There are many ways to increase horsepower, but most of us have restrictions surrounding our personal projects. These limitations may stem from a lack of funds or mechanical know-how, or perhaps the reliability of the vehicle in question is the limiting factor. Such obstacles are precisely the sort of things gearheads love to overcome, and this prompted us to take another look at bolt-on hp. How much can engine output be boosted with a single power-adder and how simply?

The Mandates

Our criteria: Boost the output of a small-block Chevy by 100 hp. The power-level bogey had to be achieved without major changes to the host (the long-block would remain undisturbed). Further, the test-engine would be fairly mild and include mostly production parts. The new-found grunt would have to be infinitely available, and said power-adder would have to be installed with handtools by someone with basic knowledge.

The Method

Since we wanted usable power at will, this ruled out nitrous and led us to forced induction of some sort. Turbos were dismissed for complexity of installation and plumbing, leaving the direct-acting supercharger as our savior. The B&M Powercharger is a Roots-type compressor which mounts to the top of the engine via a special intake manifold and is intended to fit beneath the hood of a typical passenger car or light truck.

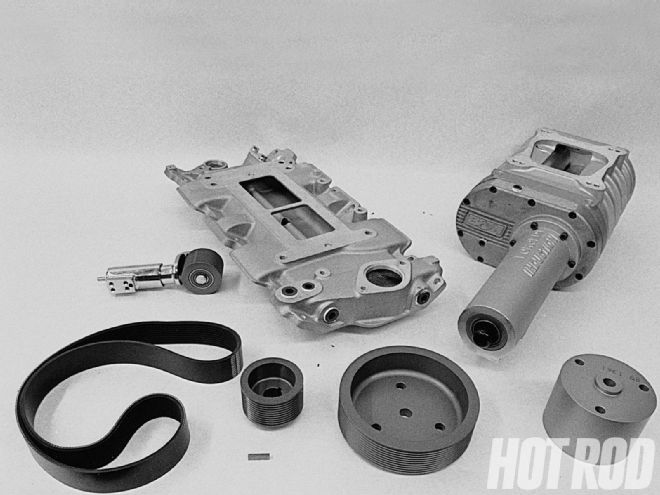

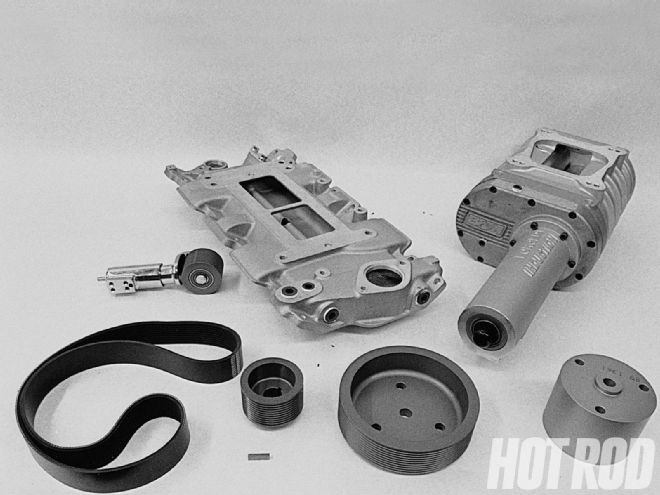

The Powercharger is available in kit form and includes everything from a blower and drive pulleys to the intake manifold, fasteners, belt, and gaskets. The only variable in the small-block Chevy kit is the blower pulley, which determines the amount of boost. B&M's technicians assist consumers in selecting the proper pulley size based on the engine it will service. We consulted with Robert Tchamkertenian, who recommended the Powercharger 144 kit. The "144" designation represents cubic-inch displacement per revolution of the supercharger. Tchamkertenian felt that our goal of 100 hp would be no problem with the 5-6 psi of positive manifold pressure he recommends for relatively stock engines equipped with cast pistons.

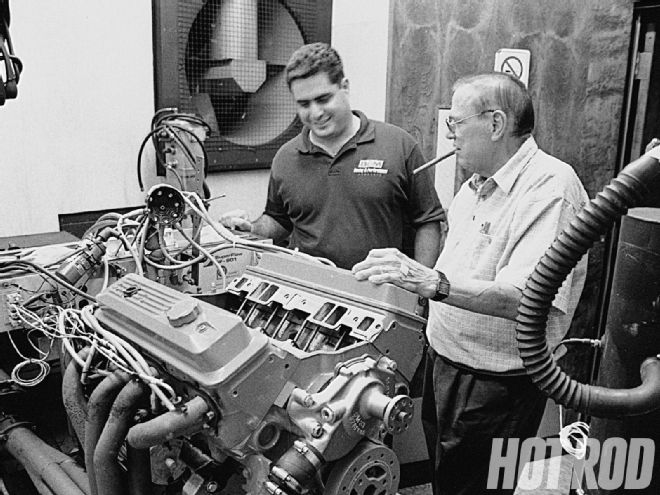

Robert Tchamkertenian (left) of B&M surveys our test mule with racing legend and DLI proprietor Dick Landy. The 350 Chev was a 1990-spec L98 Corvette engine, featuring factory aluminum heads with 1.94/1.50 valves and 9.8:1 compression. The stock roller cam has .415/.430 lift and .203/.208 duration on a 116-degree lobe separation.

