It seems that lately everybody thinks we should all be satisfied to make 400 hp on 92 octane with a Chevy 350. That's great if you think 400 ponies is a lot of power. But the pace of development in cams, heads, and carbs has made it easy and affordable to go beyond that level of performance. For this project, we wanted to go way past it while still maintaining pump-gas and basic bolt-together parts compatibility. Our goal was 500 hp using off-the-shelf parts with no machine work required.

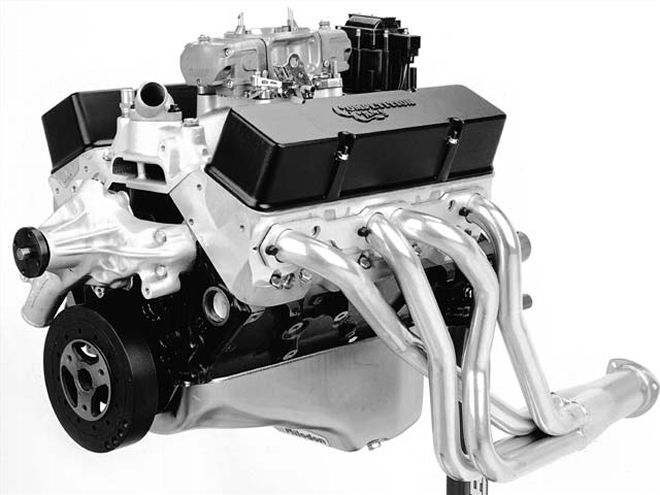

Here's the basic recipe: a GM Performance Parts' ZZ4 partial engine assembly, which comes with a forged crank, four-bolt-main caps, and high-silicon aluminum pistons for about $1,700. Then grab a Comp Cams Xtreme Energy mechanical roller cam, Air Flow Research's superlative 195 Street Head, a tried-and-true Edelbrock Victor Jr. intake with a Speed Demon carb, an HEI, and 13⁄4-inch headers and throw it all on the engine.

Assembling this engine isn't a total slam dunk, however. The solid-roller cam we picked is big enough that piston-to-valve clearance needs to be checked, standard-length pushrods will probably be too short, and there's potential for rocker-arm- to-valvespring retainer and retainer-to-valveguide or -seal interference. In short, everything has to be checked, and (if necessary) corrected.

In this case, Comp's Xtreme Energy XR280R cam was slightly milder than the grind we originally intended to use (the next larger cam actually hit the factory pistons' shallow valve notches). Comp Hi-Tech pushrods (PN 7994) were 0.050-inch longer than standard and were needed to achieve proper valvetrain geometry, and the AFR head's supplied valvesprings required shims to achieve the necessary valvespring pressure. Because we ordered the wrong style cam for this late-model roller-style block (see caption), the front cam thrust-plate retainer boss required trimming to clear the early upper double-roller cam sprocket (which in turn was needed to mate with the early-style front cam nose on Comp's mechanical roller cam).

ARP fasteners--including a head bolt kit (PN 134-3601), a harmonic damper bolt kit (PN 134-2501), and an accessory bolt kit (PN 534-9801)--were needed to bolt everything together. Northern Auto Parts stocks the full ARP line, along with most of the other parts needed to build this "crate" engine from the short-block up.

ARP fasteners--including a head bolt kit (PN 134-3601), a harmonic damper bolt kit (PN 134-2501), and an accessory bolt kit (PN 534-9801)--were needed to bolt everything together. Northern Auto Parts stocks the full ARP line, along with most of the other parts needed to build this "crate" engine from the short-block up.

