E-mail your tech questions to us at carcraft@primedia.com (include the words "What's Your Problem?" in the subject line) or fax them to 323/782-2223. All correspondence must be signed with the sender's real name (not a nickname or a screen name) and include the sender's hometown and state or province. While mail cannot be answered personally, Car Craft will publish as many letters and replies as space permits. Photos are welcome, but no materials will be returned.

Aod A-Ok?I have an early Mustang with a small-block and a Holley carb, and a couple years ago I decided to replace the stock three-speed auto trans with a later-model AOD overdrive automatic. I had the trans (from an '86 Mustang police car) freshened and then installed it. The overdrive was great, but the shift timing and quality were never what I'd hoped for. After a couple years, the trans began refusing to shift into overdrive. Everything seemed correct, so I pulled it and brought it back to the guy who built it. He re-freshened it and I put it back in, and although it now goes into overdrive, it doesn't shift right at all. I know the TV (throttle-valve) cable adjustment is essential to proper operation, and I recall that last time we adjusted it using a gauge, but this time the trans guy says to just adjust the slack out of it and it should be good. Well, it's not, and I'm afraid to drive the car because I know I could wreck the trans if it's not set up properly. It shifts early and sloppily, and in Overdrive it feels like its slipping, plus it won't kickdown. My TV cable is an aftermarket unit from Lokar, and it's connected to the Holley in one of the lower holes that would be used for a GM kickdown cable. Am I doing something wrong, or does the trans have to come out again?Dave SharpPhoenix, AZ

You're correct about the importance of proper TV adjustment on Ford's AOD trans, and wise for parking the car until you can sort this out. It sounds like your trans wasn't set up correctly even before you had it rebuilt the second time, though it was probably adjusted for too much TV engagement rather than too little, which may be what you are experiencing now.

First of all, your main problem is probably that the place you've connected the TV to the Holley carb is incorrect. The AOD's TV cable has to travel in exact proportion to the throttle cable (1:1 ratio), so the distance from the throttle shaft for the throttle cable should theoretically be the same as that for the TV cable. However, most kickdown-style linkages don't require as much travel as the throttle cable for proper operation, and the kickdown portion of the carb's throttle lever (the lower half) is probably shorter than the top side, where the throttle cable (or rod) hooks up. The result is insufficient travel of the TV cable, which means that you either have too much throttle valve actuation at idle, or too little at WOT.

Step One in correcting this is obviously to set up your TV cable connection so that a 1:1 ratio is achieved between the throttle linkage and the TV linkage. For the Holley carb, this may require you to fabricate an extension for the lower portion of the throttle lever, and again, you're trying to obtain the same distance from the throttle shaft to the TV cable hookup as you have from the throttle shaft to the throttle cable.

Once that's taken care of, you still need to properly adjust the cable. There are several methods listed from various sources to do this. All methods require the trans to be properly filled and the trans fluid to be at normal operating temperature. A mechanical adjustment is a good place to start. Most sources specify that at WOT, the TV cable should be fully extended. Final adjustment may cause the cable to fall short of full extension, but it's important to verify that the cable isn't reaching the end of its travel before the throttle is completely open. This would cause the throttle to be limited slightly, and likely would eventually result in damaged linkage to the throttle-valve. After verifying the WOT position of the TV cable, check to make sure that there is no slack in the cable at idle. Slight tension is acceptable, but a loose cable is not. Some sources advise that after these adjustments have been made, fine-tuning based on road test feedback is required. If shifts occur too soon and feel soft, tighten the cable adjustment slightly and try again. If the shifts seem delayed and are harsh, loosen the cable. It's better to err on the high side, with a slightly firmer shift, as soft, early shifts indicate a lack of line pressure as a result of an overly loose TV cable adjustment, and this is what causes premature failure.

