Here’s a scenario for you: One day while you’re driving to work, you are abruptly alerted to the fact that something is not happy in the rear end of your ride. Maybe something has either A) broken, or B) maybe you haven’t checked the fluid in your Mopar’s rear end in quite a long time. Either way, by abruptly alerted, we mean that a strange noise is now being emitted. As with any mechanical parts, a strange noise is usually the first sign of trouble. But, knowing the kind of noise you hear can help you determine what the cause of the trouble actually is. In the case of a rear end, the noise can be a humming sound, a growl, or even a knock. Although any noise is bad, the noise does help in diagnosis. But, making sure what activity is being performed when the noise actually occurs is another piece of the puzzle. Do you hear the noise when the vehicle runs straight, or is the noise produced when the vehicle is taking a turn? Does it get louder when you speed up, cruise, or slow down? Ring and pinion gear-noise changes with vehicle speed and is usually unaffected by loads and turns. It is difficult to diagnose the drive axle and the differential noise by running the vehicle in the shop with the wheels raised, road testing is the best method to diagnose such noise in the vehicle.

In regards to our parts-hauling Ram, our growling noise came about one afternoon when making a run to the local parts store. It started out as a faint growl, but got progressively worse as we continued to drive. At first, we thought that a bearing was going bad, but until we really started to diagnose the situation, we wouldn’t know.

Like I said, in our case, the noise was more of a growl, but there are several different noises that you might hear from your rear end, and knowing what they mean can help with the diagnosis.

Humming Noise

A humming noise is often caused by an incorrectly installed ring and pinion gear that needs to be adjusted. Incorrect installation of the ring and pinion gear prevents proper tooth contact and can cause rapid tooth wear and gear failure. This humming noise converts into growling noise when the wear increases. Humming noise can also be due to worn out bearings, which need to be replaced.

Noise When Accelerating/Decelerating

A noise that gets louder while you’re vehicle is accelerating, probably means that there is heavy contact of the pinion-gear teeth on the outer ends of the ring-gear teeth (pinion gear not set deep enough). Conversely, a noise that is louder when the vehicle is coasting, probably means there is not enough tooth contact (too much backlash).

Knocking Noise

A knocking or clicking sound may be due to the splines on the axle shafts being worn out, in which case the defective shaft has to be replaced. Another reason for this may be chipped teeth on one or more of the gears in the differential. Again, they’ll need to be replaced.

07 If you want to easily get the tone ring and ring gear on the new differential, simply place the differential in the freezer overnight. When you take it out of the freezer, immediately place the not cold tone ring and ring gear on the very cold differential. It will practically fall in place. Once on the differential, torque it."> <strong>07</strong> If you want to easily get the tone ring and ring gear on the new differential, simply place the differential in the freezer overnight. When you take it out of the freezer, immediately place the not cold tone ring and ring gear on the very cold differential. It will practically fall in place. Once on the differential, torque it.

<strong>07</strong> If you want to easily get the tone ring and ring gear on the new differential, simply place the differential in the freezer overnight. When you take it out of the freezer, immediately place the not cold tone ring and ring gear on the very cold differential. It will practically fall in place. Once on the differential, torque it.

Noise When Turning

A noise that is heard when the vehicle is taking a turn is usually due to trouble in the axle shaft or a problem inside the differential itself. A bad axle bearing is usually the main reason for noise when cornering. When the noise comes on the right side of the car during a right turn, it usually means that the outside axle bearing is worn. Making a turn in the opposite direction will usually reduce or eliminate the noise from a bad axle bearing.

If the cause of the noise is inside the differential, this can be due to either tight-meshing pinion gears, or too much backlash on these gears. Another cause could be worn out differential-case bearings, and these can also cause noise when turning. These parts are inside the differential and move relative to each other during turning of the vehicle.

What’s What?

In order to properly set up or diagnose a differential problem, you should know a few easy terms.

Backlash

This is the term used to describe the clearance between the ring and pinion gears and is usually measured in thousandths-of-an-inch by a dial indicator.

Drive/Coast

The drive side of the tooth on the ring gear is the side of the tooth that is contacted by the pinion gear when the vehicle is accelerating. The coast side is the side of the tooth on the ring gear that is contacted by the pinion gear when the vehicle is slowing down.

