Ever get what you never bargained for? Sure you have. We all have. And our pal Chris Schimke just did.

Recently he sought the services of our other pal, Marshall Woolery at Thun Field Rod & Custom in Tacoma. The subject, a 1940 Ford coupe, is a real pretty little black job that Schimke's dad left to him. A month or so prior, a third pal of ours, illustrator Eric Black, rendered an interior for the car. Schimke took it to Thun Field to freshen it up sufficiently to match its proposed threads. It looked like a slam-dunk deal.

"This thing's been slammed all right," Woolery says as he points out undercoating obscuring a non-Ford seam in the trunk, the by-product of a rear-clip swap. Then other things start making sense: the kinked rear quarter-panels, ill-fitting doors, and wrinkled cowl suggest this car got squeezed like an accordion at a Balkan festival. Woolery consents to work on the car only if it goes for blasting. "Then at least we'll know what we're working with," he says.

The results were surprising. Maybe because we expected the worst the car looked really good. The light we saw at the end of the tunnel really wasn't a train after all.

Woolery sees an opportunity. "When's the last time you saw one of these things sectioned right?" he asks. He explains that the rather tall bodies on '39 and '40 Fords make them look a little stuffy and antiquated, not to mention a little heavy. He proposes that thinning one ever so slightly through the midsection would make the car look a lot sleeker without compromising its iconic shape. We conclude that it's the antithesis of chopping the top, a modification that usually makes the body look even taller and heavier and the windows squinty.

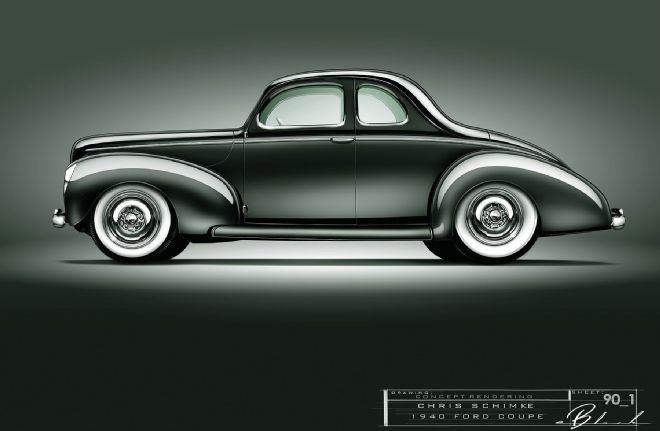

Chopping an earlier car’s top makes sense but Ford made the top somewhat small compared to the body from 1938-40. Eric Black’s illustration shows how sectioning restores the balance, which is at its core the reason to modify a car in the first place.

Chopping an earlier car’s top makes sense but Ford made the top somewhat small compared to the body from 1938-40. Eric Black’s illustration shows how sectioning restores the balance, which is at its core the reason to modify a car in the first place.

To be fair he asks rhetorically because he knows no way in hell that Schimke, more specifically his budget, will let such a thing happen. Chopping a top is big enough and all it requires is taking some out of the roof posts; sectioning a car requires taking a strip out of the entire body. It's one of the reasons you seldom see it done well and rarely see it done well.

But oddly enough it does happen. As Schimke explains, he already budgeted for a lot more repairs than the car really needed and that sectioning a car would make a lot more of a statement than a bunch of damage repair that he expected in the first place. Some measurements indicated that a 1-3/4-inch strip would make a visual impact without making a mess of the strip between the fenders and decklid, the part of the body most vulnerable to sectioning.

Before Schimke came to his senses we asked Black to render the car in a side profile. There's a reason noteworthy builders hire illustrators; they can translate ideas to visible proof, in this case to see if it's totally nuts to tastefully section a '40 coupe (it's not, not even by a long shot). There's also an equally powerful (yet largely overlooked) reason: with a road map to follow, owners aren't so likely to change direction. By simply locking everyone to a common goal, illustrations usually save significantly more money than they cost. And there's a third, probably more critical reason: illustrators have ideas. In this case Black suggested opening the wheelwells just a touch so the opening follows the wheel radius when the car sits lower.

