Advancements in camshaft grinding technologies have improved the surfacefinish on the lobe so that in some cases, for the cash-strapped racer,micropolishing isn't a necessity.

Advancements in camshaft grinding technologies have improved the surfacefinish on the lobe so that in some cases, for the cash-strapped racer,micropolishing isn't a necessity.

As the money and competition in the Nextel Cup Series have skyrocketedin recent years, the image of a Nextel Cup engine builder has changed.The old mechanic who learned about engines working in his daddy's garageis still there, but working right alongside him is a mechanical engineerwho spent his youth studying the laws of thermodynamics. It's adifferent world from the old days (Maurice Petty told us once that heused to scrounge junkyards looking for parts for Richard Petty's cars),but that's OK because that's what is needed to continue the pace ofinnovation.

Much of that innovation, however, doesn't come from insidethe engine shop but from outside sources. Many of the advancements inrace engine technology actually come from the parts manufacturersworking closely with the race teams to give them what they need. That'sthe good news for a Saturday night racer. After all, the last thing aNextel Cup team wants to do is pass along its discoveries to anyoneelse, but an innovative parts manufacturer can take what it learnsracing on the Nextel Cup level and use that knowledge to help everyonego a little faster.

To find out more about how high-end racing affectsthe little guy, we called up the folks at Comp Cams and asked afew personal questions. Comp Cams is a perfect example of thisphenomenon because the company produces a wide range of engine parts andis a big player in everything from Nextel Cup, to drag racing, toSaturday night stock cars, all the way to go-karts. Interestingly,there's a lot more going on than we originally thought.

Camshaft Technology

Super-precise measurement equipment such as this Adcole machine allowscam grinding technicians to repeatedly check their work and hone theirprocedures until they are able to hold previously unthinkabletolerances.

Super-precise measurement equipment such as this Adcole machine allowscam grinding technicians to repeatedly check their work and hone theirprocedures until they are able to hold previously unthinkabletolerances.

"When it comes to the camshafts, the demands of theNextel Cup and Indy Car teams that we work with required us to go togreat lengths to meet their specs," says Chris Brown, Comp's vicepresident of operations. "But once we figured out how to meet theirrequirements, it was relatively easy to continue those improvements toour other cams.

"The number one thing that we've done is have ourcamshaft design team work with every type of engine out there. We've gotthree cam designers, and instead of having them specialize in certaintypes of engines, they all work on everything from Nextel Cup, to TopFuel drag racing, to street cars, to oval track stock car racing. Theyeven do the cams for go-kart racing. That's really paid off for usbecause of the depth of knowledge that those guys have acquired. Theyunderstand what's happening inside an engine a lot more than somebodywho only has access to one style of engine. So now when they encounter aproblem for a Saturday night race engine, they can draw on theirexperiences with how drag racers or Nextel Cup racers solved a similarproblem.

"The upper-level guys are always raising the specs that theyneed for their products. That's why we acquired an Adcole machine thatchecks cam tolerances. But what happened was our guys on the manual camgrinders started using it to tune up their machines and methods for alltheir stuff. In the past couple of years, they have gone from having awindow on their duration specs from 0.5 to 0.75 of a degree down to 0.2to 0.25. Without having to tell them, their own pride in theirworkmanship has brought them down that path.

Advancements, including holes that feed pressurized oil to the needlebearings and tool steel axles, have filtered down from NASCAR BuschSeries racing to make even budget roller lifters more efficient anddurable.

Advancements, including holes that feed pressurized oil to the needlebearings and tool steel axles, have filtered down from NASCAR BuschSeries racing to make even budget roller lifters more efficient anddurable.

"We've also learned a lotabout surface finishes, what works best on a roller (cam) and what worksbest on a flat tappet. We've taken what we've learned frommicropolishing and used it to test different types of grinding stones sothat the stone itself leaves a different finish on the cam lobes. That'shelped us improve the lobe surface finish for guys that don't want to orcannot pay for micropolishing. All that stuff is directly related tosome of the high-end cams we have done for NASCAR teams because theyoften put a spec on the surface finish.

"Something that's prettyinteresting is one of the biggest advancements for the racer running aflat tappet cam didn't come from the NASCAR guys, but from working withan Indy Car team. When we first started working with Toyota's Indy Carprogram a few years ago, they said the cams had to be nitrided. And wesaid, 'What's nitriding?' "Nitriding improves the cam's surface finish,and as it turns out, it's not just good for Indy Car racing--it's alsohelpful in just about any flat tappet application. We're doing it on allour overhead cams, and it's made a big difference in the cams for the2300cc Ford motors. Those cams for the four-cylinder motors we used tocall boomerang cams because you could count on three out of four comingback. So much on those heads has to be just right or the cam will fail.It isn't the cam's fault, but that's what usually got the blame. Anyway,to make a long story short, we started nitriding the 2300 cams and wentfrom a 70 percent failure rate to a 2 percent failure rate in two years.The difference is just incredible, and it can be just as helpful in theV-8 stuff, too."

