'"Just put a 9-inch in it!" That has been the rallying cry for Ford enthusiasts for more than 40 years. If there is an industry standard for rearend strength and durability, it has to be the Ford 9-inch. But the days of finding a Mustang-width 9-inch housing in the junkyard that you can use for a typical leaf-spring street machine are rare. Even the big rear-axle companies like Currie, Moser, and Strange now make their own housings rather than try to find decent cores. But there is an alternative-the Ford Mustang 8.8-inch rearend.

We were wrenching at Tim Moore's shop one afternoon when he suggested the 8.8 is the Blue Oval equivalent of the Chevy 12-bolt. The advantages of the Ford 8.8 are that it's light, durable (with a couple of upgrades), and, the best part is, there are thousands of them lying in junkyards right now, ripe for the picking at far more affordable prices than either the 9-inch or the Chevy 12-bolt. We did some research and discovered on Randy's Ring & Pinion Web site a list of no fewer than 24 different Ford vehicles that use the 8.8 rear-axle assembly. Not all of these are worthwhile options, but the list suggests plenty of choices.

Why should you care about the Ford 8.8? The biggest reason is there are thousands of Fox-body Mustangs with 8.8 rearends in boneyards all over this country that can be easily purchased for $100 or less. This rearend is lighter than a 9-inch and is as strong as a 12-bolt (except for the axles), and many Mustangs came from the factory with Traction-Lok limited-slip differentials. All you have to do is cut off the coil-spring brackets, weld on leaf-spring mounts, and perhaps add a different pinion snout, and you're ready to go with an inexpensive yet strong rear-axle assembly. It will never get any easier or cheaper than this.

For us, it started with a search for a performance replacement for the lame 8-inch rearend in our Car Craft '67 six-cylinder Mustang. The stock four-lug axles had to go and there was no good reason to invest in the weak 8-inch. We also had an 8.8 rear sitting in a wrecked '88 Mustang we bought for the 302 engine, and we discovered that the Fox-body Mustang 8.8 rear is a mere 31/48-inch wider than the stock 8-inch '67 Mustang rear. This led us to consider that this inexpensive 8.8 Ford could be used in all kinds of leaf-spring-equipped cars, like the '62-'67 Novas, early Camaros, and the '68-'74 Novas. Frankly, we don't expect a ton of Chevy guys to pick up on this idea, but that just leaves more 8.8 rearends for budget-strapped Ford guys to hoard. We're already planning on snapping up another 8.8 to go through in more depth that will eventually find its way into our '67 Mustang. But for now, let's see how this 8.8 stacks up as a swap axle and what parts are available to make it stronger.

Ford 8.8 Strength Comparison

The truth is that the Ford 8.8 is virtually a clone of the Chevy 12-bolt and therefore almost as strong. Most rear axles are described by their ring-gear diameters, with larger being better. A Ford 9-inch has a ring-gear diameter of, you guessed it, 9 inches closely followed by the 12-bolt at 8.875, with the Mustang rear at 8.80 inches. Another strength consideration is pinion-shaft diameter. Here, the 8.8 and the 12-bolt are identical at 1.625 inches and in fact use the same pinion bearings. By comparison, the Ford 9-inch pinion shaft measures only 1.313 inches. The Achilles' heel of the stock 8.8 Ford rearend is its 28-spline axles, especially when compared to the Chevy 12-bolt's stronger 30 splines. Ford eventually rectified this oversight and upgraded the '94-'99 Mustang 8.8 rears with 31-spline axles and larger axletubes. These rear-axle assemblies are now beginning to populate the recycling yards and should be available at a decent price. These housings are slightly wider than the '86-'93 housings and may actually fit some of the wider leaf-spring-car requirements, so keep that in mind as well.

The point of all this is that the Ford 8.8 has all the basic components to create a performance rearend; it just needs a little aftermarket help to make it stronger. The original Fox-body 8.8 used from '86-'93 can be easily upgraded with better axles, a stronger limited slip with more clutches, and bigger axle bearings to become a very durable yet light rearend assembly. And the best part is you won't spend a ton of money to get there.

