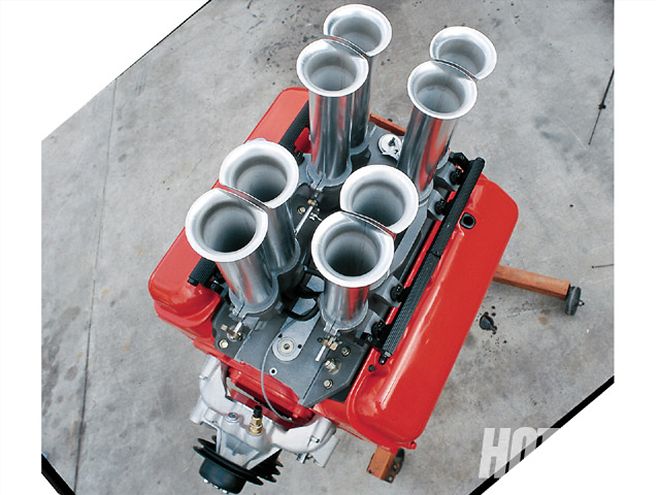

Free horsepower. What a great idea. In the case of resonant manifold tuning, most commonly known as ram tuning, an engine can actually realize additional horsepower and torque simply by catching the wave. We wanted to see what effect different length ram tubes would have on horsepower and torque output. To explore this phenomenon, we plopped a Hilborn/Electromotive EFI setup on a fresh-from-the-crate GM Performance Parts ZZ 502/502 big-block and strapped it to the Superflow dyno at John Baechtel's Westech Performance Group. To help decipher the data, we asked Bill Shope, a founding member of Chrysler's legendary Ramchargers factory drag-racing team and an expert on the subject of ram tuning, to be our guide.

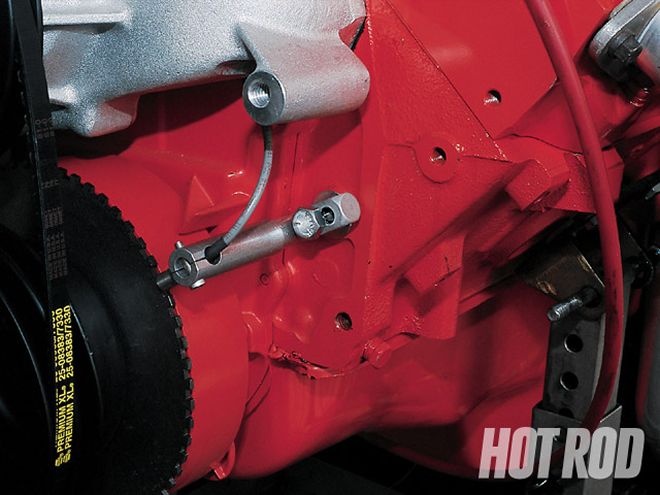

The Electromotive EFI handily avoids the usual hassle of mounting a belt- or cam-driven mechanical fuel pump to the front of a ram-tube-injected engine. To keep things simple on our guerrilla Nova Funny Car, we used a long-style Edelbrock aluminum water pump (PN 8851) and reproduction LS6/L78 deep-groove pulleys from Original Parts Group.

The Electromotive EFI handily avoids the usual hassle of mounting a belt- or cam-driven mechanical fuel pump to the front of a ram-tube-injected engine. To keep things simple on our guerrilla Nova Funny Car, we used a long-style Edelbrock aluminum water pump (PN 8851) and reproduction LS6/L78 deep-groove pulleys from Original Parts Group.

What Is Ram Tuning?

Ram tuning surfaced in the racing community during the early 1950s. The idea is both simple and quite complicated, depending on how deep you dig. On the surface, ram tuning simply takes advantage of the inertia contained within a moving column of air/fuel mixture as it comes to a stop against the closed intake valve. Traveling at close to 100 mph through the intake runner, you can imagine there is plenty of energy waiting to be released. By adjusting the length of the intake runners, this energy can be used to improve cylinder filling when the valve opens again. The more pent-up energy waiting to crash the gate, the more air to pack the chamber. But there's much more to it than this.

