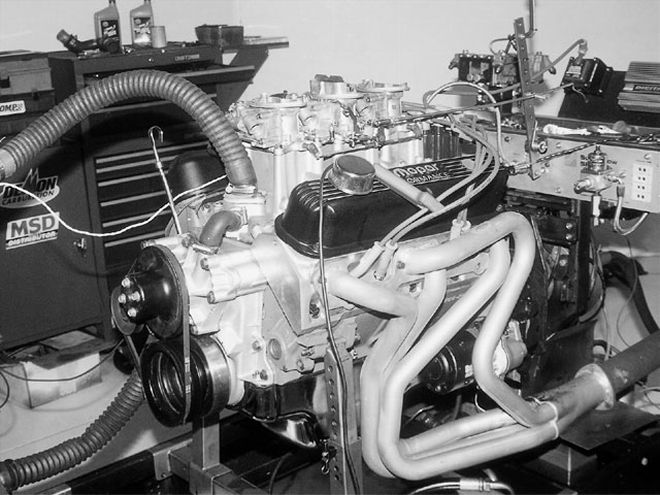

All the testing was performed with a 360 small-block on Westech Performance Group's Superflow 901 engine dyno. The results were surprising.

All the testing was performed with a 360 small-block on Westech Performance Group's Superflow 901 engine dyno. The results were surprising.

Capping any high-performance V8 engine will usually be an aftermarket chunk of cast aluminum with a bunch of passages linking the carb (or carbs') barrels to the head's intake ports. Though technically any intake manifold can be seen as a simple conduit for the air-fuel mixture, there are a wide variety of designs on the market, with each designed and created to handle the job a little differently. The most significant variation on a given intake's design concept is in how the runners are arranged, with the most common types being either single-plane or dual (two)-plane designs. Though most any motorhead can distinguish a single-plane intake from a two-plane just by looking at it, surprisingly few know what the difference is conceptually. Let's take a look at dual-planes first.

The Two-Plane

Though the earliest Mopar small-block engines used single-plane manifolds, for the most part, auto manufacturers overwhelmingly favor the two-plane design in OE applications. Looking at a two-plane-with some runners crossing over from side to side, a two-level divided plenum, and the obviously greater complexity in casting such a piece-we have to ask why the manufacturers would go through the trouble. A single-plane, open-plenum intake would obviously be easier to design and cheaper to build, so why bother with a two-plane?

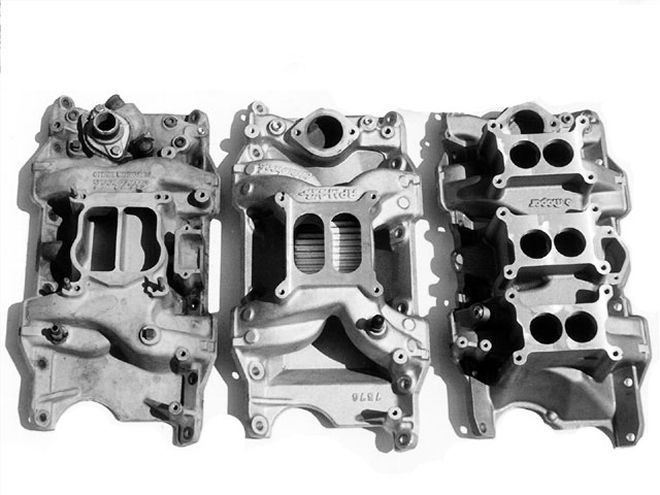

The lineup. In this corner representing the dual-planes, we have (1) the Edelbrock Performer, (2) the Edelbrock Performer RPM, and (3) the Mopar Performance 340 Six Pack; the single-planes are the tough Edelbrock Torker II (4), and the race Holley Strip Dominator (5).

The lineup. In this corner representing the dual-planes, we have (1) the Edelbrock Performer, (2) the Edelbrock Performer RPM, and (3) the Mopar Performance 340 Six Pack; the single-planes are the tough Edelbrock Torker II (4), and the race Holley Strip Dominator (5).

