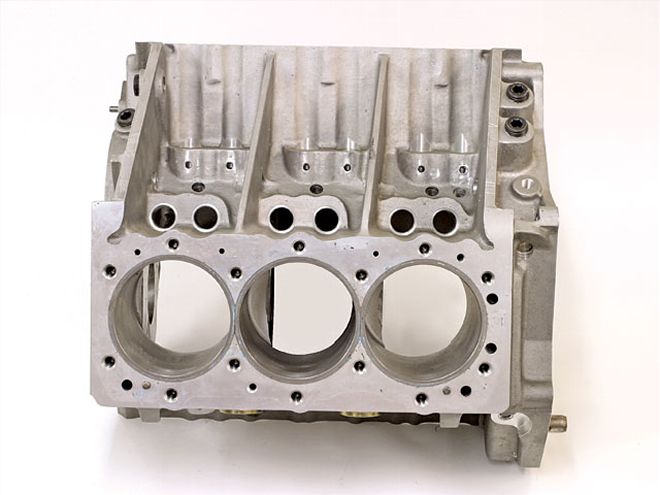

Cylinder Block

TA Performance's aluminum block is based on original iron turbo Buick V-6 production and race blocks. Both off-center and on-center block castings are available. "Off-center" is the same as stock production and accepts original accessory brackets. The engine used in this buildup utilizes the "on-center" configuration, as first introduced on the Buick Stage 2 race blocks. With the on-center design, the cylinder bores are centered over the rod journals for less piston drag; however, stock brackets won't work because the block's front timing-cover sealing surfaces are raised 1⁄8 inch, and the heads are shifted forward.

Another thing to watch is the motor-mount pads. First-production TA blocks use the original two-bolt mount configuration, but current production blocks have a three-bolt configuration that's much beefier. Even on the two-bolt blocks, stock mounts don't work because the block's outer wall has been moved outboard. TA sells dedicated poly heavy-duty mounts for Regal and GN applications; other applications require custom mounts.

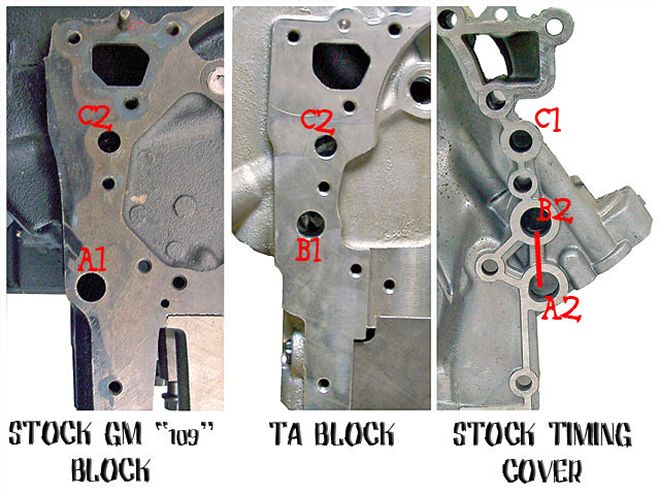

Oiling System

Whether V-6 or V-8, Buicks are plagued by a restrictive oiling system. The oil pump is located in the front cover and the oil has to go through a bunch of twists and turns to get there. Just priming the pump for initial fire-up is a nightmare. The TA blocks have a revised oil-feed hole that eliminates two 90-degree turns. Duttweiler uses an external oil feed/supply system that bypasses the internal feed passages entirely. Either way, Buick oiling problems are now just urban legends.

On stock blocks, oil is sucked out of the pan through hole A1 into front cover hole A2, where it's forced to make a 90-degree turn through an internal transfer slot (dotted line). It then makes another 90-degree turn toward the oil-pump cavity, flowing into a passage coinciding with hole B2, which is present (but not used) on all stock covers. TA's block moves the suction hole (B1) higher to line up with B2 so the oil gets a direct shot to the pump cavity, eliminating two 90-degree turns. In both cases, oil is pumped out of the cover through C1 and back into the block through hole C2.

Rotating Assembly

The rotating assembly is designed for ultimate strength rather then extreme lightness--this engine makes its power through boost, not rpm. Capable of supporting over 1,500 hp, the beefy assembly uses a 3.625-inch-stroke billet Crower crank, heavy-duty Clevite main and rod bearings, CP pistons, Diamond pins, Crower billet rods, and a Total Seal file-fit ring-set with a 1⁄16-inch plasma-moly top ring, a 1⁄16-inch ductile-iron second, and a 3⁄16-inch standard-tension oil ring. Top and second compression ring gaps are a large (for the 3.940-inch bore-size) 0.030-inch, necessary because turbo engines generate lots of heat, and aluminum blocks grow when hot.

Cam and Valvetrain

TA aluminum blocks use a special cam profile that has even-fire cam lobes, but with a modified '77-and-earlier odd-fire nose design that has a removable distributor drive gear. This is necessary because the large thrust plate on stock-style even-fire cams hits the front oil-galley plugs, as well as to accommodate a special bronze thrust/antiwalk spacer to prevent the camshaft from damaging the aluminum block's front surface. The profile itself is a mild Comp Cams hydraulic-roller grind. It has a duration of just 215 degrees at 0.050 inch and 0.534-inch valve-lift with 1.60:1 rocker arms. See what we mean about streetable?

