In the November issue we showed the absolute bare-bones cheapskate way to build an engine at home with the most rudimentary tools. If you've already built a few engines that way and have stuff like a torque wrench and engine-cleaning brushes, then you're ready for more advanced motor assembly. Whether it's an engine kit you've purchased through the mail or one you've had carved on by your local machine shop, the quality of the final product depends heavily on your ability to check the machining specs and assemble it the right way.

With a huge line of engine tools for many skill levels, Powerhouse makes it affordable to do just that. We flipped through the company's catalog to put together the following overview of tools best suited for those wanting to get their feet wet with precision engine building. We'll tell you the price the part number, and, since few tools come with instructions, how to use this stuff. Once you master these gadgets you'll be more confident with your engine, you'll save bucks by locating machining miscues before they go boom, and you'll look like a pro to all your buddies. As per usual, prices are as of press time and may change by the time you're ready to buy.

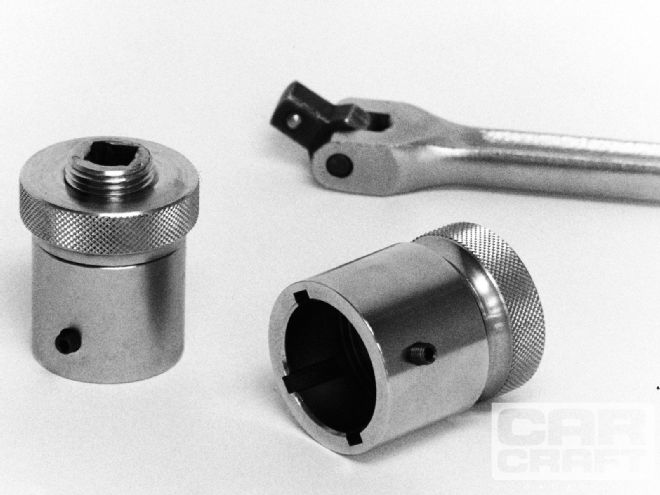

Pro Crank Socket

What it Does: Lets you spin the crank in an assembled engine without using the balancer bolt. It's handy because you can rotate the engine counterclockwise (which would loosen the bolt), and because it keeps you from mangling the crank-snout threads. The Powerhouse sockets also have a knurled nut that allows you to mount a camshaft degree wheel; the design makes it easy to rotate the degree wheel without risk of rotating the engine and ruining your settings.

Powerhouse Part Number: Small-block, V-6, and four-cylinder Chevy, POW103050; big-block Chevy, POW103055; all Ford, Buick, and Pontiac, POW103060; all Chrysler and Olds V-8s, POW103070

The Price: $28, except for the small Chevy, which is $26, and the Chrysler/Olds at $30

Extra Stuff You'll Need: A 1/2-inch drive ratchet or breaker bar, plus a degree wheel to really take advantage of the Pro socket

How to Use It: Once the balancer and bolt have been removed, just slip the socket over the crank snout, locating it over the key in the crank. Now you can turn the crank with a 1/2-inch breaker bar. A set screw on the socket further affixes it to the crank for extra precision when using the socket to mount a degree wheel.

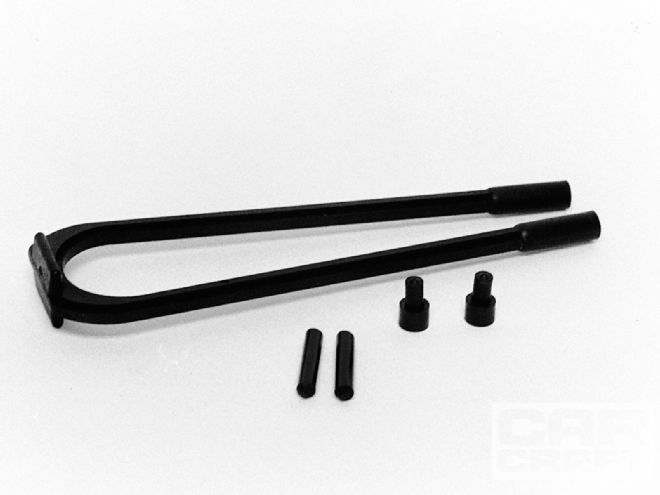

Rod Guide

What it Does: Prevents you from gacking the crankpin with the rod bolts while you're installing the rod and piston, and also helps align the rod to the crank during installation. Powerhouse says it also helps in removing rods from the engine, but we had a tough time making it work that way.