Pumping Iron-Strength-Building The 8.8

The keys to bulking up the 8.8 Ford are pretty simple. If you are planning to put at least 400 hp through a Ford 8.8, the first step is better axles. Rather than buy aftermarket 28-spline axles, the smart move is to upgrade to stronger 31-spline pieces. This will also require a 31-spline limited slip. Moser, Strange, and others offer both better axles and several choices when it comes to differentials with the clutch-type Eaton-style limited slips being the least expensive. An excellent choice if you plan on doing both drag racing and abusing the apexes on the occasional road course is Eaton Detroit Truetrac gear-style limited slip. This unit is more expensive but applies the power in a corner more efficiently than clutch-type units and will not wear out in your lifetime.

If your plans include going really quick on the dragstrip, there is a C-clip safety issue that also needs to be addressed. NHRA bans C-clip axles on any car running 10.99 or quicker. C-clip rearends are dangerous because if you break an axle, the axleshaft can slide right out of the housing and push the tire into your quarter-panel. While there are loads of C-clip eliminator kits out there, there's a better solution. The smart move would be to invest in a set of big-bearing housing ends from Currie, Moser, or Strange, and have a professional shop cut the stock 8.8 housing ends off and weld these larger ends in place. Strange, for example, offers a housing end that will accommodate a much larger Ford axle bearing and a matching retaining strap yet maintains the 8.8 Ford bolt pattern. This allows the choice of stronger 31-spline axles combined with a larger axle bearing. Currie, Moser, and Strange (among others) offer several axle choices. This makes for a killer combination that is mucho strong.

If you plan on really abusing this 8.8, we'd suggest adding Ratech's solid-pinion bearing spacer that replaces the stock crush sleeve. This solid spacer adds strength, but does require a little more time to properly set the pinion preload. At this same time, you could also get rid of that small stock U-joint in favor of a larger, more robust 1350-style U-joint. This will require changing the pinion yoke, which Currie, Moser, and Strange make out of steel instead of cast iron. This works best with a larger-diameter, stronger driveshaft. Moser offers a main-cap stud kit that may offer some additional strength along with the reinforced aluminum rearend covers that offer preload help for the main caps to prevent deflection, although these covers are a bit pricey. Also, if you feel the need, Mark Williams makes steel-billet rear main caps for the 8.8 Ford. Other ideas that are common upgrades for other Salisbury-style rearends include having a professional shop weld the axletubes into the centersection to increase strength. Ford merely plug-welds the tubes in two spots for each tube, which can easily be twisted and broken with a high-torque car on sticky tires. A tube-welded housing with strong 31-spline axles, a good limited slip, professionally installed gears, and larger housing ends is plenty strong enough to take the abuse that any street car can dish out.

Five-Lug Axle Swap

The very first thing to change on a Mustang 8.8 is the lame four-lug axles. In typical Ford fashion, this four-lug pattern isn't even the same as the early Mustang six-cylinder stuff from the '60s, so you can't even reuse the old wheels. The least expensive swap is the classic Ranger switch. Search the boneyard for a couple of late '80s to early '90s Ranger pickups. You'll need to find two trucks because you'll have to pull the left-side (driver) axles from these two trucks, which are the same length as the stock Mustang axles but have the five-lug pattern. One little red flag Jeff Stange of Strange Engineering informed us of is that once an axle takes a torsional set, it does not like to suddenly be twisted in the opposite direction. So the Ranger axle that goes on the right side (passenger) could fail if subjected to enough abuse.

When yanking the Ranger axles, if you can find two serviceable drums you might want to snag them too since you will need five-lug drums to match the axles. This is also a great time to install new axle bearings in the housing. The bearings are pressed into the housing using the axleshaft as the inner bearing race, just like a 12-bolt Chevy. This also means that when you pull the Ranger axles, inspect the bearing surface carefully. If there are pits in the axle-bearing race area, avoid that axle because it will soon fail, even with a new bearing. Of course, another alternative is to invest $235 for new axles from Moser that will bolt right in.