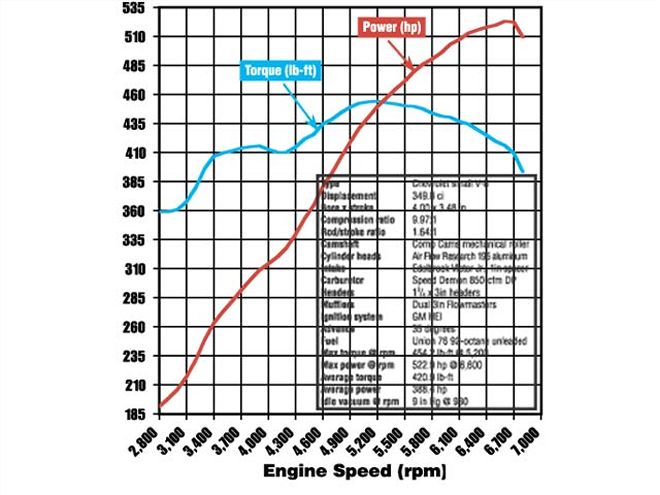

Once bolted together, this engine liked to rev, and on top a 750-cfm carb was just too restrictive. The engine ended up making the best top-end power with a Speed Demon 850-cfm carb atop a Wilson Manifolds 1-inch open spacer. Once we switched to the larger carb, added the spacer, and dialed in 35 degrees of advance, the engine performed as we'd hoped, exceeding our 500hp goal by over 20 hp--522.9 ponies at 6,600 rpm, to be exact. GM's stock HEI distributor was up to the job despite a 4-degree top-end retard; peak advance was actually somewhere around 39 degrees in the midrange, but the slight retard actually helps the engine make power upstairs.

Even with the big cam, the engine still made good torque, albeit at fairly high rpm. Torque production exceeded 400 lb-ft from 3,400-6,700 rpm, with the peak 454.2 lb-ft occurring at 5,200. But as you'd expect from a raspy motor, it only made 9 inches of vacuum at 930 rpm--not enough to operate power accessories without a vacuum pump.

In fact, getting this engine to run in a real car requires at least a 3,000-stall converter and 3.90:1 or steeper gears. With the required precision assembly checks (performed here by Westech), this approach isn't for everyone. Yet it definitely is one viable solution for getting a quick and affordable 500-plus hp out of a pump-gas compatible, 350ci small-block. If you want to take the plunge, the required parts outlay is about $5,500, assuming you shop around for a friendly GM dealer, mail-order the hard parts, and do the assembly work yourself.

The Third Degree

Mechanical roller cams can be tricky. You must check all clearances to avoid binding or interference. And roller cam lobes aren't tapered like those on a flat-tappet cam, so with a rear-mounted distributor they tend to walk forward in the block. Late-model blocks designed for use with factory hydraulic roller cams have a no-hassle thrust plate to prevent this walk, but mechanical roller cams must be special-ordered with the late-style "nose" to work with it, which we neglected to do. Using a conventional-nose mechanical roller cam (as we did) requires the installation of a thrust button in the center of the sprocket. Shim or sand as needed to establish the correct endplay against the cover.

Heads Up

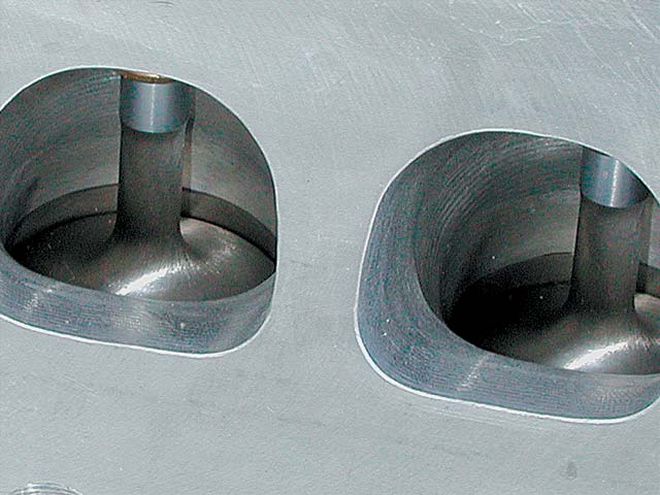

Air Flow Research 195 heads are arguably the best-flowing 23-degree small-block Chevy heads available out of the box for a street-driven engine. These heads have CNC-ported runners and are available with 68cc or 74cc chambers, straight or angled plugs, and with an emissions-legal heat-riser for '69-'94 models. Machining for early and late valve-cover patterns and early or '87-and-up (except Vortec) intake bolt patterns are other options.

We ordered AFR's 2.02/1.60-inch valve versions with angled plugs, no heat risers, and roller-cam-compatible valvesprings. To avoid losing compression with the standard ZZ4 pistons, AFR angle-milled the heads to reduce their standard 68cc chambers to 58cc, the same volume as the heads normally installed by GM on ZZ4 engines.