We decided to feature this engine build in a two-part series in order toget a little more in depth. We're shooting for 600 hp, and that soundsachievable. But read on for the stipulations we belted ourselves downwith. Do you think we can do it? Tune in next month for the part twofinale.

We decided to feature this engine build in a two-part series in order toget a little more in depth. We're shooting for 600 hp, and that soundsachievable. But read on for the stipulations we belted ourselves downwith. Do you think we can do it? Tune in next month for the part twofinale.

What makes for a great street engine? For the normal public, fueleconomy, reliability, low maintenance, and decent power probably sum itup. For us, when considering our dual-purpose Mopar toys, the attributesare probably not too radically different, except in how we define theterms. Good fuel economy? Might be that getting into the teens ratherthan 6-8 mpg is accomplishment enough to feel good about economy.Reliability? This might mean not having to worry about the engine for atleast a decade while clocking 3,000-5,000 miles a year. Low maintenancemay just equate to checking the fluids, getting in and driving, withouthaving to re-adjust the valves every few months. What's decent power?For the average motorist, it might be defined as enough get-up-and-gofor nimble acceleration in traffic and on-ramps. Decent power for aMopar enthusiast may well mean having enough on-hand to tear trenches inthe asphalt and to take out anything that dares challenge on the openroad.

In contemplating a powerplant for my own street driver 'Cuda,these same questions looking for answers came to mind. What would be agreat street engine? This machine wasn't being built as an everydaycommuter, mind you, but it would be nice to be capable of extended roadtrips, anytime, anywhere, at the twist of the key. It would be nice topull power brakes and A/C without the engine wanting to stall at idle,maybe with an easy 12 inches or more vacuum at idle. It would also benice if that idle would sit between 800 and 850 rpm without the clatterand instability of a deep lope.

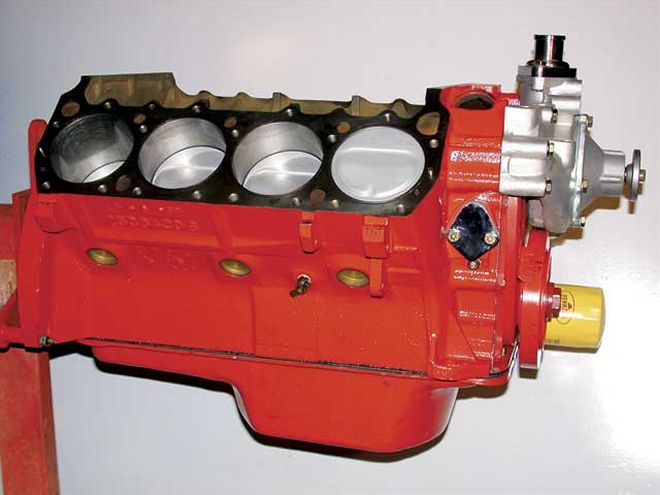

The foundation for our 'Cuda engine build-up was this seasoned 440block, a retired .030-inch over bored dyno test block. The 1970 "F"block had seen duty in many configurations, and had survived over 750 hpon nitrous. The block had been decked approximately .070-inch when usedwith low-compression SpeedPro 2266 flat-top pistons, and also had thedecks grooved and fitted with copper O-rings.

The foundation for our 'Cuda engine build-up was this seasoned 440block, a retired .030-inch over bored dyno test block. The 1970 "F"block had seen duty in many configurations, and had survived over 750 hpon nitrous. The block had been decked approximately .070-inch when usedwith low-compression SpeedPro 2266 flat-top pistons, and also had thedecks grooved and fitted with copper O-rings.

Sure, a melodic and steady rhythm ofpower from the headers, exhaust, and cam is acceptable, but not thatragged-edge big-cam stagger that blows out enough toxic hydrocarbongasses to make your eyes water. It would be nice to have the quiet,maintenance-free operation of a hydraulic flat-tappet camshaft. It wouldalso be nice to a have a torque curve that starts right when you can useit, pulling strongly against a high gear ratio at low rpm withoutstumbling. Better still if that torque will carry up the rpm ladder tomake peak horsepower in the neighborhood of 6,000 rpm. So far, the goalsaren't too difficult to achieve, but wouldn't it be nice if it made asavage 600 hp on the street? That would be a great street engine.

Theengine we are building here is an attempt to meet these insanelyincompatible objectives with a regular 440 without any overly exoticcomponents, but rather through a carefully considered parts selection.

Next, the upper half of the rear main seal was installed and lubed. Theseal's lip faces inward to the crankcase. The crankshaft is carefullylowered in place, as the studs can easily score a journal. With the capson and torqued, spin the crank to confirm it rotates smoothly. To setthe thrust bearing, slack the center main cap bolts and run them in tojust seated. Then, using a block of wood and a heavy mallet, strike thecrank at the rear flange with a heavy blow and re-torque the center cap.Check that the endplay is within specs. If not, the studs may bepreventing the cap from floating to position, and may require the cap'sfastener holes be enlarged slightly. Confirm by checking the endplaywith the center cap removed. Ours went together with no problem, and nomods required.

Next, the upper half of the rear main seal was installed and lubed. Theseal's lip faces inward to the crankcase. The crankshaft is carefullylowered in place, as the studs can easily score a journal. With the capson and torqued, spin the crank to confirm it rotates smoothly. To setthe thrust bearing, slack the center main cap bolts and run them in tojust seated. Then, using a block of wood and a heavy mallet, strike thecrank at the rear flange with a heavy blow and re-torque the center cap.Check that the endplay is within specs. If not, the studs may bepreventing the cap from floating to position, and may require the cap'sfastener holes be enlarged slightly. Confirm by checking the endplaywith the center cap removed. Ours went together with no problem, and nomods required.