It all begins at the piston. After expelling spent combustion gases through the open exhaust valve during the exhaust stroke, the piston reaches TDC. At approximately the time the piston begins its journey back down the cylinder during the intake stroke, the intake valve opens and suction draws in a fresh air/fuel charge through the intake tract. By the time the piston reaches BDC, the intake valve is closing, and it is here that we can begin our examination of the occurrences along the length of the intake tract. For these few milliseconds, we aren't concerned about what is happening inside the cylinder or the combustion chamber. Our attention is focused on the column of air that exists between the back of the closed intake valve and the opening of the ram tube or, on a carbureted engine, the entrance to the plenum directly below the carburetor.

The instant the intake valve closes, it initiates a chain of events within that column of air. A set of four of these events will always occur in a particular order. These four events constitute a harmonic cycle. Each event involves a change in the pressure and velocity of the air/fuel mixture in the tube. These changes always begin at one end of the tube (either the closed valve or the open end) and progress to the other end. This progression, or traversal, occurs at the speed of sound; a harmonic cycle consists of four traversals.

The ZZ502 endured nearly 30 vicious full-throttle dyno pulls without breaking a sweat... or anything else. Here, we test without ram tubes; see results in accompanying graph, "Ram Tuning Tests."

The ZZ502 endured nearly 30 vicious full-throttle dyno pulls without breaking a sweat... or anything else. Here, we test without ram tubes; see results in accompanying graph, "Ram Tuning Tests."

The first traversal is the result of the fuel mixture adjacent to the valve coming to a sudden stop. As it does, it builds up a pressure which is equal to the product of the air density, the air velocity, and the sonic velocity. As the incoming molecules of air hit this pocket of air that is already stopped, they also stop, and the volume of stalled air grows in size, creating a division between the two zones; this "front" is like a weather front on the evening news. The front separates regions that are at different pressures. This front moves away from the valve and toward the open end of the tube at sonic velocity. It is the front between the two regions that traverses the tube at the speed of sound, not a portion of the air/fuel mixture itself. Each wave actually moves through the air without being of it.

When the front reaches the open end of the tube, the molecules of air nearest the open end begin to flow away from the opening of the tube. This volume of zero-pressure air flowing away from the engine then extends toward the closed valve at the speed of sound, constituting the second traversal, where the air in the tube is at zero pressure and negative flow. Then, the air at the closed valve experiences a negative pressure equal in magnitude to the positive pressure initially developed when the valve first closed, thus initiating the third traversal which also travels away from the engine. Once the front reaches the end of the tube, the air inside is entirely stagnant, and at the negative pressure, air once again begins to flow into the open end of the tube. This represents the beginning of the fourth traversal, where all the air in the tube is at zero pressure and has a positive velocity traveling toward the engine.

An Electromotive ignition employs a 60-tooth, crankshaft-mounted trigger wheel and magnetic pickup that measures engine speed and crank position every 6 degrees. This allows plus-or-minus 1/4-degree timing accuracy up to 12,000 rpm and eliminates spark scatter. Direct ignition eliminates cap and rotor, so the spark goes straight from the coils on the TEC-II unit to the plugs.

An Electromotive ignition employs a 60-tooth, crankshaft-mounted trigger wheel and magnetic pickup that measures engine speed and crank position every 6 degrees. This allows plus-or-minus 1/4-degree timing accuracy up to 12,000 rpm and eliminates spark scatter. Direct ignition eliminates cap and rotor, so the spark goes straight from the coils on the TEC-II unit to the plugs.