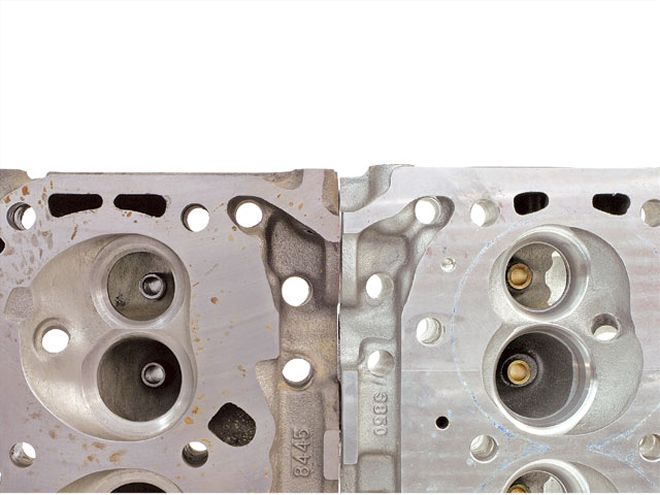

Cylinder Heads

The TA Street Eliminator heads (PN TA V3850 SE) are designed for serious street/strip and race use. With heavy porting they have made as much as 1,200 hp on a 274ci twin-turbo motor. As used in this motor, the heads have mild Duttweiler porting in the valve-bowl and short-turn radius.

The TA Street Eliminator heads (PN TA V3850 SE) are designed for serious street/strip and race use. With heavy porting they have made as much as 1,200 hp on a 274ci twin-turbo motor. As used in this motor, the heads have mild Duttweiler porting in the valve-bowl and short-turn radius.

Stock turbo Buick heads (left) have a quenchless open-chamber design--not much mixture motion there. For an improved flame kernel and detonation resistance, TA uses a heart-shaped chamber and orients the spark-plug toward the exhaust (right). Duttweiler slightly unshrouds the chamber to take advantage of the motor's larger bore.

Stock turbo Buick heads (left) have a quenchless open-chamber design--not much mixture motion there. For an improved flame kernel and detonation resistance, TA uses a heart-shaped chamber and orients the spark-plug toward the exhaust (right). Duttweiler slightly unshrouds the chamber to take advantage of the motor's larger bore.

TA solves the problem of Buick V-6 new performance head availability with its line of aluminum V-6 heads. Two versions are offered: the Street Intimidator that can use stock valvetrain parts, and the Street Eliminator designed for serious engines. The latter require the use of full-on racing pedestal-type roller rocker systems. Both have provisions for 14 head bolts, but will also work on stock 8-bolt blocks.

This engines uses the Eliminator heads, packed with Manley 0.100-inch-long "small-block Chevy" valves--1.940-inch Severe-Duty NK-844 stainless steel (PN 11886) on the intakes (back-cut 30 degrees by Duttweiler), and 1.600-inch, Extreme-Duty, turbo-heat-resisting, XH-428 Inconel (PN 11701) on the exhaust side. The valves ride in bronze-wall guides, sealed with Duttweiler preferred U.S. Seal metal-body/rubber-top valve-seals to control oil--detonation kills turbo engines. Duttweiler bolts the heads to the block with the full 14 head bolts and Fel-Pro PN 1007 Lok-Wire copper-wire gaskets that require machining O-ring receiver grooves in the heads.

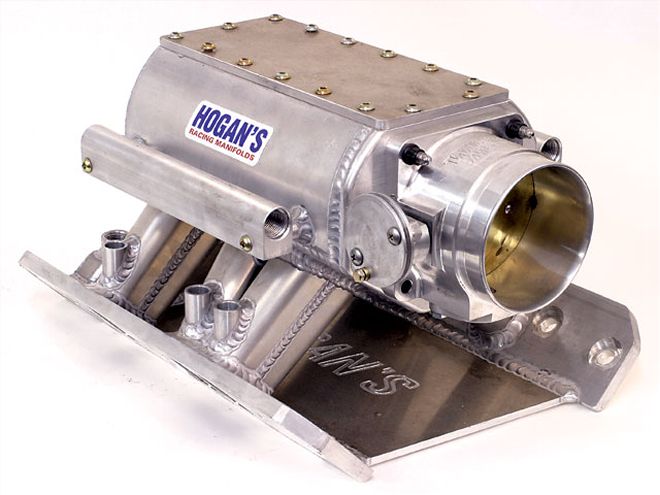

Hogan built the sheetmetal intake. Duttweiler says it's important to keep the plenum on the small side but has found runner length "is not super-critical" on turbo motors. This example's runners are relatively short to clear the top-mount intercoolers. Also due to packaging needs, the manifold was flipped backward to rear-mount a Wilson 90mm Ford throttle-body.

Hogan built the sheetmetal intake. Duttweiler says it's important to keep the plenum on the small side but has found runner length "is not super-critical" on turbo motors. This example's runners are relatively short to clear the top-mount intercoolers. Also due to packaging needs, the manifold was flipped backward to rear-mount a Wilson 90mm Ford throttle-body.