Lifters

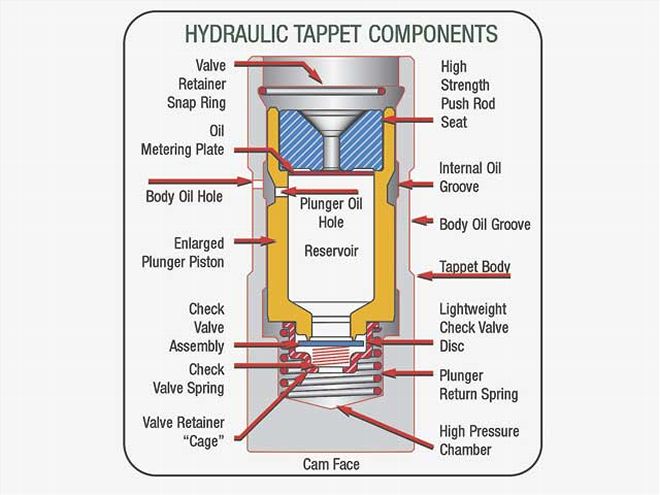

Comp's engineers say that using lifters that restrict the movement ofthe pushrod seat can increase the maximum rpm range in a racing enginewith a hydraulic cam.

Comp's engineers say that using lifters that restrict the movement ofthe pushrod seat can increase the maximum rpm range in a racing enginewith a hydraulic cam.

"Over the years we had two types of solid roller lifters--let'scall them better and best," Brown continues. "The NASCAR Busch and Truckteams used the 'best' lifters and the Saturday night racers used the'better' lifters. But the advantages of the best lifters have bled downuntil there's really not much difference between the two. There's no onebig thing that you can point to. It's really just different things welearned and applied to other lifters. These are things like changing thesize of the needle bearings in the roller to reduce the load on them,drilling oil holes in the body that inject pressurized oil directly intothe bearing assembly, and making the axles of tool steel rather thanmild steel. It's just a lot of little things that add up to make thelifter a more durable part with a longer life.

"The same thing hashappened with the hydraulic roller lifters. A lot of the road racers anddrag racers have to use them, and what we've learned there can be reallyhelpful to the Street Stock-type racer that is required to use astock-type hydraulic lifter. We've learned that by controlling thepushrod seat location in those things, we can get a lot better valvecontrol. We've gone from a tappet that maxed out at 6,000 rpm justbecause things got so out of control, to stuff we now are running at7,200 rpm. We restrict the amount of movement the pushrod seat hasinside the lifter. What that does is prevent it from depressing too farand getting enough hydraulic pressure behind it that it would expand thelocation of the pushrod seat, which would hold the valve open a littlelonger."

Pushrods

"Pushrods are no longer simply pencil-sized metal rods,"asserts Brown. "Now they are available in a variety of diameters andshapes with different wall thicknesses. That's because we've learnedthat pushrods are important for controlling harmonics as well as simplyproviding a connection between the lifter and the rocker arm. All thatstuff is directly related from extensive spintron testing. For example,the LS1 engine from the factory has a terrible problem with bending thepushrods if you over-rev it. Well, just by going from the factorypushrods to a one-piece pushrod with an 0.080 wall thickness, we'veeliminated those issues and gained about 500-700 (rpm) on the redline.The same thing is going on in race engines where you can add a littleweight to the pushrods and still gain a lot because you are getting ridof the bending and limiting the harmonics. As little as five years ago,racers were running 5/16-inch-diameter, 0.080 wall pushrods, and nowthey are using 7/16-inch-diameter pushrods. It looks like a Lincoln login there, but it works."

ValveSprings

Beehive springs were originally created for restrictor-plate racing, butthe design is so successful that it has made its way to over-the-roadautomobiles. The varying diameter of the coils makes the springresistant to harmonic failures, and the small diameter of the top coilmeans a smaller retainer can be used. Currently, these springs may besuitable in Street Stock-level cars where OEM parts are required, butComp Cams representatives say it won't be long until ovate wire beehivesprings are capable of functioning with the high-lift racing cams inSaturday night engines.

Beehive springs were originally created for restrictor-plate racing, butthe design is so successful that it has made its way to over-the-roadautomobiles. The varying diameter of the coils makes the springresistant to harmonic failures, and the small diameter of the top coilmeans a smaller retainer can be used. Currently, these springs may besuitable in Street Stock-level cars where OEM parts are required, butComp Cams representatives say it won't be long until ovate wire beehivesprings are capable of functioning with the high-lift racing cams inSaturday night engines.

"The valvesprings are a pretty interesting area fordevelopment because the beehive-style springs are really catching on,"Brown says. "The first beehive spring we made was for a NASCARrestrictor-plate application, and now they are everywhere. We are alsousing an ovate wire spring where the wire itself is an oval shapeinstead of the conventional round cross section. The extra surface areaof the wire gives it extra strength without adding excess weight.