It has been found that a two-plane intake favors low-speed response. The longer runners and smaller plenum typical of a two-plane are easy to see, and these are the factors generally attributed to the low-speed (read street) advantage of a two-plane, but that's only part of the story. A V8 engine fires a cylinder every 90 degrees of crank rotation, and the induction cycle of any given cylinder will greatly overlap the induction cycle of the next cylinder in the firing order. The two-plane design isolates each side of the manifold and connects the cylinders in such a way that each side "sees" only every other firing pulse. Rather than having overlapping intake pulses coming into the plenum every 90 degrees as with a single-plane, each side of a dual-plane gets a much cleaner induction pulse every 180 degrees of crank rotation. That's why a dual-plane intake is often referred to as a 180-degree manifold. With the induction pulses coming into the carb every 180 degrees (or actually only half of the carb in a divided plenum two-plane), the induction pulse seen at the carb is greatly enhanced, especially at low air speed. This translates to enhanced lower rpm carb booster function and atomization, resulting in better low-end output, enhanced driveability, and economy.

Perhaps the greatest benefit to lower rpm and part-throttle operation with the 180-degree design is that it also separates out the communication of the induction pulse from the exhaust system. With a single-plane, the wide-open intake valve of a cylinder at peak piston speed on the intake stroke is communicated directly into the plenum, as it should be. However, at the same time, another cylinder in the overlap phase is also open to the same plenum. At low speed, especially with high overlap cams, this tends to draw exhaust gases into the cylinder in the overlap phase. This reversion causes rougher low rpm running and a penalty in torque production until the air speed and overlap tuning effect overcomes the tendency toward reversion at higher rpm. With the 180-degree system, this pathway is eliminated.

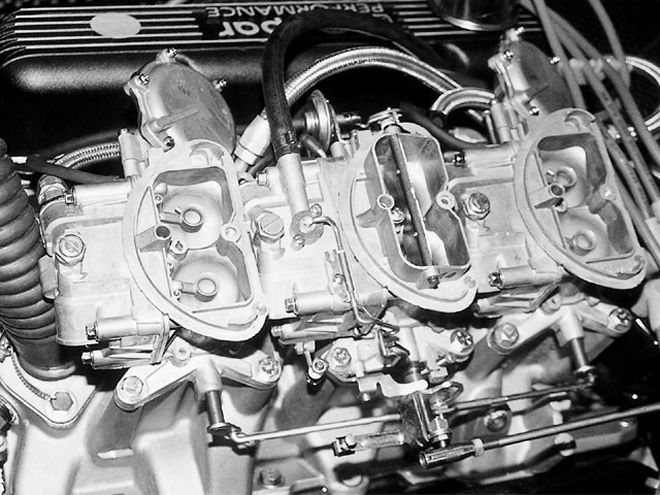

The dual-plane Six Pack setup gets our vote for sexiest induction. Let it breathe.

The dual-plane Six Pack setup gets our vote for sexiest induction. Let it breathe.

Given the two-plane's apparent advantage at lower air speed, what about as things move faster at higher rpm? The first consideration is the basic runner layout itself. Since the two-plane connects cylinders firing 180 degrees apart, given the firing order inherent in a V8 with a conventional crank, the runners have to cross over from side to side. This is physically accomplished by splitting the runner layout in two horizontal planes (thus, the two-plane name), with runners from one side routed up high and the other side of the manifold having runners passing underneath the upper runners. The compromise comes in because limited height can be practically engineered into the manifold if it's going to fit under the hood.

The upper runners generally have a nice, straight approach into the head ports, while the lower runners aren't usually as fortunate. Since the plenum is divided, its volume is necessarily halved, and plenum volume is an important resource for the engine to draw on as the rpm increases. Conversely, the lower runners provide more room for a more generous plenum and a better transition into the ports, but the high runners are hampered by a shorter, more abrupt plenum on that side. Still, most of these potential high-rpm pitfalls of the two-plane can be greatly overcome with increased manifold height (ever hear of a high riser?), and well-laid-out runner and plenum design.

A final note is that each side of a two-plane, divided-plenum manifold has only half the carb capacity to draw on (a primary and a secondary barrel), compared to a single-plane where the entire carb is wide open to whatever cylinder is drawing.