With this fourth traversal, one harmonic cycle is completed, although it's difficult to imagine all of this taking place in the short timespan between valve closure and valve opening. The beginning of the first cycle of the next harmonic occurs when this flow region reaches the closed valve, and, again the pressure rise is equal to the product of the density of the charge, the velocity of the charge, and the speed of sound, which-at 60 degrees F-is equal to 13,420 inches per second! Shope divulged that tests conducted at Chrysler in the mid-'50s concluded that the most effective time to open the valve was after the third harmonic-the intake valve is opened just as the pressure rise begins to occur at the valve head after the 12th traversal. These experiments also showed that when tuning for the fourth harmonic, the intake runner had to be too short and couldn't contain enough air/fuel mixture to completely charge the cylinder. And efforts to tune for the second harmonic resulted in extremely long runners and the acceleration of an excessive air/fuel mass, so the third harmonic was the most advantageous.

Chrysler testing resulted in a formula to calculate where the ram effect will come into play. To wit: N x L = 84,000, where N represents the desired engine rpm to tune for and L is the length in inches from the opening of the ram tube to the valve head. Shope explains: "Let's say you're running at Bonneville with an engine that develops peak horsepower at 8,400 rpm and want to tune for maximum ram effect at that level. Then, L should equal 10 inches, as in 8,400x10 inches=84,000." To achieve ram tuning at 5,500 rpm, simply divide the constant, 84,000 by 5,500 rpm. The result of 84,0005,500=15.27, the ideal distance for the intake tract as measured from the opening of the ram tube to the valve head.

The oxygen sensor measures the oxygen content of exhaust gases, thus allowing the air/fuel ratio of the intake charge to be monitored and controlled in closed-loop operation.

The oxygen sensor measures the oxygen content of exhaust gases, thus allowing the air/fuel ratio of the intake charge to be monitored and controlled in closed-loop operation.

The effects of ram tuning reveal themselves as blips in the horsepower and torque curves which can either be tailored (by manipulating runner length) to coincide with, and enhance, the power peak or to bolster some other area of the power curve. In other words, just because a given engine may make maximum horsepower at 7,000 rpm doesn't mean you have to utilize the benefit of ram tuning at that speed. In fact, in most cases, you wouldn't. A drag-race engine, for instance, would have its intake system tuned for a speed a bit above the midpoint of the engine-speed range. Is ram tuning responsible for where peak torque and horsepower are made? Well, it can shift the peaks a few rpm, but the more dominant contributors are found elsewhere (camshaft, compression ratio, and so on). But there is no doubt ram tuning can be a useful tool for enhancing the power curves.

The Engine

In upcoming issues, we'll feature our 1963 Nova "The Wilshire Shaker," a street-legal replica of a mid-'60s altered-wheelbase match-race Funny Car. And what better powerplant to totally capture the "run what ya' brung" vibe than this Hilborn-injected Rat? But unlike the Hilborn-injection setups of yore, modern units are completely adaptable to EFI. By incorporating an Electromotive Total Engine Control (TEC) ignition and fuel-management system, our Nova will have street manners that match its power output.

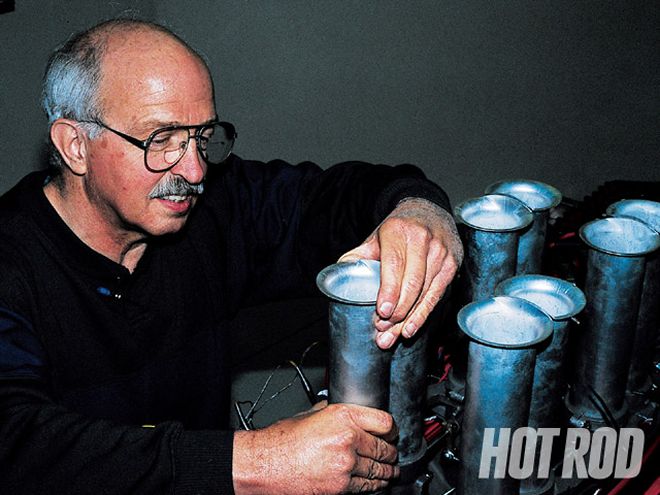

Bill Shope was studying for his master's degree in automotive engineering at the Chrysler Institute in 1958 when a lunchtime discussion with other engineers resulted in the formation of The Ramchargers. Here, Shope prepares to make a ram-tube length adjustment.