"Thebeehive shape also has a couple of advantages. First, because each coilis a different diameter than the one above and below it, they all havedifferent natural frequencies. They are more forgiving when it comes toharmonics than a conventionally shaped spring. Also, the smallerdiameter at the top means a smaller retainer is used, and that can savearound five grams per spring.

"The only problem with a beehive spring isyou cannot run an inner spring, which limits the maximum springpressure. That shouldn't be a problem for too long. In fact, it won't belong before we have a single ovate beehive spring that you can run on aSaturday night, 0.700-lift roller cam."

Distributor Gears

Camshaft gear variances can lead to spark scatter at high-rpmlevels--exactly where you race. To solve this problem, Comp can have thecamshaft gears cut separately on high-tolerance CNC machinery and thenpress it onto the cam.

Camshaft gear variances can lead to spark scatter at high-rpmlevels--exactly where you race. To solve this problem, Comp can have thecamshaft gears cut separately on high-tolerance CNC machinery and thenpress it onto the cam.

"Traditionally, the gears on the cam to turn thedistributor are cut with a machine called a hob," Brown states. "But todo a really good job, the hob needs a wide range of motion. That's notpossible with the distributor gears on a cam because they are sittingright next to a journal, which restricts the hob's access. We startedusing a second machine called a shaper after the hob, and that improvedthe quality of the ignition gears, but it still wasn't enough for theNASCAR guys. Ignition timing is critical to them because of the amountof time their engines spend at high rpm. They wanted to reduce the sparkscatter to practically nothing.

"Spark scatter is simply a variance inthe timing of the spark. Let's say you are running an engine at 9,000rpm and you put a timing light on it. When you look at the timing with atypical camshaft and distributor setup, it's going to be jumping allover with about five degrees of variance. Normally, it's the slack, orthe backlash, between the gears on the cam and the distributor shaftthat allows this variance in timing. One solution has been to press thedistributor gear into the cam gear so that there is no slack, but if thegear is the slightest bit out of concentricity, it will cause the wholething to bind up and kill the distributor gear.

"So we finally came upwith the idea for a Chevrolet cam to take the rear journal anddistributor gear off the cam and just leave a spud there. Then we canCNC-machine the cam gear to very tight tolerances and press it and thejournal back on. Now everything is located and the spark scatter isreduced to two degrees at most. Plus, you regain the ability to indexthe distributor gear in and out from the cam so that you can nail thebacklash perfectly."

So, What is Nitriding, Exactly?

Of all the innovations Brown pointed out, he said nitrided camshaftswill likely be one of the most helpful advancements for Saturday nightracers. For more information on nitriding and what it means to you, wespent a little time with Billy Godbold, one of Comp Cams' camshaftdesigners.

"Nitriding is best for racers using flat tappet camshaftsbecause it is only beneficial for reducing sliding friction," heexplains. "The biggest problem for a flat tappet cam is lobe failure.There is only so much lobe lift you can run before the lobe gets toopointy and it wears the nose out. There is only so much spring you canrun before it wears the nose out. And there is the velocity limit whenyou are running flat tappet lifters. All of those limits have to do withwear.

"Wear is even a problem in the limited lift classes. In thatsituation, you are trying to open the valve as quickly as possible, holdit near max lift for as long as possible, and then close the valve atthe last minute. What you wind up with is a cam lobe with corners onboth sides of the cam lobe, and it's those corners that can be damagedunder harsh conditions.

"So, what we really are trying to do is keepthose from wearing. There are two solutions that can decreasewear--increase the cam's hardness and increase its lubricity--andnitriding the cam does both things.

"The type of nitriding we use iscalled a plasma nitride. The other method is salt bath nitriding, butthat produces only a very thin case, sometimes less than 0.001 inch.Plasma nitriding can produce thick case depths, around 0.01 inch, whichis ten times the capability of a salt bath.

"What you are doing isputting the camshaft in a big vacuum vessel. You take most of the airout and pump in nitrogen. Then you put the camshaft and the walls of thecontainer to different potential, like across a battery. The nitrogencooks up to itself and forms needles. Those nitrogen needles are rapidlyaccelerated and then crashed into the surface of the camshaft. It's alot like shot-peening, except instead of shot you are bombarding thesurface of the cam with nitrogen, which imbeds itself into thematerial's atomic structure.

"Nitrogen behaves a lot like carbon. Itgives the cam a very hard, slick surface. It is almost like puttinglittle ball bearings along the surface of the cam lobes. This means thecamshaft is going to last much longer. Engine builders can go with moreaggressive lobes they couldn't use before, and you are going to decreasewear tremendously. It's not twice as long or three times as long for thetypical cam versus a nitrided cam; it's 10 or 12 times more life span.Getting a cam nitrided will cost around $150, but given the benefits, Ithink it's a very cost-efficient upgrade."