GEAR RATIOS Factory 8.8 Gear Ratios Aftermarket 8.8 Gear Ratios (with Traction-Lok) (Randy? Ring & Pinion) 2.73 2.73 4.11 3.08 3.08 4.56 3.27 3.27 4.88 3.55 3.31 5.13 3.55 5.71 3.73 6.14 3.{{{90}}} AXLE-STRENGTH CHART Rear Spline Strength Axle Count Comparison {{{Ford}}} 8.8 28 - 19.3 % (weaker) GM 12-bolt 30 Baseline Ford 9-inch 31 + 10.7 % (stronger) Ford 9-inch 33 + 34.3 % (stronger) (courtesy of Mark Williams Enterprises)Adding a 31-spline axle to a Ford 8.8 rearend means you are increasing the strength of that axle by 30 percent (19.3 + 10.7 = 30 percent increase in strength).

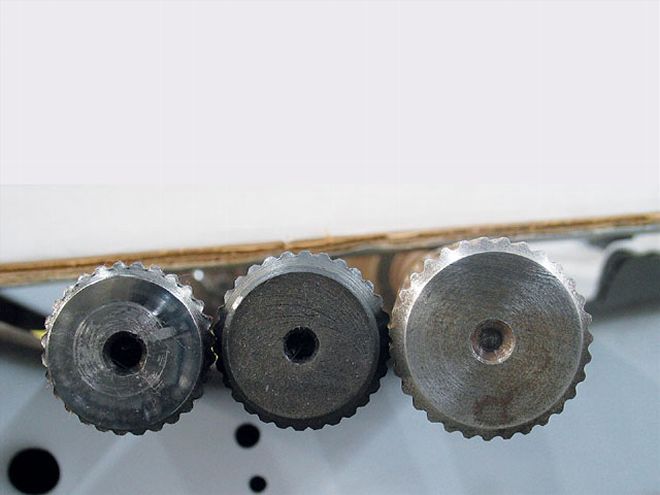

Here is a comparison between the stock 28-spline 8.8 axle (left), a 30-spline 12-bolt axle (middle), and a 31-spline 9-inch Ford axle (right).

Here is a comparison between the stock 28-spline 8.8 axle (left), a 30-spline 12-bolt axle (middle), and a 31-spline 9-inch Ford axle (right).

Axles: Bigger is Better

To increase the spline count on an axle automatically means the diameter of the shaft itself must also increase. We found an interesting strength-comparison chart created by Mark Williams that uses a 30-spline GM axle as a standard. This gives you an idea of why bumping the 8.8 to a 31-spline axle is such a good idea.

In addition, most aftermarket axles use a stronger material than stock. The Ford OE axles are made of SAE 1055 or 1541 carbon steel that are induction-hardened, which means they are hardened only about 0.150-inch deep while the majority of the axle remains relatively soft. Not only do performance axles use a superior alloy steel, but they also benefit from a thicker wheel-mounting flange and a stronger design with a gentler radius between the wheel flange and the axleshaft.

Axle Widths

All rear-axle widths listed here use the axle-flange measurement (wheel-locating surface or drum-to-drum) to establish the overall width. The variable that affects overall width compared to housing width is the stand-off distance of the axle flange to the housing.

Many of these widths were obtained through various sources, so we cannot vouch for their complete accuracy. We recommend using these widths as guidelines and actually measure the housing you wish to replace because we have found slight variations even within housings of the same design. Other variables include the thickness of a disc-brake rotor hat versus a drum brake.

Vehicle Application Axle Width (inches) '86-'93 Ford Mustang 8.8 59 11/44 FORD '65-'66 Mustang 57 11/44 '67-'70 Mustang 8.0 59 51/48 '71-'73 Mustang 61 11/44 '67-'71 Comet, Cougar 59 11/44 '71-'77 Maverick 56 11/42 and 57 CHEVROLET '67-'69 Camaro 59 51/48 '70-'81 Camaro 60 51/48 '62-'67 Chevy II 58 71/48 '68-'74 Nova 59 51/48

Cutting, Welding, And Tweaked Tubes

The most popular procedure for the Ford 8.8 is to saw off the coil-spring brackets and weld on new leaf-spring brackets for an early Mustang, which is exactly what we're going to do with our notchback '67 Mustang. While we could take this housing to a professional shop to have all this work done, the budget way is to do all this work yourself. But there are a couple of tricks you need to know so you don't screw up.