However, the net effect on carb capacity requirements isn't as drastic as it may appear, since with a single-plane, the carb is also feeding two cylinders at the same time because of the induction pulse overlap.

The Single-Plane

The single-plane is a more simple-looking design than a 180 degree manifold, and it sure looks more racy to the eye. The plenum is usually large and wide open, with short direct passages (the runners) leading to the head's ports.

Considering this basic layout, it's far easier to achieve a more equal port-flow distribution with a single-plane design. As rpm increases, the air velocity and the valve overlap tuning effects negate the low speed advantages of a two-plane intake, and satisfying the engine's airflow requirement becomes the primary consideration.

The direct runners of a single-plane are about as good as it gets for moving air from the carb to the head ports, and therein lies much of the single-plane's high-rpm advantage. Without having to route the runners across and underneath each other and splitting between a high and low plenum, the single-plane can be designed to do its main job well: flow air. Add the effective port runner entrance of a well- designed single-plane's open plenum and we have the formula for a great race or high-rpm intake style. Further enhancing the high-rpm ability of the single-plane is the shorter runner length. Shorter runners tune in at a higher rpm.

To The Dyno

OK, enough theory; the bottom line always comes down to the question of how things stack up in power production on a real engine. We had a fresh 360 small-block, so we gathered up a broad selection of intakes and headed to Westech's dyno facility to see how these various small-block intakes stack up. The two-planes we included in the lineup were Edelbrock's original Performer, one of Edelbrock's new Performer RPM AirGaps, and a new MP Six Pack setup. For single-planes, we brought along an Edelbrock Torker II and a Holley Strip Dominator. Our small-block is a street mill but no powder puff, running 10:1 compression, mildly ported Edelbrock heads, and a very high velocity, custom-grind Comp solid lifter cam (see sidebar: Solid Street 360). All of the manifolds were run out-of-the-box stock, with the exception of the Torker II-which had been port-matched and received minor plenum work, along with a heat shield underneath. Read on for the lowdown on what we found.

Dyno Results

HorsepowerSuperflow 901 Engine DynoTested at Westech Performance GroupRPMTest 1Test 2Test 3Test 4Test 53,000234.8232.2226.9N/R221.83,200251.6248.1241.8241.5240.63,400276.8279.2272.3268.0266.23,600302.5311.5301.4297.8297.33,800319.2339.3327.0325.7323.64,000341.7357.7342.4342.6342.94,200360.7374.1356.3357.4361.04,400371.1387.1376.5377.2380.64,600384.5404.1393.4398.1400.54,800400.7419.4407.8418.3416.15,000413.1433.5420.5434.8432.35,200423.3445.3429.2448.2443.55,400433.8453.1443.2458.7453.15,600441.1460.6453.7468.0460.55,800448.2464.5461.9470.3467.86,000451.2472.9462.5473.3472.26,200449.2475.4462.7475.7473.8

Test 1: Edelbrock Performer

Test 2: Edelbrock Performer

RPM AirGap

Test 3: Mopar/Holley Six Pack

Test 4: Edelbrock Torker II

Test 5: Holley Strip Dominator

TorqueSuperflow 901 Engine DynoTested at Westech Performance GroupRPMTest 1Test 2Test 3Test 4Test 53,000411.1406.4397.3N/R388.33,200412.9407.3396.8396.3394.93,400427.6431.3420.6413.9411.23,600441.4454.4439.7434.4433.73,800441.1468.9452.0450.1447.34,000448.7469.7449.6449.9450.24,200451.1467.7445.6447.0451.14,400443.0462.1449.4450.3454.34,600439.0461.4449.1454.6457.34,800438.5458.9446.2457.7455.35,000434.0455.4441.7456.7454.05,200427.5449.7433.5452.7447.95,400421.9440.7431.1446.1440.75,600413.7432.0425.5438.9431.95,800{{{405}}}.9420.7418.3425.9423.66,000395.0414.0404.9414.3413.46,200381.1402.7392.0403.0401.3The Edelbrock Performer

Intake: Edelbrock No. 2176Type:Two-plane four-barrelRated rpm range:Idle to 5,500Max hp:451.2 at 6,000 rpmMax torque:452.0 at 4,100 rpmAverage hp 3,000-6,300 rpm:375.9 hpAverage torque:426.7 lb-ft

