| Question It - April 2008

| Question It - April 2008

Vtec Un-Control

I had an A'PEXi AFC Neo Fuel Computer installed on my S2000. The computer has a lot of functionality that the installer did nothing with, like VTEC controls. Can you provide some insight on how to best use the settings on this unit? I had the installer turn on the VTEC controller and set it at 4,500 rpm to kick in, but this just made the check engine light go on and little else. What settings did he miss that would make this feature usable and how can I get rid of the damned light?--Harleyvrod57, via importtuner.com forums

The AFC Neo is handy for quick analog adjustments, tweaks to the fuel curve and VTEC switchover points. However, fuel tuning and VTEC switchover points should be done on a dyno by a professional tuner. Why? Because a professional tuner knows what he's doing and if you're asking these questions, you don't. He has the expensive tools and equipment to help him safely make those adjustments. A dyno also helps to quantify the adjustments made to the fuel curve and VTEC switchover points. By setting the VTEC point too low without raising the engine's compression ratio, often times huge dips in the power curve will appear. On a stock compression car, you can drop the VTEC point several hundred rpm's as a rule of thumb and sometimes even more with cam timing changes (which should also be done on a dyno). As for the check engine light, your installer probably messed up on the VTin and VTout wires on the Neo. The Neo has a method of keeping the factory computer happy which will keep the check engine light off while the Neo controls the VTEC switchover point. Visit your local tuner and he can fix your problem.

STROKE JOB

I drive a '95 Civic coupe with a T3/T04E turbocharged B18C5 (USDM Integra Type-R) engine and five-speed LS transmission. I've always liked the high-revving, late power delivery of a highly boosted ITR engine (especially useful in FWD) but want to take it even further. Since the next step for my engine is a total build, I'm thinking about boring the block and having a custom crank machined to actually de-stroke the engine to a final displacement of around 1.6L. After that, I'd plate the deck and have custom rods machined to match to increase the rod ratio. The head would be fully rebuilt as well, to rev-friendly specs, but here are my questions: Will the decrease in stroke require custom-ground cams? And will the increase in deck height require them to be timed differently? Is the whole project worth the effort, or not at all?--FWDdragKiller68, via importtuner.com forums

Let me let you in on a little secret: It's called a B16A crank. You can probably find one on hondatech.com for $50 since most people are probably giving them away. You will need a custom long rod (143mm center to center) to match the deck height of the B18 block and the stroke of a B16 crank, but once you have everything dialed in you'll have an increased rod ratio (1.86). Of course custom pistons will have to be made to accommodate the shorter stroke to hit your target compression ratio. You'll end up with a 1.6L displacement since the B16 and B18 share the same bore (81mm). Keep in mind however, that higher rpm's mean exponentially higher wear on the engine parts including piston rings, piston skirts, etc. The shorter stroke will lower the piston speed, and the longer rod will reduce the side loading of the piston to the bore, but higher quality and lighter weight valve train parts will be needed to ensure valves don't drop or valve springs break.

To answer your questions: It's big money to develop a camshaft for a specific engine design. I would suggest trying some of the more popular grinds and concentrate on cam timing to achieve your desired powerband. Whenever something is changed in an engine, cam timing should always be re-optimized for the intended purpose of the engine and gearing. Is it worth the effort? On street cars, I always subscribe to the old adage, "There's no replacement for displacement." However, I never discourage anybody from trying something different. Good luck.

The Right Combo

I have a '95 Mitsubishi Eclipse GSX that I plan to build for big power. I've seen 400-plus whp on stock block 4G63s running pump gas and was wondering what their recipe was for reliable power. I've heard that if you don't do it right that you'll get crank walk and blow your motor. I can't remember what I read, but it was something about having to mix and match engine parts from different generations. Does this make sense? What's the right way to go?--Sammy Jones, Providence, R.I.

Wow it's been years since I've worked on an Eclipse, but back in the day, to get 400 whp on a stock bottom end, we would bolt on a first-generation Eclipse head, intake manifold, and throttle body because of the significantly larger intake ports, larger plenum volume, and larger throttle plate. We would also send the throttle body out to RC Engineering to have them work their magic and stuff a larger throttle plate in there. With the right turbo, intercooler, 272 cams, and good tuning, 400 whp wasn't a problem.