Bill Shope was studying for his master's degree in automotive engineering at the Chrysler Institute in 1958 when a lunchtime discussion with other engineers resulted in the formation of The Ramchargers. Here, Shope prepares to make a ram-tube length adjustment.

The object of port fuel injection is to eliminate flow restrictions caused by the nozzles and venturis present in a carburetor and to optimize mixture distribution between the cylinders-fuel sprays into the individual ports, enabling equal flow. But the hassle associated with a constant-flow mechanical-fuel-injection setup on the street centers on fuel metering. Typically, the fuel pump is driven at a direct ratio to engine speed. The fuel pressure rises with speed and feeds more fuel to supply the greater demand of the engine as rpm ascends. Despite the use of metering valves and bypass circuits, it is virtually impossible to obtain optimum performance over a wide range of engine speeds. If you adjust for best power at the top end, the mixture will be lean at the bottom end and vice versa.

The Electromotive TEC-II system adapts easily to the Hilborn 396-C-8LEL EFI-specific intake manifold (2 7/16-inch-diameter throttle bores) to provide accurate fuel metering for any driving condition. A complement of sensors (TPS, MAP, 02, CTS, IAT); eight 55lb/hr injectors (specified for this particular application); and a powerful computer which utilizes a direct-fire, distributorless, crank-triggered ignition system and phase-sequential injector firing. No, the Southern match-race stocker boys never tuned their motors with a laptop PC, but they never dreamed of running on the street either. We're nuts, though. The work is based around a GM Performance Parts 502 (PN 12371171) which was checked for proper bearing clearances before commencing a grueling 30-pull dyno party.

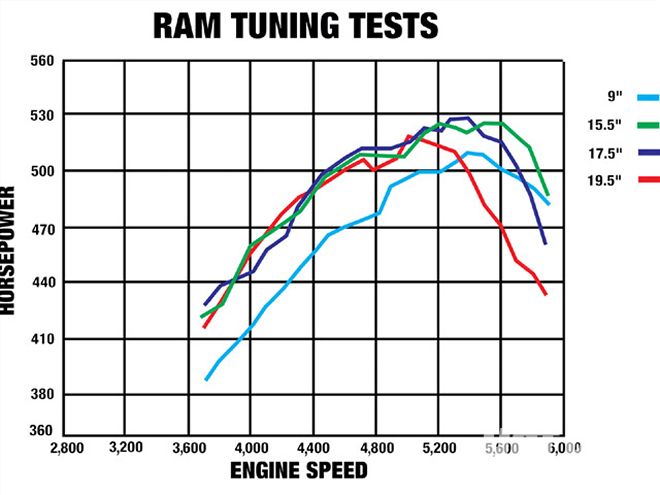

Ram Tuning Tests: The effect of ram-tube length on horsepower

Ram Tuning Tests: The effect of ram-tube length on horsepower

The Test

Dyno runs were first made with runner lengths of 19 1/2 inches-the distance from the intake-valve head to the bellmouth of the ram tube, which we achieved with the standard 12-inch stacks and the Hilborn throttle-body casting. Shope soon discovered that the calculated engine speed for the appearance of the blip on the torque curve didn't match the dyno-pull results. A comment by test-assistant Steve Abruzzese as to the possible effect of intake duration, caused Shope to remember that Chrysler's testing was done with comparatively mild camshaft events, while the cam in the 502 is a hotter 224 degrees duration at 0.050-inch lift and is a fast-acting roller to boot. For this engine, Shope calculated that a better formula would be NxL=80,300.

After a 30-minute break-in, Baechtel let 'er rip. The best of three pulls yielded 518.1 hp at 5,000 rpm and 602.3 lb-ft of torque at 3,500 rpm. Compare that to a stock carbureted ZZ502 (502 hp at 5,200 rpm and 567 lb-ft at 4,200 rpm), and it is clear that the Hilborn/Electromotive EFI unleashed a wall of bottom-end torque and a respectable dollop of horsepower as well. And just as Shope had predicted, there's a blip in the torque curve which reflects the increased cylinder filling brought on by the harmonic tuning (see "Proof of the Pudding"). Shope also calculated that the ram effect was good for a whopping 3psi boost in intake-charge pressure at 4,800 rpm. That's close to the output of some small blowers-and it's free!