The first manifold in the lineup would be Edelbrock's entry-level street intake, the standard Performer. We bolted it on, along with Holley's new Street Avenger 770 vacuum-secondary carb, which we would use as the base four-barrel for all the intake tests to maintain consistency. Though we still kicked out some solid horses, the original Performer manifold was out of its league on an engine this stout, really being more suitable for milder, lower rpm engines. The Performer has smaller runners than any of the other manifolds tested, since it was designed to work on either the small-port 318 heads or on the larger 340/360-style big-port heads. With our mildly ported Edelbrock heads and the high-lift cam, the port flow on this manifold held back the top-end power production. However, it is a perfect match for an engine with 318 heads, and with a mild 360, the Performer would be a good choice as well. It will benefit from opening up the ports at the manifold flange to match the 360 heads.

The Edelbrock Performer RPM AirGap

Intake:Edelbrock AirGap No. 7576Type:Two-plane four-barrelRated rpm range:1,500-6,500-plusMax hp:475.4 at 6,200 rpmMax torque:469.8 at 4,100 rpmAverage hp 3,100-6,200 rpm:391.6 hpAverage torque:443.7 lb-ft

The RPM AirGap was designed by Edelbrock as its "killer" series of two-plane manifolds, and the engineers at Edelbrock told us that the Mopar small-block version was perhaps the best of the line. Look at those numbers; 1.29 ft/lbs per cube! In fact, the 391.6 power average over our entire test range would make someone proud if they were getting those figures at peak. Plus, check out those torque numbers; we're talking torque like a good big-block and the horsepower that would be respectable for a stout street 440. In the end, the AirGap cleaned house as far as best overall power producer, with bucket loads more torque in both the low- and midrange, yet gave nothing up to the single-planes for high rpm power. It's more than a pretty face-this thing takes no prisoners.

The Edelbrock Torker II

Intake:Edelbrock No. 5076Type:Single-plane four-barrelRated rpm range:2,500-6,500Max hp:476.5 at 6,300 rpmMax torque:457.7 at 4,800 rpmAverage hp 3,100-6,200 rpm:387.2 hpAverage torque:437.0 lb-ft

The Torker II is a street single-plane, though the one we used was kind of a ringer, having had some mods done to it in a previous life. The ports were already gasket-matched, some mild plenum massaging had been done, and there was a sneaky heat shield screwed in underneath. What these mods added in horsepower is debatable, but this was a run-what-you-brung test, and that's what we brung. The Torker II is a great single-plane manifold, and the top-end power narrowly edged out the RPM AirGap for the horsepower title. Making comparisons with the AirGap theory held true, however, and the AirGap held a significant torque advantage all the way up the scale over the single-plane. Note how much higher the torque peak moved up in rpm when switching to a single-plane, though peak torque was actually less. What was so unexpected was that the AirGap held in to within a few odd horsepower at the top end. That, frankly, in an application such as this high-powered 360, is unheard of from a dual-plane.

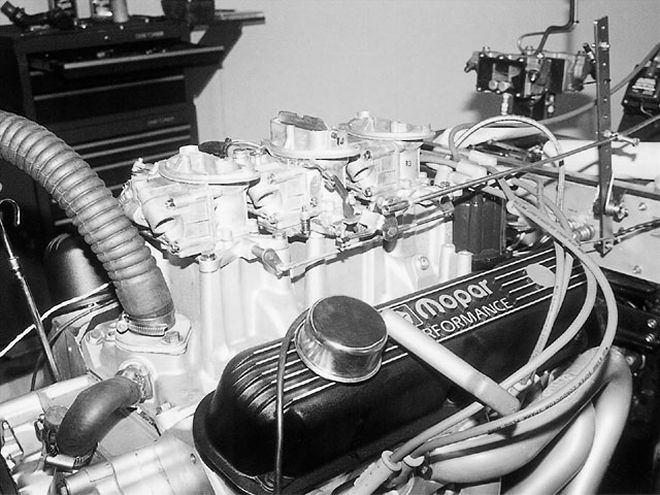

The MP Six Pack setup is available complete from Mopar Performance, adding unreal eye dazzle to righteous performance. We picked the entire setup from Mopar parts guru Troy Bray at Westoaks Dodge, a leading Mopar Performance dealer. They have all the goodies ready to ship.

