The common problem that almost all race teams face is that there are never enough hours in the day nor dollars in the bank account. And because of that, we have to make decisions on what needs to be accomplished now and what can be put off for another week (or more).

This is the foundation for our decal wrap project: a freshly rebodied Dirt Late Model. It’s a Mastersbilt by Stuckey chassis with one of Five Star’s new high-downforce MD3 noses.

This is the foundation for our decal wrap project: a freshly rebodied Dirt Late Model. It’s a Mastersbilt by Stuckey chassis with one of Five Star’s new high-downforce MD3 noses.

More often than not the pecking order on the racer's to-do list goes something along the lines of: 1. Fix broken items and problem areas. 2. Do whatever you can to make the car faster or more durable. 3. Safety. And coming in last is 4. Looks.

With the exception of moving "Safety" up to the top spot, that's probably how it should be. Very few of us are ever going to be racing for a living, so the first priority after making sure you're as safe as possible, should be simply making it to the track and getting in the race so you can have a good time.

Next, improving your program and scoring better finishes should be every racer's goal—and it's a topic we try to tackle every month in Circle Track. And finally, make yourself and your race car presentable. After all, who doesn't want to have an operation their friends and family can be proud of?

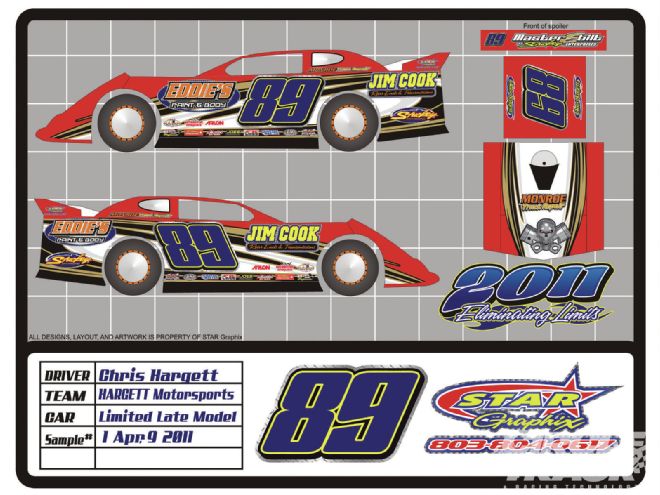

Here’s the proof that Star Graphix sent us for the project. A proof like this will allow you to get an idea of how the finished product will look. This way, any changes can be made now before the final product is printed on the decal material and things start to get expensive. Starnes says that emailing a proof like this allows him to work with race teams anywhere in the country and by being able to quickly make changes digitally he can dial in the design until it fits the team’s wishes perfectly. The square blocks on the righthand side represent (from top to bottom) the rear spoiler, the roof, and the hood.

Here’s the proof that Star Graphix sent us for the project. A proof like this will allow you to get an idea of how the finished product will look. This way, any changes can be made now before the final product is printed on the decal material and things start to get expensive. Starnes says that emailing a proof like this allows him to work with race teams anywhere in the country and by being able to quickly make changes digitally he can dial in the design until it fits the team’s wishes perfectly. The square blocks on the righthand side represent (from top to bottom) the rear spoiler, the roof, and the hood.

But that's not all there is to it. Fans identify with great-looking race cars. You may not have to look fast to be fast, but from the stands it definitely helps. And besides having more people cheering you on, a professional look is a proven factor when potential sponsors are considering joining a particular race team. If you show that you can promote a sponsoring company in an attractive, professional way that will automatically give you a leg up on the team with the raggedy race car that's also talking to the same company.

With that in mind, we contacted Justin Starnes, owner of Star Graphix, about current decal technology and what the average racer can do to improve the looks of his race car.

Just a few years ago, decal wraps were in the nearly exclusive territory of NASCAR Cup teams with big budgets and the need to turn around complex designs quickly from week to week. But that technology has become more affordable for Saturday night level racers who want a great look as well as a comprehensive design that carries all the way around the car.

Star Graphix owner Justin Starnes wipes down the sheetmetal to remove any grease, oil, or dust that may be on the car. You can wrap a previously raced car, just make sure to clean the panels with a degreaser (Windex will work) thoroughly. You may also notice the Clecos still being used to hold some body panels together. Starnes says its best to wrap the car with as few rivets, brackets, and other accessories that might get in the way as possible. After the decal is fully installed, the rest of the riveting work will be finished.

Star Graphix owner Justin Starnes wipes down the sheetmetal to remove any grease, oil, or dust that may be on the car. You can wrap a previously raced car, just make sure to clean the panels with a degreaser (Windex will work) thoroughly. You may also notice the Clecos still being used to hold some body panels together. Starnes says its best to wrap the car with as few rivets, brackets, and other accessories that might get in the way as possible. After the decal is fully installed, the rest of the riveting work will be finished.

Starnes says that advancements in new decal materials are making it easier than ever for teams to install their own wraps. For example, for most race cars Starnes now uses a printable decal material from Arlon called DPF 4560 GTX. The material can be printed on with an ink-jet printer that applies vibrant inks that don't bleed, can be stretched to fit (although there are limits), can be removed and reapplied if you make a mistake, and is generally very forgiving to inexperienced installers. We're sure part of it has to do with Starnes' experienced hand, but it also seems to go down with very few bubbles to be worked out—the bane of every decal installer.

In addition, the newest decal materials use a pressure-sensitive adhesive that doesn't become permanent until you "lock down" the decal with pressure. In the old days, which were just a few years ago, the decal sheets stuck like glue to anything and everything they touched. Even professional installers kept a spray bottle handy filled with water and liquid dish detergent and had to spray down both the race car body and the decal backing just so it could be repositioned if it wasn't applied perfectly the first time.

The sides of the car use the largest sections of the wrap by far and are definitely a two-person job. Begin by placing the number approximately where you want it and then extending the wrap toward the front and rear of the car.

The sides of the car use the largest sections of the wrap by far and are definitely a two-person job. Begin by placing the number approximately where you want it and then extending the wrap toward the front and rear of the car.

The problem with this is that even with the soapy water applied, the decal material would cling to itself quite vigorously and created wrinkles when you tried to pull it apart, and in general, it was just aggravating. But that's a thing of the past. Today, with the new adhesives the decal material can be applied and removed multiple times as long as you don't apply pressure with the squeegee.

So if you've ever considered sprucing up your car without spending a wad of cash, that's easier now than ever. Companies like Star Graphix can provide you a professional design and the materials, and you can save on the labor costs by applying the decal wrap yourself. There are a few tricks to doing it right and making it as easy as possible, however. And that's what we're here to show you.