Do not use a torch to remove the brackets from the 8.8 housing. Instead, use a cutoff wheel, which will remove the brackets but not put heat into the thin-wall tubes.

Do not use a torch to remove the brackets from the 8.8 housing. Instead, use a cutoff wheel, which will remove the brackets but not put heat into the thin-wall tubes.

The easiest way to remove the coil-spring and control arm brackets from a Fox-body Mustang 8.8 is with an acetylene torch. But Ray Currie warns that this is a recipe for disaster. The 8.8 housing tubes are extremely thin, which means the heat from a cutting torch will easily bend the tubes. Instead, he suggests using a cutoff wheel on a high-speed die grinder to remove the brackets. Then use an angle grinder to smooth what's left.

Next, Currie also says that it's possible to weld new leaf-spring brackets on these thin tubes and not affect axle alignment, but you have to work slowly. Currie suggests welding an inch or shorter bead on one portion of the leaf-spring mount and then moving to the opposite mount and doing the same thing, allowing enough time for the weld to cool to the touch before applying more heat to that mount. This will minimize heat concentration in the tubes and prevent them from warping.

PARTS LIST DESCRIPTION PN SOURCE PRICE Strange 3.55 gears RSE7888355 Strange $158.00 Strange 3.73 gears RSE7888373 Strange 158.00 Strange 3.{{{90}}} gears RSF888390 Strange 158.00 Strange 4.10 gears RSO7888410 Strange 169.00 Moser 28-spline axles, C-clip, five-bolt A882851 Moser 235.95 Moser 31-spline axles, C-clip, five-bolt A883151 Moser 235.95 Currie 31-spline axle package, custom CE-0012 Currie 449.95 Strange 31-spline custom axle A3100 {{{Summit}}} Racing 288.95 FRPP* five-lug axle kit {{{M}}}-1126-A Summit Racing 379.95 FRPP 28-spline Traction-Lok M-4204-F288 Summit Racing 214.88 FRPP 31-spline Traction-Lok M-4204-318 Summit Racing 249.95 FRPP 31-spline Traction-Lok M-4204-F318C Summit Racing 298.95 Detroit Truetrac 31-spline 913A311 Ntl. Drivetrain 413.00 Eaton 31-spline 19588-010 Summit Racing 474.95 Strange 31-spline, clutch type N1869 Strange 385.00 FRPP Traction-Lok rebuild kit M-4700-B Summit Racing 44.95 FRPP Traction-Lok rebuild kit, carbon M-4700-C Summit Racing 95.88 Ratech Traction-Lok adj. shim 1803 Ratech 15.00 Ratech Deluxe install kit 3008K Ratech 110.00 Ratech solid-pinion bearing spacer 4105 Ratech 15.00 Strange pinion yoke, 8.8, 1350 joint U1630 Strange 89.50 Strange housing ends 8.8 (3.15 id) H1138 Strange 70.00 Strange retainer plates for ends H1138B Strange 12.84 Currie housing ends 8.8 large bearing CE2008-T Currie 49.95 Raybestos brake drum, five-lug, pair 2604R Rock Auto 31.10 Raybestos brake shoes, set 569RP Rock Auto 16.45 Raybestos wheel cylinders, pr. 2037400 Rock Auto 14.18 Axle bearing, BCA, stock, pr. RP5707 Rock Auto 47.58 Moser, {{{Ford}}} leaf-spring perch 7220 Moser 20.00 Moser, Chevy multileaf perch 7210 Moser 60.00 Moser 8.8 pinion yoke, 1350 joint PY088 Moser 130.00 Moser main-cap studs 7116 Moser 25.00 Moser 9-inch housing '79-'93 {{{Mustang}}} 7HMU Moser 510.00 Moser 9-inch housing, ends and axles BPH1 Moser 885.00 FRPP 8.8 assembly, 3.55, Traction-Lok M-4066-B355 Summit Racing 999.95 *FRPP - Ford Racing Performance Parts