The MP Six Pack setup is available complete from Mopar Performance, adding unreal eye dazzle to righteous performance. We picked the entire setup from Mopar parts guru Troy Bray at Westoaks Dodge, a leading Mopar Performance dealer. They have all the goodies ready to ship.

The Holley Strip Dominator

Intake:Holley No. 300-8Type:Single-plane four-barrelRated rpm range:4,500-8,500Max hp:476.5 at 6,300 rpmMax torque:457.4 at 4,500 rpmAverage hp 3,100-6,200 rpm:385.5 hpAverage torque:435.2 lb-ft

The Strip Dominator is a race single-plane that has been around for years. It was, like many of the early Holley single-planes, a highly advanced and refined design for its time. Featuring gently sweeping runners arcing sweetly into the ports, these Holley manifolds pioneered design features that are now the industry standard. Peak horsepower was an exact dead heat with the modified Torker II, and torque was very close, as can be seen by the averages. Also, the Strip Dominator was still climbing at the end of our pull at 6,300 rpm, though from the shape of the curve, it looked like the peak output had been reached. We noted that the port outlet of this intake begged to be port-matched, since there was plenty of meat to come out to meet the port size of the heads. The rated rpm was way up above our engine's rpm range, but the 360 seemed very happy with it anyway. It still works just fine lower in the rpm range, despite the very high rpm rating.

The Mopar Performance Six Pack

Intake:M/P Six Pack No. P4529054Type:Two-plane three two-barrelRated rpm range:2,500-6,500Max hp:464.1 at 5,900 rpmMax torque:455.4 at 3,900 rpmAverage hp 3,100-6,200 rpm:381.2 hpAverage torque:431.4 lb-ft

Though its design is more than 30 years old, the Six Pack was our sentimental favorite-and for sheer eye appeal, it was the hands-down winner. The Six Pack tuned in at a lower rpm than any of the other manifolds tested, with both peak torque and horsepower coming in a few hundred rpm lower. But the big numbers were still impressive-solidly in the pack with some of the more modern racy single four-barrel intakes. As with the Holley Street Avenger four-barrel used on the others, the Six Pack carbs were run out of the box, and the dyno instrumentation showed they were slightly lean, though pretty close. With a port match and some razor-sharp mixture tuning, this thing could be right in the thick of it near the top. When you consider that just about any other manifold we've tested from that era doesn't typically even come close to the output of the latest intake designs, you have to be in awe of how far ahead of its time the A-motor Six Pack really was.

The Holley Street Avenger

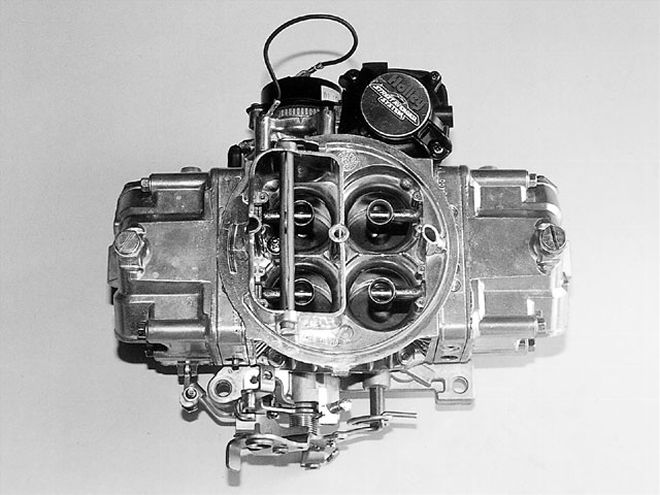

Holley recently introduced an updated series of is traditional 4150 carb, calling them Street Avengers. These are vacuum-secondary carburetors available in 570-, 670-, 770-, and 870-cfm sizes. Holley emphasizes that these carbs come calibrated close right out of the box; the packaging the carb comes in says "Bolt it on and go!" We had a 770-cfm version of the carb and bolted it on for all of the four-barrel testing.