Pattern

This is how you know if you have the gears set up correctly. Pattern refers to the visible tooth-contact area on the ring gear where the ring gear and the pinion gear contact each other. The pattern is made visible with contact dye.

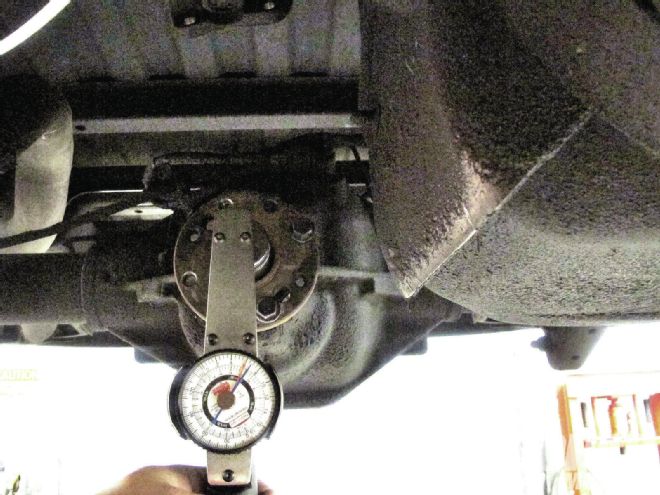

Preload

The pinion bearings and the differential’s carrier bearings must run a little tight. This is similar to the way a wheel bearing should be loaded during assembly. The tapered bearings are adjusted (loaded), in order to eliminate any play within the bearing, and then they are set just slightly tighter. This “preloading” is measured by checking the torque that is required to turn the bearings with a dial torque wrench.

Pinion Depth

This is set with pinion shims, and controls how the pinion contacts the ring gear in relation to the axle center. Pinion depth can be made deeper or shallower by adding or removing shims.

Crush Sleeve

Not all Mopar rear ends use a crush sleeve, but for those that do, it’s basically a soft bushing or spacer that is used to hold the pinion bearings apart and offer some resistance for the pinion nut. When installed, the pinion nut is tightened down, crushing the “crush sleeve,” until proper pinion preload adjustment is achieved. The downside of having a crush sleeve, is that if you over tighten the pinion, you have to replace the sleeve—it’s not reusable.

The Gear

Finally, the toe of the gear is the portion of the tooth surface that is towards the center of the ring gear. The heel of the gear tooth is the portion of the tooth surface at the outer edge of the gear. The top land of a gear tooth is the surface of the top of each tooth

12 This is where it gets a little monotonous. Without the crush sleeve installed on the pinion gear, install the gear in the housing, place the outer bearing on the shaft, and install the flange. This is only temporary, and you need to do this to get the pinion depth correct."> <strong>12</strong> This is where it gets a little monotonous. Without the crush sleeve installed on the pinion gear, install the gear in the housing, place the outer bearing on the shaft, and install the flange. This is only temporary, and you need to do this to get the pinion depth correct.

<strong>12</strong> This is where it gets a little monotonous. Without the crush sleeve installed on the pinion gear, install the gear in the housing, place the outer bearing on the shaft, and install the flange. This is only temporary, and you need to do this to get the pinion depth correct.

Time for a Change

Every gear has a required characteristic pattern that needs to be established so that it doesn’t make noise when driving, and so it lasts as long as possible. When installing new gears and/or making pinion gear-position changes (pinion depth), shims should be changed in the range of .002-inch to .004-inch at a time, until the correct pattern has been obtained.

When a change in backlash is required, shims approximately 11⁄2 times the amount of change required are typically needed to bring the gears into spec. For example, if the backlash needs to be changed by .004 inch, the shim pack should be changed by .006 inch as a starting point. The actual amount of change obtained will vary depending upon the gear ratio and gear size.

A high backlash (too much), is corrected by moving the differential/ring gear closer to the pinion gear. A low backlash (not enough), is corrected by moving the differential/ring gear away from the pinion. These corrections are made by switching shims from one side of the differential case to the other, or by threaded adjusters (depending on rear end).

When making any changes, you should note that two variables are involved. Example: If you have the backlash set correctly to specifications and you change the pinion depth shim, you may have to readjust the backlash to get the correct specification before eventually checking the wear pattern on the gears.

Like we previously mentioned, we needed to do a little diagnosis and repair, and we thought this would be the perfect opportunity to show you guys what it takes to diagnose and repair your differential.