Penciling It Out

Our goals here were pretty well defined, andconceptually we had a plan on how to get there. To spell it out, theengine would feature high compression, short duration, and very highlift at the valves, thermal management, and great cylinder heads withlarge ports. The first consideration was how big to build it. Strokersare the popular trend, but in this case, a 500-inch stroked 440 wouldprovide more cubes than we could really use or wanted in this particularapplication.

A 446-cube RB bottom end would already supply more torquethan we could ever hook on the street, and would allow a very cheap andsimple factory forged crank combo to be assembled. There just wasn't anycompelling desire to fuel a 500ci engine for street and open highwaydriving, and given equivalent components, the 440 would pull higher andharder than a bigger engine up top.

For a vehicle that will always beriding on street radials, we were willing to trade excess low-end gruntfor top-end charge. Our 440 block was .030-inch over in the bores,setting the final displacement to 446 ci with a factory 3.750-inchcrank. The stock displacement approach saves money that can be appliedto other aspects of the build.

Rods will have a deep chamfer on the side that sits against the cheek ofthe crank journal. This is important to note for orientation of theparts when the rods and pistons are assembled.

Rods will have a deep chamfer on the side that sits against the cheek ofthe crank journal. This is important to note for orientation of theparts when the rods and pistons are assembled.

We had a set of SpeedPro number 2295forged pistons that seemed ideal for this combo, featuring a moderate12cc dome configuration to get our compression ratio up to themid-11-second range (depending upon final chamber volume), just where wewanted to see it. That compression ratio may seem rather high for ourintentions, however with this engine, the plan was to push the envelopeon pump-gas compression ratio. Compression is power and efficiency, andwe were after as much of both as we could cheat out of our 440.

Anotheroften-overlooked attribute of high compression is the beneficial effecton idle quality gained by the reduction in clearance volume at TDC.These pistons are heavier than some racing pistons on the market, butgiven our hydraulic cammed street stipulation, the added weight wouldnot be a real detriment in the anticipated operating range. We do notexpect to see more than 6,500 rpm from this 440, and it would take avery well-scienced valvetrain to be effective with a hydraulic cam evenat 6,000 rpm.

To aid in the assembly process, each part is assigned to a specific boreand marked with its number and orientation. The SpeedPro pistons usedouble snap rings at each side of the floating pin for retention. Withthe pistons on the rod, the rings are wound on and the bearings insertedand lubed.

To aid in the assembly process, each part is assigned to a specific boreand marked with its number and orientation. The SpeedPro pistons usedouble snap rings at each side of the floating pin for retention. Withthe pistons on the rod, the rings are wound on and the bearings insertedand lubed.

The SpeedPro pistons were prepped by massaging the domesand valve reliefs to radius any sharp edges. Then a coating was added tothem for thermal efficiency on the crowns using a thermal barriercoating, and moly coating the skirts to reduce friction. These number2295 pistons are cut for a 1/16-, 1/16-, 3/16-inch ring package, whichalso helps to reduce friction as compared to the stock 5/64-inchcompression rings. Childs & Albert Dura-Moly rings were selected to sealthe cylinder pressure. To complete the bottom end, we upgraded theconnecting rods to Scat's very strong H-beams.

The camshaft was, asusual, the most critical component to get right if we were to meet ourgoals. We were after the quickest acting hydraulic cam we could find, sothat once the valves start opening, they reach as high of a lift aspractical before again closing. Comp Cams' Xtreme Chrysler Hydraulicsseemed like the logical choice, with intensity approaching a moderateroller cam, but with the price, low maintenance and reliability of ahydraulic. These are a variation of Comps' successful Xtreme Energyprofiles, but spiffed up to take advantage of the greater velocity andlift allowed by Chrysler's large .904-inch diameter lifter tappets.

The bores were given a wipe of Childs & Albert assembly lube, as werethe rings and piston skirts. Then, with the crank rotated to bottom deadcenter, the piston and rod assemblies were fitted to the bores. Rotatethe crank through a full revolution with each piston's installation tofeel for any binding or unusual resistance.

The bores were given a wipe of Childs & Albert assembly lube, as werethe rings and piston skirts. Then, with the crank rotated to bottom deadcenter, the piston and rod assemblies were fitted to the bores. Rotatethe crank through a full revolution with each piston's installation tofeel for any binding or unusual resistance.

Thesmallest lobe in this series is the number 5964, measuring 275 degreesof gross duration, and 231 degrees of duration at .050-inch tappet rise,and 149 degrees at .200-inch. Lobe lift measures .350-inch. That's avery quick hydraulic flat tappet lobe, and we selected this lobe forboth the intake and exhaust in ordering our custom single patterncamshaft. The single pattern reduces exhaust overlap for a given intakeduration, and to further reduce the overlap, the cam was ground on arelatively wide 112-degree lobe separation. Good cylinder heads cantolerate a wider lobe separation, and we sought to constrain the overlapas it is a chief contributor to idle quality deterioration.

With theparts chosen, putting the bottom end of the engine together was assimple as any basic 440 rebuild. With the non-stock pistons and rods,the internal engine components were balanced, and we whipped theshort-block assembly together in a weekend. We're really looking forwardto completing the engine with our trick top end, and seeing how close weare to meeting our goals.

*Originally Published in March 03 Issue