Before we say anymore, the dyno over at Westech is equipped with excellent air/fuel ratio recording systems, with a wide-band Lambda meter, calculated air/fuel ratio through precise air and fuel flow meters, as well as the brake-specific fuel consumption numbers, which calculates how efficiently the fuel is being converted to horsepower. Dyno operator Steve Brule has run countless combinations over the years, and with three distinct channels of data related to mixture, can instantly see where the fuel curve is, and where it needs to be.

Needless to say, every dyno session begins with some pulls to see where the mixture numbers come in, usually followed by jetting changes to dial the carb in exactly right for max power. We bolted on the Street Avenger and got the jets out to start tuning. Guess what? The mixture was bang on right out of the box. We put the jetting kit away, made a change to the lightest secondary opening spring through the Street Avenger's "No-Trouble" Quick Change vacuum diaphragm (quick opening is a must for dyno duty), and went through all of the manifold testing without having to touch the carb except to swap it from each manifold. We were impressed.

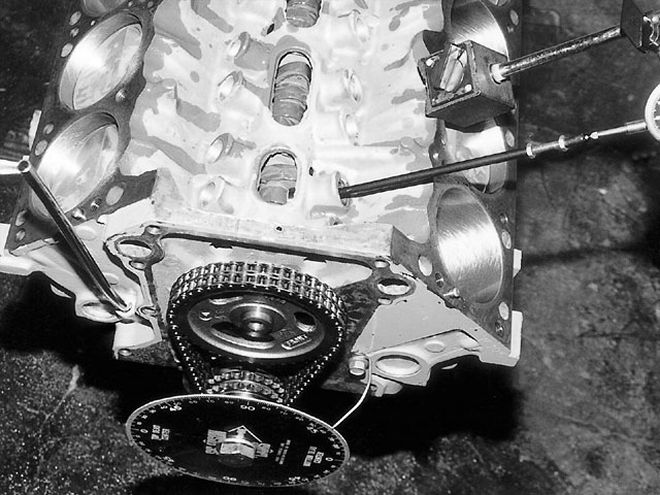

Our Solid Street 360

Although we were testing intakes in this story, we figured that since we showed almost 480 streetable horsepower from our 360 test engine, we'd spill the beans on how it was done. It's really quite simple, with the right combo of parts. The bottom end was a junkyard-core 360, bored and fitted with Federal-Mogul No. 116 CP Hypereutectic 10.1:0 pistons and Speed Pro molybellum rings. The rods are stock, resized, and fitted with Milodon bolts, while the crank is the stock cast-iron piece with an economy regrind. A Probe/Romac damper is hung up front on the crank, and the bottom end is bolted in with Milodon studs and their tray kit. The rest of the bottom end is regular rebuilder stuff: Clevite bearings, replacement oil pump, and so on.

One of the key aces up our sleeve is a custom Competition Cams solid lifter grind, a lightning-quick profile featuring a short 272/276 advertised duration, but delivering a monster .558/.564-inch lift after valve lash with a set of 1.6:1 Probe roller rockers. Want one? Just call Comp, tell them to grind you a 7131/7132 on 108 plus 4. Note these Comp Cams lobes aren't street lobes, having been designed for serious circle-track racing to deliver the maximum area under the lift curve with a minimum tappet diameter of 0.875 inches. If you decide to run one, make sure you've got the heads and valvetrain to back it up.

Speaking of heads, we used a set of Edelbrocks, which included all the goodies we needed to run the big Comp solid, like a nice set of strong single valvesprings which Edelbrock sets up at a much taller-than-stock 1.800-inch installed height, allowing up to 0.575-inch lift out-of-the-box. These heads were mildly ported, giving us a about a 10 percent flow gain over the already good-as-delivered flow. Headers were Hooker 151/48-inch A-Body street tubes, and the ignition was handled by a new MSD billet distributor, firing the top-of-the-line MSD Digital 7 multispark ignition-which is part of the Westech dyno. The wires were also MSD: 8.5mm Super Conductors with straight multiangle boots and terminals on the plug side, which we liked so much we had to mention 'em.