The "Wilshire Shaker"-our fiberglass and steel tribute to the ancestors of the modern flopper-features an altered wheelbase, a straight front axle, a push-button Torqueflite, and a ram-injected 502. It looks like we'll be replacing rear bumpers weekly.

The "Wilshire Shaker"-our fiberglass and steel tribute to the ancestors of the modern flopper-features an altered wheelbase, a straight front axle, a push-button Torqueflite, and a ram-injected 502. It looks like we'll be replacing rear bumpers weekly.

We made more pulls to test the efficiency of different runner lengths and achieved this by shortening the Hilborn tubes in 2-inch increments. With 17 1/2-inch runners, we gained 5 hp and 10 lb-ft, producing 528.3 hp at 5,400 rpm and 607.2 lb-ft at 3,700 rpm. Trimming 2 more inches from the tubes reduced total runner length to 15 1/2 inches; horsepower and torque fell off slightly to 525.1 hp at 5,500 rpm/604.3 lb-ft at 4,000 rpm. We also tested the naked throttle-body casting (no tubes), resulting in a runner length of only 9 inches. This placed the third harmonic tuning speed at 8,900 rpm, well above our redline. Output diminished to 508.8 hp at 5,500 rpm and 547.1 lb-ft at 4,200 rpm, indicating the effect of turbulence which will form just inside the throttle body when the bell-mouth entry is absent. This turbulence reduces pressure, the flow area, and power.

As the sample tune-speed graph indicates (see "Proof of the Pudding"), agreement between calculated speeds and observed blips is quite good. Still, this procedure is not an exact science. No two dyno runs are exactly the same, and the general slope of the torque curve can cause the peak of the blip to occur at a different engine speed than that calculated by the equation. Regardless, ram tuning is very real. If you have any doubts, check out the intake manifold of practically any engine designed during the last 15 years. From the Ford 5.0 to the Chevy TPI to the Dodge Magnum, you'll see tuned runners-a sure sign that Detroit is quite hip to the lure of free horsepower and torque.

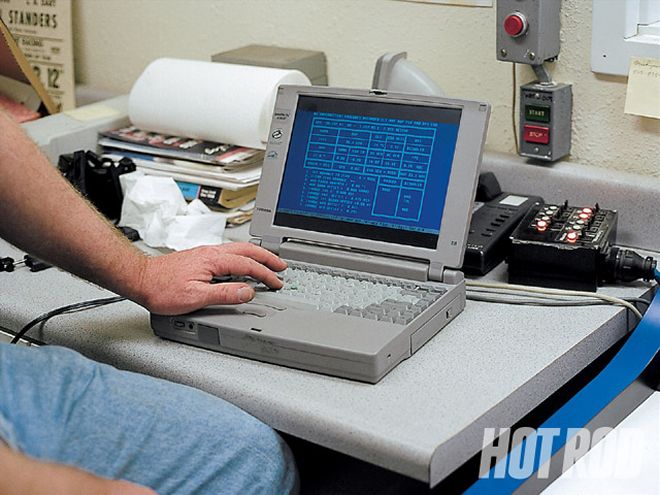

Electromotive introduced the concept of PC-based engine tuning to the aftermarket in 1987. The interactive engine monitor function is shown here. The screen displays engine rpm, oxygen-sensor data, fuel enrichment, knock severity (when a knock sensor is used), throttle position, battery voltage, spark-advance angle, coolant temperature, and manifold-pressure data in real time, so you can tune on the fly. The 64 position Volumetric Efficiency Table, with individually selectable break points, allows precise tailoring of the raw fuel curve to match exact needs, a key feature that allows the Hilborn direct-port, ram-tube injection to be friendly on the street or the strip.