Powerhouse Part Number: POW101295

The Price: $19.95

Extra Stuff You'll Need: Long-stroke big-blocks will need extensions (POW101296) for $9.95

How to Use It: When installing pistons and rods, slip each piston part-way into the cylinder, then reach through the bottom of the crankcase to slide the rod guide over the crankpin and onto the rod bolts. Smack the piston and rod into place, then remove the guide and install the rod cap.

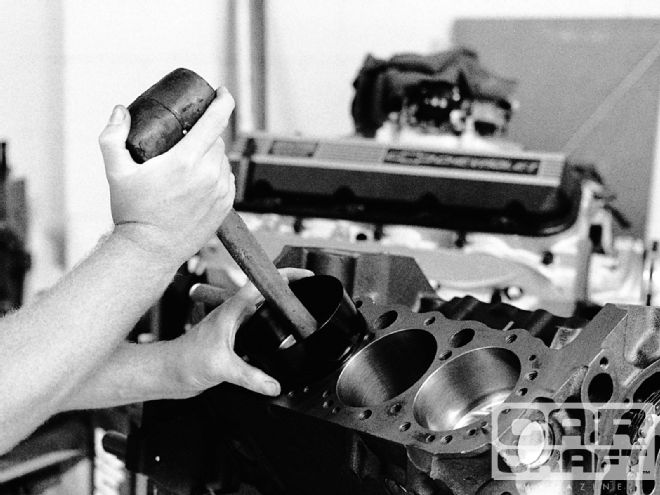

Tapered Ring Compressor

What it Does: Makes sure you never again have to use one of those cheesy thin-steel adjustable ring compressors that make your fingers bleed every time. Slipping piston/rod/ring assemblies into the block will become easier than you thought possible. We prefer the Powerhouse hard-anodized aluminum compressor to its less expensive composite versions.

Powerhouse Part Number: There are 49 part numbers for compressors as small as 3.500 inches and as large as 4.830. Don't expect us to list 'em all here-just order the one for the exact bore size of your engine after overbore machining.

The Price: Ranges from $28-$32 depending on size

Extra Stuff You'll Need: An extra tapered ring compressor for the bore size of every engine you work on

How to Use It: Center the compressor over the cylinder and hold it flush with the deck, lube it and the cylinder with engine oil, slip the rod and piston (with rings installed) into the hole, protect the crank with a Powerhouse rod guide, then tap the piston into the block with a hammer handle as shown. Powerhouse also has a Pro Piston Knocker (POW101290, $26) and piston-ring expander pliers (POW105060, $9.95).

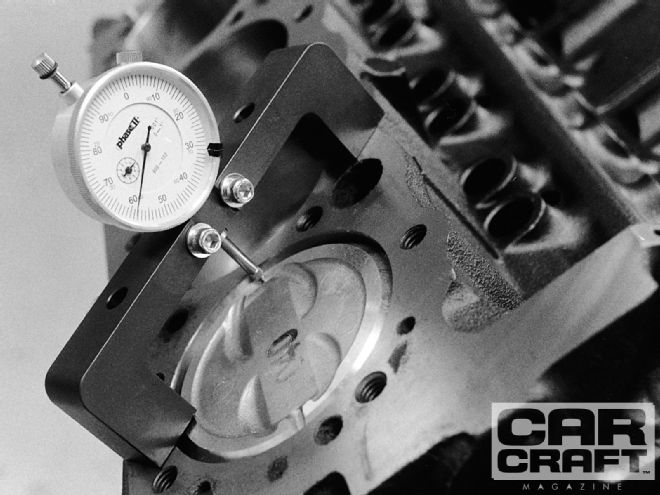

Pro Magnetic Deck Bridge

What it Does: Provides a solid base from which to mount a dial indicator or dial calipers to check the travel of a piston in its bore. Perfect for checking piston deck height and rock, and also handy (along with a degree wheel) for finding true TDC when degreeing a cam.

Powerhouse Part Number: POW101315

The Price: $49; There's also a standard $19 bridge (POW101310), but it's not magnetic

Extra Stuff You'll Need: At least one dial indicator, but it'll mount as many as three

How to Use It: With the cylinder head removed, mount the bridge to the deck to span one of the cylinders. A dial indicator slips into any of the three holes in the bridge and is secured lightly with a thumbscrew. The dial indicator is generally placed to contact the piston inline with the piston pin, though two indicators may be used to check piston rock from top to bottom. To determine piston deck height, zero the dial indicator on the block deck, then move it onto the piston and read how far the needle travels counterclockwise to see how far below the deck height the top of the piston sits; the needle will travel clockwise if the piston is above the deck.