Crank walk is generally a result of using too heavy of a clutch pressure plate and/or too tight of a thrust clearance. Single diaphragm clutches with 2,600 pounds of pressure tend to piss-off the thrust bearing and you end up with crank walk. I recommend you use a twin-plate clutch that uses surface area over pressure to keep your engine from crank walking. Remember, there's a 100 ways to skin a cat. This is the way I used to skin the cat for a 400 whp Eclipse.

Running Wild

I accidentally ran off the road in my '96 Prelude the other day and took out a couple of orange barrels. Afterwards, I took it to a shop and learned it was running rich. As long as I've owned the car, I've never had this problem and am wondering if it has anything to do with my little wreck, and if so, what could have been damaged to cause this problem. I also thought I smelled burning wires, and the alternator seems to be fried.--Vitukovawild, via importtuner.com forums

Chances are, if the problem came about after the wreck, the problems were caused by the wreck. Diagnosing the fuel system and electrical system is better left to a professional. Asking questions to a magazine will do nothing for you since I'm not psychic. Take it to the body shop and repair the body and then have a mechanic do the rest.

Legal Supra Power?

I'm in the middle of building a '94 Supra Turbo. I'll be swapping out the stock turbos for twin HKS GT2835s, adding all the goodies and plan to tune it with an HKS F-Con V-Pro and 1,000cc injectors. It sounds funny, but I still want to keep the car street legal. I want to retain a catalytic converter and have the car be able to pass emissions on pump gas and a low-boost setting. The problem for high-boost tuning is that all the necessary fuels are leaded which (I'm told) will ruin my cat. Is this true? Are there any high-octane, unleaded fuels available that I can tune with? And why are high-octane fuels leaded anyway?--Ediya Ree, San Jose, Calif.

First off, the fact that you're installing GT2835s, a V-Pro and 1,000cc injectors alone is already making the car illegal to drive on the street. What you want is a legal street car that's illegal. That's an oxymoron if I ever heard of one. To fully utilize turbos that large, you'll have to install aftermarket camshafts, but the valve overlap introduced from these cams will almost certainly fail any sniffer type smog test. Although only a few states require a tail pipe emissions test, more and more states are implementing a sniffer test. It would require a lot of tuning to ensure the car would pass a sniffer test with 1,000cc injectors and camshafts.

For high horsepower and big boost, you'll need to run race fuel. There are many very good unleaded race fuels. I use Sunoco GT+ in all of XS Engineering's race cars. GT+ has a R+M/2 rating of 104 octane and is probably the best knock proof unleaded fuel I've used so far. At the 2007 PRI Show, I spoke to a Shell representative who told me that Shell will be releasing a 108 R+M/2 fuel in 2008. Keep in mind that Shell blends race fuels for some of the top teams in motorsport including Ferrari in F1, Audi in Le Mans, etc.

As for why the high end race fuels are leaded, well that's a question for a chemist or an engineer. I was told before by a NHRA Pro Street engine builder that the lead slows the burn time of fuel by increasing the amount of time that the fuel can be exposed to heat before it autoignites. This is probably why leaded fuels seem to have a higher octane rating.

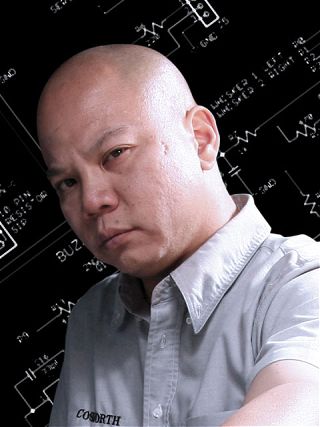

You have questions and we have answers. Well not us, per say, but Eric Hsu. Currently at world-renown Cosworth for performance parts development, Eric brings over 15 years of experience-five years as Chief Engineer for A'PEXi and a founder and current consultant for XS Engineering-to help with your woes. As a tuning guru, unlike the guy on the forums who thinks he knows everything, he actually knows what he's talking about. That is, unless your topic of conversation is about APC taillight fitments, upon which we must specify all of Eric's opinions are his and his alone. Except on Altezza taillights. It's the reverse of Nikes logo: Just don't do it.

For questions, comments, banal exchanges of your own, email them to questionit@importtuner.com.