You’d almost have to go out of your way to overlook the work our pal Frank Wallic does. He’s an editor’s dream come true: he has a way with the tools, cameras included. And for the past five years he’s trained that camera on tasks that most deemed impossible or at least improbable by mere mortals. Among the many things he does, he crafts seats that are spitting images of the ones in World War II–era Fairchild PT-19 trainers.

Frank Wallic begins by rolling vertical beads into the seat-face panel. Note that he already drilled the perimeter rivet holes and attached a narrow vertical doubling plate. It rivets exclusively to the face panel.

Frank Wallic begins by rolling vertical beads into the seat-face panel. Note that he already drilled the perimeter rivet holes and attached a narrow vertical doubling plate. It rivets exclusively to the face panel.

Even luckier for us, he’s not content with leaving well enough alone. Though the seats he crafts look the part of old aircraft seats, they’re usually not in the exact same shape. Because he’s starting from scratch he can make ’em as wide, tall, or deep as necessary to fit just about any automobile and its occupants.

This proved especially appealing to Editor Brennan; in case you haven’t noticed, he’s building a Model A pickup—the stretched version from Nostalgia Speed & Cycle. And in case you haven’t occupied one before, their cabs are quite cozy—some say too cozy for bucket seats. Like houses built on community property to skirt easement regulations, driver and passenger often occupy the same space in a Model A pickup cab. (Although the Nostalgia Speed & Cycle cab is stretched 6 inches.) Sharing a ride in one is reason enough to choose attractive passengers, since two adults in those cabs can look like they’re starting a family.

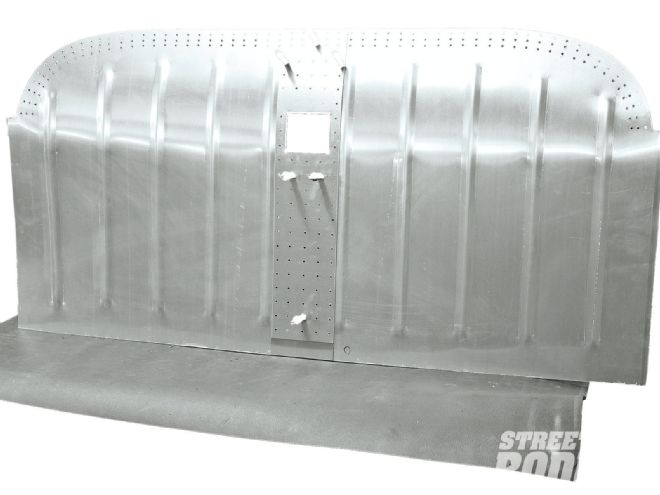

He rolls horizontal beads into the seat-back panel. Note the beaded horizontal doubling plate. Note the absence of perimeter rivets and how much taller this piece is than the front panel.

He rolls horizontal beads into the seat-back panel. Note the beaded horizontal doubling plate. Note the absence of perimeter rivets and how much taller this piece is than the front panel.

Rather than a nuts-and-bolts tutorial on how to make a seat from scratch, this is a general information exercise fortified with a reprisal of at least two articles. To learn in greater detail how Wallic builds these seats—including a pretty comprehensive outline on how to rivet together panels—we suggest referring to the following articles: “Cockpit Confidential” (July ’07) for seat construction, “Thinking Inside the Box” (March ’08) for seat risers, “Let it Slide” (April ’10) for seat sliders, and “Well Heeled” (June ’10) for riveting basics.

Or if bucking 1,500 or so rivets doesn’t sound like your cup of tea, give Frank Wallic a call. If he can find as much room as he did in Brennan’s pickup cab, chances are he can eke out a few more inches from your cockpit.