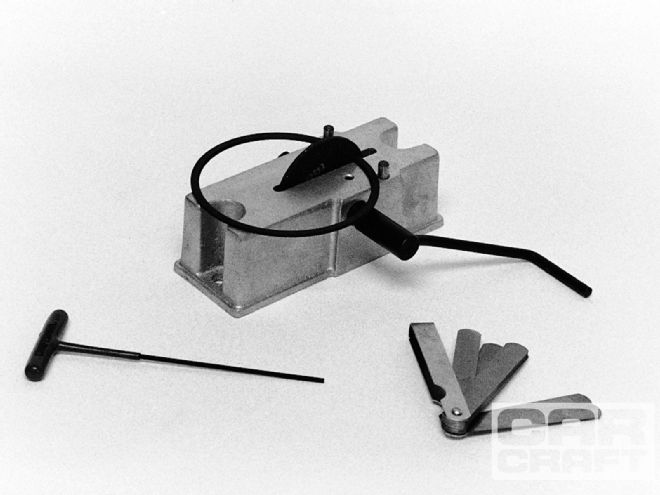

Ring Endgap Filer

What it Does: Makes quick work of filing rings to set the endgaps, and makes the ends square with more accuracy than a file

Powerhouse Part Number: POW105050

The Price: $65-a bit cheaper than the Powerhouse Ringmaster Filing Jig (POW105080) we showed you in the Sep. '98 issue ("Ring Filing How-To")

Extra Stuff You'll Need: A tiny Allen wrench is needed to assemble the filer. Replacement carbide wheels (POW105055) are available for $14.95, but you'll probably never need one. A blade-type feeler gauge will be required.

How to Use It: Learn the optimum ring-endgap from your engine builder or piston/ring manufacturer. To make sure the gaps are within spec, put a ring in the cylinder and use an upside-down piston to square it about a half inch below the deck. Powerhouse also makes eight sizes of piston-ring squaring tools if you want to spend $24 on one. Next, use a feeler gauge to judge the endgap. If it's too big, the ends of the ring can be carefully filed with the Powerhouse tool clamped into a vise or bolted to a workbench. Go slow as the carbide wheel works quickly, and recheck the gap until it's right. Keep each ring matched with the cylinder it was checked in.

2- to 3-Inch Outside Micrometer

What it Does: Measures the outside size of stuff like crank journals

Powerhouse Part Number: Tons of mics are available, but we chose the 2- to 3-inch version from the least expensive line-it's POW151003

The Price: $32

Extra Stuff You'll Need: You may want other sizes or quality levels-Powerhouse has anything you need. Even mic stands are offered.

How to Use It: Good question! Using a mic takes a lot of practice to develop the right feel for accurate measurement. A 2-inch standard for calibrating the mic was included, and it can be used to develop that feel since it's a known size. The photos show mic-reading basics.

Pro Connecting Rod Vise

What it Does: Clamps up to two connecting rods at once without nicking or galling like regular vise jaws. Makes it easier to remove rod caps on freshly machined rods or to torque caps in place with the rods out of the engine.

Powerhouse Part Number: POW351180

The Price: $129

Extra Stuff You'll Need: A regular vise, preferably with soft jaws. You can also bolt the rod vise to a solid work surface. An Allen wrench is needed to set the opening size of the jaws.

How to Use It: Adjust the jaw opening with the Allen screw on the underside of the top jaw (arrow) so that the vise firmly grips your rods without chewing up the vise jaws. Once it's set, the quick release arm is used to get rods in and out fast.

Magnetic Dial Indicator Stand

What it Does: Holds a dial indicator in any position you want for checking valve travel, rocker-arm action, lifter curves, crank endplay, and more.

Powerhouse Part Number: Many are available from Powerhouse, but the cheapest is POW151125

The Price: $29

Extra Stuff You'll Need: A dial indicator

How to Use It: Photo 1 shows the unassembled stand, and photo 2 shows how to put it together with the adjustable collars that allow it to contort into any position. Arrow A shows the thumbwheel that attaches to the nub on the back of the dial indicator, and Arrow B shows the fine-adjustment fixture. Finally, photo 3 demonstrates the dial indicator in use, checking the travel of a valve. The most critical thing is to make sure the dial indicator's plunger travels exactly inline with the travel of the item being checked. For example, when checking crankshaft endplay, make sure the plunger is exactly parallel to the crank centerline.

Dial-Bore Gauge

What it Does: Tells you the diameter of holes like cylinder bores and main bearing bores so you can check bore taper and bearing clearances.