Robert Tchamkertenian (left) of B&M surveys our test mule with racing legend and DLI proprietor Dick Landy. The 350 Chev was a 1990-spec L98 Corvette engine, featuring factory aluminum heads with 1.94/1.50 valves and 9.8:1 compression. The stock roller cam has .415/.430 lift and .203/.208 duration on a 116-degree lobe separation.

The Mule

Our mule was a 350-cubic-inch L98 Corvette engine featuring aluminum cylinder heads with 1.94-/1.50-inch valves, and 9.8:1 compression with factory-style dish pistons. The factory roller cam has .415-/.430-inch lift and .203/.208 degrees duration with a 116-degree lobe separation angle. Typical blower grinds favor the exhaust side, which helps to evacuate the cylinders of the extra atmosphere they're stuffed with under boost. The 116-degree lobe separation is a little excessive for forced induction-B&M prefers 112-114 degrees-but it's better than going the other way (110 or less) which creates lots of overlap and bleeds boost right out the exhaust.

All L98 Corvette engines were equipped with Tuned Port Injection, but we wanted to run the same Holley 750 cfm carb for the baseline figures and with the Powercharger as well. The double-pumper (PN 4778) would be big enough to feed the hungry huffer but not big enough to drown the stocker. We put it on a Holley Street Dominator dual-plane intake manifold to maintain the typical boulevard small-block persona.

Since we ditched the EFI, we wouldn't need the ECM, so we opted for an MSD electronic distributor (PN 8570) specifically for its small-diameter cap and a low-profile housing. However, the blower was designed to clear even the mammoth HEI-distributor, but better safe than sorry. We hooked the distributor to a MSD 6AL box.

The Mentors

To perform our comparison test, we needed a dynamometer, and the personnel to analyze the results and assist in parts swapping. Dick Landy Industries (DLI) fit the bill. Dick's brother, Mike, was our mentor for the test. We dropped off the engine and a pile of parts and returned a couple of days later to find it up and running. In naturally aspirated tune, the 350 sounded quite healthy through the 1 3/4-inch headers, and after a brief warm-up, Landy put the ignition timing at 15 degrees initial and 35 degrees total advance. Finally, it was time to make a pull. Landy set the water brake, pulled back on the throttle, and a few moments later, we had our baseline-329 hp at 5,200 rpm and 393 lb-ft of torque at 4,000 rpm. The power curves were nice and flat, exhibiting good torque and hp over a broad rpm range. Our goal of 100 hp without going inside the motor began to seem optimistic.

The B&M Powercharger 144 kit includes everything for the conversion, including the manifold, billet crank pulley and spacer, blower-drive pulley, belt, and tensioner, as well as gaskets and fasteners (not shown). The size of the blower-drive pulley determines the amount of boost generated-6-7 psi for our mule.

The B&M Powercharger 144 kit includes everything for the conversion, including the manifold, billet crank pulley and spacer, blower-drive pulley, belt, and tensioner, as well as gaskets and fasteners (not shown). The size of the blower-drive pulley determines the amount of boost generated-6-7 psi for our mule.

The Madness

Converting to forced induction with the B&M kit is a breeze. Of course, performing the transformation on the dyno is easier than it would be in a car, but we couldn't help thinking the average rodder could do the deed inside of a couple hours on a Camaro, Chevelle, or the like.

Kevin Mesirow of DLI did most of the wrenching. He removed the distributor and the intake manifold, bolted down the B&M manifold and torqued it to factory spec, and screwed the huffer in place. He replaced the crank-pulley bolts with the longer ones included in the kit and threaded them through the billet spacer and blower-drive pulley.

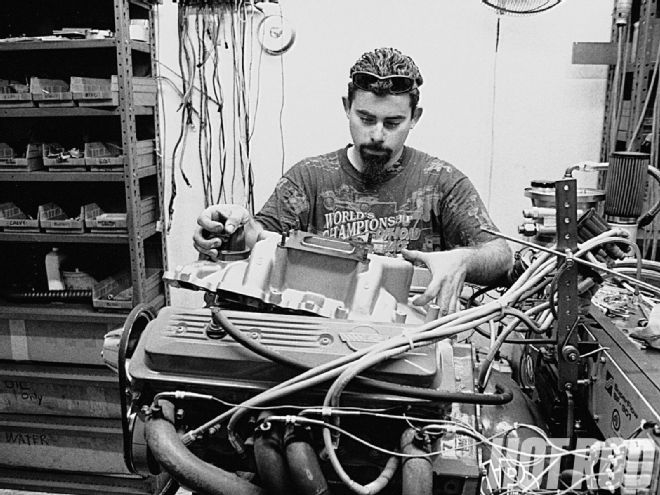

On the dyno it took only about an hour to swap from naturally aspirated trim to forced induction. Kevin Mesirow of DLI handled most of the wrenching. In a typical Camaro or Chevelle, the job would probably consume 2-3 hours.