Twin Precision GT30-R turbos make 18 psi of boost. Duttweiler says the dual ball-bearing design makes for "a good, durable turbo." Dyno analysis of the manifold pressure differential indicates the engine could use more airflow on the compressor side, with more volume on the exhaust, so upgraded units are on order. Eventually this combo should see over 800 hp.

Twin Precision GT30-R turbos make 18 psi of boost. Duttweiler says the dual ball-bearing design makes for "a good, durable turbo." Dyno analysis of the manifold pressure differential indicates the engine could use more airflow on the compressor side, with more volume on the exhaust, so upgraded units are on order. Eventually this combo should see over 800 hp.

Fuel and Air Management

Combined with a good set of cylinder heads, it's the turbos and intercoolers that are responsible for the big power numbers, permitting a mild cam for kitty-cat idle quality. Duttweiler has put together a judicious combination of twin Precision turbos and big intercoolers. That latter are top-mounted for the intended application's specific packaging requirements. Funco, the intended owners, are no-compromise dudes; they sprung for only the best: a MoTeC controller and exotic Type 321 stainless headers.

Engine Builder's Specs

All dimensions in linear inches, except as noted.

SHORT BLOCK

Displacement: 265.2 ci

Bore x stroke: 3.940 x 3.625

Rod length: 6.300

Rod/stroke ratio: 1.74:1

Block deck height: 9.530

Piston compression height: 1.400

Piston deck height: 0.0175

Piston volume: -35 cc (dish)

Head gasket compressed volume: 8.6 cc

Compression ratio: 8.46:1

Bore finish: Sunnen 623

Piston-to-wall clearance: 0.0045 cold

Main-bearing clearance: 0.0022

Rod-bearing clearance: 0.0020

Rod side-clearance: 0.012

Crankshaft thrust clearance: 0.005-0.007

Piston compression-ring endgap: 0.030/0.030

Piston oil-ring rail endgap: 0.012 minimum

Floating piston pin-to-rod: 0.0012

Piston-to-head clearance: 0.0565

Engine oil: Lucas 10W30 synthetic, 7 quarts with filter

CYLINDER HEADS

Valve size: 1.940/1.600

Combustion-chamber volume: 50 cc

Intake-port volume: 156 cc before porting

Max flow as ported: 250/190 cfm @ 28 in H20

Exhaust/intake flow: 76%

Valvespring od/id: 1.509/0.697

Valvespring seat pressure: 122 lb @ 1.790

Valvespring open pressure: 311 lb @ 1.256

Valvespring coil-bind height: 1.150

CRITICAL FASTENERS

Values are with ARP lube, except as noted.

All studs: Bottom hand-tight (dry or light oil)

ARP main stud nuts (1⁄2): 100 lb-ft

ARP main stud nuts (7⁄16): 60-65 lb-ft

ARP main stud nuts (3⁄8): 45 lb-ft

ARP main cross-bolts (7⁄16): 55-lb-ft nominal*

ARP main cross-bolts (3⁄8): 35 lb-ft nominal*

ARP head stud nuts (7⁄16): 80 lb-ft

Crower rod bolt (7⁄16): 0.005-0.007 stretch @ minimum of 75 lb-ft

ARP balancer bolt (3⁄4): 200-250 lb-ft (oil)

TA rocker-shaft-stand stud nuts (7⁄16): 55 lb-ft (oil)

Cam bolt: 45 lb-ft (red thread-locker)

*Tighten after vertical main stud nuts; adjust torque as needed to maintain a round main bore as measured with a dial-bore gauge.

CAMSHAFT

Type: Hydraulic roller-tappet

Grind: Comp Cams Magnum 3108S

Duration, 0.006 tappet lift: 271/271 degrees

Duration, 0.050 tappet lift: 215/215 degrees

Lobe displacement angle: 114 degrees

Installed intake centerline: 114 degrees

Lobe lift: 0.334/0.334

Rocker-arm ratio: 1.60:1

Valve lift at zero lash: 0.534/0.534

Valve lash: Zero plus 1⁄2 turn

Pushrods: 5⁄16 od x 8.600 long

Piston-to-valve clearance: Ample

Camshaft thrust: 0.005-0.015

FUEL, SPARK AND AIR

Engine management: MoTeC M-600

Fuel injectors: MSD 72 lb/hr

Fuel pressure: 50-psi base, increasing 1 psi per 1 psi of boost

Throttle-body: Wilson 90 mm

Ignition: GM Gen III coil-packs

Spark plugs: Champion C63YC, 0.030 gap

Fuel (on dyno): VP-112, 112 octane

Max boost: 18.36 psi @ 5,700-5,800 rpm

Timing: 38 degrees base; 22 degrees at max boost

PERFORMANCE

Max torque @ rpm: 668.4 lb-ft @ 4,100

Max power @ rpm: 707.8 hp @ 5,700

Peak BMEP: 380 psi

Power/ci: 2.67 hp/ci

Cost (parts and labor): $35,000

Dollars/hp: $49.45 HRM