Powerhouse Part Number: POW256467 is shown, but POW205025 is cheaper and only slightly less accurate

The Price: $299 for the POW256467, $99 for POW205025

Extra Stuff You'll Need: An outside micrometer that will span the bore size you want to check

How to Use It: Check the photos to learn how to measure with it. Once you have that down, you can check cylinder-bore out-of-round by taking measurements 90 degrees from each other, or cylinder taper by taking measurements at the top and bottom of the cylinder. To check main- or rod-bearing clearances, measure the size of the main bore or rod bore with the bearings in place and the caps torqued to spec. Next, use a micrometer to check the true size of the main or rod

journal on the crank. Subtract the bore size from the journal size and divide by two to learn the bearing clearance.

Pro Head CC Kit

What it Does: Allows you to check the volume of your combustion chambers in cc's so you can calculate compression ratio or verify consistency of chamber size cylinder-to-cylinder.

Powerhouse Part Number: POW351150 for the model with the 100cc burette. Sizes up to 250 cc are available.

The Price: $99

Extra Stuff You'll Need: White grease and some colored fluid, such as shop solvent. A set of peg-style head holders (POW351410, $26) might be handy.

How to Use It: The clear Plexiglas plate is sealed to the head with a ring of white grease around the perimeter of the chamber to be measured. Next, the fragile glass burette is mounted to the stand and filled to the top of the scale marks with colored fluid. Fill the head's chamber with fluid through the hole in the Plexiglas plate using the petcock at the bottom of the burette. Once the chamber is filled with fluid (no bubbles, no leaks), read the scale on the burette to find how many cc's of fluid were used, and that's the size of the chamber.

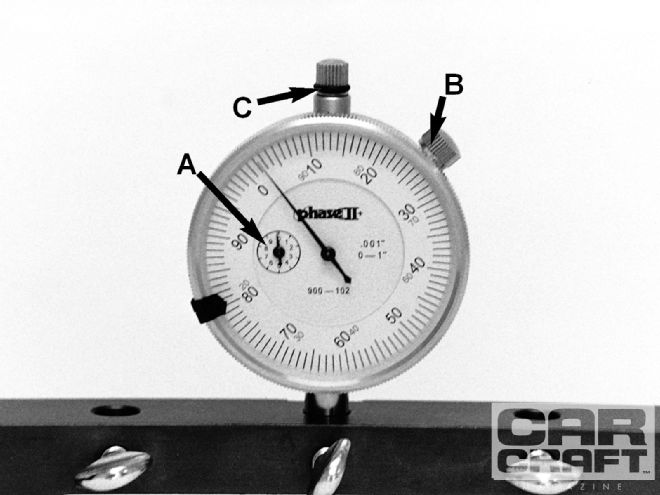

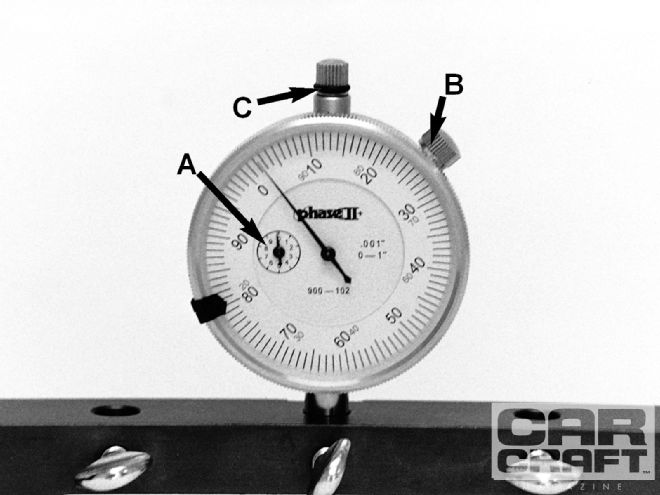

Dial Indicator

What it Does: Measures the travel of linear-moving parts with accuracy to one thousandth of an inch

Powerhouse Part Number: POW151100 for the 0- to 1-inch model

The Price: $29

Extra Stuff You'll Need: A dial indicator is useless without either a deck bridge or a magnetic base, both of which are described in this story

How to Use It: Once mounted in the deck bridge or magnetic base, preload the plunger about 0.100-inch against the item being measured (arrow A points to the revolution counter-each revolution of the big needle is 0.100-inch). Next, zero the dial by loosening the set screw (arrow B) and rotating the face. Check that the plunger will accurately reset to zero by moving the plunger (arrow C). Now you're ready to measure.