On the dyno it took only about an hour to swap from naturally aspirated trim to forced induction. Kevin Mesirow of DLI handled most of the wrenching. In a typical Camaro or Chevelle, the job would probably consume 2-3 hours.

The crank pulley has a 6-inch diameter, and, as we mentioned, the diameter of the blower pulley varies depending on the amount of boost desired. Our engine was healthy and running on premium fuel, and the aluminum heads would dissipate more heat than iron castings, so we opted for 6-7 psi. Kevin mounted the belt tensioner to the blower snout, tightened the belt, and put the carb, ignition, and lines in place. Landy ran the warm-up procedure, then set ignition timing at 15 degrees initial and checked for a total of 35 degrees. Soon, the 350's roar was overshadowed by the shriek of the blower, a sound synonymous with power. At six-grand, he shut her down, and we checked the readout-421 hp at 5,100 rpm. Torque was equally impressive-460 lb-ft at 3,800 rpm. Best of all, at 2,500 rpm we were making 418 lb-ft, almost 30 more than our naturally aspirated peak!

Landy made several more pulls to verify output and all fell within 5 hp of the initial run. Although we had fallen short of our goal, the mood was positive. We were eight hp shy of 100, but we had generated lots of torque, and that's what a street machine really needs.

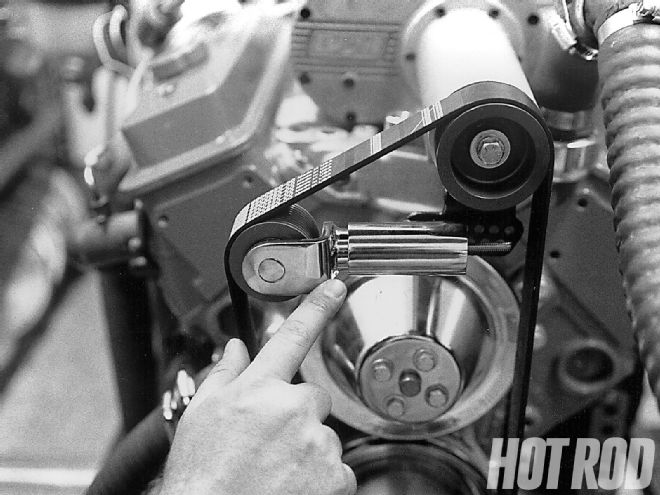

The blower-belt tensioner mounts to the blower snout via a multi-holed bracket. The installer must select the set of holes that allow the spring-loaded tensioner pulley assembly to protrude from the mount approximately 1/4 inch when released. Any more than this and the belt will not have enough tension; any less and the tensioner will bottom out at high engine rpm. Both can lead to belt failure.

The blower-belt tensioner mounts to the blower snout via a multi-holed bracket. The installer must select the set of holes that allow the spring-loaded tensioner pulley assembly to protrude from the mount approximately 1/4 inch when released. Any more than this and the belt will not have enough tension; any less and the tensioner will bottom out at high engine rpm. Both can lead to belt failure.

The Moral

We discussed with Tchamkertenian and Landy what could have been done to further enhance performance. We witnessed high boost levels (nearly 10 psi at 6,000 rpm) above 5,000 rpm which indicated that the exhaust side of our equation needed to be addressed, and a "blower" cam, like the one offered by B&M, would have helped to evacuate the cylinders more efficiently. Exhaust port work also would have aided evacuation, enhancing power production and keeping boost levels more even across the rpm range.

In addition to making lots of power, performing the swap illustrated how simple the B&M kit is to install. And the cost? Right around $1,100. How's that for return on investment?

Mesirow and Landy put the finishing touches on the installation. Minutes later, the 350 was churning out 421 hp at 5,100 rpm and 456 lb-ft at 3,500. Even at 2500 rpm, the force-fed small-block was making 418 lb-ft, nearly 30 more than its peak with natural aspiration.

Mesirow and Landy put the finishing touches on the installation. Minutes later, the 350 was churning out 421 hp at 5,100 rpm and 456 lb-ft at 3,500. Even at 2500 rpm, the force-fed small-block was making 418 lb-ft, nearly 30 more than its peak with natural aspiration.