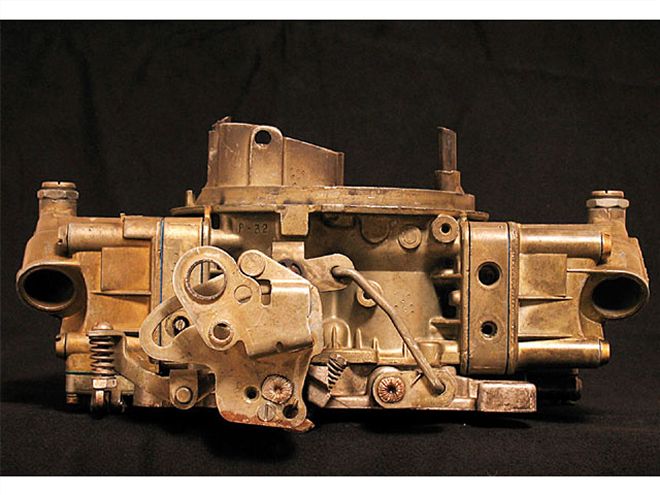

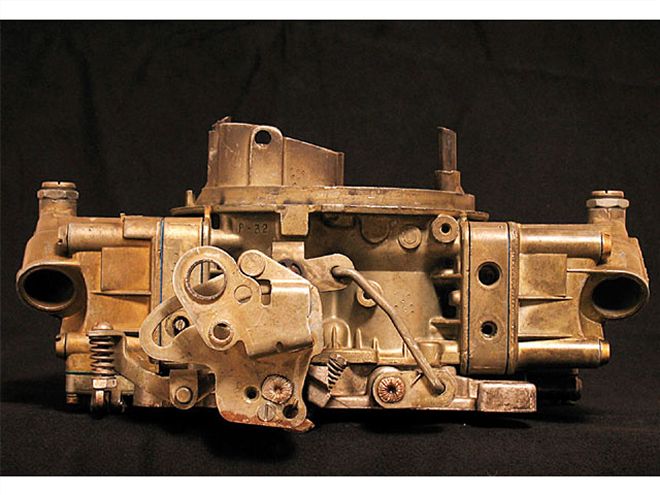

For more precise fine-adjustment, a pressure gauge can be used. TCI (using a Ford service procedure) recommends using a pressure gauge that reads to 100 psi connected to the proper port on the transmission (see photo). However, it also instructs to take pressure readings at a precise amount of throttle opening, which is to be achieved using a special tool to hold the throttle open the specified amount. For vehicles using rod-type factory linkage, the tool is PN D84P-7032-A, and it's a "block" that fits between the throttle cable lever and the adjustment screw on the TV rod lever. The spec on the block's thickness is 0.390-0.404 inch, and the instructions say that you can make your own or even use the shank of a properly sized drill bit if you're careful. With the spacer of choice in place, the gauge should read between 28-38 psi, with 33 considered ideal.

Unfortunately, the instructions for cable-style linkage are for a factory-style cable only, and no alternative or thickness specs are listed for the special tool (PN T86L-70332-A). This would be of no value to you anyway, since the Lokar cable adjusts differently than a factory cable. However, the instructions also advise that at idle, the pressure reading should not be more than 5 psi, and if it is, the cable should be adjusted to lower the reading accordingly, though the part-throttle reading shouldn't dip below 28 psi.

Instructions given by noted AOD specialist LenTech Automatics are geared more for the D.I.Y. wrencher. LenTech produces a wide range of transmission assemblies and accessories, but race-prepped AODs are its main focus. LenTech also recommends a gauge, but one that reads only to 30 psi. Then, at idle, the reading should be adjusted to between 2-5 psi. LenTech echoes the specifications of the mechanical adjustments, and reiterates that too much TV tension is better than too little.

Your Lokar cable is a good piece, though you didn't mention what brackets you're using. Aftermarket universal throttle cable brackets, such as those offered by TransDapt or Moroso, can be used in situations where the original or other factory-style brackets can't be retained. Windsor-Fox and Total Performance also offer retrofit AOD TV cables.

While you're at it, you should check to make sure your shifter linkage is working properly. Since you have an early Mustang, it's likely you retained the stock shifter to operate the AOD, which is fine, as long as it's functioning properly. If the shifter isn't positioning the transmission's manual shift valve in the proper location, trans failure could result. Support the car on proper jackstands or a lift and have someone operate the shifter while you verify that the trans shift lever actually clicks into the proper detent when the shifter does. If the shifter clicks into its gate at the wrong point, it could hold the transmission's shift lever in a slightly incorrect position, causing improper fluid flow and reduced line pressure, which in turn leads to premature failure.