But we're getting ahead of ourselves. Before we can embark on any modifications we first must restore the car's foundation. And that means new floors and firewall. We found it a perfect opportunity to showcase the panels that Dennis Carpenter offers. More than manufacture a complete '40 body, Carpenter offers its panels individually. And as paying customers we can honestly say they're simply beautiful parts that faithfully represent the original design right down to the fit. They're really that nice.

Naturally a job like this is pretty intense, so follow along over the following months to see what it really takes to tastefully section a '40 Ford coupe. It'll surprise you for reasons you never thought possible, among them it's a lot simpler than you think, certainly easier than chopping a '40 top if you can believe it.

1. You East Coasters are gonna cry foul; the floor is largely intact and would likely fly in a more conventional build. But they're lacy and part of the tunnel got hacked from a TH350 install. It's cheaper to replace than fix the many little ills.

2. Without the floor to support it there's little chance that the doors will line up properly when the body comes loose. Tie into an area that meets the tubing in at least two points wherever possible. Also make sure that the doors fit with the braces in place.

3. Probably the most labor-intensive part of this job is drilling spot welds. The cowl offers easier access so Woolery demonstrated there. Lightly sanding the surface reveals the spots far better than any other way.

4. Since he's discarding the interior panels Woolery really doesn't need to use a spot-weld cutter; they work best if you're removing the outer skin and don't want to drill through the inner structure. But he has one and they're relatively fast so he used it.

5. The wheelwell spot welds are easy enough to see without sanding but the area makes up for it by offering the most spot welds in one area.

6. Ford also gas welded the body to the subrails in several spots, most notably in the doorjambs and at the firewall feet. Just cut through them.

7. When stripped of its floor the body is light enough for a few people to lift. However, it invites damage so Josh Higgins used the chain-fall hoist. He supported the body with steel tubing under the wells.

8. This shot of the trunk floor better shows why Woolery chose an entirely new floor. That kink in the foreground shows where the body buckled. Removing the floors caused the quarter-panels to relax with no effort. Otherwise it would've taken hydraulics and lots of hammering.

9. There's no real reason to show the floor going in place; it just dropped on and lined up. Higgins and Woolery moved the body back in place.

10. The body dropped right back on with zero fanfare. It's just the wheelwell design that required Higgins to pry the body over the floor.

11. Small temporary panel fasteners (like CLECO brand) sometimes distort under heavy loads like a whole body. Sheetmetal screws grab a bit better and will hold until Higgins can rosette weld the body to the subrails through the holes.

12. Prepare for more drilling; Higgins counted 85 spot welds.

13. Removing the firewall made it possible to work out the cowl kinks, a critical element to front-clip fit, an issue that plagues even pristine '40 Fords. Woolery also straightened the flange.

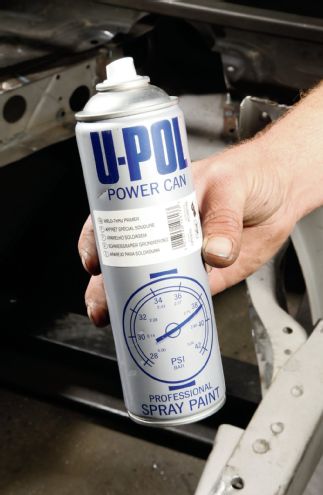

14. Seams are necessary but they aren't perfect; at the least they trap water. A clean surface is critical to weld penetration and insurance against bubbling seams.

15. An exposed surface invites rust but a painted one won't weld properly. The solution: U-Pol's weld-through primer. It doesn't protect quite as aggressively as E-coats on modern car panels but it's one foundation for trouble-free paint.

16. Woolery fit the cowl to the firewall and clamped it judiciously. Don a respirator before plug welding the panels; the weld-through primer and the real E-coat on Carpenter's firewall emit zinc fumes when heated, stuff you don't want to breathe.

17. Another exceptional feature of the Carpenter firewall is its feet. This car didn't need them so Woolery kept the originals if only for their stamping detail.